Professional Documents

Culture Documents

Vol-3 Rev0 15.09.2016 Employers Requirement

Uploaded by

anrsrinivasanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vol-3 Rev0 15.09.2016 Employers Requirement

Uploaded by

anrsrinivasanCopyright:

Available Formats

Tender for an EPC Contract for Construction of

Liquid Storage Yard Facility at Owendo (GABON)

VOLUME 3- EMPLOYER'S REQUIREMENTS

SEPTEMBER 2016

Tender for an EPC Contract for Construction of

Liquid Storage Yard Facility at Owendo (GABON)

Volume 3- Employer's Requirements

September 2016

General information

Author(s)

COWI

Project name

Construction of Liquid Storage Yard Facility

Document name

Tender documents

Volume 3 - Employers Requirements

Date

SEP 14, 2016

Version

Draft 0

Reference

RFQ#GSEZ TFA/02/002

Recipients

Name

Company

Comments

Sunil Patel

GSEZ Ports S.A.

Construction Head

Subhash Gangaraju

GSEZ Ports S.A.

Head - Contracts

Srinivas Boddapati

GSEZ Ports S.A.

Manager - Planning

Mahendra Borkar

GSEZ Ports S.A.

Manager- Construction

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

CONTENTS

1

1.1

1.2

1.3

1.4

1.5

INTRODUCTION

Background Information

Contract Documents

Objectives of the Employers Requirements

Definitions

Abbreviations

11

11

11

12

12

14

2

2.1

2.2

2.3

2.4

2.5

PROJECT DESCRIPTION

Project background

Traffic forecast

Project Phasing

Tank farm layout

Scope and description of the Works covered by

this Tender

Phasing of the Works and Works Sections

18

18

18

18

19

GENERAL PROVISIONS

Documents & Publications

Permits & Permissions

Co-ordination

General Obligations

Project controls

Contractors Design and Documents

Contractors Facilities and Equipment

Attendance on and facilities for the Employers

personnel

Health and safety

Quality systems

Local goods and services

32

32

32

34

35

36

41

53

2.6

3

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

3.10

3.11

22

31

55

55

59

64

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

4

4.1

4.2

65

65

4.3

4.4

4.5

4.6

ACCESS AND USE OF THE SITE

Possession of the Site

Cooperation with other Contractors & Users of

the Site

Setting-Out of the Works

Protection of the Environment

Site Restrictions and Access

Services, Structures and Works

5

5.1

5.2

5.3

5.4

5.5

5.6

5.7

5.8

5.9

5.10

5.11

DESIGN CRITERIA

Introduction

Loads

Loads from Container Trailers

General cargo handling equipment

General material requirements

Concrete

Steel materials

Steel protective treatment

Rock including Metal Aggregates

Testing and monitoring

Training of Employers personnel

76

76

76

77

78

78

80

83

83

84

85

85

6

6.1

GENERAL DESIGN REQUIREMENTS

Climatic and environmental exposure

classification works

Prevention Level to Alkali-Silica reaction

Workmanship & Testing

86

6.2

6.3

7

7.1

7.2

7.3

7.4

7.5

7.6

7.7

8

8.1

8.2

8.3

8.4

DESIGN REQUIREMENTS FOR ONSHORE

WORKS

Earthworks - Levelling Of Hill Portion

Pavement

Networks

Security Systems

Palm Oil Storage and Un/Loading Facilities

Civil Works for Pipelines and Connection Pits

Miscellaneous Facilities and Equipment

MEP TENDER SPECIFICATION

Scope of Work

Specific Requirement and Specification

Developing Phase-1 Tank farm for Hydrocarbon

Products, Palm Oil and Firewater Tank

Tank Design

65

65

66

67

73

86

86

86

88

88

114

119

138

144

153

153

158

158

164

168

170

6

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

8.5

8.6

8.7

8.8

8.9

8.10

8.11

8.12

8.13

8.14

8.15

8.16

8.17

8.18

8.19

8.20

8.21

8.22

8.23

8.24

Local Loading

Corrosion

Platforms and Walkways

Nameplate

General Details of Tank Farms

Materials Specification and Fabrication

General Fabrication

Welding

Inspection and Testing

Protective Coating and Painting

Safety Requirements

Quality Assurance and Quality Control

Document Submittals:Plate and Structural Steel Material

Specification:Specification for Aluminium Internal Floating

Roof

Oil Water Separator (OWS)

