Professional Documents

Culture Documents

Connections

Uploaded by

siva0810Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Connections

Uploaded by

siva0810Copyright:

Available Formats

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

Title Slide

S T E E L

STRUCTURE OF THE EVERYDAY :

a teaching primer for colleges of architecture

Structural Steel Connections

STEEL

American Institute of Steel Construction1

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

S T E E L

PRODUCTION TEAM College of Architecture

UNC - Charlotte

Project Director

David Thaddeus, AIA

Slide Design & Graphics

Deborah J. Arbes, RA

Modeling & Animations

Production Assistants

Joe Corsi

Dave Mayo

Jennifer August

Brittany Eaker

Kathy Phillips

IT Coordination Matt Parker

Photography

David Thaddeus, AIA

John Cerny

Software PowerPoint

Photoshop

Cinema 4D (Mac)

For additional information,

please contact:

College of Architecture,

UNC-Charlotte

David Thaddeus, AIA, Associate Professor

Thaddeus@email.uncc.edu

Structural Steel Connections | CREDITS

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

S T E E L

Acknowledgements

This project was made possible through funding from the American Institute of Steel Construction (AISC)

with support from the College of Architecture at the University of North Carolina at Charlotte

Special thanks to the following people at AISC for their support and help over the duration of the project:

Fromy Rosenberg,PE, Director, AISC University Programs

Megan Maurer, Coordinator, AISC University Programs

The following people have my sincere gratitude for serving on the Focus Group and offering their

comments and feedback in the development of this project :

Kurt Baumgartner, AIA, JIA, University of Illinois at Urbana Champaign

Terri Meyer Boake, Associate Professor, University of Waterloo

Thomas Fowler, Associate Professor, California Polytechnic State University

Harry Kaufman, PE, NCARB, Professor, Southern Polytechnic State University

Kemp Mooney, Kemp Mooney Architects

Tim Mrozowski, AIA, Professor, Michigan State University

Ryan Smith, Assistant Professor, University of Utah

The following AISC members have provided invaluable insight into the content of this teaching aid:

Ron Bruce, PE, President, Builders Steel Company, North Kansas City, MO

Lawrence Kruth, PE, Engineering & Safety Manager, Douglas Steel, Lansing, MI

David McKenzie, PE, Vice President - Engineering, SP International, North Kansas City, MO

Structural Steel Connections | ACKNOWLEDGEMENTS

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

S T E E L

Terms

The American Institute of Steel Construction (AISC) is a non-profit technical

institute and trade association established in 1921 to serve the structural steel

design community and construction industry in the United States.

AISC is offering this teaching aid and learning tool for educational purposes only.

The data and information in this presentation is not intended for use in the

physical construction of steel structures.

The information presented here is considered public information and as such may

be distributed or copied. The use of appropriate credit to for images, byline,

animations, and content is requested.

We hope that you and your students will find this information useful.

Please contact Fromy Rosenberg (rosenberg@aisc.org) for further information

on AISC or for feedback on this teaching / learning product.

Please contact David Thaddeus (thaddeus@email.uncc.edu) for questions or

comments on the content of this project.

Structural Steel Connections | TERMS

a teaching primer for colleges of architecture

Structural Steel Connections

Steel to Steel Connections

Overview

Bolted Connections

Welded Connections

Comparison

Shear Connections

Moment Connections

Column Splices

Additional Animations

Roller Connection

Curtain Wall to Steel Frame

S T E E L

STRUCTURE OF THE EVERYDAY

Contents

Module III

Contents :

Structural Steel Connections | CONTENTS

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

S T E E L

Steel Connections | Overview

Connections are the glue that

holds a steel structure together.

Historically, most major structural failures have

been due to some form of connection failure.

Connections depend on:

Type of loading

Strength and stiffness

Economy

Difficulty or ease of erection

Structural Steel Connections | OVERVIEW

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

Steel connections have a direct influence

on the cost of the framing system.

While a connection may be efficient in the use

of material, it may still be very expensive to erect.

