Professional Documents

Culture Documents

2013 181 X-Em6h X-Ew6h X-Ef7h X-Em8h X-Em10h Ew10h - Threaded Studs For Steel

Uploaded by

Difa LiuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2013 181 X-Em6h X-Ew6h X-Ef7h X-Em8h X-Em10h Ew10h - Threaded Studs For Steel

Uploaded by

Difa LiuCopyright:

Available Formats

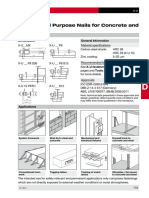

X-EM / X-EW

X-EM6H, X-EW6H, X-EF7H, X-EM8H,

X-EM10H, X-EW10H Threaded Studs for Steel

Product data

Dimensions

General information

X-EM6H/EW6H-__-9 FP8

M6/W6

X-EF7H-7-9 FP8

F7

o8

o 3.8

1.7

Lg

o8

o 3.8

X-EM8H-__-12 P8

M8

Lg

12

o 10

15

3.5

W10

o 5.2

o 10

24

12

39.5

o 10

14

30

513 m

Recommended fastening tools

DX 460, DX 76, DX 76 PTR, DX 600 N

See X-EM/ X-EW fastener program in the next

pages and Tools and equipment chapter for more

details.

X-EW10H-30-14 P10

o 4.5

o 5.5

3.5

12

30.5

X-EM10H-24-12 P10

M10

o 4.5

o 5.5

HRC 56.5

Zinc coating: 1)

) Zinc coating (electroplating for corrosion protection during construction and service in protected

environment)

X-EM8H-15-12 FP10

o8

Carbon steel shank:

1

20

M8 o 4.5

3.5

10

10

1.7

o 5.5

Material specifications

o 3.7

o 3.7

44

For dimension details see chapter fastener selection

Approvals

ICC-ES ESR-2347

(USA):

X-EW6H, X-EW10H,

X-EM8H

FM 3026695:

X-EW6H, X-EW10H

UL: EX2258:

X-EW6H, X-EW10H

ABS, LR:

all types

Applications

Examples

Base plates for pipe

rings

12 / 2013

Hanging with threaded

couplers

Electrical boxes

Miscellaneous attachments

181

X-EM / X-EW

Load data

Recommended loads

Fastener

designation

Shank

ds x Ls [mm]

Nrec [kN]

Vrec [kN]

X-EM6H, X-EW6H, X-EF7H 3.7 x 8.5

1.6

1.6

5.0

X-EM8H, X-EM10H

4.5 x 12.0

2.4

2.4

9.0

X-EW10H-30-14

5.2 x 15.0

3.0

3.0

14.0

Conditions

Redundancy (multiple fastening) must be provided.

Global factor of safety for static pull-out >3 (based on 5% fractile value).

Predominantly static loading.

Strength of fastened material must be considered.

Observance of all application limitations and recommendations.

The recommended loads in the table refer to the resistance of the individual fastening and may not be the same as the loads FN and FV acting on the fastened part.

Mrec [Nm]

M

N

Note: If relevant, prying forces need to be considered in design, see example.

Moment acting on fastener shank only in case of a gap between base and fastened

material.

Arrangement to prevent moment on shank:

Coupler tight against steel

Z2

Z1

FV

Z3

FN

FV

F

FN

182

12 / 2013

X-EM / X-EW

Application requirements

Thickness of base material

tll

X-EM6H/EW6H, X-EF7H

4 mm

X-EM8H/EW8H, X-EM10H/EW10H

6 mm

tII

Minimum steel thickness:

Thickness of fastened material

tI Lg twasher tnut 1.533.0 mm

tI

Trec

Spacing and edge distances

tII

Edge distance and spacing: c = s 15 mm

Corrosion information

The intended use only comprises fastenings which are not directly exposed to external

weather conditions or moist atmospheres. For further detailed information on corrosion see

relevant chapter in Direct Fastening Principles and Technique section.