Piping Work in The Tank farm

Fire Alarm and Fire Protection System

Electrical Work

Tank farm Management and Terminal

Automation

171

172

174

175

175

178

178

179

180

182

183

184

189

190

190

191

195

196

198

207

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

Tables

Table 2-1 Traffic Forecast

Table 2-2 Functional elements of Phase 1 and scope

Table 3-1 Tentative list of permits and approvals

required for NGCT

Table 3-2 Design life criteria for civil works

Table 3-3 Design life criteria for Mechanical and

Electrical

Table 3-4 Design life criteria for Pavement

Table 3-5 Design life criteria for Bulk storage facilities

and equipment

Table 3-6 Design life criteria for networks

Table 3-7 Review and approval of contractors

documents

Table 5-1 Loads

Table 5-2 Tractor trailer axle loading

Table 5-3 Requirement of concrete design

Table 5-4 Frequency of testing

Table 5-5 Minimum material grade- Steel for piling

works

Table 5-6 Minimum material grade- Steel for structural

works

Table 5-7 Schedule of Protective Treatment to

Steelwork and Metalwork

Table 7-1 Criteria of Cat.3.1. Materials coming from

soft rock are the following

Table 7-2 Criteria of cat. 3.1. Materials coming from

alluvial gravels

Table 7-3 Criteria of Cat. 3.2: Granular material

insensitive to water

Table 7-4 Assumption of capping layer design

Table 7-5 EV2 modulus at top of capping layer for

platform

Table 7-6 Frequency of laboratory tests for Cat. 1 and

Cat. 2 materials

Table 7-7 Frequency of laboratory tests for Cat. 3.1

Table 7-8 Frequency of laboratory tests for Cat. 3.2

materials

Table 7-9 In situ tests frequency

Table 7-10 Pavement types

Table 7-11 Traffic data and Sizing2

Table 7-12 Dimensional Deviation of Pavers

Table 7-13 Storm water drainage network

Table 7-14 Runoff coefficients

Table 7-15 Sewage network

18

20

33

42

43

43

44

44

49

77

78

80

81

83

83

84

90

90

90

104

104

110

111

111

111

114

115

117

121

121

124

8

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

Table

Table

Table

Table

Table

Table

Table

Table

Table

Table

Table

Table

Table

Table

Table

Table

Table

Table

Table

Table

Table

Table

Table

Table

Table

Table

7-16 CIE S008 standards for shipyard and docks

7-17 CIE S008 standards for shipyard and docks

7-18 Lighting requirements per area

7-19 Power supply for lighting

7-20 Voice and data network

7-21 Power supply network

7-22 Palm Oil product characteristics

8-1 Piping Material Specification

8-2 Applicable codes and standards

8-3 Loads on nozzle due to attached piping

8-4 Allowable stresses for local load analysis

8-5 Compressive stresses

8-6 Notations

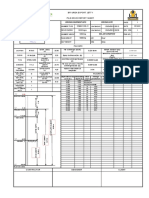

8-7 Tank Dimensions

8-8 Tank Nozzle Details

8-9 Plate & Structural Steel Material Specification

8-10 Protective Coating and Painting

8-11 Quality Assurance and Quality Control

8-12 Quality Assurance Plan for Construction Of

piping Work

8-13 Item checking acceptance and form of

record

8-14 Quality Assurance Plan for Oil Water

Separator

8-15 Quality Assurance Plan for Slop Pump

8-16 Quality Assurance Plan for Fire Fighting

System

8-17 Plate and Structural Steel Material

Specification

8-18 Maximum span and bottom elevation of pipe

8-19 Voltage levels

126

126

126

127

131

134

145

167

168

171

171

171

172

175

176

178

183

184

185

187

187

187

188

190

196

201

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

Figures

Figure 1-1 Operational areas

Figure 2-1 Plot showing the overall phasing for the

project

Figure 2-2 Features of the final terminal layout for

Phase 1

Figure 5-1 Container trailers wheel layout

Figure 7-1 Slope protection made of bamboo grid.

Figure 7-2 Trench filling (excerpted and adapted from

Fascicule 70)

Figure 7-3 Block Flow Diagram for the Palm Oil Storage

and Un/Loading Facilities

14

19

20

77

96

123

147

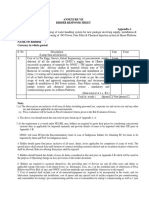

APPENDICES

Appendix A

List of drawings

224

10

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

INTRODUCTION

1.1

Background Information

1.1.1 Information to the bidder

The tender is for inviting offer from experienced and bonafied bidders for design,

development of scheme for petroleum & palm oil terminal with tank truck

loading along with automation and having desired experience of implementing

the complete work including construction of road along the pipeline and laying of

pipelines for sourcing the hydrocarbon products and palm oil.

1.1.2 Project Proposal

Gabon Special Economic Zone, a Govt. owned company of Republic Gabon,

Africa, intends to build a multipurpose storage yard called Gabon Liquid Storage

yard (GLSY) facility at near Port-a-Bois, Owendo near its upcoming New General

Cargo Terminal (NGCT)

1.1.3 Base line data

Gabon Special Economic Zone the Employer has engaged a consultant EGIS

for carrying out the Master Plan studies with base line information for developing

the GLSY proposal. With the study the owner is having the proposal to

develop the Gabon Liquid storage yard facility GLSY in two phase meeting with

the growth potential.

1.1.4 Phase-1 Scheme

Under first Phase (Phase-1) the construction of GLSY covers developing the site

limited to phase-1 area, consolidation of backfill, reinforced slope, providing

retaining wall, heavy traffic bituminous road, concrete paving for maintenance

area, container terminal, developing hydrocarbon terminal and palm oil terminal

with all associated facilities and utilities.

1.2

Contract Documents

These Employers Requirements shall be read in conjunction with the Contract

Documents listed in the Contract Agreement.

The Definition Drawings are provided in Appendix A

Each given dimension, line, level or point on a Definition Drawing is a specified

requirement, and is the responsibility of the Employer, unless such dimension is

referred to as approximate or nominal. Where a dimension is not given, or is

11

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

referred to as approximate or nominal, the dimension shall be determined by the

Contractor.

1.3

Objectives of the Employers Requirements

The Employers Requirements set out the minimum purpose, scope, design and

other technical criteria for the Works.

The overall project in which the Works are included consists of development of

GLSY with hydrocarbon and palm oil storages with road along the pile line and

laying hydrocarbon and palm oil pipelines between GLSY and NGCT.

These Employers Requirements relate to the marine and land based civil

engineering components of the work required for Phase 1 of the overall bulk

storage development project at GLSY.

The Employers overriding technical and engineering requirement is that the

Works are suitable in all respects for the safe, efficient, reliable and continuous

use under actual operational conditions at the GLSY and that they comply with

these Employers Requirements, including the design Criteria in chapters 5 and 6

presented in this document.

1.4

Definitions

Definition Drawings means drawings which show elements of the scope,

standard, design criteria or programme of work as included in the Contract.

Information Drawings means drawings which show existing facilities,

wrecks/obstructions, services, structures etc. Information Drawings form

part of the Site Data.

Other Contractors means the contractors working on the Site and Site as

defined in Section 4.2 of this document.

OPRAG means the Port Authority of Gabon (Office des Ports et Rades du

Gabon)

Drawings include sections, elevations, drawings, specifications, programs

and method statements;

Onshore works means all works to be performed on the Land Plot and the

works to be carried out on the GLSY;

Marine works includes reclamation with consolidation and reclamation

containment structure;

12

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

Site comprises: the Hydrocarbon and palm oil tank forms, two lane road

and pipe line corridor within the project perimeter as defined on drawing

Figure 1-1

ISPS Enclosed area designates the restricted area subject to ISPS

requirements (as opposed to the public areas).

DMC Platform is the platform constructed of sheet piles and backfill, as

built by the company Divers Marine Contracting.

Third Party Approvals or TPA means all permits, licenses and approvals,

as required by the law or otherwise, in relation to the design, execution and

completion of the Works, that require to be obtained from organisations

other than the Employer

Works mean the Permanent Works and Temporary Works, or either of

them as appropriate.

NGCT Land Plot is the section of the Site located to the north of the

existing railway. It comprises: the Service Area, the Bulk Storage Area and

adjacent areas within the project perimeter a defined on drawing GE-LI-001

provided in Appendix A, and on following figure.

Container Yard is the section of the Site located foreshore and nearshore,

to the south of the existing railway. It comprises: the container stacking

area, the Main Berth, the Service Berth, adjacent quay strips and adjacent

areas within the project perimeter as defined on drawing GE-LI-001

provided in Appendix A, and on following figure.

13

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

Figure 1-1 Operational areas

1.5

Abbreviations

APSAD

Assemble Plnire de Socits d'Assurances Dommages

CCTV

Closed-Circuit Television

CD

Chart Datum

CEMP

Construction Environmental Management Plan

CPO

Crude Palm Oil

CWMP

Construction Waste Management Plan

DDOPN

Dry Density of Optimum Proctor Normal

DGEN

Direction Gnrale de lEnvironnement (National Environment

Agency)

DMC

14

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

Divers Marine Contracting LLC.