Repetitive connection design may save costs.

S T E E L

Structural Steel Connections | OVERVIEW

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

Most connections have the connecting material (plates,angles, ) attached

to one member in the fabrication shop and to the other members in the field.

It is a common practice to weld shop attachments and to bolt field attachments.

If the supporting girder and a supported beam have the same depth,

the supported beam must be double coped.

End-plate connections are always shop welded.

S T E E L

Structural Steel Connections | OVERVIEW

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

S T E E L

Steel Connections | Bolted Connections

Bolting is the preferred method of

connecting members on the site.

Staggered bolt layout allows easier

access for tightening with a pneumatic

wrench when a connection is all bolted .

High strength bolts may be snug-tightened

or slip-critical.

Snug-tightened connections are referred

to as bearing connections

Bolts in a slip-critical connection act like

clamps holding the plies of the material

together.

Structural Steel Connections | BOLTED CONNECTIONS

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

S T E E L

Bearing type connections may have threads

included ( Type N ) or excluded ( Type X )

from the shear plane(s).

Including the threads in the shear plane

reduces the strength of the connection

by approximately 25%.

Loading along the length of the bolt

puts the bolt in axial tension.

If tension failure occurs, it usually takes

place at the threaded section.

Cy Twombly Gallery. Houston, Texas

Renzo Piano

Milwaukee Art Museum. Milwaukee, Wisconsin

Santiago Calatrava

Structural Steel Connections | BOLTED CONNECTIONS

10

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

S T E E L

Three types of high strength bolts

A325, A490 (Hexagonal Head Bolts),

and F1852 (Button Head Bolt)

A325 may be galvanized

A490 bolts must not be galvanized

F1852 bolts are mechanically galvanized

High strength bolts are most commonly

available in 5/8 1 diameters

Bolting requires punching or drilling of holes

Holes may be standard size holes,

oversize holes, short slotted holes,

long slotted holes

Slotted holes allow for thermal

expansion / contraction

Oversize holes allow for tolerance

in assembling the frame

Structural Steel Connections | BOLTED CONNECTIONS

11

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

S T E E L

Steel Connections | Welded Connections

Due to high costs of labor, extensive field -welding

is the most expensive component in a steel frame.

Welding should be performed on bare metal.

Shop welding is preferred over field welding.

The weld material should have a higher strength than the pieces being connected.

De Menil Collection Museum

Houston . Texas

Renzo Piano

BCE Place Galleria

Toronto . Canada

Santiago Calatrava10

Structural Steel Connections | WELDED CONNECTIONS

12

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

S T E E L

Single-pass welds are more economical

than multi-pass welds.

The most economical size weld

that may be horizontally deposited

in one pass has 5/16.

Fillet welds and groove welds make up

the majority of all structural welds.

The strength of a fillet weld is directly

proportional to the welds throat dimension.

The capacity of a weld depends on the

welds throat dimension and its length

Miller Outdoor Theater

Houston . Texas.

Crown Hall at IIT Campus

Chicago . Illinois

Ludwig Mies van der Rohe

Structural Steel Connections | WELDED CONNECTIONS

13

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

S T E E L

Steel Connections | Shear Connections

Shear connections are the most prevalent

type of connections in a steel frame building.

Shear connections are called simple connections

Since they are assumed not to transfer bending moment,

thus allowing end rotation of the member.

Shear connections may be made to the web of the

supported member while the flanges remain unconnected.

Cantilevered Beam with Shear splice

Shear Connections transfer load from beam web

to column flange. No moment transfer occurs

since the flanges are free to rotate

Structural Steel Connections | SHEAR CONNECTIONS

14

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

S T E E L

The Corning Museum of Glass

Corning . New York

Smith - Miller + Hawkinson

The weld material should have a higher strength than the pieces being connected.

Seat

or hanger connections are the only type of shear connections that connect to the flange

of the supported beam.

Angles for shear connections may be attached to supporting members by bolting or welding.