12 / 2013

183

X-EM / X-EW

Application limits

X-EM6H, X-EW6H, X-EF7H

Steel thickness tII, [mm]

20

18

16

14

12

10

8

6

4

350

S235Jxx

S275Jxx

400

450

500

DX 460 tool:

X-EF7H-__-9

X-EM6H-__9,

X-EW6H-__-9

S355Jxx

550

600

Steel strength, Rm [N/mm2]

650

700

Steel thickness, tII [mm]

X-EM8H

20

18

16

14

12

10

8

6

350

DX 460 tool:

X-EM8H-__-12

2

1

S235Jxx

S275Jxx

400

450

500

DX 76 / DX 76 PTR tool

with X-76-F10-PTR fastener guide:

X-EM8H-15-12

S355Jxx

550

600

Steel strength, Rm [N/mm2]

650

700

Steel thickness tII, [mm]

X-EM10H / EW10H

20

18

16

14

12

10

8

6

350

184

S235Jxx

S275Jxx

400

450

500

DX 76 / DX 76 PTR tool:

X-EM10H-24-12

DX 600 N tool:

X-EW10H-30-14 P10

S355Jxx

550

600

Steel strength, Rm [N/mm2]

650

700

12 / 2013

X-EM / X-EW

Fastener selection and system recommendation

Fastener program

Base material

thickness

tll,min [mm]

4.0

6.0

Fastened

Fastener

thickness

Designation1)

tl,max [mm]

Item no.

Threading

length

Lg [mm]

Shank

lengths

Ls [mm]

DX tools

1.5

X-EM6H-8-9 FP8

271965

8.5

DX 460

4.5

X-EM6H-11-9 FP8

271963

11

8.5

DX 460

13.5

X-EM6H-20-9 FP8

271961

20

8.5

DX 460

4.5

X-EW6H-11-9 FP8

271973

11

8.5

DX 460

13.5

X-EW6H-20-9 FP8

271971

20

8.5

DX 460

21.5

X-EW6H-28-9 FP8

271969

28

8.5

DX 460

31.5

X-EW6H-38-9 FP8

271967

38

8.5

0.5

X-EF7H-7-9 FS8

271975

10

DX 460

2.0

X-EM8H-11-12 P8

271983

11

12

DX 460

6.0

X-EM8H-15-12 P8

271981

15

12

DX 460

6.0

X-EM8H-15-12 FP10 271982

15

12

DX 76 PTR, DX 460

14.0

X-EM10H-24-12 P10 271984

24

12

DX 76 PTR, DX 460

20.0

X-EW10H-30-14 P10 271985

30

14

DX 600 N

DX 460

) Type of threading: M = metric; W6, W10 = Whitworth 1/4; 3/8; F7 = French 7 mm

Cartridge recommendation

Tool energy adjustment by installation tests on site

Fastener

Tool

X-EM6H, X-EW6H DX 460

Base material

Base material thickness (mm) Cartridge selection

S235

S355

410

1020

4 6

620

420

6.8/11M green

6.8/11M yellow

6.8/11M green

6.8/11M yellow

6.8/11M yellow

S235

4 8

6.8/11M green

820

4 6

620

420

6.8/11M yellow

6.8/11M green

6.8/11M yellow

6.8/11M yellow

6 8

820

620

6.8/11M red

6.8/11M black

6.8/11M black

S275

X-EF7H

DX 460

S275

S355

X-EM8H

DX 460

S235, S275

S355

12 / 2013

185

X-EM / X-EW

Fastener

Tool

X-EM8H

DX 76 PTR S235

Base material

6 8

820

6 7

712

1220

610

1020

6 20

6 7

7 8

820

6 8

820

6 8

815

1520

6 8

812

1220

6 7

720

S275

S355

X-EM10H

DX 76 PTR S235

S275

S355

X-EW10H

DX 600 N

Base material thickness (mm) Cartridge selection

S235

S275

Fastening quality assurance

S355

6.8/18M blue

6.8/18M red

6.8/18M blue

6.8/18M red

6.8/18M black

6.8/18M red

6.8/18M black

6.8/18M yellow

6.8/18M yellow

6.8/18M blue

6.8/18M red

6.8/18M red

6.8/18M black

6.8/18 blue

6.8/18 red

6.8/18 black

6.8/18 blue

6.8/18 red

6.8/18 black

6.8/18 red

6.8/18 black

Fastening inspection

X-EM6H, X-EW6H, X-EF7H

X-EM8H, X-EM10H, X-EW10H

hNVS

Trec

hNVS

Nail standoff

Fastener

Tightening torque

hNVS

Trec

[mm]

[Nm]