DWT

Dead Weight Tonnage

HSE (or

HSE)

Environment Hygiene Safety (Health, Safety & Environment)

ECM

Electronic Content Management

EPC

Engineering, Procurement and Construction

Environmental and Social Impact Assessment (Environmental

Impact Assessment)

ESIA (EIA)

Environmental and Social Management Plan (Plan de Gestion

Sociale et Environnementale)

ESMP

GCC

General Conditions of Contract

GPM

Gabon Port Management

GSEZ

Gabon Special Economic Zone

GLSY

Gabon Liquid Storage Yard

Ha

Hectare

HV

High Voltage

HSE

Health Safety and Environment

IALA

International Association of Lighthouse Authorities

ILO

International Labour Organization

IP

Indice de protection Protection class

ISPS

International Ship and Port Facility Security Code

IT

Information Technology

JV

Joint Venture

15

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

LAT

Lowest Astronomical Tide

LOS

Level of Service

LV

Low Voltage

MCM

Mitigation, Compensation and Monitoring

MHC

Mobile Harbour crane

MLW(L)

Mean Low Water (Level)

MSL

Mean Sea Level

MV

Medium Voltage

NFPA

National Fire Protection Association

NGCT

New General Cargo Terminal

NGG

Niveau General du Gabon Gabon Vertical Reference

Level/Datum

MOV

Motorised Operated Valve

TLF

Truck Loading Facility

MCC

Motor Control Centre

HSD

High Speed Diesel

SKO

Superior Kerosene Oil

MS

Motor Spirit

VFD

Variable Frequency Drive

CCTV

Close Circuit TV

PLC

Programmable Logic Control

ESD

Emergency Shut Down

OPRAG

Office des Ports et Rades du Gabon

PCC

Particular Conditions of Contract

16

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

PGA

Peak Ground Acceleration

Plan de Gestion Sociale et Environnementale (Environmental and

Social Management Plan)

PGSE

PKO

Palm Kernel Oil

PPE

Personal Protective Equipment

PST

Plateforme Suprieure des Terrassements Earthwork upper

platform

RC

Reinforced Concrete

Socit dEau et dElectricit du Gabon Gabon Water and

Electricity Company

SEEG

SGEPP

Socit Gabonaise dEntreposage de Produits Ptroliers

SOW

Scope of Work

TOS

Terminal Operating System

TPA

Third Party Approvals

UTM

Universal Transverse Mercator

VHF

Very High Frequency

WWTP

Waste Water Treatment Plant

ZLT

Zone Load Testing

17

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

PROJECT DESCRIPTION

2.1

Project background

GSEZ Ports S.A. intends to develop the GLSY with hydrocarbon and Palm oil

storages with appurtenant facilities for administration, evacuation, etc and

laying of pipelines from NGCT to GLSY and construct road along the pipeline

from GLSY to NGCT.

The Works are related to Phase 1

2.2

Traffic forecast

The bulk storage facilities and palm oil jetty will be developed to accommodate the

following estimated traffic:

Table 2-1 Traffic Forecast

SI. No

Cargo

Type

Import/Export

Annual

Throughput

(tonnes per

annum)

Palm oil

Bulk

Export

30,000

Hydrocarbons

Bulk

Import

250,000

2.3

Project Phasing

The project will be built in two phases to cope with the expected traffic

increases. This tender covers Phase 1. The overall phasing for the project is

illustrated in the figures below.

Phase 1:

Developing tank farm covering

4 Nos (HSD Diesel) - tanks cone roof

3 Nos (M.S. - Petrol) - tanks cone roof with internal floating roof

2 Nos (SKO Kerosene) - tanks cone roof

3 Nos Palm oil - tank cone roof

2 Nos Palm Kernel oil - tank cone roof

2 Nos fire water - tanks cone roof

18

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

Figure 2-1 Plot showing the overall phasing for the project

These Employers Requirements concern the Phase 1 Works, as described above,

2.4

Tank farm layout

The main features of the final terminal layout for Phase 1 of the development

are shown on the following figure and table (see also the GE-PL-001 in Appendix

A)

19

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

Figure 2-2 Features of the final terminal layout for Phase 1

The main features for each component of the terminal are described below. They

are further developed in subsequent sections of this document.

Table 2-2 Functional elements of Phase 1 and scope

No.

Description

Details

Hydrocarbon storage for

import (30,000t) and

inland distribution

Tanks for the storage of Hydrocarbons (HSD, MS

& SKO) of Capacity 30,000 tonnes.

Unloading/loading to the terminal through

pipelines / tanker trucks. Transfer of

hydrocarbons from tanks to inland through

trucks. Sampling Station, automation, truck

loading facility and all other networks.

Interfacing with NGCT Contractor and connecting

the pipes with existing NGCT pipe network.

Palm Oil storage for

export (10,500 t)

Tanks for the storage of palm oil (CPO, KPO).

Capacity 10,500 tonnes. transfer of palm oil to

the NGCT terminal. Unloading/loading to the

terminal through pipelines / tanker trucks.

Unloading of palm oil from trucks to tanks and

loading to NGCT storage tanks and or ships

through pipe line. Sampling Station, automation,

truck loading facility, cathodic protection, heating

20

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

arrangement, insulation and all other networks.

Interfacing with NGCT Contractor and connecting

the pipes with existing NGCT pipe network.

3

Sampling and weighting

station

Station for controlling the entry and exit of

material to the Bulk Storage Area by truck. It

includes the secondary weighbridge, a sampling

station and a guard room, along with all

necessary fittings and operation systems

Entrance/Exit Gates

Three gates in each direction. Scope includes

access control, construction gate complex and all

other associated works.

Parking for cars

For cars of administrative, operational and

customs personnel.

Buffer parking for trucks

Parking area for trucks waiting for

loading/unloading inside the terminal (capacity

20 road trucks)

Weighbridge

Located at the entrance to the terminal for the

weighing of trucks entering/exiting to/from the

terminal. 80 T capacity Pitless type weigh bridge.

10

Rail crossing/road crossing

Rail crossing/road crossing facilities for

hydrocarbon/palm oil pipe line

12

Area for water tank for Fire

water storage and Fire

pumping station

Reserved area for installation of drinking water

and fire-fighting water tanks included in the

Contractors scope

This area can be relocated as per the

Contractors design subject to approval of the

Employers Representative

Road along the pipeline

Two lane Road along the pipe line from NGCT to

entry of Port Bois Entrance security gate with

side berms and revetment, Signage's and road

markings

14

Earth works

Site clearance, Excavation , Filling, compaction,

consolidation, Reinforced slopes, Retaining wall,

diversion of existing utilities, dismantling of

existing buildings; geotechnical works

15

Pavement

All type of pavements. Road signs, markings

16

Fencing and Gates

Temporary and permanent fencing and gates

conforming to ISPS

17

Networks

Storm water, drainage, sewage, water and fire

fighting including oil water separator etc. WWTP,

chlorination system and connecting all the pipe

lines to outfall and or into the sea.

18

Power Supply network

Power supply, lighting, high mast, cabling ,DG

set for back up, Earthling , substation

equipment, cabling from NGCT process

substation to GLSY substation. Interfacing with

NGCT Contractor and connecting the pipes with

existing NGCT pipe network.

19

CCTV and VOIP

All works covering hydrocarbon, palm oil area

with cabling ,UPS, server, connection from

Gabon telecom .display, etc.

