Professional Documents

Culture Documents

GP-12 Activity Checklist Ensures Quality Flatpacks

Uploaded by

Lam NguyenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GP-12 Activity Checklist Ensures Quality Flatpacks

Uploaded by

Lam NguyenCopyright:

Available Formats

GP-12 ACTIVITY PERFORMED BY T/A

Flatpack (FP) and Pulse Count (PC) only

LINE (circle one):

DATE:

PRODUCT NUMBER:

CREW:

PRODUCT NAME:

Check one:

CHANGEOVER / STARTUP

IMMEDIATELY RESPOND AND COUNTERMEASURE ANY NO OR NG DATA RECORDED.

Accepted,

Rejected (NMR # _________)

GP-12 ACTIVITY.

PERFORM THE FOLLOWING AT STARTUP AND CHANGEOVER PER CREW FOR

7/7/02 C crew to 7/22/02.

Are the normal inspection standard checks completed by the lead and is the paperwork completed properly?

Applies to Line 6 worm press and motor push. This section also applies to Line 8's Level 1 Containment person at the end of the line.

Line 6: Is the GP-12 inspection standard checks completed by the operators and is the paperwork completed properly?

Line 8: Is the Level 1 containment person completing 100% Packard gaging of every part? Is the paperwork completed properly?

N

(

Line 5 P/C: Is the Level 1 containment person completing 100% Packard gaging of every part? Is the paperwork completed properly?

)

Y

(

/

Y

N

/

)

N

Before line can start, verify that all operators have read the work instructions (MPS, PSU) and understand how to perform the job junction.

Has all operators read and understand the work instructions? Do all operators understand how to perform their job functions? (Only required at startup

per crew.) ( Y / N )

CHECK #2:

VERIFY THE FOLLOWING OPERATOR DEPENDENT PROCESSES.

If a defect is found, stop the line and review correct procedure with the operator and the lead.

FP: After pushing the motor, verify no

FP: Confirm that the operators

damaged/broken motor posts and

understand how to push motors

other shafts.

without causing debris from the motor

posts.

OK

NG

OK

NG

N/A: PC

PF/PC: Verify that mixed parts do not

occur at changeovers

OK

NG

NG

OK

(Available for additional checks

based upon OFM discretion.)

OK

NG

N/A: ___

OK

NG

FP/PC: Verify that the 100% shake

test is being performed by the offload

operator

OK

NG

Verify the operators understand the IDC only: Verify that the operators are

Verify off load is checking labels,

100% tug test for Level 1

performing the correct procedure for performing visual check and shaking

containment of loose contact sockets.

the IDC.

the part.

OK

OK

N/A: PC

FP/PC: Check the bowls for the

correct gears.

NG

NG

N/A: PC

(Available for additional checks

based upon OFM discretion.)

OK

NG

N/A: ___

OK

NG

N/A: IDC

(Available for additional checks

based upon OFM discretion.)

OK

NG

N/A: ___

OK

NG

N/A: ___

(Available for additional checks

based upon OFM discretion.)

OK

NG

N/A: ___

CHECK 10 PIECES FOR THE FOLLOWING VISUAL

DEFECTS.

Can be checked at the applicable

station.

(Startup/Changeover)

Damage

or

Is C-1 biased

inward?

Loose motor

Missing Screws

Raised Screws

deformation?

Bent pins

(Red FP only)

brackets?

OK

NG

Is the correct label

being used?

OK

NG

Is internal grease ok?

OK

NG

OK

NG

Is the julian date

correct?

OK

NG

No grease outside of

the actuator?

OK

NG

OK

NG

Containment

symbols?

OK

NG

No grease in the

connector area?

OK

NG

OK

NG

Is the information

readable?

OK

NG

Check grease nozzle

placement?

OK

NG

OK

NG

Packing: verify label

remains on part

OK

NG

(Available for additional checks

based upon OFM discretion.)