8.011.0

X-EM8H-11-12

11.515.5

10.5

X-EM6H- / X-EW6H-11-9 9.512.5

X-EM8H-15-12

15.519.5

10.5

X-EM6H- / X-EW6H-20-9 18.521.5

X-EM10H-24-12

26.529.5

10.5

X-EW6H-28-9

26.529.5

X-EW10H-30-14

28.031.0

15.0

X-EW6H-38-9

36.539.5

9.012.0

Fastener

X-EM6H-8-9

X-EF7H-7-9

186

Tightening torque

hNVS

Trec

[mm]

[Nm]

tI

tI

Trec

Nail standoff

12 / 2013

You might also like

- 2013 201 - X-FCM Grating Fastening SystemDocument7 pages2013 201 - X-FCM Grating Fastening SystemDifa LiuNo ratings yet

- 2014 195 X-CR M - DFTM 2015 Engpdf Technical Information ASSET DOC 2597844Document5 pages2014 195 X-CR M - DFTM 2015 Engpdf Technical Information ASSET DOC 2597844Difa LiuNo ratings yet

- 2014 139 - X-EGN - X-GHP - X-GN - DFTM - 2015 - Engpdf - Technical - Information - ASSET - DOC - 2597819 PDFDocument5 pages2014 139 - X-EGN - X-GHP - X-GN - DFTM - 2015 - Engpdf - Technical - Information - ASSET - DOC - 2597819 PDFDifa LiuNo ratings yet

- Wind Turbines in Cold Climates: Icing Impacts and Mitigation SystemsFrom EverandWind Turbines in Cold Climates: Icing Impacts and Mitigation SystemsNo ratings yet

- PL F4 VB V5Document12 pagesPL F4 VB V5Anonymous PJP78mSxNo ratings yet

- MTN1185C DS0006 03Document2 pagesMTN1185C DS0006 03ancardenNo ratings yet

- 2014 119 X-U - DFTM 2015 Engpdf Technical Information ASSET DOC 2597808Document9 pages2014 119 X-U - DFTM 2015 Engpdf Technical Information ASSET DOC 2597808Difa LiuNo ratings yet

- The Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsFrom EverandThe Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsSylvain ClercNo ratings yet

- Bolt StandardDocument42 pagesBolt StandardSHIVASHANKARNo ratings yet

- 2014 237 X-HS X-CC - DFTM 2015 Engpdf Technical Information ASSET DOC 2597991Document6 pages2014 237 X-HS X-CC - DFTM 2015 Engpdf Technical Information ASSET DOC 2597991Difa LiuNo ratings yet

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- LEXMARK x204n Parts MaanualDocument12 pagesLEXMARK x204n Parts MaanualTiberiu RotilăNo ratings yet

- Which Process?: A Guide to the Selection of Welding and Related ProcessesFrom EverandWhich Process?: A Guide to the Selection of Welding and Related ProcessesNo ratings yet

- Hilti CatalogueDocument194 pagesHilti CatalogueFeleki AttilaNo ratings yet

- 2013 157 - X-CR - Steel - DFTM - 2015 - Engpdf - Technical - Information - ASSET - DOC - 2597828 PDFDocument4 pages2013 157 - X-CR - Steel - DFTM - 2015 - Engpdf - Technical - Information - ASSET - DOC - 2597828 PDFDifa LiuNo ratings yet

- PEM Self Clinching Miniature FastenersDocument6 pagesPEM Self Clinching Miniature FastenersAce Industrial SuppliesNo ratings yet

- Seco - Square 6 InsertosDocument12 pagesSeco - Square 6 InsertosRafael MundimNo ratings yet

- Komatsu O-Ring KitsDocument3 pagesKomatsu O-Ring KitsAlexander RuizNo ratings yet

- Kit KomatsuDocument4 pagesKit KomatsuAlexander RuizNo ratings yet

- Hilti HIT-HY 150 MAX anchor systemDocument12 pagesHilti HIT-HY 150 MAX anchor systemMihnea-Bogdan NicolaescuNo ratings yet

- DT 750 MOMF 5 Parker Check ValveDocument3 pagesDT 750 MOMF 5 Parker Check ValveMROstop.comNo ratings yet

- Thomson Roundrail 1PB SpecsheetDocument2 pagesThomson Roundrail 1PB SpecsheetElectromateNo ratings yet

- SEW Brake Motor Part ListDocument3 pagesSEW Brake Motor Part ListVenkateswara Rao TummalaNo ratings yet