13

21

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

20

Pipe line

Pipelines between NGCT and GLSY for

unloading/loading of Hydrocarbon and Palm oil

(above ground/underground), cathodic

protection, insulation, heating arrangement,

route markers etc.

21

Land Scape

Provision of land scaping as per scheme

approved by Employer.

2.5

Scope and description of the Works covered

by this Tender

The scope of work under this tender include

2.5.1 Pipeline from New General Cargo Terminal (NGCT) to

Gabon Liquid Storage yard (GLSY)

Carrying out detailed route survey between NGCT to GSLY,

Pipeline facilities including loading hoses, manifold, pigging stations, air and

nitrogen purging arrangements for one pipeline for handling HSD (Diesel) &

SKO (Kerosene) unloading and one pipeline for handling MS(Petrol) - (500600 m3/hr withdrawal rate). ). One pipeline for palm oil transfer (300 t/hr)

withdrawal rate on the NGCT Berth.

Carrying out route survey for laying three no's (3 no's) of above ground

pipelines, two no's lines for hydrocarbon and one no. line for palm oil, in

line with corridor identified, establishing the crossings for railway line,

crossings for vehicles, concrete paving, service road, establishing pipe

support saddles for laying the pipeline, identity special supports at marshy

stretch, developing terminal and facilities, preparation of flow diagram, bill

of materials for the transfer pipeline system complete from NGCT to GSLY

end and getting approval of the Employer.

Preparation of specification for pipe, pipe fittings, forged bends (for piggable

pipeline), valves, scrapper barrels at both ends, air and nitrogen purging

scheme and material, loading / unloading manifold, hose and connected

pipeline, coating external for saline / coastal environment for complete

system, internal coating of jet fuel line, facilities at jetty and at terminal

complete in all respect.

Procurement of all material for the scheme including all fitting fixtures

accessories complete in all respect.

Fabrication and Laying of the pipeline as per the approved scheme including

all civil pedestals, special crossings, construction of road, organizing third

party inspection complete in all respect, testing, painting, cleaning, air

drying and keeping the system ready for operation.

22

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

Assistance during commissioning and initial operation phase interfacing with

suppliers for smooth taking over of the complete system by the Employer.

The owners approval.

Preparation of specification for pipe, pipe fittings, pumps, valves, manifolds,

unloading hose and connectors, support and painting scheme.

Procurement of all materials for the complete scheme.

Fabrication, erection, testing, painting of the system, air drying and keeping

the system ready for commissioning.

Assistance during commissioning and initial phase of operation interfacing

with suppliers for smooth takeover of the system by Employer.

2.5.2 Developing Phase-1 Tank Farm for Hydrocarbon

Products, Palm Oil Storage and Fire Water Storage

Tanks.

Site clearance of tank farm area and tanker truck loading area, excavation

and filling, consolidation of back filling in layers (with desired proctor

density) reinforced with approved material on the slopes, developing

retaining walls, grading for smooth flow of rain water towards sea as per

scheme approved by Employer.

Soil investigation and establishing the soil strengthening, identify the type

of tank pad foundation for tank and seek approval of Employer for soil

consolidation / bearing capacity improvement solution over and above sand

pad construction.

Developing the scheme for complete tank farm for phase-1 including tank

pad construction for tanks, concrete wall, dyke surface drain, oily water

drain, piping scheme from incoming manifold to tank farm and from tank

farm to transfer pit drain line, all inter connected piping, fittings, valves,

transfer pumps within tank farm area, hume pipe network for oily water

outlet, surface drain and storm water drainage developing dynamic type

oily water separator with storage pond for oily water, two stage oil

separator, oil in water meter at outlet point with recirculation arrangement,

sump tank and slope tank system, firefighting system for fire water, water

spray system and injection, provision for all instrument gauges at tanks for

maintaining and transform automation, developing service road around tank

farm, earthing scheme, tank farm lighting and other electrical work for

valve actuation and power supply arrangement for pumps, developing

corridor for electrical and instrumentation cables in tank farm area,

developing painting scheme for tank and piping complete in all respect and

approval of the Employer.

23

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

Procurement of steel plates, pipes, pipe fittings, steel structures valves,

motor operated valves, thermal relief valves, surge relief system, pumps for

transfer of palm oil, firefighting pumping units, saucy pump, oily water

system, material for all civil work for developing tank farm covering

4 Nos (HSD Diesel) - tanks cone roof

3 Nos (M.S. - Petrol) - tanks cone roof with internal floating roof

2 Nos (SKO Kerosene) - tanks cone roof

3 Nos Palm oil - tank cone roof

2 Nos Palm Kernel oil - tank cone roof

2 Nos fire water - tanks cone roof

The above tank sizes are indicative only. Contractor can propose sizes

based on the project requirement

Pump shed and pumping system for palm oil transfer to NGCT, Pump shed

and unloading pumps, palm oil from tank truck, pump shed and loading

pumping units for hydrocarbon transfer, pipeline for tank farm, tank truck

transfer system in TLF shed and all related piping facility for hydrocarbon

facility and palm oil firefighting facility, firefighting pump units, engine

driven, direct online type jockey pump, fire hydrant network for tank farm,

TLF area, cooling water spray system and foam proportion, foam pourer

system for TLF, foam pourer piping for tank.

Compete material for electrical work for tank farm and TLF gantry area

covering PCC, MCC panel, power cable, lighting cable, earthing material,

lightening arrestor material, DG set power backup, UPS system, material for

dynamic type oily water separator scheme.

All MOVs and power supply connection material.

All civil work items covering tank farm development, tank pad construction,

pump shed, TLF gantry, firefighting pump shed area, palm oil truck

unloading pump shed area, control room and for all civil pedestals and

supports for piping, pump foundation, service road, paving work in tank

farm, road side drain, storm water drain, complete.

Facility for underground sump tank with vertical mounted transfer pump to

one of the tank with facilitator truck loading provision of slop tank and

mounting slop tank pump for transfer of the slop oil to tanker truck.

Construction work covering

Compound grading of tank farm and TLF gantry area

Tank pad construction for HSD, SKO, MS, palm oil and fire water,

storage tanks

Fabrication, erection, testing of complete tanks for HSD, SKO, MS,

palm oil and fire water service

24

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

Construction of oil water sump installation of dynamic type oil water

separator and associated work

Installation of pumping units, execution of piping systems, covering

hydrocarbon products, palm oil in tank farms and TLF area and truck

unloading piping in palm oil area and for transfer pipeline

Installation of firefighting pumping units and jockey pump

And execution of fire hydrant network and foam water piping to tanks

in tank farm area, cooling water spray system, foam proportional foam

generation system for TLF gantry, hydrant network for TLF gantry.

Execution of all electrical work of setting up PCC feeder and MCC

panels, cable laying, termination testing and commissioning of all

pumps, MOVs and electrical system

Complete earthing scheme covering tank farm, TLF, pump shed and

oily water scheme area

Construction of all accessories and fittings for tank farm and terminal

instrumentation work for tank farm terminal and construction work.