Although single plate connections, are the most economical, they must sometimes be

evaluated for eccentricity.

Single angle connections allow end-rotation for flexible connections.

Single angle connections tend to have lower load capacities than double-angle connections.

Structural Steel Connections | SHEAR CONNECTIONS

15

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

S T E E L

Steel Connections | Moment Connections

Moment connections are also called rigid connections.

Moment connections carry a portion or the full

moment capacity of the supported member thus

preventing any end-rotation of the member.

Moment connections are typically designed

to also carry the shear component of the load.

The Royal Ontario Museum

Toronto . Canada

Daniel Libeskind

Structural Steel Connections | MOMENT CONNECTIONS

16

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

S T E E L

Moment connections provide continuity between

the supported and supporting members.

Relative rotation between the supporting

and supported members is negligible.

The flanges of the supported member are

attached to either a connection element or

directly to the supporting member.

The De Menil Collection Museum

Houston . Texas

Renzo Piano

Structural Steel Connections | MOMENT CONNECTIONS

17

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

S T E E L

Steel Connections | Welding vs. Bolting

WELDING

BOLTING

Advantages:

Advantages:

Eliminates need for punching or drilling.

Easy method of connecting members

on the site.

Simplifies complicated joints.

Disadvantages:

Greater level of skill required

for welding than bolting

More expensive than bolting.

Field-bolting is cheaper than

field-welding.

Disadvantages:

Requires drilling or punching through

all plies.

Weld inspection is required and is

expensive.

Structural Steel Connections | WELDING vs. BOLTING

18

a teaching primer for colleges of architecture

S T E E L

STRUCTURE OF THE EVERYDAY

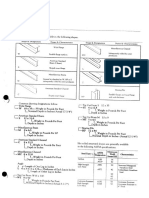

Shop-Bolted Double Angle | Field-Bolted Beam to Girder or Column

Double angles are shop-bolted to the web of the beam.

If the beam and girder have the same depth, then both

flanges of the beam are coped to meet flush with the top

flange of the girder.

The double angles are then field-bolted to the web

of the girder.

The holes on the beam and the girder may be offset

with respect to each other for ease of fastening.

Some rotation is possible in the gap between the beam

flanges and the column web. This happens by the yielding

of the connection material (the outstanding angle leg)

This is a shear connection since the double angles are

fastened to the web, and transfer the load in shear.

The bolts on the beam web are in double shear.

Those on the girder web are in single shear.

Structural Steel Connections | SHEAR 1

19

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

S T E E L

Shop-Bolted Double Angle | Field-Bolted Beam to Girder or Column

Structural Steel Connections | SHEAR 1

20

a teaching primer for colleges of architecture

Double angles are shop-welded to the web of the beam.

If the beam and girder have different depth, the top flange of the

beam is coped to meet flush with the top flange of the girder.

The double angles are then field-bolted to the web of the girder.

Some rotation is possible in the gap between the beam flanges and the

column web. This happens by the yielding of the connection material

(the outstanding angle leg).

This is a shear connection since the double angles are fastened to the web,

and transfer the load in shear.

The bolts on the girder web are in single shear.

S T E E L

STRUCTURE OF THE EVERYDAY

Shop-Welded Double Angle | Field-Bolted Beam to Girder or Column

Structural Steel Connections | SHEAR 2

21

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

S T E E L

Shop-Welded Double Angle | Field-Bolted Beam to Girder

Structural Steel Connections | SHEAR 2

22

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

S T E E L

Shop-Welded Double Angle | Field-Welded Beam to Column Web

Double angles are shop-welded

to the web of the beam.

If the beam flanges are too wide to fit in between

the column flanges, the beam flanges will be coped.

Some rotation is possible in the gap between

the beam flanges and the column web. This

happens by the yielding of the connection

material (the outstanding angle leg)

This is a shear connection since the double angles

are fastened to the webs of the beam and column.

The vertical segment of the weld transfers the

load from the beam web to the column web.