OK

NG

OK

NG

Shake the part. No

rattle?

OK

NG

(Available for additional checks

based upon OFM discretion.)

OK

NG

Tear down 5 pieces of good product at the first startup per crew per line. Only 5 pieces at startup per crew per line is required.

If so, was it

If so, was it

If so, was it

Line 3: Was a defect

immediately

Line 4: Was a defect

immediately

Line 5: Was a defect

immediately

found?

countermeasured?

found?

countermeasured?

found?

countermeasured?

Yes

No

Line 6: Was a defect

found?

Yes

No

If so, was it

immediately

countermeasured?

Yes

No

Yes

FORM 630-14-, WI 0919.630

No

Yes

No

Line 8: Was a defect

found?

Yes

No

Yes

No

If so, was it

immediately

countermeasured?

Yes

No

Yes

No

Yes

No

Other lines are represented on other sheets.

Yes

After completion, submit to Q.E.

GP-12 ACTIVITY PERFORMED BY T/A

Flatpack (FP)

LINE (circle one):

DATE:

PRODUCT NUMBER:

CREW:

PRODUCT NAME:

Check one:

CHANGEOVER / STARTUP

IMMEDIATELY RESPOND AND COUNTERMEASURE ANY NO OR NG DATA RECORDED.

Accepted,

Rejected (NMR # _________)

GP-12 ACTIVITY.

PERFORM THE FOLLOWING AT STARTUP AND CHANGEOVER PER CREW

TO 7/22/02.

CHECK #1:

7/8/02

Verify that all the paperwork for the normal checks and the paperwork for the GP-12 is being performed and recorded by the lead. Verify

the Supervisor is signing off the GP-12 paperwork. (Startup/Changeover)

Are the normal inspection standard checks completed by the lead and is the paperwork completed properly?

The following applies to the GP-12 Inspection Standard completed by the lead.

Is the GP-12 inspection standard checks completed by the lead and is the paperwork completed properly?

Is the supervisor signing off the GP-12 paperwork?

CHECK #2:

VERIFY THE FOLLOWING OPERATOR DEPENDENT PROCESSES.

If a defect is found, stop the line and review correct

FP: After pushing the motor, verify no

FP: Confirm that the operators

damaged/broken motor posts and

understand how to push motors

other shafts.

without causing debris from the motor

posts.

OK

NG

OK

NG

N/A: PC

PF/PC: Verify that mixed parts do not

occur at changeovers

OK

NG

N/A: PC

FP/PC: Check the bowls for the

correct gears.

OK

NG

FP/PC: Verify that the 100% shake

test is being performed by the offload

operator

OK

NG

Verify the operators understand the IDC only: Verify that the operators are

Verify off load is checking labels,

100% tug test for Level 1

performing the correct procedure for performing visual check and shaking

containment of loose contact sockets.

the IDC.

the part.

OK

NG

OK

NG

OK

NG

OK

NG

OK

NG

CHECK 10 PIECES FOR THE FOLLOWING VISUAL DEFECTS. Can be checked at the applicable station. (Startup/Changeover)

Missing Screws

Raised Screws

OK

OK

NG

Is the correct label

being used?

OK

NG

NG

Is the julian date

correct?

OK

NG

No grease outside of

Is internal grease ok?

the actuator?

OK

NG

Line 3: Was a defect

found?

Yes

No

Line 6: Was a defect

found?

OK

NG

Damage or

deformation?

OK

NG

Containment

symbols?

OK

NG

No grease in the

connector area?

OK

NG

Bent pins

OK

NG

Is the information

readable?

OK

NG

Check grease nozzle

placement?

OK

NG

Is C-1 biased inward?

(Red FP only)

OK

NG

Packing: verify label

remains on part

OK

NG

(Available for additional checks

based upon OFM discretion.)

OK

NG

Tear down 5 pieces of good product at each startup. Not necessary at changeover.