Painting of tanks, piping, civil structure and all facilities and utilities

Assistance during initial phase of operation interfacing with suppliers

for smooth takeover of system by the Employer

2.5.3 Instrumentation scheme and automation of tank

farm and terminal with PLC system

A computerized automation system is envisaged for the hydrocarbon

products being handled through this tank farm or terminal.

The palm oil storage system instrumentations limited to manual and local

operations. The following shall be controlled by terminal automation system

a)

Tank truck entry sub system for hydrocarbon products

b)

Tank truck loading for hydrocarbon product tanks

c)

Truck loading by queuing

d)

Tank farm management for hydrocarbon product tanks

e)

Pump automation using VFD based energy saving system

f)

MOV automation

25

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

g)

Fire water system operation through PLC along with makeup water

systems

h)

Terminal security system

Scheme development for instrumentation system to core palm oil tanks,

pumps protection and pipeline systems for palm oil unloading, loading are

also to be covered.

Scheme for status of oil water system operation and control shall be

developed

Developing scheme for linking fire water pumping units starting on fire

alarm system detection, local activation of break glass through fire hydrant

system panel and linking the same to PLC shall be covered.

CCTV monitoring system to be incorporated as a part of this scope covering

tanks, terminals, TLF area, pump shed and other critical area.

2.5.3.1 With the above objective scheme development shall be involved

in the terminal automation system.

2.5.3.2 Providing all materials and accessories covering the complete

system:

All instruments / systems / fittings, cables for tank entry sub systems for

hydrocarbon products

All instruments, fittings, cables and loading arm assembly with metering,

sensors including earthing materials and all related etc complete for TLF

loading system at TLF gantry with provision for incorporation of dozing

system.

All instruments, sensors for monitoring truck queuing

Radar type tank gauging system, temperature and pressure sensors as per

scheme on all hydrocarbon product tanks and transmitters for taking the

signal for tank farm management through PLC

Auto start and stop of transfer pump through VFD controlled energy saving

motor system

Instruments for control of all MOVs through PLC based tank farm / terminal

automation

Supply of instrument system complete for palm oil tank including level

indicator, temp sensors, pressure sensors, flow meter, pump protective

system etc for operation of palm oil, unloading and transfer of palm oil.

26

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

Loading arms for unloading palm oil from truck

All material hardware subsystem for CCTV covering tank farm, terminal, TLF

gantry, pump shed area

All material, system for foam proportioning system for TLF gantry

All material, system for water spray sprinkler system for TLF gantry

Supply of all cables for instrumentation, automation, covering, hydrocarbon

product tanks, palm oil tanks, fire water tanks, TLF gantry, pump shed,

tank truck entry system, tank truck loading system, oily water system,

CCTV system, devised earthing materials and all related accessories

PLC type control panel for achieving terminal automation and tank farm

management including system for generation of various status and MIS

reports as detailed.

2.5.3.3 Carrying out all civil and structural works for mounting

instrumentation work providing all materials, laying all instrument cable

as per approved scheme and instrument earthing scheme, installation of

radar type tank gauge, temp sensors, pre scan sensors for tanks,

pumps, flow meter, sensors complete for loading arm hydrocarbon

products, flow meter sensors and all other field instruments for safety of

the installation and the tank farm terminal automation.

Installation of CCTV system complete

Installation of instrument status connection system to PLC panel on oily

water separator.

Fire alarm system for tank farm and all connections to PLC system for

terminal automation for auto start of pump on alarm

ESD operation system

Installation of loading arm with flow meter and sensors with earthing

scheme complete with line to PLC system for terminal automation

Installation of tank entry subsystem and all connection to PLC based

automation systems

Provision for dozing system of dozing incorporated at later stage

Installation of all instruments and transmitters for actuation on MOVs

through PLC based terminal automation

Installation of all instruments, fittings and transmitters for actuation of

transfer pumps for hydrocarbon products

27

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

VFD based motor with PLC based terminal automation

Installation of cooling water spray system for TLF gantry

Installation of foam proportioner and foam system for TLF gantry

Public address system connectivity to PLC based automation

Installation of level gauges, temperature sensors for palm oil tanks

Instruments for safety operation of transfer pumps of palm oil in unloading

gantry and transfer pumps to NGCT

2.5.4 Developing scheme for heat tracing for palm oil tanks

Supply of all materials, heating tape, power supply arrangement, sensors,

trip systems cabling, earthing complete.

Installation of the heat tracing system for palm oil tanks.

Thermic fluid heater and circulating system and heating coils of at the

bottom of all Palm oil tanks, Fittings and accessories.

2.5.5 Providing fencing for TLF area with access gate for

petroleum products with card punching system at

gate.

2.5.6 Providing weighing machine for the TLF and palm oil

truck tanker weighing at entry road complete and

connecting the system to automation.

2.5.7 Carrying out comprehensive HAZOP studies for the

complete tank farm, TLF loading system through an

experienced agency for finalizing the layout of the

terminal and the safety distance to other facilities

and external facilities are in order.

2.5.8 Developing parking for the empty in coming tank

trucks with rest room for the drivers with public

address system for parking a minimum of 20 trucks.

28

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

2.5.9 Carrying pile foundation for some of the tanks where

sand pad foundation may not be adequate based on

detailed soil investigation.

Developing a testing laboratory at control room with all desired facility for

testing hydrocarbon products and palm oil.

The Contractor shall design, construct, test, commission, rectify defects

and complete all facilities and systems of the kinds required to complete

the Works as described herein and as shown on the Definition Drawings,

including but not limited to:

The earth work excavation and filling of low lying areas at GLSY

including:

Consolidation, compaction and construction of sub base, base;

Construction of revetment, embankment, retaining wall or any

structure at the excavated portion of the GLSY Yard.

Sanitation facility for GLSY users.

The internal and external roadways ( From NGCT to Port a Bois

security);

The connection pits, RC trenches, supports and protections for the

Palm oil pipe;

All necessary utilities, lighting networks and security equipment;

All necessary pavement for truck loading, vehicle parking areas

The main access gate comprising:

2 inbound lanes

2 outbound lanes

Gatehouses for inbound and outbound lanes;

The Car Park and dedicated accesses;

The Trucks and car Park;

The area for Fuel station;

The main weighbridge;

The Rail crossing;

All adjacent areas and facilities of the Land Plot which are not included

in the Bulk Storage Area;

All necessary utilities, networks, lighting;

All necessary fencing and security equipment

The Bulk Storage Area comprising :

The storage and unloading facilities for Hydrocarbons

HSD(Diesel),SKO(Kerosene) & MS(Petrol)

The Storage and un/loading facilities for Palm Oil (Crude Palm Oil

(CPO) and Palm Kernel Oil (PKO)):

storage (capacity 10,500 tonnes in 5 tanks);

unloading (2 truck capacity);

piping, pumping, heating system, pigging system and all fittings

and equipment for loading ships at 300 t/h at the NGCT Berth;

The check point of the Bulk Storage area including weighbridge,

sampling station, guard room;

The RC trenches, supports and protections for the Hydrocarbon

pipelines

29

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

The RC trenches, supports and protections for the Palm oil pipe;

The internal and external roads;

All necessary utilities, networks, lighting;

All necessary fencing and security equipment.