Welding all around the outstanding leg will

inhibit the flexibility of the connection.

The weld at the top is limited to a weld-return.

The weld at the bottom is optional.

Structural Steel Connections | SHEAR 3

23

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

S T E E L

Shop-Welded Double Angle | Field-Welded Beam to Column Web

Structural Steel Connections | SHEAR 3

24

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

S T E E L

End Plate Connection | Field-Welded Beam to Girder Web

End plate is shop-welded to the web of the beam.

Holes in the end plate are punched in the shop.

Some rotation is possible in the gap between the

beam flanges and the column web. This happens

by the yielding of the connection material

(the outstanding angle leg) The end plate is then

field-bolted to the web of the girder.

This is a shear connection as the end plate is

fastened to the web of the girder (beam flanges

are not secured against rotation)

The bolts attaching the end plate to the girder

web are in single shear.

Structural Steel Connections | SHEAR 4

25

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

S T E E L

End Plate Connection | Shop-Welded Field-Bolted

Structural Steel Connections | SHEAR 4

26

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

S T E E L

Unstiffened Seat | Shop-Welded and Field-Bolted

The angles are pre-drilled or punched in the shop

before they are welded to the girder or column.

The bottom angle is called the seat.

The seat is where the girder transfers its load

to the column in bearing.

The top angle provides stability to the girder.

The seat angle is larger and thicker since it

transfers the load from the girder to the column.

Unlike others, this shear connection is not

made to the web.

Structural Steel Connections | SHEAR 5

27

a teaching primer for colleges of architecture

QuickTime and a

Cinepak decompressor

are needed to see this picture.

S T E E L

STRUCTURE OF THE EVERYDAY

Shop-Welded Seat (Unstiffened) | Field-Bolted to Column Flange

Structural Steel Connections | SHEAR 5

28

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

S T E E L

Shop-Welded Single Plate | Field-Bolted Plate to Beam or Column

The single plate is pre-drilled or punched and

then shop-welded to the supporting column or

girder web.

The beam may be swung into place instead of

lowered into place.

The top flange of the beam is coped to match

the girder elevation.

This is a shear connection since the single plate

is fastened to the web of the beam.

The bolts shown are in single shear.

This connection can transfer a small amount of

moment to the supporting member

Structural Steel Connections | SHEAR 6

29

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

S T E E L

Shop-Welded Single Plate | Field-Bolted Plate to Beam Web

Structural Steel Connections | SHEAR 6

30

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

S T E E L

Shop-Welded Flange Plates | Field-Bolted Girder to Column

The top and bottom flange plates are pre- drilled

and then shop-welded to the column.

The top and bottom flange plates are field-bolted

to the girder flanges.

The flange plates are cut to fill the space between

the column flanges.

The single plate on the girder web transfers shear to the column.

The flange plates prevent rotation and thus the transfer of moment forces

to the column

Allowance for shims must be made. Mill tolerance on beam depth needs

to be accommodated

The Corning Museum of Glass

Corning . New York

Smith - Miller + Hawkinson

Structural Steel Connections | MOMENT 1

31

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

S T E E L

Shop-Welded Flange Plates | Field-Bolted Girder to Column

Structural Steel Connections | MOMENT 1

32

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

S T E E L

Shop-Welded Flange Plates | Field-Bolted Girder to Column

The top and bottom flanges are pre-drilled

and then shop-welded to the column.

The single plate is shop-bolted to the web of the girder.

The top and bottom flange plates are field-welded

to the girder flanges.

The single plate is field-welded to the column web.

The flange plates are cut to fill the space between

the column flanges.

The corners of the flange plates are clipped

to eliminate the development of stress

concentrations at the re-entrant (back) corners.

These corners are left open and are not welded.

The single plate on the girder web transfers shear to the column

The flange plates prevent rotation and thus the transfer of moment

forces to the column, which makes this a moment connection

Allowance for shims must be made.