- Post TensionDocument56 pagesPost TensionanoopsurendranNo ratings yet

- Pan-Steel Stainless Steel Fully Coated Ties and Tools SystemDocument4 pagesPan-Steel Stainless Steel Fully Coated Ties and Tools SystemGrimmo1979No ratings yet

- X BT Brochure en W3987Document68 pagesX BT Brochure en W3987Paul RobbinsNo ratings yet

- 2013 87 - X-EnP Siding and Decking NailDocument8 pages2013 87 - X-EnP Siding and Decking NailDifa LiuNo ratings yet

- Tratos Flex000Document64 pagesTratos Flex000twinvbooksNo ratings yet

- Tabela Completa Fusiveis PDFDocument57 pagesTabela Completa Fusiveis PDFJose Miguel MarquesNo ratings yet

- NAF Unex Butterfly 4141 GB PDFDocument8 pagesNAF Unex Butterfly 4141 GB PDFganeshanNo ratings yet

- Hilti - Calculo Manual de Re500Document41 pagesHilti - Calculo Manual de Re500James ClaytonNo ratings yet

- Three-point grippers optimize handling tasksDocument10 pagesThree-point grippers optimize handling tasksmohan raoNo ratings yet

- EJOT-pds-sw-8-rt-4-8-EN SURUB CU CALOTA PENTRU ACOPERIS CU PROFIL TRAPEZOIDALDocument2 pagesEJOT-pds-sw-8-rt-4-8-EN SURUB CU CALOTA PENTRU ACOPERIS CU PROFIL TRAPEZOIDALproteor_srlNo ratings yet

- Post-tensioning steel strands technical dataDocument28 pagesPost-tensioning steel strands technical datanovakno1No ratings yet

- Indesit Widl 106ex SMDocument34 pagesIndesit Widl 106ex SMDaniel Cristina50% (2)

- X ST GR Data Sheet Technical Information ASSET DOC 7304093Document5 pagesX ST GR Data Sheet Technical Information ASSET DOC 7304093Matt ThompsonNo ratings yet

- Base CHS X 10tDocument7 pagesBase CHS X 10tCollin NguNo ratings yet

- Beam End Connection ReportDocument6 pagesBeam End Connection ReportHibri HalimNo ratings yet

- Alternates TO Surface Mount Tantalum Electrolytic CapacitorsDocument21 pagesAlternates TO Surface Mount Tantalum Electrolytic CapacitorsGuGazNo ratings yet

- XOMOXLinedPlugValvesEMEA TechnicalDataDocument20 pagesXOMOXLinedPlugValvesEMEA TechnicalDataperoooNo ratings yet

- Transducer AccessoriesDocument6 pagesTransducer AccessoriesMohan ArumugavallalNo ratings yet

- Metric Prestomatic Air Brake Push-In Fittings: Advantages Technical DataDocument3 pagesMetric Prestomatic Air Brake Push-In Fittings: Advantages Technical DataZMCONTROLNo ratings yet

- Series: Vacuum PadDocument83 pagesSeries: Vacuum PadElias Ulises Manriquez FuentealbaNo ratings yet

- Sae and Din HosesDocument5 pagesSae and Din Hosesapi-247972389No ratings yet

- Siemens 3TF ContactorsDocument15 pagesSiemens 3TF ContactorsDavid tangkelangiNo ratings yet

- Cedarapids 6x20 - 54780Document40 pagesCedarapids 6x20 - 54780Blake Cooley Anderson100% (4)

- TECHLOK Clamp Connector Technical WebversionDocument32 pagesTECHLOK Clamp Connector Technical WebversionAndresNo ratings yet

- Hilti HST 1Document11 pagesHilti HST 1Mihnea-Bogdan NicolaescuNo ratings yet

- Hilti Hvu & HasDocument2 pagesHilti Hvu & HasSatyam Kumar MishraNo ratings yet

- Insulator PDFDocument11 pagesInsulator PDFmanoj_2027100% (1)

- Catálogo Conectores StäubliDocument0 pagesCatálogo Conectores StäubliFernando TulcánNo ratings yet

- TECHLOKDocument32 pagesTECHLOKgk_corina100% (1)

- Specs of Ducted UnitsDocument2 pagesSpecs of Ducted UnitsAdil MohdNo ratings yet

- Fiche - Prod - TFC - UD - 75 - 350-ACI - en - V04 Version TempDocument2 pagesFiche - Prod - TFC - UD - 75 - 350-ACI - en - V04 Version TempDifa LiuNo ratings yet