The Works included shall be as detailed in the Contract and shown in the

definition drawings and include the following major items:

Design Engineering and studies;

Site surveys;

Installation, maintenance and removal of the Construction Camp and

facilities for the Employer/ Employer representative;

Mobilization, maintenance and demobilization of construction

Equipment;

Setting out and site clearance;

Diversion of existing networks, services;

Earthworks;

Rockworks, earthworks and /or structural works for associated

embankments, revetments and/or retaining walls;

Construction of Road along the pipeline corridor;

Installation of pumping systems & un/loading facilities for hydrocarbon

(with pigging facilities) palm oil;

Pavement of roads, loading and parking areas and sidewalks;

Road marking;

Provision and erection of road signs and road furniture;

Construction of the storm water drainage system at GLSY;

Construction of the network of water supply and fire-fighting. Including

water tanks and booster;

Construction of the sewage system including WWTP;

Construction of the floodlighting and general lighting systems;

Construction of the power supply network;

Construction of the telecommunication network;

Supply and installation of security equipment;

Construction and supply of Hydrocarbons storage and un/loading

facilities

Construction and supply of Palm Oil storage and un/loading facilities;

Construction of the trenches, supports and protections for Hydrocarbon

pipelines, Palm oil pipes.

Construction of the connection pits for Hydrocarbon and Palm oil pipes.

Construction of road/rail crossing;

Construction and supply of weighbridges;

Supply of spare parts;

Training of operating staff.

The Contractor shall be fully responsible for all aspects of the design of the

Works and for providing such plant, materials and workmanship and

30

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

whatever else may be necessary or desirable to meet the Employer's

Requirements.

The Contractor shall be fully responsible for the design and construction of

the Works to comply with the requirements of the Environment and Social

Management Plan.

Notwithstanding the detailed requirements set out in these Employers

Requirements, the Contractor shall be responsible for ensuring that the

works are technically and economically feasible; practical, safe and

economical to fabricate/construct; and safe, efficient and economical to

operate and maintain.

2.6

Phasing of the Works and Works Sections

All works for construction of the Hydrocarbon storage tanks, Palm Oil

tanks and related un/loading facilities and equipment as described in

sections 7.6 and 7.7 hereafter with corresponding pavement, networks,

utilities and security systems

31

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

GENERAL PROVISIONS

3.1

Documents & Publications

The Contractor shall maintain current copies of the following documents and

publications on site at all times:

1

A full set of the contract documents

Copies of all correspondence

Copies of all design standards and construction specifications required for

the works

Copies of relevant legislation and regulations applicable to the works

Records of all on and off site quality testing

All progress photographs

Baseline and up to date topographic and bathymetric surveys

All current design and construction documents (reports, drawings,

schedules, etc.)

Marked-up copies of the design and construction documents to be used for

recording the as-built Works

10

All necessary documentation that may be required for inspection by

the Port, Customs, Environmental, Labor, Fiscal and other Government

authorities

11

Full documentation relating to all material and equipment delivered to site

3.2

Permits & Permissions

The following table provides the tentative list of permits and approvals required

for NGCT and identifies which approvals and permissions are to be borne by the

Contractor.

32

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

Table 3-1 Tentative list of permits and approvals required for NGCT

TENTATIVE LIST OF PERMITS AND APPROVALS REQUIRED FOR GSLY

Employer's scope

Contractor's

scope

SI. No

Details

Building Permit

ESIA

ICPE

Authorization for

storage of petroleum

and gas products

Authorization for

storage of chemicals

Authorization for raw

water supply

Authorization for

Power supply

Authorization

for

temporary power

supply

for

construction activities

TENTATIVE LIST OF PERMITS AND APPROVALS REQUIRED FOR GSLY

Employer's scope

S. No

Details

Authorization for

waste water

management

10

11

Authorization for

telecommunicat

ion (

wireless

communication,

VHF)

Authorization to

operate a quarry

during construction

Contractor's

scope

33

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

3.3

Co-ordination

3.3.1 Main Stakeholders and Third Parties

The completion of the project requires the intervention of organisations

other than the Employer. For the purposes of these Employers

Requirements such organisations are termed Stakeholders. The Contractor

is required to coordinate with the Stakeholders for all matters that concern

the execution of the Contract.

The following organisations have been identified as key Stakeholders.

Ministere Du Petrole Et Des Hydrocarbures

OPRAG is the Port Authority of Gabon. Contractor shall comply with all

OPRAG rules and stipulations;

Customs Authorities;

DGEN and the entities in charge of Environmental monitoring;

The governmental entities, Police, Fire Services, etc.;

SGEPP, for storage and hydrocarbon pipelines;

SETRAG railways company;

Marine Marchande;

SEEG;

GPM Gabon Port Management;

CIM Gabon Cement;

The other operators at the port.

The Contractor shall comply with all relevant regulation. In addition to

Ministere Du Petrole Et Des Hydrocarbures/OPRAG/SGEPP, other

Authorities may be involved for some issues concerning the Works. All

these authorities are named as Third Parties.

3.3.2 Third Party Approval

The Works shall be designed, constructed, commissioned, maintained and

operated in accordance with these requirements and those of Ministere Du

Petrole Et Des Hydrocarbures/OPRAG/ SGEPP and ancillary consents and

agreements.

The Contractor shall also obtain all necessary Third Party Approvals (TPA) to

permit the construction of the Works

In the event of a conflict between the legal requirements of statutory

authorities and of these Employers Requirements, those legal

requirements shall take precedence. Contractor shall incorporate all such

requirements of Authorities in his design/ drawing/ construction without

any additional cost to Employer. Should any conflicts between these

requirements be identified, these shall be referred to the Employer for

information, as soon as possible.

Concurrently with the issue of the notice of the Commencement Date, the

Contractor shall give not less than seven days' notice to attend a meeting

34

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

that shall be held to determine a programme and plan for obtaining all

TPA.

The Employer shall be entitled to attend all meetings held related to the

gaining of the TPAs. The Employer shall also be copied in on all

correspondence related to the TPAs. This information shall not relieve the

Contractor of its responsibility for gaining the TPAs.

The Contractor shall supply copies of all TPAs and notices to the

Employer to allow the Employer to comply with any obligations imposed

by TPA.

After gaining TPA, the Contractor shall not amend the conditions of the

approvals without the written approval of the Employer.

The Contractors work shall at all times progress in compliance with all TPAs.

Should the Contractor for any reason whatsoever cause or permit such TPA

to be withdrawn, the Contractor shall be fully responsible for their

reinstatement or re-issuance.

3.3.3 Agreements, Approvals and Consents

The Contractors general obligations shall include, without

limitation,

complying with the relevant agreements, approvals and consents in the

design, construction and commissioning of the Works.

This shall include but not be limited to complying with:

Relevant requirements of the Employer.

