Professional Documents

Culture Documents

Procedure To Detect Misalignment Between Engines and Gas Compressors - by Jose Luis Rattia

Uploaded by

Jose Luis RattiaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Procedure To Detect Misalignment Between Engines and Gas Compressors - by Jose Luis Rattia

Uploaded by

Jose Luis RattiaCopyright:

Available Formats

PROCEDURE TO DETECT

MISALIGNMENT BETWEEN

INTERNAL COMBUSTION

ENGINES AND GAS

COMPRESSORS WITH FFT

Short Description

[Practical procedure to detect misalignment conditions in packages to gas

compression Stations]

JOSE LUIS RATTIA Industrial Maintenance Engineer

Predictive Maintenance to Reciprocant Machinery

Email: JOSELRATTIA@GMAIL.COM

Note: This procedure was developed by the author to help identify misalignment through a

practical procedure, however the author give thanks everyone that can use this and can

demonstrate their application.

PROCEDURE TO DETECT MISALIGNMENT BETWEEN INTERNAL COMBUSTION ENGINES AND GAS

COMPRESSORS

By: JOSE LUIS RATTIA PREDICTIVE MAINTENANCE ENGINEER

I will bring a procedure to diagnostic of misalignment between Engines and Gas

compressors this model has their basis in the hypothesis of a point that turns

around of a circle, how is showed below; in this figure a, there are two points 1 and

2, this model means that both shaft; engines and compressor should be collinear

within conditions of shaft alignment. This model consider the energy accumulated

in the points; 1, y 2, this energy can be sensed through a sensor that measure the

quantity of energy in both points.

Figure a. Elements to Model of diagnosis misalignment in coupled shafts

For that, we use the correct units to take amplitude of vibration due to forcing force

in the coupled shaft to engines and compressor, in this case is selected; Mils P-P,

to capture all energy in bearings shell depending what kind of machine be

evaluated. We need to draw a line that represent the position of both shaft under

conditions of alignment.

This model take; 1X and 2X order to plotting the line that say us, in what position

is running the shaft to engine and compressor, you can take until 6X to evaluate

wear in connrod and main bearings shell under correlation analysis, but at this time

we only treat 1X and 2X order to know about misalignment.

It is very important to take in account that all collected energy by sensor of

vibration permit us identify correct position of common shaft both of them; engine

and gas compressor, considering information in 1X and 2X orders.

PROCEDURE TO DETECT MISALIGNMENT BETWEEN INTERNAL COMBUSTION ENGINES AND GAS

COMPRESSORS

By: JOSE LUIS RATTIA PREDICTIVE MAINTENANCE ENGINEER

After through an excel spreadsheet, you can graph data collection to see the profile

of misalignment. In the model arose you can consider the following condition to

have when the package is in functioning but with a forcing force inside of

crankshaft to rated speed, and this forcing force is presented with two face; angular

or parallel, and how a combination from both of them.

Figure b. Angular and Parallel Misalignment

If both points, 1 and 2, are considered to turns around of coupling circle, you could

have a factor called angular velocity that depend of; mass, turning radio, to obtain

a value of force in each unit to english or international system. This unit can be

related by the expression: F=m.r.w, when you increase radio, then the force

increase proportionally. An example of this you can see in the following figure c;

Figure c. Measurement of energy in main bearings with sensor using FFT.

In the figure c; this model present two differents conditions, the first with blue circle

fill line, and last one stroke line, the first have r1 how their turning radio, and the

Second, have r2 turning radio. The first measurement with r1 hope have less force

than second r2. By the way, you could have misalignment conditions generating

PROCEDURE TO DETECT MISALIGNMENT BETWEEN INTERNAL COMBUSTION ENGINES AND GAS

COMPRESSORS

By: JOSE LUIS RATTIA PREDICTIVE MAINTENANCE ENGINEER

high rates of wearing in main and connrod bearings to engines and gas

compressor under cycle of life to r2.

Why this model suppose difference between; 1X and 2X?

