Professional Documents

Culture Documents

2014 195 X-CR M - DFTM 2015 Engpdf Technical Information ASSET DOC 2597844

Uploaded by

Difa LiuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2014 195 X-CR M - DFTM 2015 Engpdf Technical Information ASSET DOC 2597844

Uploaded by

Difa LiuCopyright:

Available Formats

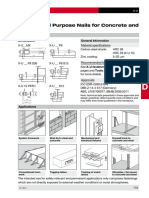

X-CRM

X-CR M Stainless Steel Threaded Studs for

Concrete and Steel

Product data

Dimensions

General information

X-CR M8-__-42 P8 (DX-Kwik)

Material specifications

Shank:

CrNiMo alloy

fu 1800 N/mm2

(49 HRC)

Threaded sleeve:

A4 (AlSI 316)

o8

M8

o 6.3

o 4.5

Threaded sleeve: A4 (AlSi 316)

Lg

42

L

X-CR M8-__-12 FP10 X-CR M8-__-12 P8

Threaded sleeve: A4 (AlSi 316

5

4

M8 o 4

Threaded sleeve: A4 (AlSi 316

M8 o 4

o 10

Lg

12.5

30

o8

Lg

12.5

30

Zinc coating to facilitate

anchoring in concrete

(X-CR M8-__-42):

513 m

Washers/

guidance sleeve:

polyethylene

Recommended fastening tools

DX 460, DX 36, DX 2, DX 76, DX 76 PTR

See X-CR M fastener program in the next pages and

Tools and equipment chapter for more details.

Approvals

DIBt (Germany):

X-CR M8-__-42 P8

(DX-Kwik)

ICC ESR-2347:

X-CR M8-9-12,

X-CR M8-15-12

ABS, LR:

all types

Note: technical data presented in these approvals and

design guidelines reflect specific local conditions and

may differ from those published in this handbook.

10 / 2014

195

X-CRM

Applications

Examples

Base plates for pipe

rings

Installation rails

Facade brackets

Special purpose

connections

Load data

Recommended loads

Fastening to steel

Nrec [kN]

Vrec [kN]

Mrec [Nm]

X-CR M8

1.8

1.8

5.5

Conditions:

For safety-relevant fastenings sufficient redundancy of the entire system is required.

Fastening to concrete DX-Kwik method (pre-drilling)

Nrec,1 [kN]

Nrec,2 [kN]

Vrec [kN]

Mrec [Nm]

X-CR M8-__-42 P8

3.0

0.9

3.0

5.5

Conditions:

Nrec,1: concrete in compressive zone

Nrec,2: concrete in tension zone

fcc 20 N/mm2

A sufficient redundancy has to be ensured, that the failure of a single fastening will not lead

to collapse of the entire system.

Observance of all pre-drilling requirements

Arrangements to reduce or prevent moment on shank:

FV

FN

196

10 / 2014

X-CRM

Application requirements

Thickness of base material

Steel

tll 6 mm

tII

Concrete DX-Kwik

hmin = 100 mm

Thickness of fastened material

X-CR M8

tl Lg - twasher - tnut up to 13.0 mm

Spacing and edge distances (mm)

Fastening to steel

c

c, s 15 mm

tII

Fastening to concrete

Pairs

Row along edge

20

200

50

100

150

200

200

Reinforced * Non-reinforced

200

50

General (e.g. group of fasteners

80

150

Reinforced * Non-reinforced

Reinforced * Non-reinforced

80

150

80

100

* Minimum 6 reinforcing steel continuous along all edges and around all corners. Edge bars must be enclosed

by stirrups

Corrosion information

For fastenings exposed to weather or other corrosive conditions. Not for use in highly corrosive surroundings like swimming pools or highway tunnels.

10 / 2014

197

X-CRM

Application limits

Concrete:

No general restrictions existent. Limitations are dependent on application and user requirements.