Mill tolerance on beam depth needs to be accommodated

Structural Steel Connections | MOMENT 2

33

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

S T E E L

Shop-Welded Flange Plates | Field-Bolted Girder to Column

Structural Steel Connections | MOMENT 2

34

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

S T E E L

Shop-Welded End Plate | Field-Bolted Girder to Column

The end plate is pre-drilled and shop-welded

to the end of the girder.

The corresponding holes in the column flange

are pre-drilled.

The two transverse stiffener plates are shopwelded to secure the column flanges against

the load transferred from the girder flanges.

Extended end-plate connections require

tight fabrication and erection tolerances.

Extended end plate prevents rotation and thus

transfers moment forces to the column, which

makes this a moment connection.

Structural Steel Connections | MOMENT 3

35

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

S T E E L

Shop-Welded Plate | Field-Bolted Girder to Column

Structural Steel Connections | MOMENT 3

36

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

S T E E L

Field-Bolted Moment Splice | Girder to Girder or Column Connection

All holes in this connection are

pre-drilled in the shop.

The web and flanges of each girder

are pre-drilled.

(2) Shear plates are field-bolted in

each side of the webs.

The plates that attach the (2) webs to each

other are responsible for transferring shear.

Pre-drilled flange plates are field-bolted to

the top and bottom flanges.

The flange plates are responsible for transferring

bending moments across the connection.

The bolts fastening the web plates

are in double shear.

The flange plates prohibit any rotation

and so this is a moment connection.

The Royal Ontario Museum

Toronto . Canada

Daniel Libeskind

Structural Steel Connections | MOMENT 4

37

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

S T E E L

Field-Bolted Moment Splice | Girder to Girder or Column Connection

Structural Steel Connections | MOMENT 4

38

a teaching primer for colleges of architecture

The plates are pre-punched and then shop-welded

to the lower (larger) column.

The flange splice plates are field-bolted together.

If the two columns have the same depth, but different flange thickness,

then a filler plate or shim is used to make up the difference in thickness.

S T E E L

STRUCTURE OF THE EVERYDAY

Shop-Welded or Shop Bolted Splice | Connecting Two Different Columns

Structural Steel Connections | COLUMN SPLICE 1

39

a teaching primer for colleges of architecture

S T E E L

STRUCTURE OF THE EVERYDAY

Shop-Welded or Shop Bolted Splice | Connecting Two Different Size Columns

Structural Steel Connections | COLUMN SPLICE 1

40

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

S T E E L

Field - Welded Column Splice

A temporary plate or erection aid

is either welded or bolted to the

web and / or flange of the lower

(larger) column in the shop.

Flange plates may also be

required for stability of the

column during erection.

This plate helps align the upper

and lower columns.

The upper and lower columns

may be of different sizes.

The flanges and webs of the

two columns are field- welded

to each other.

This type of weld is called a

groove weld.

Steel Columns are most economical when

they extend over 2 or more stories

Groove welds

Structural Steel Connections | COLUMN SPLICE 2

41

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

S T E E L

Shop-Welded, Field - Bolted Column Splice

Structural Steel Connections | COLUMN SLPICE 2

42

a teaching primer for colleges of architecture

S T E E L

STRUCTURE OF THE EVERYDAY

Thermal Expansion and Contraction for a Highway Girder on a Roller Connection

Structural Steel Connections | Rock & Roll Connection

43

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

S T E E L

Curtain Wall Connection to a Steel Frame

Structural Steel Connections | Envelope to Frame

44

a teaching primer for colleges of architecture

STRUCTURE OF THE EVERYDAY

S T E E L

the end

Structural Steel Connections | The American Institute of Steel Construction

45

You might also like

- Mechanic Diesel: Competency Based CurriculumDocument52 pagesMechanic Diesel: Competency Based CurriculumManpreet50% (2)

- Introduction To Selecting Turning ToolsDocument31 pagesIntroduction To Selecting Turning Toolssanad321No ratings yet

- Machinist (Grinder) PDFDocument33 pagesMachinist (Grinder) PDFsiva0810No ratings yet