This model use the differences of fundamental order 1X, in relation to 2X taking in

account two elements; inertial force and average changes in the speed due to

acceleration when reciprocating mass reach final stroke and both force are

opposite.

Figure d. Primary and Secondary force opposite at the ending stroke

The figure d; show us, how can be related both forces; primary and

secondary forces. In this case, primary force is opposite to secondary force, what

represent an arithmetic sum to both values considering their signs; positive and

negative.

What amplitude unit we can use to monitoring energy in main and connrod

bearings?

To measuring amplitude of vibrations in main and connrod bearings, you can use;

displacement: Mils P-P.

PROCEDURE TO DETECT MISALIGNMENT BETWEEN INTERNAL COMBUSTION ENGINES AND GAS

COMPRESSORS

By: JOSE LUIS RATTIA PREDICTIVE MAINTENANCE ENGINEER

Given that you need plot a line that represents the coupled crankshaft to engine

and gas compressor, is required use same units in both case engines and gas

compressor measurements. This give us a reliable graph to see profile of

misalignment between engine and gas compressor.

Now, is time to develop

procedure with a spreadsheet to look at complete profile. To do this procedure we

use Windrock 6320 PA to take data fft from main and connrod bearings shell in

engines and gas compressors. It is very important be clear in your mind what you

want to obtain, for that is necessary take data on reliable way to achieve a

successful data.

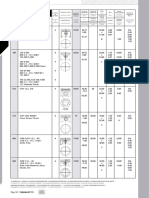

Figure e. Data of FFT main bearings on packages Engine Cat 3612.

Figure f. Data of FFT main bearings on Compressor Ariel JGC/4.

PROCEDURE TO DETECT MISALIGNMENT BETWEEN INTERNAL COMBUSTION ENGINES AND GAS

COMPRESSORS

By: JOSE LUIS RATTIA PREDICTIVE MAINTENANCE ENGINEER

The datas before showed were collected in a package Caterpillar 3612 with Ariel

Gas compressor JGC/4.

Coming up next, proceed to create a data table to engine and gas compressor to

the seven (7) data collected from main bearings engines and four (4) data from

main bearings gas compressor. Here do not be show all data table to engine and

gas compressor for space reasons, however same procedure was followed to the

others data taken from engine and gas compressor.

Figure g. Data table to Engine Cat 3612

Figure h. Data table Ariel JGC/4

These data were taken directly from software windrock 6320 PA, later these were

proposed to organize how a differences between fundamental of run speed 1X,

and second order of run speed 2X, getting results up showed.

PROCEDURE TO DETECT MISALIGNMENT BETWEEN INTERNAL COMBUSTION ENGINES AND GAS

COMPRESSORS

By: JOSE LUIS RATTIA PREDICTIVE MAINTENANCE ENGINEER

Then procedure to plot the graph that define profile to misalignment between

engines and gas compressor.

The graph below, show us; which is the profile followed to shafts coupled in normal

operation. The report delivered for technical support after inspection to check

alignment condition confirmed; misalignment between engine and gas compressor.

Figure i. Profile to alignment between engine and gas compressor.

Figure j. Technical report from Field service Caterpillar.

PROCEDURE TO DETECT MISALIGNMENT BETWEEN INTERNAL COMBUSTION ENGINES AND GAS

COMPRESSORS

By: JOSE LUIS RATTIA PREDICTIVE MAINTENANCE ENGINEER

Conclusions

The procedure to detect misalignment in packages internal combustion engines

and gas compressors has been until now a practical procedure to identify

misalignment and take early corrective actions to guarantee reliability of the

package engine and gas compressor during normal operation.

Their application do not need stop the machine, besides it permit take control of

wearing in engines and gas compressor bearings.

The plot line can visualize the profile that could have the engines and gas

compressor crankshaft to full load conditions.

This procedure is been tested in differents packages units currently in Venezuela,

however their application have had successful until now in differents test

performed.

