Professional Documents

Culture Documents

Uploaded by

Nageswar Reddy100%(1)100% found this document useful (1 vote)

52 views3 pagesOriginal Title

dfmpro.geometricglobal.com.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

52 views3 pagesUploaded by

Nageswar ReddyCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

DFMPro provides Sheet Metal Design Guidelines

Page 1 of 3

DFMPro for Sheet Metal

DFMPro provides pre-configured design guidelines DFM best practices which helps to develop better qualityparts at reduced cost.

Some of the common sheet metal design guidelines included areminimum distance between holes, cutouts, slots, distance

between holes, cutouts, slots to part edge and bends, multiple bends in same direction, minimum bend radius, minimum radius of

rolled hem, open hem and tear drop hem, minimum flange width, minimum size of slots, holes and many other design guidelines.

DFMPro is highly customizable and provides theflexibility to configure the available sheet metal design rules as per organization

specificdesign rules.It also provides the ability to add new design for manufacturingrules easily into its existing database.

Sheet Metal Design Guidelines

The section below contains examples of some design guidelines for sheet metal. These

guidelines may help companies to avoid rejections and rework due to engineering

errors leading to higher cost of quality and delay in the delivery to customer.

Minimum Distance from Extruded Hole to Part Edge

Extruding metal is one of the most extreme pressure applications in press working and generates

lot of friction and heat. If an extruded hole is too close to the part edge, it can lead to deformation

or tearing of the metal. It is recommended that the minimum distance between the extruded holes

to part edge should be at least three times the thickness of sheet.

Minimum Distance Between Extruded Holes

Certain distance should be maintained between two extruded holes in sheet metal designs. If

extruded holes are too close it can lead to metal deformation. It is recommended that the

minimum distance between two extruded holes should be six times the thickness of sheet metal.

Minimum Distance Between Extruded Hole to Bend

A certain distance must be maintained between extruded hole to bend to avoid metal deformation

and fracturing. It is recommended that the minimum distance between extruded hole and bend

should be three times the thickness of sheet metal plus bend radius.

http://dfmpro.geometricglobal.com/processes/dfmpro-for-sheet-metal/

11/29/2016

DFMPro provides Sheet Metal Design Guidelines

Page 2 of 3

Minimum Hole Diameter

The diameter of the hole in sheet metal part should not be very small, small holes are created by

piercing operation and for manufacture small holes, small sizes punches are required. Small hole

size in sheet metal requires smaller size punching tool which may leads to break during the

operation. It is recommended that the diameter of the hole should be equal or more than the

thickness of the sheet metal.

Maximum Embossment Depth

Embosses are small, shallow formed projections on the surface of stamped parts. During this

operation, stretching is the main deformation mode resulting in high tension. Thereby the

metal is subject to excessive thinning or fracturing. Consequently, the depth of the embossed

feature is restricted by the materials thickness and ability to stretch in addition to the emboss

geometry.It is recommended that the maximum depth of embossment be less than or equal

to three times material thickness.

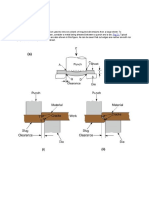

Minimum Bend Radius

Minimum bend radii requirements can vary depending on applications and material. For aerospace

and space applications, the values may be higher. When the radius is less than recommended, this

can cause material flow problems in soft material and fracturing in hard material. Localized

necking or fracture may also occur in such cases. It is recommended that minimum inner bend

radius should be at least 1 times material thickness.

Curl Feature Guidelines

Curling sheet metal is the process of adding a hollow, circular roll to the edge of the sheet.The

curled edge provides strength to the edge and makes it safe for handling. Curls are most often

used to remove a sharp untreated edge and make it safe for handling.It is recommended that:

The outside radius of a curl should not be smaller than 2 times the material thickness

A size of the hole should be at least the radius of the curl plus material thickness from the

curl feature

A bend should be at least the radius of the curl plus 6 times the material thickness from

the curl feature

Hem Feature Guidelines

Hemming is nothing but to fold the metal back on itself. In Sheet Metal hems are used to

create folds in sheet metal in order to stiffen edges and create an edge safe to touch. Hems

are most often used to remove a sharp untreated edge and make it safe for handling. Hems

are commonly used to hide imperfections and provide a generally safer edge to handle. a

combination of two hems can create strong, tight joints with little or minimal fastening.Hems

can even be used to strategically double the thickness of metal in areas of a part which may

require extra support. It is recommended that:

For tear drop hems, the inside diameter should be equal to the material thickness.