- As Per ACI 318 Anchor Bolt With Tension and Shear MomentDocument7 pagesAs Per ACI 318 Anchor Bolt With Tension and Shear Momentsiva0810No ratings yet

- Offshore Structural DesignDocument36 pagesOffshore Structural Designmesserklinge100% (1)

- Bolta Mech PDFDocument59 pagesBolta Mech PDFsiva0810No ratings yet

- Final - Approval Process Handbook 2017-18Document274 pagesFinal - Approval Process Handbook 2017-18Mohanaprakash EceNo ratings yet

- Sub Assembly DWGS To TEKLA SupportDocument1 pageSub Assembly DWGS To TEKLA Supportsiva0810No ratings yet

- Vacancies Executives May 2017 - Fin MarineDocument8 pagesVacancies Executives May 2017 - Fin Marinesiva0810No ratings yet

- As Per ACI 318 Anchor Bolt With Tension and Shear Moment PDFDocument7 pagesAs Per ACI 318 Anchor Bolt With Tension and Shear Moment PDFsiva0810No ratings yet

- ALRO Structural ShapesDocument18 pagesALRO Structural ShapesFWICIPNo ratings yet

- ALRO Structural ShapesDocument18 pagesALRO Structural ShapesFWICIPNo ratings yet

- Implement SEEMP Fleet ManualDocument21 pagesImplement SEEMP Fleet ManualChakma NhikiNo ratings yet

- Steel SizesDocument15 pagesSteel Sizessiva0810No ratings yet

- Steel Sizes PDFDocument15 pagesSteel Sizes PDFsiva0810No ratings yet

- Temp SensorsDocument1 pageTemp Sensorssiva0810No ratings yet

- 06 Eurocodes Steel Workshop WALDDocument136 pages06 Eurocodes Steel Workshop WALDIonut SavaNo ratings yet

- Macalloy July 2016 Newsletter - Tension Structures, Rods, Struts & ServicesDocument16 pagesMacalloy July 2016 Newsletter - Tension Structures, Rods, Struts & Servicessiva0810No ratings yet

- Imported Italian Marble Flooring Products PricesDocument23 pagesImported Italian Marble Flooring Products Pricessiva0810No ratings yet

- Implement SEEMP Fleet ManualDocument21 pagesImplement SEEMP Fleet ManualChakma NhikiNo ratings yet

- Home Remedies For DiabitiesDocument24 pagesHome Remedies For Diabitiessiva0810100% (2)

- Mac Alloy TensionDocument16 pagesMac Alloy Tensionsiva0810No ratings yet

- Engineering since 1904: Ellehammer ejectors guideDocument100 pagesEngineering since 1904: Ellehammer ejectors guidesiva0810No ratings yet

- Imported Italian Marble Flooring Products PricesDocument23 pagesImported Italian Marble Flooring Products Pricessiva0810No ratings yet

- Reaffirmed 2002Document10 pagesReaffirmed 2002siva0810No ratings yet

- Elastic Modulus of Concrete: - IntroductionDocument20 pagesElastic Modulus of Concrete: - IntroductionTaubatun DiansyahNo ratings yet

- Power & Thrust at 0-Speed For FP Propeller(s) : Project T41158Document1 pagePower & Thrust at 0-Speed For FP Propeller(s) : Project T41158siva0810No ratings yet

- Is 14909Document17 pagesIs 14909siva0810No ratings yet

- ISO Fastener and Threads Handbook-2012 PreviewDocument28 pagesISO Fastener and Threads Handbook-2012 PreviewmarcoskelpenNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Action Research ProposalDocument9 pagesAction Research ProposalNonia Zabel EvangelistaNo ratings yet

- Westbridge 2Document18 pagesWestbridge 2carlo deguzmanNo ratings yet

- Personal and Family Values - Big Life JournalDocument9 pagesPersonal and Family Values - Big Life JournalElona Jane Capangpangan100% (1)