Steel:DX 460

20

18

Steel thickness, tII [mm]

Steel thickness, tII [mm]

Steel: DX 76, DX 76 PTR

20

16

2

14

12

10

8

400

450 500 550 600 650

Steel strength, Rm [N/mm2]

18

16

12

10

8

400

700

X-CRM8-15-12 FP10 / DX 76 (impact)

X-CRM8-15-12 FP10 / DX 76 (co-acting)

14

450 500 550 600 650

Steel strength, Rm [N/mm2]

700

X-CRM8-15-12 P8 / DX 460 (impact)

X-CRM8-15-12 P8 / DX 460 (co-acting)

Fastener selection and system recommendation

Fastener program

Fastened thickness Fastener

Designation 1)

tI,max [mm]

Item no.

Lg [mm]

Ls [mm]

Tools

Base material concrete, DX-Kwik method

5.0

X-CR M8-14-42 P8

255911

14

42

DX 460, DX 36, DX 2

13.0

X-CR M8-22-42 P8

255910

22

42

DX 460, DX 36, DX 2

DX 460

Base material steel

6.0

X-CR M8-9-12 P8

372031

12.5

6.0

X-CR M8-15-12 P8

372033

15

12.5

DX 460

6.0

X-CR M8-9-12 FP10

372032

12.5

DX 460, DX 76, DX 76 PTR

6.0

X-CR M8-15-12 FP10 372 034

15

12.5

DX 460, DX 76, DX 76 PTR

) Type threading: M = metric; W6 = Whitworth 1/4

Cartridge selection and tool energy setting

Base material

Designation

Tool

Concrete

6.8/11M yellow or red cartridge

DX 460, DX 36, DX 2

Steel

6.8/11M red cartridge

DX 460

Steel

6.8/18M cartridge

DX 76, DX 76 PTR

Tool energy adjustment by setting tests on site.

198

10 / 2014

X-CRM

Fastening quality assurance

Fastening inspection

Fastening to steel

hNVS

Fastening to concrete

DX-Kwik (pre-drilling)

Fastener

hNVS [mm]

X-CR M8-14-42 P8

12.0 16.0

X-CR M8-22-42 P8

20.0 24.0

Fastener

hNVS [mm]

X-CR M8-9-12 P8

12.0 15.0

X-CR M8-15-12 P8

17.0 20.0

X-CR M8-9-12 FP10

12.0 15.0

X-CR M8-15-12 FP10

17.0 20.0

Installation

Fastening to concrete

Fastening to steel

DX-Kwik (pre-drilling)

X-CR M8-__-42 P8

Pre-drill with drill bit

TE-C-5/23B (Item-no.

28557) or TE-C-5/23

(Item no. 00061787)

tI

23

o5

Trec

tI

Trec

Tightening torque

Trec = 10 Nm

Tightening torque

X-CR M8

Trec = 8.5 Nm

These are abbreviated instructions which may vary by application.

ALWAYS review/follow the instructions accompanying the product.

10 / 2014

199

You might also like

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- 2013 157 - X-CR - Steel - DFTM - 2015 - Engpdf - Technical - Information - ASSET - DOC - 2597828 PDFDocument4 pages2013 157 - X-CR - Steel - DFTM - 2015 - Engpdf - Technical - Information - ASSET - DOC - 2597828 PDFDifa LiuNo ratings yet

- 2013 201 - X-FCM Grating Fastening SystemDocument7 pages2013 201 - X-FCM Grating Fastening SystemDifa LiuNo ratings yet

- 2014 119 X-U - DFTM 2015 Engpdf Technical Information ASSET DOC 2597808Document9 pages2014 119 X-U - DFTM 2015 Engpdf Technical Information ASSET DOC 2597808Difa LiuNo ratings yet

- 2015 187 X-BT - DFTM 2015 Engpdf Technical Information ASSET DOC 2597837Document8 pages2015 187 X-BT - DFTM 2015 Engpdf Technical Information ASSET DOC 2597837Difa LiuNo ratings yet

- 2014 237 X-HS X-CC - DFTM 2015 Engpdf Technical Information ASSET DOC 2597991Document6 pages2014 237 X-HS X-CC - DFTM 2015 Engpdf Technical Information ASSET DOC 2597991Difa LiuNo ratings yet

- 2013 181 X-Em6h X-Ew6h X-Ef7h X-Em8h X-Em10h Ew10h - Threaded Studs For SteelDocument6 pages2013 181 X-Em6h X-Ew6h X-Ef7h X-Em8h X-Em10h Ew10h - Threaded Studs For SteelDifa LiuNo ratings yet