- BUILDING - ForevaDocument3 pagesBUILDING - ForevaDifa LiuNo ratings yet

- R 181 Piles in Rock PDFDocument144 pagesR 181 Piles in Rock PDFDifa LiuNo ratings yet

- Aluminium AnalysisDocument38 pagesAluminium AnalysisDifa LiuNo ratings yet

- ICP Brochure Technical Specs January 2019 HR PDFDocument16 pagesICP Brochure Technical Specs January 2019 HR PDFLavanyanNo ratings yet

- SC Corrosion Book FinalDocument64 pagesSC Corrosion Book FinalDifa Liu100% (1)

- R 181 Piles in RockDocument42 pagesR 181 Piles in RockDifa LiuNo ratings yet

- BRIDGES - ForevaDocument4 pagesBRIDGES - ForevaDifa LiuNo ratings yet

- THERMALDocument7 pagesTHERMALZabihullah SafiNo ratings yet

- BC1 Handbook Amd ADocument54 pagesBC1 Handbook Amd ACLEMENTNo ratings yet

- Eurocode example ex3.1.4 connection designDocument4 pagesEurocode example ex3.1.4 connection designРостислав Василев100% (2)

- Circular Publication of The Fire Code 2018 EditionDocument3 pagesCircular Publication of The Fire Code 2018 EditionDifa LiuNo ratings yet

- 2nd Choice Steel Connection (All Type) DHAN Good MahfuzDocument19 pages2nd Choice Steel Connection (All Type) DHAN Good MahfuzDifa LiuNo ratings yet

- Bolt DesignDocument5 pagesBolt DesignDifa LiuNo ratings yet

- Msds-Grout HGG 70spDocument2 pagesMsds-Grout HGG 70spDifa LiuNo ratings yet

- Grout Optiroc HGG 70spDocument2 pagesGrout Optiroc HGG 70spDifa LiuNo ratings yet

- Method of Statement For OPTIROC HGG 70SPDocument1 pageMethod of Statement For OPTIROC HGG 70SPDifa LiuNo ratings yet

- Design Guide For Structure & FoundationDocument50 pagesDesign Guide For Structure & FoundationDifa Liu100% (1)

- Msds-Grout HGG 70spDocument2 pagesMsds-Grout HGG 70spDifa LiuNo ratings yet

- Hilti2015 Hi ResDocument674 pagesHilti2015 Hi ResDifa LiuNo ratings yet

- 2014 257 X-FB - DFTM 2015 Engpdf Technical Information ASSET DOC 2598645Document4 pages2014 257 X-FB - DFTM 2015 Engpdf Technical Information ASSET DOC 2598645Difa LiuNo ratings yet

- 2013 209 - X-GR-RU Grating Fastening SystemDocument4 pages2013 209 - X-GR-RU Grating Fastening SystemDifa LiuNo ratings yet

- 2013 265 - X-ET For Fastening Plastic Electrical Cable Trays and Junction Boxes PDFDocument4 pages2013 265 - X-ET For Fastening Plastic Electrical Cable Trays and Junction Boxes PDFDifa LiuNo ratings yet

- 2014 423 HT Metal Frame AnchorDocument4 pages2014 423 HT Metal Frame AnchorDifa LiuNo ratings yet

- 2015 177 X-M6 X-W6 X-M8 M10 W10 - DFTM 2015 Engpdf Technical Information ASSET DOC 2597835Document4 pages2015 177 X-M6 X-W6 X-M8 M10 W10 - DFTM 2015 Engpdf Technical Information ASSET DOC 2597835Difa LiuNo ratings yet

- 2014 237 X-HS X-CC - DFTM 2015 Engpdf Technical Information ASSET DOC 2597991Document6 pages2014 237 X-HS X-CC - DFTM 2015 Engpdf Technical Information ASSET DOC 2597991Difa LiuNo ratings yet

- Access Covers Grates & AccessoriesDocument60 pagesAccess Covers Grates & AccessoriesBarrasons Engineers TeamNo ratings yet

- Hydrogen Embrittlement - Identifying AppearanceDocument2 pagesHydrogen Embrittlement - Identifying AppearanceeragornNo ratings yet

- Aerospace Fasteners and Supplier GuideDocument2 pagesAerospace Fasteners and Supplier GuideCTN2010No ratings yet