If so, was it

If so, was it

immediately

Line 4: Was a defect

immediately

Line 5: Was a defect

countermeasured?

found?

countermeasured?

found?

Yes

No

If so, was it

immediately

countermeasured?

Yes

No

Yes

FORM 630-14-, WI 0919.630

No

Yes

No

Line 8: Was a defect

found?

Yes

No

Yes

No

If so, was it

immediately

countermeasured?

Yes

Yes

No

Loose motor

brackets?

OK

NG

Shake the part. No

rattle?

OK

NG

(Available for additional checks

based upon OFM discretion.)

OK

NG

If so, was it

immediately

countermeasured?

Yes

No

No

After completion, submit to Q.E.

You might also like

- Apqp PpapDocument50 pagesApqp PpapEvandro Ribeiro50% (2)

- GP 12Document2 pagesGP 12Antonio Lara100% (8)

- Laptop Power SequenceDocument16 pagesLaptop Power SequenceDelwar Hossain90% (10)

- Mastercam Book 5 Axis Bai 1Document31 pagesMastercam Book 5 Axis Bai 1tuanvn76100% (3)

- SPG-MPS-007 BDocument14 pagesSPG-MPS-007 BLam NguyenNo ratings yet

- PFMEA ExampleDocument14 pagesPFMEA Examplekalebasveggie100% (1)

- Launch Readiness Audit (LRA) ChecksheetDocument19 pagesLaunch Readiness Audit (LRA) ChecksheetBaljeet100% (2)

- Apqp PpapDocument50 pagesApqp PpapsunilbholNo ratings yet

- Ppap Worksheet (GM 1411) : S Master Status: Lab StatusDocument6 pagesPpap Worksheet (GM 1411) : S Master Status: Lab Statuscong daNo ratings yet

- Appendix 25 VDA 6 3 Process AuditDocument12 pagesAppendix 25 VDA 6 3 Process AuditSeda De Drasnia100% (1)

- 1SM6 2015Document63 pages1SM6 2015chikoo499No ratings yet

- APQP TemplateDocument7 pagesAPQP TemplateBob ZepfelNo ratings yet

- Ice-Cream ProductionDocument65 pagesIce-Cream ProductionMujtaba HaseebNo ratings yet

- Questions Process Audit: P2. Project ManagementDocument11 pagesQuestions Process Audit: P2. Project ManagementR JNo ratings yet

- GM 1927-35 Run at Rate Form - 121049 - 01032010151508Document3 pagesGM 1927-35 Run at Rate Form - 121049 - 01032010151508Jetesh Devgun100% (1)

- APQP ENG SiemensDocument12 pagesAPQP ENG SiemensVikash KumarNo ratings yet

- Product Audit Report SummaryDocument44 pagesProduct Audit Report SummaryEnis SirbegovicNo ratings yet

- Product Characteristic Matrix (PCM) & Safe Launch Plan - Alignment & AgreementDocument8 pagesProduct Characteristic Matrix (PCM) & Safe Launch Plan - Alignment & AgreementDavid MorenoNo ratings yet

- 4th Edition PPAPDocument83 pages4th Edition PPAPTerri Paleno Lebow100% (1)

- PPAPDocument51 pagesPPAPjakirshaikh100% (2)

- 7 Step ChecklistDocument11 pages7 Step ChecklistLam Nguyen100% (1)

- AIAG PPAP Cover SheetDocument1 pageAIAG PPAP Cover SheetSCHOPENHAUERNo ratings yet

- APQP Documentation ChecklistsDocument67 pagesAPQP Documentation ChecklistsNeumar NeumannNo ratings yet

- GM1927-35 Run at Rate (GP9) ProcedureDocument9 pagesGM1927-35 Run at Rate (GP9) Procedurejb_coelhoNo ratings yet

- APQP Supplier ProcedureDocument20 pagesAPQP Supplier ProcedurepharmatonNo ratings yet