You might also like

- Rev.6 MotorViewDocument286 pagesRev.6 MotorViewdford8583No ratings yet

- $XWR6WDWIRU$06 6XLWH 0Dfklqhu/+Hdowk 0dqdjhu: Automated Statistical LimitsDocument108 pages$XWR6WDWIRU$06 6XLWH 0Dfklqhu/+Hdowk 0dqdjhu: Automated Statistical LimitsluisrosavNo ratings yet

- Practical BalancingofflexiblerotorsforpowergenerationDocument10 pagesPractical BalancingofflexiblerotorsforpowergenerationJose Luis RattiaNo ratings yet

- Limites Ariel CompressorDocument1 pageLimites Ariel CompressorJose Luis RattiaNo ratings yet

- Testing: Valvetrain Systems For Combustion EnginesDocument48 pagesTesting: Valvetrain Systems For Combustion EnginesJose Luis RattiaNo ratings yet

- 868844Document7 pages868844Jose Luis RattiaNo ratings yet

- Gear WearsDocument13 pagesGear WearsJose Luis RattiaNo ratings yet

- Rim and Face AlignmentDocument8 pagesRim and Face Alignmentnazir305No ratings yet

- Orbit v27n207 RunoutDocument14 pagesOrbit v27n207 Runoutsant_100% (1)

- Understanding Vibration Can Help Prevent Pump FailuresDocument4 pagesUnderstanding Vibration Can Help Prevent Pump FailuresvfrpilotNo ratings yet

- Windrock PortableDocument4 pagesWindrock PortableJose Luis RattiaNo ratings yet

- Discussion Enpac 2500Document13 pagesDiscussion Enpac 2500Jose Luis RattiaNo ratings yet

- 868843Document6 pages868843Jose Luis RattiaNo ratings yet

- Piston Speed Lube ChartDocument1 pagePiston Speed Lube ChartJose Luis RattiaNo ratings yet

- Flange specifications for pipesDocument2 pagesFlange specifications for pipesJose Luis RattiaNo ratings yet

- Reciprocating Compressor Basics GuideDocument5 pagesReciprocating Compressor Basics GuideJose Luis RattiaNo ratings yet

- Gile NT Eautiful UtterflyDocument7 pagesGile NT Eautiful UtterflyPedagogíaNo ratings yet

- 3 Steps To Establish An Effective Lubrication ProgramDocument5 pages3 Steps To Establish An Effective Lubrication ProgramJose Luis RattiaNo ratings yet

- Conecting RodDocument1 pageConecting RodJose Luis RattiaNo ratings yet

- Rutina At-25Document3 pagesRutina At-25Jose Luis RattiaNo ratings yet

- 3 Steps To Establish An Effective Lubrication ProgramDocument5 pages3 Steps To Establish An Effective Lubrication ProgramJose Luis RattiaNo ratings yet

- 02 Effects of Amplitude and Phase 7Document1 page02 Effects of Amplitude and Phase 7Jose Luis RattiaNo ratings yet

- Motocompressor Cooper BessemerDocument1 pageMotocompressor Cooper BessemerJose Luis RattiaNo ratings yet

- Phase MeasurementDocument2 pagesPhase MeasurementJose Luis RattiaNo ratings yet

- Con RodDocument15 pagesCon Rodgaurav311098No ratings yet

- Theory of MachineDocument1 pageTheory of MachineJose Luis RattiaNo ratings yet

- 3 Steps To Establish An Effective Lubrication ProgramDocument5 pages3 Steps To Establish An Effective Lubrication ProgramJose Luis RattiaNo ratings yet

- Reciprocating Compressor Basics GuideDocument5 pagesReciprocating Compressor Basics GuideJose Luis RattiaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 006693497Document1 page006693497manuali-calogeroNo ratings yet

- G30 PSL44 EAL - WebDocument23 pagesG30 PSL44 EAL - WebaeroglideNo ratings yet

- Chrysler JX Stratus Sebring Convertible LHD RHD 1997 Service Manual Ignition SystemDocument28 pagesChrysler JX Stratus Sebring Convertible LHD RHD 1997 Service Manual Ignition SystemjjrmgNo ratings yet