- Civil SpecsDocument136 pagesCivil Specsshravan.office11No ratings yet

- Wood ConnectionsDocument289 pagesWood ConnectionsMelissa Graham100% (1)

- Section 06 4023 - Interior Architectural WoodworkDocument32 pagesSection 06 4023 - Interior Architectural WoodworkMuhammad AbuBakarNo ratings yet

- Peikko Katalog 2011Document64 pagesPeikko Katalog 2011Vilandas CeNo ratings yet

- Approval Standard For Explosion Venting SystemsDocument15 pagesApproval Standard For Explosion Venting Systemsrafael1978No ratings yet

- 2013 181 X-Em6h X-Ew6h X-Ef7h X-Em8h X-Em10h Ew10h - Threaded Studs For SteelDocument6 pages2013 181 X-Em6h X-Ew6h X-Ef7h X-Em8h X-Em10h Ew10h - Threaded Studs For SteelDifa LiuNo ratings yet

- Null ADMSNo 304591v1nullDocument16 pagesNull ADMSNo 304591v1nullThanga PandiNo ratings yet

- MIL-DTL-1222J Detailed Specification for High Reliability FastenersDocument51 pagesMIL-DTL-1222J Detailed Specification for High Reliability Fastenerswmish7419No ratings yet

- X-ECT MX, X-UCT MX and X-EKS MX fasteners and toolsDocument4 pagesX-ECT MX, X-UCT MX and X-EKS MX fasteners and toolsDifa LiuNo ratings yet

- Bolted ConnectionsDocument9 pagesBolted ConnectionsClaudioDuarte100% (1)

- Fasteners - Stainless Steel: Profile No.: 120 NIC Code:24109Document10 pagesFasteners - Stainless Steel: Profile No.: 120 NIC Code:24109Sabhaya ChiragNo ratings yet

- Bollhoff Rivnut USADocument36 pagesBollhoff Rivnut USAAce Industrial SuppliesNo ratings yet

- Vandanfasteners.comDocument62 pagesVandanfasteners.comVandan786No ratings yet

- Building Estimate... PWD ModelDocument240 pagesBuilding Estimate... PWD ModelEr Pranabesh Sen67% (6)

- Avdel RevetDocument104 pagesAvdel RevetvinodmysoreNo ratings yet

- DME - TWO MARK QUESTIONS & ANSWERS ON FASTENERS AND WELDSDocument5 pagesDME - TWO MARK QUESTIONS & ANSWERS ON FASTENERS AND WELDSDamotharan Sathesh Kumar100% (1)

- A307-14 Standard Specification For Carbon Steel Bolts, Studs, and Threaded Rod 60000 PSI Tensile StrengthDocument6 pagesA307-14 Standard Specification For Carbon Steel Bolts, Studs, and Threaded Rod 60000 PSI Tensile Strengthmasv792512No ratings yet

- Workshop VivaDocument14 pagesWorkshop VivaharoldjoysonNo ratings yet

- 1 Swot RohitDocument16 pages1 Swot RohitRohit TripathiNo ratings yet

- Ec 1110-2-288 Standard Designs For Lock Dam and Waterway SignsDocument50 pagesEc 1110-2-288 Standard Designs For Lock Dam and Waterway Signssonjo_suaNo ratings yet

- Process Industry Practices Structural: PIP STF05530 Grating Fabrication DetailsDocument13 pagesProcess Industry Practices Structural: PIP STF05530 Grating Fabrication DetailsloukmanNo ratings yet

- Evaluation of Alternatives To Electrodeposited Cadmium For Threaded Fasteners Applications (III)Document13 pagesEvaluation of Alternatives To Electrodeposited Cadmium For Threaded Fasteners Applications (III)mp87_ingNo ratings yet

- Astm A193 - 2019 - ObsoletoDocument13 pagesAstm A193 - 2019 - ObsoletoRicardo Ricardo100% (1)

- Suspender ELCODocument8 pagesSuspender ELCOTahir Waseem KhanNo ratings yet

- Stress Analysis of Riveted Lap JointDocument7 pagesStress Analysis of Riveted Lap JointMeck LotfiNo ratings yet

- GTTPL Technical Specifications Full EpcDocument10 pagesGTTPL Technical Specifications Full EpcPinku MaitiNo ratings yet

- PLP TH Solar RoofDocument38 pagesPLP TH Solar RoofTuấn NguyễnNo ratings yet