- Newsletter Year 5 Spring Term 2016Document3 pagesNewsletter Year 5 Spring Term 2016DownsellwebNo ratings yet

- Running Head: Critical Reflection 1Document5 pagesRunning Head: Critical Reflection 1api-313097878No ratings yet

- Module 2: English Journalism 8Document15 pagesModule 2: English Journalism 8Kris Labios100% (1)

- Science of Happiness Paper 1Document5 pagesScience of Happiness Paper 1Palak PatelNo ratings yet

- Instructional Design Documents - Funk EmilyDocument25 pagesInstructional Design Documents - Funk Emilyapi-595583917No ratings yet

- EVALUARE MOBILITATE ONLINE PadletDocument5 pagesEVALUARE MOBILITATE ONLINE PadletDanielaRăducănescuNo ratings yet

- Generation Gap - WorksheetDocument3 pagesGeneration Gap - WorksheetLisaStembelNo ratings yet

- Advantages and Disadvantages of Regression AnalysisDocument9 pagesAdvantages and Disadvantages of Regression AnalysisAPOORVA PANDEYNo ratings yet

- Philippine Christian University: The Problem and Its BackgroundDocument30 pagesPhilippine Christian University: The Problem and Its BackgroundumbrellaNo ratings yet

- No IELTS Canada GuideDocument4 pagesNo IELTS Canada GuideOluwadamilola Shitta-beyNo ratings yet

- NITK Surathkal Placement Report 2010-11Document9 pagesNITK Surathkal Placement Report 2010-11Mohit KwatraNo ratings yet

- Classical Conditioning and Learning TheoriesDocument1 pageClassical Conditioning and Learning TheoriesMLG FNo ratings yet

- Strauss on the Direct Relationship Between Classical Political Philosophy and Political LifeDocument21 pagesStrauss on the Direct Relationship Between Classical Political Philosophy and Political LifeDei FenixNo ratings yet

- Francisco G Perez ResumeDocument1 pageFrancisco G Perez Resumeapi-370775881No ratings yet

- Symbolic Consumption and Identity ConstructionDocument121 pagesSymbolic Consumption and Identity ConstructionDaniel Hein Mikkelsen100% (2)

- W Edwards Deming TQMDocument16 pagesW Edwards Deming TQMapi-302134896No ratings yet

- OCC - Q1 - Module 9-Communicative strategies-EDITEDDocument15 pagesOCC - Q1 - Module 9-Communicative strategies-EDITEDAMYTHEEZ CAMOMOT50% (2)

- PMC Module 11 Assignment Sada Gul Roll D12903Document17 pagesPMC Module 11 Assignment Sada Gul Roll D12903Alishba FaixanNo ratings yet

- Multi Sensory ApproachDocument11 pagesMulti Sensory Approachmahesh thampi100% (1)

- Format Muka Surat HadapanDocument2 pagesFormat Muka Surat HadapanAwang ZulkipliNo ratings yet

- SMEA.1st Quarter.2019Document49 pagesSMEA.1st Quarter.2019Anonymous asInEYaZQNo ratings yet

- HeritageDocument246 pagesHeritageIKE ONANo ratings yet

- The Nature and Relevance of ResearchDocument42 pagesThe Nature and Relevance of ResearchAdie TolinganNo ratings yet

- NEBOSH International Diploma in Occupational Health & SafetyDocument1 pageNEBOSH International Diploma in Occupational Health & SafetyVignesh ShenoyNo ratings yet

- Mohini Jain Vs State of KarnatakaDocument13 pagesMohini Jain Vs State of KarnatakardandapsNo ratings yet

- THE SAMIN MOVEMENT: A STUDY OF PEASANT RESISTANCE IN JAVADocument35 pagesTHE SAMIN MOVEMENT: A STUDY OF PEASANT RESISTANCE IN JAVAErik IndraprastaNo ratings yet

- Impact of Television ViolenceDocument8 pagesImpact of Television Violenceombudslady100% (1)