- C18 ACERT Tier 3 Commercial Sales PresentationDocument29 pagesC18 ACERT Tier 3 Commercial Sales PresentationPhamLeDanNo ratings yet

- Desig Alternatives For Moto GP EnginesDocument14 pagesDesig Alternatives For Moto GP Enginesrudey18No ratings yet

- Locomotive Cranking and Shutdown ProceduresDocument28 pagesLocomotive Cranking and Shutdown ProceduresPrashant Sharma100% (1)

- CBR1000RR 2008-2014 Service ManualDocument912 pagesCBR1000RR 2008-2014 Service ManualGiromotoNo ratings yet

- Back Pressure Vs Delta PressureDocument5 pagesBack Pressure Vs Delta Pressurejameel babooramNo ratings yet

- 32-40 IMO Tier II - MarineDocument450 pages32-40 IMO Tier II - MarineDaniel AlvarezNo ratings yet

- Deutz TCG2032 Limit ValuesDocument19 pagesDeutz TCG2032 Limit ValuesKhokon Kumer Saha100% (2)

- Fuel Injection Pump #73112988Document144 pagesFuel Injection Pump #73112988rjcp0194% (17)

- Gas Turbine Engine Construction: Intake and DuctsDocument49 pagesGas Turbine Engine Construction: Intake and DuctsIdrisNo ratings yet

- Honda CBR650F Parts Catalogue MJEADocument138 pagesHonda CBR650F Parts Catalogue MJEAHeng Tian YapNo ratings yet

- Bosch Spares Price List 1Document8 pagesBosch Spares Price List 1Venkat CmrlNo ratings yet

- Fiat piston specificationsDocument15 pagesFiat piston specificationsAstrid PintoNo ratings yet

- Audi A4 No. 41 / 1Document23 pagesAudi A4 No. 41 / 1Martins JansonsNo ratings yet

- Introduction of Service Tool List For The 107E-1 EngineDocument2 pagesIntroduction of Service Tool List For The 107E-1 EnginejoseNo ratings yet

- Hydraulic Auxiliary Drive (HAD)Document62 pagesHydraulic Auxiliary Drive (HAD)academy.michael.jensenNo ratings yet

- Alfa MiTo 1.4 16V Multiair - enDocument164 pagesAlfa MiTo 1.4 16V Multiair - enAJUSA Asistencia Técnica100% (1)

- Error Code Volvo TruckDocument130 pagesError Code Volvo Truckandra50% (2)

- Service Manual 8-Cyl TDI (AKF) Engine MechanicsDocument285 pagesService Manual 8-Cyl TDI (AKF) Engine MechanicsAJUSA Asistencia TécnicaNo ratings yet

- 1A BOGE Tech Data SRHV-Series Piston Booster 10-25-230620 - 111636Document3 pages1A BOGE Tech Data SRHV-Series Piston Booster 10-25-230620 - 111636Cristian GuerreroNo ratings yet

- Engine Manual 24i / 28iDocument17 pagesEngine Manual 24i / 28iJose PardellasNo ratings yet

- Pionjar 120Document40 pagesPionjar 120almirNo ratings yet

- PRODUCTION, DISTRIBUTION AND PREPARATION OF COMPRESSED AIRDocument29 pagesPRODUCTION, DISTRIBUTION AND PREPARATION OF COMPRESSED AIRJose Lapera Jr.No ratings yet

- 2010 To 2011indmar Operators ManualDocument94 pages2010 To 2011indmar Operators Manualinforlex100% (3)

- Dgca & Easa Module 15Document160 pagesDgca & Easa Module 15Dibyendu Sahu80% (5)

- Perkins 20 Kva (404D-22G)Document2 pagesPerkins 20 Kva (404D-22G)RavaelNo ratings yet

- STK 169DDocument1 pageSTK 169DPhilip ThomasNo ratings yet

- Energy Auditing and Volumetric Efficiency of A C.I EngineDocument4 pagesEnergy Auditing and Volumetric Efficiency of A C.I EngineSIDDHARTH JAINNo ratings yet