The requirements of the Environmental and Social Management Plan

The relevant requirements of Ministere Du Petrole Et Des

Hydrocarbures/OPRAG/ SEPBG/SEEG/SGEPP/SETRAG/CIMAF:

a)

for approval for construction of storage and Hydrocarbon and Palm

oil ,

b)

3.4

in respect of electricity, water and sewerage met works

General Obligations

3.4.1 Compliance with Environmental Controls

The Contractor shall comply with the Environment and Social Management

Plan and any other environmental regulation of the Country. The Contractor

shall follow international best practices for the avoidance and mitigation of

environmental impacts.

3.4.2 Payment of Port and other Dues

The Contractor shall pay all applicable Port and other Dues in accordance with

the Contract and the Port Regulations and Laws of the Country.

35

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

3.4.3 Co-ordination with Other Contractors

The Contractor shall liaise with the Employer and Other

Contractors to

coordinate all works and to co- operate in ensuring health and safety on

the Site. The Contractor shall attend overall project co-ordination meetings

as and when required by the Employer.

The Contractor shall co-ordinate his works with the on-going operations

of the Employer and other contractors, utility companies and authorities.

The Contractor shall ensure that access to its operations and its ability to

operate are maintained at all times unless otherwise agreed in writing.

Shut-down, re-routing connection to or diversion of existing access

routes (permanent and temporary), berthing facilities, communication

networks, sewerage, drainage and other services shall be subject to

notice, and shall be co-ordinated to minimize disruption to on-going

operations. All such works shall be undertaken only at times as agreed

with the authorities and the other users and will be subject to review by the

Employer.

Shut-down, decommissioning, re-routing or diversions of the existing

utilities shall be subject to notice, and shall be co-ordinated to minimize

disruption to on-going operations. All such works shall be undertaken

only at times and using a methodology as agreed with Authorities and

subject to review by the Employer.

Other contractors employed by the Employer will be carrying out other

works on and adjacent to the Site throughout the duration of the Contract.

These include, but are not limited, the contractors listed in Chapter 4.2

Cooperation with other Contractors & Users of the Site.

The Contractor shall provide all necessary design and as-built information

as may be required to allow other contractors (including designers) to

advance their works.

3.5

Project controls

3.5.1 Document Control

The Contractor shall submit a

document submission plan before the start

of the Works. This document submission plan shall provide:

The detailed list of documents to be provided by the Contractor

Short descriptions of the contents

The schedule of delivery

All correspondence and submissions including letters, drawing,

calculations, programs and documents shall be submitted to the Employer

in both hard copy and electronic format. Three hard copies and a digital file

in CD/DVD, USB or any suitable memory device of all documents shall be

submitted to the Employer unless otherwise specified. If discrepancies

arise between the hard and electronic versions the hard copy shall take

precedence over the electronic copy.

36

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

Electronic copies shall also be submitted by way of an internet based

Electronic Content Management System that is to be provided and

maintained by the Contractor. The Electronic Content Management

(ECM) System shall be fully accessible to the Employer and all

persons/organisation for which the Employer instructs access is to be

given. The system shall notify the relevant personnel that new information

is available. Uploading shall be carried out at the same time as hard copy

transfer so that the electronic system reflects the true situation on

correspondence transfer. Unsecured / unapproved methods of transmission

shall not be used.

Each submission shall be a complete package fully indexed and

referenced. Submissions will form part of the Contractors Documents.

Contractors Documents shall follow a recognized international standard for

drafting in respect of drawing size, scale, format etc. The standard shall

be proposed by the Contractor and submitted to the Employer and the

Employers Representative for review. The language of all documents shall

be English.

The Contractor shall produce, maintain and update a register of all

drawings and design documents in circulation identifying current status.

Superseded drawings and documents are to be clearly so marked

(S/S). This register can be performed through the ECM .The Contractor

shall schedule the submission of Contractors Documents to match the

programme for the Works.

All documents shall be marked with an individual identification number

revision numbering, status indication, and issue date and modification

description.

3.5.2 Meetings

All meetings shall be held on Site or at any other agreed location in the

Libreville area at a date and time to be agreed with the Employer and/or

the Employers Representative.

Regular meetings shall be held between the Contractor and the

Employer and / or the Employers Representative to ensure that all

parties are fully informed on any matters relating to the execution of the

Works. Normally the meetings shall be chaired, and minutes taken, by the

Employers Representative. As a minimum the Employers and the

Contractors representatives shall hold the following meetings:

3.5.2.1 Weekly meetings

The purpose of the weekly meetings shall be to review the Contractors

programme for the next four weeks, to review the previous weeks

37

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

progress, to raise any concerns by the Employer or the Contractor on the

rate of progress and identify matters which need to be resolved.

3.5.2.2 Monthly meetings

The purpose of the monthly meetings shall be to review the

Contractors monthly report, identify any problems and agree a course of

action to resolve same. The meetings shall normally be held mid-month

after receipt of the Contractors monthly progress report and application for

interim payment.

Monthly meetings shall be arranged with the Employer.

Monthly meetings shall include the review of the programme, the progress

of the works, safety issues and quality reporting, as well as all topics listed

in GCC Clause 4.21.

3.5.2.3 Quarterly Review meetings

The Employer may convene Quarterly Review Meetings to be held at

approximately three monthly intervals. These shall be held on dates to

be notified by the Employer at least 28 days before such a meeting is to

be held. Such meetings shall be held over a 1 to 2 day period in order to

review the overall progress of the Works and to address and resolve any

issues relevant to the execution and progress of the Works. Such Quarterly

Review Meetings shall be chaired by a Director of the Employer and the

Contractor shall have in attendance one senior representative from each of

the companies comprising the Contractor including:

The Company leading the Joint Venture / Consortium comprising the

Contractor;

All senior sub-contractors;

Such other senior staff of the Contractor as may be nominated by the

Contractor or required by the Employer.

The identities of the persons proposed by the Contractor to represent

the Contractor at the Quarterly Review Meetings shall be agreed prior to

such meetings being held.

3.5.2.4 Third Party Liaison / Co-ordination meetings

Whenever deemed necessary by the Employer, a meeting shall be called to

discuss interfaces with any relevant third party or other contractors to

ensure that any interfacing problems are identified and resolved. This does

not remove the obligations on the Contractor to coordinate with all

stakeholders and third parties, with whom he will organise meeting as he

deems necessary for the progress of the Works.

3.5.3 Reporting

The Contractor shall submit, in a format to be agreed with the Employer,

the following reports:

38

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

3.5.3.1 Daily Report:

The daily report shall provide details of the site activities as per the agreed

format.

3.5.3.2 Weekly Report:

The weekly report shall provide a summary of the activities for the previous

and forthcoming week and a detailed rolling programme showing planned

activities for the next four weeks.

Weekly reports shall include Photographs.

3.5.3.3 Monthly Progress Report

Monthly progress reports shall be submitted in accordance with the

requirements of GCC Clause 4.21.

The content of the monthly progress reports shall be presented in a format

to be agreed with the Employer and shall form the main basis for discussion

at the monthly meetings. The reporting period cut-off date shall be the last

Sunday in each calendar month.