- Apqp VolvoDocument7 pagesApqp Volvofdsa01No ratings yet

- APQP GoodDocument70 pagesAPQP Goodtrung100% (1)

- Advanced Product Quality Planning Timing Chart: Plan and Define Programme - PP Trial StageDocument6 pagesAdvanced Product Quality Planning Timing Chart: Plan and Define Programme - PP Trial Stagerajesh sharma100% (2)

- GM Quality Systems Basics Plus Fast ResponseDocument262 pagesGM Quality Systems Basics Plus Fast Responsezzza100% (2)

- Daimler Process Signoff DocumentDocument228 pagesDaimler Process Signoff DocumentWolf Villarin100% (1)

- PPAP/APQP Requirements Checklist FormDocument17 pagesPPAP/APQP Requirements Checklist FormalexrferreiraNo ratings yet

- PPAP ChecklistDocument4 pagesPPAP ChecklistHirbod HirmandNo ratings yet

- APQP ChecklistDocument18 pagesAPQP ChecklistmichaelbarkovicNo ratings yet

- Root Cause & Corrective Action Corrective Action (RCCA) (RCCA)Document37 pagesRoot Cause & Corrective Action Corrective Action (RCCA) (RCCA)Bisma MasoodNo ratings yet

- APQP FormsDocument23 pagesAPQP FormsJOECOOL670% (1)

- PPAP Process Checklist / Sign Off Sheet InstructionsDocument7 pagesPPAP Process Checklist / Sign Off Sheet InstructionsSantosh TiwariNo ratings yet

- GM 1927 08 Potential Supplier Assessment (PSA)Document12 pagesGM 1927 08 Potential Supplier Assessment (PSA)Juan Carlos Murillo Larrota100% (1)

- Air Blue E-TicketDocument1 pageAir Blue E-TicketMuneeb Ahmed100% (3)

- Pass Through CharacteristicsDocument10 pagesPass Through CharacteristicsmirosekNo ratings yet

- Advance Planning Ensures Timely PPAP ApprovalDocument19 pagesAdvance Planning Ensures Timely PPAP ApprovalmoezNo ratings yet

- VDA FMEA TemplateDocument53 pagesVDA FMEA Templatewatna0% (2)

- Fsqm-080 Ppap ChecklistDocument14 pagesFsqm-080 Ppap ChecklistMohamed Khalifa100% (1)

- Printout Final IATF 16949 2016 - Key ChangesDocument89 pagesPrintout Final IATF 16949 2016 - Key ChangesSudhagar100% (3)

- PPAP ChecklistDocument2 pagesPPAP ChecklistSudhagarNo ratings yet

- Supplier Quality Management A Complete Guide - 2020 EditionFrom EverandSupplier Quality Management A Complete Guide - 2020 EditionNo ratings yet

- GM SQD Bulletin 1927 36 2018Document3 pagesGM SQD Bulletin 1927 36 2018Oscar DiazNo ratings yet

- SPC 001 PDFDocument240 pagesSPC 001 PDFSalah BennourNo ratings yet

- APQP Checklist Combined Rev 5 - 2Document17 pagesAPQP Checklist Combined Rev 5 - 2Neil SarkarNo ratings yet

- GM 1927-33 GM Global GP-12 Audit March 13, 2008Document8 pagesGM 1927-33 GM Global GP-12 Audit March 13, 2008Neumar NeumannNo ratings yet

- D 020 4 03 EN RevEDocument28 pagesD 020 4 03 EN RevEnrupbalarNo ratings yet

- COVER SHEET SUBMISSIONDocument6 pagesCOVER SHEET SUBMISSIONSeval GünaltayNo ratings yet

- Manufacturing ProcessesDocument477 pagesManufacturing ProcessesVinod89% (19)

- Kit Comunicatie ANPQP-V23Document20 pagesKit Comunicatie ANPQP-V23djclaudiuNo ratings yet