For open hem the bend will lose its roundness when the insidediameteris greater than the sheet metal thickness.

For bends, the minimum distance between the inside edge of the bend and the outside of the hem should be 5 times material

thickness plus bendradiusplus hem radius.

Notch Feature Guidelines

Notching is a shearing operation that removes a section from the outer edge of the metal strip or

part. In case, distance between the notches to bend is very small then distortion of sheet metal

may take place.To avoid such condition notch should be placed at appropriate distance from bend

with respect to sheet thickness. Notching is a low-cost process, particularly for its low tooling costs

with a small range of standard punches. Recommendations for Notch Feature:

http://dfmpro.geometricglobal.com/processes/dfmpro-for-sheet-metal/

11/29/2016

DFMPro provides Sheet Metal Design Guidelines

Notch width should not be narrower than 1.5 * t

Length of notches can be up to 5 * t

Recommended corner radius for notches should be 0.5 * t

http://dfmpro.geometricglobal.com/processes/dfmpro-for-sheet-metal/

Page 3 of 3

11/29/2016

You might also like

- Design Tips For Sheet Metal BendingDocument2 pagesDesign Tips For Sheet Metal Bendingjitendertalwar1603No ratings yet

- Product DesignDocument36 pagesProduct DesignvkrishnarajNo ratings yet

- Presentation On Sheet Metal DesignDocument27 pagesPresentation On Sheet Metal Designniloy_67No ratings yet

- Design Guidelines - SheetMetal PDFDocument4 pagesDesign Guidelines - SheetMetal PDFsunilbhol100% (1)

- Plastic Part Design 09 FATPDocument34 pagesPlastic Part Design 09 FATPandrawala111No ratings yet

- Product Design IntroDocument37 pagesProduct Design IntrokavinkumarjackNo ratings yet

- Sheet Metal BasicsDocument16 pagesSheet Metal BasicsvittlevishnuNo ratings yet

- Tolerancies Generals EstampacioDocument2 pagesTolerancies Generals EstampacioAlbert SolsonaNo ratings yet

- Sheet Metal OperationsDocument22 pagesSheet Metal OperationsParveen Saini0% (1)

- Sheet Metal Design HandbookDocument9 pagesSheet Metal Design Handbooktrujillo4769No ratings yet

- Sheet Metal Design-Handbook-Rev3 PDFDocument12 pagesSheet Metal Design-Handbook-Rev3 PDFtnchsg100% (1)

- Sheet Metal Design-Handbook-Rev3 PDFDocument12 pagesSheet Metal Design-Handbook-Rev3 PDFtnchsg100% (1)

- Bend Relief Options for Accurate Sheet Metal ModelsDocument17 pagesBend Relief Options for Accurate Sheet Metal Modelsjohndesign123No ratings yet

- Sheet Metal Design - GuideDocument7 pagesSheet Metal Design - GuidechoonhooiNo ratings yet

- Design guide for plastic product attachmentsDocument16 pagesDesign guide for plastic product attachmentsSharadNo ratings yet

- Al BiwDocument3 pagesAl BiwmmanharNo ratings yet

- Lab10 Final Progressive Die PDFDocument7 pagesLab10 Final Progressive Die PDFSyed Asif Bukhari100% (1)

- Different Types of Sheet Metal Operations Are:: 1. Shearing OperationDocument10 pagesDifferent Types of Sheet Metal Operations Are:: 1. Shearing OperationSai Asrith KonagallaNo ratings yet

- Sheet Metal Design ConsiderationsDocument2 pagesSheet Metal Design ConsiderationsKrishna Teja MutyalaNo ratings yet

- Rules of Thumb For Plastic Part Design: WallsDocument4 pagesRules of Thumb For Plastic Part Design: WallsrasinvNo ratings yet

- 3 Die CuttingDocument41 pages3 Die CuttingNarendrareddy RamireddyNo ratings yet

- Sheet Metal Design Services ConsiderationsDocument3 pagesSheet Metal Design Services ConsiderationsVino KumarNo ratings yet