- X BT Brochure en W3987Document68 pagesX BT Brochure en W3987Paul RobbinsNo ratings yet

- Hilti Direct Fastening SystemsDocument17 pagesHilti Direct Fastening Systemsbharathanin100% (1)

- X-ECT MX, X-UCT MX and X-EKS MX fasteners and toolsDocument4 pagesX-ECT MX, X-UCT MX and X-EKS MX fasteners and toolsDifa LiuNo ratings yet

- X-C Nails For Concrete and Sand-lime-Masonry: General Information Dimensions Product DataDocument5 pagesX-C Nails For Concrete and Sand-lime-Masonry: General Information Dimensions Product DataDifa LiuNo ratings yet

- Hilti CatalogueDocument194 pagesHilti CatalogueFeleki AttilaNo ratings yet

- 2014 139 - X-EGN - X-GHP - X-GN - DFTM - 2015 - Engpdf - Technical - Information - ASSET - DOC - 2597819 PDFDocument5 pages2014 139 - X-EGN - X-GHP - X-GN - DFTM - 2015 - Engpdf - Technical - Information - ASSET - DOC - 2597819 PDFDifa LiuNo ratings yet

- Pan-Steel Stainless Steel Fully Coated Ties and Tools SystemDocument4 pagesPan-Steel Stainless Steel Fully Coated Ties and Tools SystemGrimmo1979No ratings yet

- Hilti HIT-HY 150 MAX anchor systemDocument12 pagesHilti HIT-HY 150 MAX anchor systemMihnea-Bogdan NicolaescuNo ratings yet

- GI - Thermowell CatalogueDocument18 pagesGI - Thermowell CatalogueMahdy MazinyNo ratings yet

- Design AnchorDocument16 pagesDesign AnchorshankerNo ratings yet

- 2013 87 - X-EnP Siding and Decking NailDocument8 pages2013 87 - X-EnP Siding and Decking NailDifa LiuNo ratings yet

- 44 - HVZ Adhesive AnchorDocument14 pages44 - HVZ Adhesive AnchorHuan VoNo ratings yet

- X ST GRDocument4 pagesX ST GRkerolcarrollNo ratings yet

- FTM '12 HAM Hard Sleeve AnchorDocument2 pagesFTM '12 HAM Hard Sleeve AnchorshankerNo ratings yet

- Chumbador HiltDocument14 pagesChumbador HiltSamanta FigueredoNo ratings yet

- X ST GR Data Sheet Technical Information ASSET DOC 7304093Document5 pagesX ST GR Data Sheet Technical Information ASSET DOC 7304093Matt ThompsonNo ratings yet

- Hilti HDA 1Document16 pagesHilti HDA 1Mihnea-Bogdan NicolaescuNo ratings yet

- HSL-3 Heavy Duty Anchor: Basic Loading Data (For A Single Anchor) : HSL-3/HSL-3-SHDocument10 pagesHSL-3 Heavy Duty Anchor: Basic Loading Data (For A Single Anchor) : HSL-3/HSL-3-SHAlexandru OlaruNo ratings yet

- Valvula Borboleta Lug z411 ADocument6 pagesValvula Borboleta Lug z411 AWellington S. FrançaNo ratings yet

- HVZ adhesive anchor installation and design guideDocument13 pagesHVZ adhesive anchor installation and design guideMihnea-Bogdan NicolaescuNo ratings yet

- 738546Document3 pages738546DmitriiSpiridonovNo ratings yet

- Hilti ClipDocument6 pagesHilti ClipmandregomesNo ratings yet

- Montavimo Technika Armaturos StrypamsDocument5 pagesMontavimo Technika Armaturos StrypamsHafidh BaequnieNo ratings yet

- HIT-TZ Injection Adhesive Anchor: HIT-HY 150 Foil Pack, MixerDocument11 pagesHIT-TZ Injection Adhesive Anchor: HIT-HY 150 Foil Pack, Mixerlael00No ratings yet