- VDA 6.3 Based Supplier AssessmentDocument11 pagesVDA 6.3 Based Supplier AssessmentGrecu Dragos100% (1)

- GM's Global APQP ProcessDocument127 pagesGM's Global APQP Processhmp90No ratings yet

- APQP Checklist: Supplier: Supplier Code: Part Name: Part NumberDocument2 pagesAPQP Checklist: Supplier: Supplier Code: Part Name: Part NumberRAHUL HERANI100% (1)

- QD83 - Global Supplier Quality Directive - Edition 2018Document66 pagesQD83 - Global Supplier Quality Directive - Edition 2018mirosek100% (1)

- CatalogDocument36 pagesCatalogLam NguyenNo ratings yet

- GM 1927-11 APQP Kick Off and SRV Workbook-GMDocument7 pagesGM 1927-11 APQP Kick Off and SRV Workbook-GMJOECOOL67No ratings yet

- Ppap Review ChecklistDocument8 pagesPpap Review ChecklistVipin RanaNo ratings yet

- Register Forum Home Page Post Attachment Files All Help Lost PasswordDocument3 pagesRegister Forum Home Page Post Attachment Files All Help Lost PasswordKirthivasanNo ratings yet

- 1h GM 1927-10 Lessons LearnedDocument0 pages1h GM 1927-10 Lessons LearnedMansoor AliNo ratings yet

- 5j GM1927 84 Drill Deep Worksheet 12 Oct 04Document2 pages5j GM1927 84 Drill Deep Worksheet 12 Oct 04jesusmemNo ratings yet

- Advanced Product Quality Planning and Control Plan PDFDocument13 pagesAdvanced Product Quality Planning and Control Plan PDFCesarNo ratings yet

- Control Plan FormatDocument1 pageControl Plan FormatMagesh WaranNo ratings yet

- Upholstery Facilities For Dynamically Tested PDFDocument14 pagesUpholstery Facilities For Dynamically Tested PDFLam NguyenNo ratings yet

- Drawing Specification for Motor Test Settings and ParametersDocument1 pageDrawing Specification for Motor Test Settings and ParametersLam NguyenNo ratings yet

- M FG RoadmapDocument24 pagesM FG RoadmapLam NguyenNo ratings yet

- Dimension 1200es 08 User GuideDocument74 pagesDimension 1200es 08 User GuideLam NguyenNo ratings yet

- 5S Audit TeamDocument4 pages5S Audit TeamLam NguyenNo ratings yet

- 5SDocument36 pages5Sgisella_garcia_1No ratings yet

- 6S CardsDocument1 page6S CardsLam NguyenNo ratings yet

- 5S ProgramDocument4 pages5S Programlam nguyenNo ratings yet

- Plastic Cutting ToolsDocument24 pagesPlastic Cutting ToolsLam NguyenNo ratings yet

- Wood Tooling CatalogDocument32 pagesWood Tooling CatalogLam NguyenNo ratings yet

- Lam Cover LetterDocument1 pageLam Cover LetterLam NguyenNo ratings yet

- 1 ModelingDocument26 pages1 ModelingLam NguyenNo ratings yet

- 2 DraftingDocument2 pages2 DraftingLam NguyenNo ratings yet

- 3 AssembliesDocument19 pages3 AssembliesLam NguyenNo ratings yet

- KL 8052N User ManualDocument33 pagesKL 8052N User ManualBiomédica HONo ratings yet

- Research Associate in The DFG Graduate Program - Collective Decision-Making - (12 Positions) - 28 Subsection 3 HMBHGDocument3 pagesResearch Associate in The DFG Graduate Program - Collective Decision-Making - (12 Positions) - 28 Subsection 3 HMBHGFiya ShahNo ratings yet

- Functional Molecular Engineering Hierarchical Pore-Interface Based On TD-Kinetic Synergy Strategy For Efficient CO2 Capture and SeparationDocument10 pagesFunctional Molecular Engineering Hierarchical Pore-Interface Based On TD-Kinetic Synergy Strategy For Efficient CO2 Capture and SeparationAnanthakishnanNo ratings yet