- Design For Mouldability-UK092010Document16 pagesDesign For Mouldability-UK092010mjobson100% (1)

- Sheetmetal Design GuidelinesDocument20 pagesSheetmetal Design Guidelinesbrpnaidu2157No ratings yet

- Ribs & Structure DesignDocument17 pagesRibs & Structure DesignHemanth KathaNo ratings yet

- LO 03 - BendingDocument61 pagesLO 03 - Bendingladyinred90No ratings yet

- Sheet Metal Design GuidelinesDocument31 pagesSheet Metal Design Guidelinessatisharigela_asrNo ratings yet

- Press Tool CalculationDocument76 pagesPress Tool CalculationPrashant AmbadekarNo ratings yet

- DFM - Sheet Metal Design PDFDocument14 pagesDFM - Sheet Metal Design PDFSivaiah AdikiNo ratings yet

- 2.17. Design Procedure For Progressive DiesDocument2 pages2.17. Design Procedure For Progressive DiesAnand Prajapati100% (1)

- Deep Drawing: Deep Drawing Is A Sheet Metal Forming Process in Which A Sheet Metal Blank Is Radially DrawnDocument4 pagesDeep Drawing: Deep Drawing Is A Sheet Metal Forming Process in Which A Sheet Metal Blank Is Radially DrawnbrahimNo ratings yet

- Plastics Part Design FundamentalsDocument48 pagesPlastics Part Design FundamentalsSrinivas TanarapuNo ratings yet

- What Are Bend Allowance, Bend Deduction and K-FactorDocument11 pagesWhat Are Bend Allowance, Bend Deduction and K-Factoritsme5616No ratings yet

- SHEARINGDocument6 pagesSHEARINGanmol6237No ratings yet

- Sheet Forming Processes: Shearing & BendingDocument50 pagesSheet Forming Processes: Shearing & Bendingsudharsans88No ratings yet

- A RUNNER-GATE DESIGN SYSTEM FOR DIE CASTING DIESDocument9 pagesA RUNNER-GATE DESIGN SYSTEM FOR DIE CASTING DIESKetan ChhedaNo ratings yet

- Fine BlankingDocument26 pagesFine BlankingHarish Ks100% (1)

- Automotive - Presentation - Plastics-3rd June-2015 (Compatibility Mode) (Repaired)Document108 pagesAutomotive - Presentation - Plastics-3rd June-2015 (Compatibility Mode) (Repaired)Annavarapu Gopalakrishna100% (1)

- Sheet Metal OperationDocument17 pagesSheet Metal Operationsekar_scribd60% (5)

- Rapid Sheet Metal Design GuideDocument17 pagesRapid Sheet Metal Design GuideNageswar ReddyNo ratings yet

- Rapid Sheet Metal Design GuideDocument17 pagesRapid Sheet Metal Design GuideNageswar ReddyNo ratings yet

- Automotive Door Trim Bezel Mold DesignDocument17 pagesAutomotive Door Trim Bezel Mold DesignagniflameNo ratings yet

- Class A SurfacesDocument23 pagesClass A Surfacespmm05479No ratings yet

- 03 Cutting ForceDocument3 pages03 Cutting ForceAhmad Mustaghfiri Asrar100% (1)

- Module2: Design and Calculations of Piercing & Blanking DieDocument89 pagesModule2: Design and Calculations of Piercing & Blanking DieVipul MetaNo ratings yet

- Sheet Metal DFMDocument3 pagesSheet Metal DFMNageswar ReddyNo ratings yet

- Deep Drawing Process GuideDocument4 pagesDeep Drawing Process GuideBalvinder PrajapatiNo ratings yet

- Metal Stamping Dies GuideDocument7 pagesMetal Stamping Dies GuideedpsousaNo ratings yet

- CH03. Sheet Metal ProcessesDocument73 pagesCH03. Sheet Metal ProcesseshizanorhudaNo ratings yet

- Chapter 5-Sheet MetalworkingDocument82 pagesChapter 5-Sheet MetalworkingSeab PisethNo ratings yet

- 04 Cutting ClearanceDocument18 pages04 Cutting Clearancegaurav deshmukhNo ratings yet