- Base CHS X 10tDocument7 pagesBase CHS X 10tCollin NguNo ratings yet

- Hilti HST 1Document11 pagesHilti HST 1Mihnea-Bogdan NicolaescuNo ratings yet

- Mitubishi APX PDFDocument24 pagesMitubishi APX PDFZeljko StamatovicNo ratings yet

- Mitsubishi Frézy APX3000Document16 pagesMitsubishi Frézy APX3000Jan MolekNo ratings yet

- 2011 HSC-I Safety AnchorDocument3 pages2011 HSC-I Safety AnchorDifa LiuNo ratings yet

- MEFA Beam ClampsDocument3 pagesMEFA Beam ClampsgeorgecisNo ratings yet

- Material Selection and NameDocument6 pagesMaterial Selection and NameHlaingm KyawNo ratings yet

- Stainless Steel Cable Ties and AccessoriesDocument5 pagesStainless Steel Cable Ties and AccessoriesAdelChNo ratings yet

- DW144 Smacna 2005Document32 pagesDW144 Smacna 2005Angel Daniel GarciajoyaNo ratings yet

- Quick Rak CatalogDocument22 pagesQuick Rak CatalogQuickRakNo ratings yet

- Rigid Flange Coupling Design & AnalysisDocument8 pagesRigid Flange Coupling Design & AnalysisAbhishek ChauhanNo ratings yet

- ELGES Alloy Steel Rod Ends: Corrosion-ResistantDocument8 pagesELGES Alloy Steel Rod Ends: Corrosion-Resistantdunareanu_marian8668No ratings yet

- I - Rectangular Ducts: II - Rectangular Ducts WeldedDocument32 pagesI - Rectangular Ducts: II - Rectangular Ducts WeldedRoy Anthone Layson100% (11)

- 100 Series Ordering GuideDocument8 pages100 Series Ordering GuideElectromateNo ratings yet

- HeliCoil Tangless InsertsDocument6 pagesHeliCoil Tangless InsertsAce Industrial SuppliesNo ratings yet

- 3 SpringDocument66 pages3 Springall_meca_allNo ratings yet

- Natsteel BRCDocument8 pagesNatsteel BRClwin_oo2435No ratings yet

- Sub Sec 1 To 9Document7 pagesSub Sec 1 To 9khan4luvNo ratings yet

- HDADocument13 pagesHDAnetozxNo ratings yet

- Trugrid Structural Final DraftDocument27 pagesTrugrid Structural Final DraftrogerngcyNo ratings yet

- 3.2.2 General Application Fasteners (31-36) r21Document9 pages3.2.2 General Application Fasteners (31-36) r21Jonathan DouglasNo ratings yet

- Dywidag DSI Baranchor enDocument8 pagesDywidag DSI Baranchor enwalitedisonNo ratings yet

- Rothoblaas - Alumidi Bracket With Holes - Technical Data Sheets - enDocument6 pagesRothoblaas - Alumidi Bracket With Holes - Technical Data Sheets - enAndrei GheorghicaNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- BRIDGES - ForevaDocument4 pagesBRIDGES - ForevaDifa LiuNo ratings yet

- 2nd Choice Steel Connection (All Type) DHAN Good MahfuzDocument19 pages2nd Choice Steel Connection (All Type) DHAN Good MahfuzDifa LiuNo ratings yet

- Fiche - Prod - TFC - UD - 75 - 350-ACI - en - V04 Version TempDocument2 pagesFiche - Prod - TFC - UD - 75 - 350-ACI - en - V04 Version TempDifa LiuNo ratings yet

- BUILDING - ForevaDocument3 pagesBUILDING - ForevaDifa LiuNo ratings yet

- Grout Optiroc HGG 70spDocument2 pagesGrout Optiroc HGG 70spDifa LiuNo ratings yet

- Eurocode example ex3.1.4 connection designDocument4 pagesEurocode example ex3.1.4 connection designРостислав Василев100% (2)

- R 181 Piles in RockDocument42 pagesR 181 Piles in RockDifa LiuNo ratings yet

- ICP Brochure Technical Specs January 2019 HR PDFDocument16 pagesICP Brochure Technical Specs January 2019 HR PDFLavanyanNo ratings yet