- Gradient of A Scalar Field and Its Geometrical InterpretationDocument3 pagesGradient of A Scalar Field and Its Geometrical InterpretationMichael100% (1)

- International Financial Management 7th Edition Eun Test BankDocument25 pagesInternational Financial Management 7th Edition Eun Test BankMatthewRosarioksdf100% (58)

- The Reference Frame - Nice Try But I Am Now 99% Confident That Atiyah's Proof of RH Is Wrong, HopelessDocument5 pagesThe Reference Frame - Nice Try But I Am Now 99% Confident That Atiyah's Proof of RH Is Wrong, Hopelesssurjit4123No ratings yet

- 10 - The Geological Interpretation of Well LogsDocument292 pages10 - The Geological Interpretation of Well LogsLorenza LorenzanaNo ratings yet

- Safety and Arming Device Timer 6-7-1976Document5 pagesSafety and Arming Device Timer 6-7-1976nguyenhNo ratings yet

- Duplichecker Plagiarism Report 3Document3 pagesDuplichecker Plagiarism Report 3Mushfiqur RahmanNo ratings yet

- Legal Opinion WritingDocument53 pagesLegal Opinion WritingBenedict AnicetNo ratings yet

- Line BalancingDocument21 pagesLine Balancingarno6antonio6spinaNo ratings yet

- Ingles Instrumental - Atividade 1Document5 pagesIngles Instrumental - Atividade 1PatriciaNo ratings yet

- Sample Quiz OM Chapter2Document2 pagesSample Quiz OM Chapter2Patleen Monica MicuaNo ratings yet

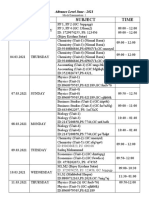

- Mock Examination Routine A 2021 NewDocument2 pagesMock Examination Routine A 2021 Newmufrad muhtasibNo ratings yet

- Standard OFR NATIONAL L13A BDREF Ed1.1 - 24 - JanvierDocument640 pagesStandard OFR NATIONAL L13A BDREF Ed1.1 - 24 - JanvierosmannaNo ratings yet

- Annexure - Subject Wise IBDP Grade BoundariesDocument4 pagesAnnexure - Subject Wise IBDP Grade BoundariesazeemNo ratings yet

- Water Is EnergyDocument96 pagesWater Is EnergyRadu BabauNo ratings yet

- Idea of CultureDocument28 pagesIdea of CultureGustavo Dias VallejoNo ratings yet

- Materials Selection For Engineering DesignDocument31 pagesMaterials Selection For Engineering Designsyamsudin2006No ratings yet

- Keurig Gourmet Single Cup Home Brewing System: Section 1Document11 pagesKeurig Gourmet Single Cup Home Brewing System: Section 1Tijuan MuhammadNo ratings yet

- Directory StructureDocument47 pagesDirectory StructureStevenNo ratings yet

- SAPA Presentation - 8-31-18Document34 pagesSAPA Presentation - 8-31-18Roi AlcaideNo ratings yet

- Experiment 4 The DC Compound Generator: Muhammad Al-Ariff Bin Selamat (112215), Muhammad Azfar Amin Bin Ahmad MokhtarDocument5 pagesExperiment 4 The DC Compound Generator: Muhammad Al-Ariff Bin Selamat (112215), Muhammad Azfar Amin Bin Ahmad MokhtarOne Love Jah LoveNo ratings yet

- 5.2 Flanged Bolt CouplingDocument11 pages5.2 Flanged Bolt CouplingShayneBumatay0% (1)

- Chapter 6 (Latest) - Value Orientation and Academic AchievementDocument21 pagesChapter 6 (Latest) - Value Orientation and Academic AchievementNur Khairunnisa Nezam IINo ratings yet