- Lecture 8 Sheet Metal Working PDFDocument6 pagesLecture 8 Sheet Metal Working PDFluisimtzNo ratings yet

- Practical Design Rules for Stamped Metal PartsDocument17 pagesPractical Design Rules for Stamped Metal PartssharenterNo ratings yet

- NX Sheet Metal Design PDFDocument2 pagesNX Sheet Metal Design PDFHussein Zein0% (1)

- Plastic Part Design TutorialDocument13 pagesPlastic Part Design Tutorialsathya_jbNo ratings yet

- Plastic Metal Forming of Metals and PowdersDocument20 pagesPlastic Metal Forming of Metals and Powdersيوسف عادل حسانينNo ratings yet

- BIW Design PDFDocument17 pagesBIW Design PDFAmolPagdalNo ratings yet

- Shearing Process GuideDocument29 pagesShearing Process GuideSriram MuruganNo ratings yet

- Assignment No 6 Shearing Process in Sheet MetalDocument5 pagesAssignment No 6 Shearing Process in Sheet MetalSameer Ahmed 20 - MCE - 60No ratings yet

- Bend Sheet Metal PDFDocument16 pagesBend Sheet Metal PDFNhan LeNo ratings yet

- Sheet Metal OperationDocument2 pagesSheet Metal OperationNageswar ReddyNo ratings yet

- Thelibraryofmanufacturing.comDocument11 pagesThelibraryofmanufacturing.comNageswar ReddyNo ratings yet

- Sheet Metal OperationDocument2 pagesSheet Metal OperationNageswar ReddyNo ratings yet

- DFM Sheet MetalDocument7 pagesDFM Sheet MetalNageswar ReddyNo ratings yet

- AFT12LDocument12 pagesAFT12LCarlos ArenasNo ratings yet

- Residual Stress MeasurementDocument10 pagesResidual Stress MeasurementNageswar ReddyNo ratings yet

- DFM Sheet Metal Guide LinesDocument5 pagesDFM Sheet Metal Guide LinesNageswar ReddyNo ratings yet

- Cryogenic Rocket Engine TechnologyDocument4 pagesCryogenic Rocket Engine TechnologyNageswar ReddyNo ratings yet

- Residual StressesDocument48 pagesResidual StressesJavier_MoliNo ratings yet

- Residual StressDocument121 pagesResidual StressNageswar ReddyNo ratings yet

- Residual StressDocument8 pagesResidual StressNageswar ReddyNo ratings yet

- Crashing of NetworksDocument1 pageCrashing of NetworksNageswar ReddyNo ratings yet

- UPSC IES Weightage For ECEDocument4 pagesUPSC IES Weightage For ECEPriyaKumar0% (1)

- Theory of RelativityDocument27 pagesTheory of RelativityNageswar ReddyNo ratings yet

- Determination of Residual Stresses by X-Ray DiffractionDocument77 pagesDetermination of Residual Stresses by X-Ray DiffractionNageswar ReddyNo ratings yet

- X-ray Diffraction Measurement of Residual Stress in Epitaxial ZnO - α-Al2O3 Thin FilmDocument21 pagesX-ray Diffraction Measurement of Residual Stress in Epitaxial ZnO - α-Al2O3 Thin FilmNageswar ReddyNo ratings yet

- Resource Allocation Using Metaheuristic SearchDocument12 pagesResource Allocation Using Metaheuristic SearchCS & ITNo ratings yet

- Using Excel To Crash A ProjectDocument6 pagesUsing Excel To Crash A Projectbabu_officeNo ratings yet

- Introduction To Convection PDFDocument16 pagesIntroduction To Convection PDFxkarezNo ratings yet

- MechanicsDocument18 pagesMechanicsNageswar ReddyNo ratings yet

- Introduction To Welding TechnologyDocument9 pagesIntroduction To Welding Technologyibnu.asad984No ratings yet

- EML 2322L - Welding - MAE Design and Manufacturing LabDocument21 pagesEML 2322L - Welding - MAE Design and Manufacturing LabBhaiJan59No ratings yet

- Using Excel To Crash A ProjectDocument6 pagesUsing Excel To Crash A Projectbabu_officeNo ratings yet

- WeldingDocument7 pagesWeldingNageswar ReddyNo ratings yet