- THERMALDocument7 pagesTHERMALZabihullah SafiNo ratings yet

- Aluminium AnalysisDocument38 pagesAluminium AnalysisDifa LiuNo ratings yet

- R 181 Piles in Rock PDFDocument144 pagesR 181 Piles in Rock PDFDifa LiuNo ratings yet

- Msds-Grout HGG 70spDocument2 pagesMsds-Grout HGG 70spDifa LiuNo ratings yet

- BC1 Handbook Amd ADocument54 pagesBC1 Handbook Amd ACLEMENTNo ratings yet

- Circular Publication of The Fire Code 2018 EditionDocument3 pagesCircular Publication of The Fire Code 2018 EditionDifa LiuNo ratings yet

- SC Corrosion Book FinalDocument64 pagesSC Corrosion Book FinalDifa Liu100% (1)

- Bolt DesignDocument5 pagesBolt DesignDifa LiuNo ratings yet

- Method of Statement For OPTIROC HGG 70SPDocument1 pageMethod of Statement For OPTIROC HGG 70SPDifa LiuNo ratings yet

- Hilti2015 Hi ResDocument674 pagesHilti2015 Hi ResDifa LiuNo ratings yet

- 2013 265 - X-ET For Fastening Plastic Electrical Cable Trays and Junction Boxes PDFDocument4 pages2013 265 - X-ET For Fastening Plastic Electrical Cable Trays and Junction Boxes PDFDifa LiuNo ratings yet

- Design Guide For Structure & FoundationDocument50 pagesDesign Guide For Structure & FoundationDifa Liu100% (1)

- Msds-Grout HGG 70spDocument2 pagesMsds-Grout HGG 70spDifa LiuNo ratings yet

- 2015 177 X-M6 X-W6 X-M8 M10 W10 - DFTM 2015 Engpdf Technical Information ASSET DOC 2597835Document4 pages2015 177 X-M6 X-W6 X-M8 M10 W10 - DFTM 2015 Engpdf Technical Information ASSET DOC 2597835Difa LiuNo ratings yet

- 2014 257 X-FB - DFTM 2015 Engpdf Technical Information ASSET DOC 2598645Document4 pages2014 257 X-FB - DFTM 2015 Engpdf Technical Information ASSET DOC 2598645Difa LiuNo ratings yet

- 2013 209 - X-GR-RU Grating Fastening SystemDocument4 pages2013 209 - X-GR-RU Grating Fastening SystemDifa LiuNo ratings yet

- 2014 237 X-HS X-CC - DFTM 2015 Engpdf Technical Information ASSET DOC 2597991Document6 pages2014 237 X-HS X-CC - DFTM 2015 Engpdf Technical Information ASSET DOC 2597991Difa LiuNo ratings yet

- 2014 139 - X-EGN - X-GHP - X-GN - DFTM - 2015 - Engpdf - Technical - Information - ASSET - DOC - 2597819 PDFDocument5 pages2014 139 - X-EGN - X-GHP - X-GN - DFTM - 2015 - Engpdf - Technical - Information - ASSET - DOC - 2597819 PDFDifa LiuNo ratings yet

- 2014 423 HT Metal Frame AnchorDocument4 pages2014 423 HT Metal Frame AnchorDifa LiuNo ratings yet

- 2013 181 X-Em6h X-Ew6h X-Ef7h X-Em8h X-Em10h Ew10h - Threaded Studs For SteelDocument6 pages2013 181 X-Em6h X-Ew6h X-Ef7h X-Em8h X-Em10h Ew10h - Threaded Studs For SteelDifa LiuNo ratings yet

- Pro/MFG Volume Milling Tutorial: ObjectivesDocument17 pagesPro/MFG Volume Milling Tutorial: ObjectivesDamodara ReddyNo ratings yet

- CLASSIFY ZINC DIE CASTING DEFECTSDocument20 pagesCLASSIFY ZINC DIE CASTING DEFECTSAnshuman RoyNo ratings yet

- Aggregate Planning Guide for Production and Resource ManagementDocument41 pagesAggregate Planning Guide for Production and Resource ManagementSeema100% (2)

- CPP103 CNC Steel Plate Marking and Punching MachineDocument7 pagesCPP103 CNC Steel Plate Marking and Punching MachineReza MuhammadNo ratings yet

- Cera Grout Ep 42Document2 pagesCera Grout Ep 42MohamedSherinCpNo ratings yet

- National Conference Proceedings on Mechanical Engineering TrendsDocument8 pagesNational Conference Proceedings on Mechanical Engineering TrendsBibekanand PadhiNo ratings yet

- KaikakuDocument11 pagesKaikakuvijay2101No ratings yet

- Axial Cylindrical Roller Bearings - Cages and WashersDocument14 pagesAxial Cylindrical Roller Bearings - Cages and WashersKamlesh DalavadiNo ratings yet

- Maruti Suzuki - CSDocument5 pagesMaruti Suzuki - CSNambi Rajan100% (1)

- ASME IX Interpretation-Part4Document46 pagesASME IX Interpretation-Part4kevin herryNo ratings yet

- Material Management 2 (B)Document30 pagesMaterial Management 2 (B)Asad AliNo ratings yet

- Astm A 564Document7 pagesAstm A 564GeorgeAzmirNo ratings yet

- Mr. A. Panchariya Dept. of Mech. Engg. MNIT JaipurDocument143 pagesMr. A. Panchariya Dept. of Mech. Engg. MNIT JaipurAnand KumarNo ratings yet

- Fabric Defects & InspectionDocument23 pagesFabric Defects & InspectionYogesh SharmaNo ratings yet

- C050205 - 0712 - 1112 - E - RGL - Specter - After Sales - FULL - 1 PDFDocument10 pagesC050205 - 0712 - 1112 - E - RGL - Specter - After Sales - FULL - 1 PDFJhonatan Isaac Zaragoza PerezNo ratings yet

- Admer - Rigid Packaging PDFDocument6 pagesAdmer - Rigid Packaging PDFHOANGVUNL1988No ratings yet

- SoleRebels PDFDocument2 pagesSoleRebels PDFnicolNo ratings yet

- Analysis of Surface Roughness on Machining of Al-5Cu AlloyDocument4 pagesAnalysis of Surface Roughness on Machining of Al-5Cu AlloyPermadi YusufNo ratings yet

- GLASS Industry of The FutureDocument108 pagesGLASS Industry of The FuturebooksengineerNo ratings yet

- Process Costing WorksheetDocument21 pagesProcess Costing WorksheetpchakkrapaniNo ratings yet

- Polymer Waste: Controlled Breakdown or Recycling? by Brigitta BODZAY and György BÁNHEGYI, Ijdst v22n2 (2016) Paper 6Document40 pagesPolymer Waste: Controlled Breakdown or Recycling? by Brigitta BODZAY and György BÁNHEGYI, Ijdst v22n2 (2016) Paper 6György BánhegyiNo ratings yet

- Power Plant Familiarisation and DCS AdvantagesDocument22 pagesPower Plant Familiarisation and DCS AdvantagesSethu NaiduNo ratings yet

- Prepack Concrete & MortarDocument4 pagesPrepack Concrete & MortarfairmatechemicalNo ratings yet

- Sika PDS - E - SikaGrout - 214-11 HF PDFDocument3 pagesSika PDS - E - SikaGrout - 214-11 HF PDFlwin_oo2435No ratings yet

- BHEL MECHANICAL Training ReportDocument118 pagesBHEL MECHANICAL Training Reportgopikrishnandotpilla50% (2)

- NORSOK M-601 Annex C Weld Inspection GuideDocument1 pageNORSOK M-601 Annex C Weld Inspection Guidehalim abas100% (1)

- Frictional Properties of Textile FiberDocument8 pagesFrictional Properties of Textile FiberMD Nazrul IslamNo ratings yet

- Chapter 1 PDFDocument12 pagesChapter 1 PDFAdoree RamosNo ratings yet

- Current Good Manufacturing Practice - Fda CGMPDocument3 pagesCurrent Good Manufacturing Practice - Fda CGMPckbhaiNo ratings yet

- Milling Machine GuideDocument15 pagesMilling Machine GuidetgimranNo ratings yet