The monthly progress report shall include, as a minimum

The contents listed in GCC Clause 4.21

A progress programme showing:

The agreed baseline programme

Actual start and finish dates of activities. Where activities are not yet

complete, current forecast dates shall be reported based upon the impact of

actual progress to date

Actual and current forecast dates compared against last period

report and baseline programme start and end dates for each activity in

the Contractors programme

A summary of actual and current forecast end dates against last period

report and baseline programme end dates for key deliverables

Details of deployment of additional resources if necessary to complete the

project on time.

HSE information including details of any accidents or incidents

Third Party Approvals status

Financial statements, invoicing and payment records

10

An updated cashflow assessment

11

Equipment and manpower statistics

Variance reported (in units of calendar weeks) shall be identified with a

narrative of proposed actions to secure delivery in line with the baseline

programme.

The monthly progress report submissions shall include electronic files in the

native format of the software used to generate the data and Adobe Acrobat.

All project programmes shall be submitted in PDF format and MS Project

2013 format.

39

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

3.5.4 Progress Photographs

The Contractor shall supply colour photographs imported within an MS Word

document with corresponding captions, on a weekly and monthly basis

throughout the Contract period. These shall record the progress of the work

during the month. The original photographs shall be provided on CD/DVD

in JPEG format.

The caption shall list the following information:

The name of the Project

Location data

Type of work

Serial number of the photographs

Date and time of photography

The Contractor shall also make video of the progress of the project stage

wise and submit documentary about progress every six months.

Aerial photographs of the Site shall be taken every three months to record

the progress of the Works.

3.5.5 Programme

A programme defined in GCC Clause 8.3 shall be prepared by the

Contractor clearly indicating the critical path for the completion of the

Works.

The work headings to be shown in the programme shall be the main

elements of the Works and the structure shall be aligned with the work

breakdown structure established and agreed with the Employer.

The programme shall clearly show the inter-relationship between approvals,

design, fabrication, delivery, construction, testing and commissioning of

each work heading. Long lead-in items and their lead-in times shall also be

identified.

Times allowed for review shall be shown in the programme. Float times

within the programme shall be clearly shown.

Each work heading shall be split into detailed activities. Work to be

undertaken by statutory undertakers and other third parties shall be shown

as separate activities. The duration of activities to be undertaken by the

Contractor shall be broken down into periods not exceeding 4 weeks.

Each activity shall be uniquely referenced. Bar charts, logic diagrams /

tables and any other necessary tabular and graphical reports shall be

submitted to show the following information for each activity on the

network:

a)

Reference

b)

Description

c)

Duration

d)

Relationship with other activities

e)

Early and Late Start and Finish Dates

f)

Resources or Unit Production Time

g)

Quantity and production rate

40

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

The Contractor shall assess and report progress on each activity and all

other input data not more than 2 days after the scheduled time for an

update. Changes in the network logic may only be made after consultation

with the Employer.

Where slippage has occurred, the Contractor shall give explanations

together with his proposals for recovery of critical activities. All project

schedules shall be submitted in MS Project 2013 format and PDF Format.

The programme shall provide durations and dates for the following activities

and milestones:

The Commencement Date

Completion and taking over of the Sections

The following design and construction activities:

a)

Key dates for design submissions

b)

Mobilization (facilities available on construction site)

c)

Mobilization (dredging vessel and marine construction equipment

operational on Site)

3.6

d)

Individual construction activities

e)

Off-site fabrication of equipment and installations

f)

Diversion of existing services

g)

Issuing of the Taking-Over Certificate

h)

End of the defect liability period

i)

Additional milestones to be proposed by the Contractor

Contractors Design and Documents

3.6.1 Contractors Design

The design of the Works is the

responsibility of the Contractor and shall

satisfy the Employers Requirements contained within this Document.

The Contractor shall, in the design and construction, minimize operating and

maintenance costs to achieve an optimum lifetime cost and shall minimize

the extent/frequency of maintenance and its disruptive effect on

operations.

Design shall be carried out by recognized specialists in the type of design

required for the Works. The Contractor shall submit to the Employer

and the Employers Representative for review details of the

Contractors Personnel who are responsible for the design.

The Contractors notice to be submitted in accordance with GCC Clause 5.2

of the shall be counter signed by the Contractors relevant design specialist

and the Independent Engineer

As construction proceeds, and as part of any procedures implemented

for offering up elements of the Works for acceptance, the Contractors

Designer shall verify the adequacy and accuracy of that element of the

Works in accordance with the approved design, as described elsewhere in

these documents.

41

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

3.6.2 Design Criteria

The Employers design and performance criteria for the Works are contained

in the Employers Requirements in sections __5, 6 and 7.

3.6.3 Design Life

The design working

life (or design life) is defined as the period for which

structural elements, pavements, electronic and mechanic (E&M) systems,

services, drainage systems, etc. are to be used for their intended purposes

with acceptable maintenance, but without major repair and/or replacement

being necessary.

Acceptable maintenance is maintenance that can be carried out within

planned periods without detriment to the Employers operations, and as

defined in the terminal Operation and Maintenance (O&M) manuals.

Major maintenance is maintenance that will require plant shutdown or

disruption to operations outside of normal maintenance periods defined in

the terminal O&M manuals.

3.6.3.1 Civil Works

Table 3-2 Design life criteria for civil works

Item

Land structures reinforced

concrete / steel piling,

buildings

Design Life

Heavy Maintenance or

Replacement Interval

50 years

50 years

Revetments:

50 years

50 years

Scour protection

50 years

50 years

Cathodic Protection, Painting

50 years

15 years

Fencing, barriers and gates

25 years

10 years

Rail Crossing

50 years

15 years

(Including culverts, retaining

walls, pits, pipes, pump

station, foundations)

42

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

3.6.3.2 Mechanical and Electrical

Table 3-3 Design life criteria for Mechanical and Electrical

Item

Design Life

Pipelines, pumps

Heavy Maintenance or

Replacement Interval

15-20 years

As per manufacturers

requirements

Weighbridge equipment

10 years

As per manufacturers

requirements

Firefighting equipment

10 years

As per manufacturers

requirements

Motorised gates and barriers

15 years

As per manufacturers

requirements

CCTV cameras sets

including remote control

and housing

10 years

As per manufacturers

requirements

Video monitors

6 years

As per manufacturers

requirements

Other CCTV central

management equipment

6 years

As per manufacturers

requirements

CCTV field cabinets

15 years

As per manufacturers

requirements

Poles for CCTV cameras

20 years

As per manufacturers

requirements

Motorised gates and barriers

15 years

As per manufacturers

requirements

CCTV cameras sets

including remote control

and housing

10 years

As per manufacturers

requirements

Video monitors

6 years

As per manufacturers

requirements

Other CCTV central

management equipment

6 years

As per manufacturers

requirements

CCTV field cabinets

15 years

As per manufacturers

requirements

Poles for CCTV cameras

20 years

As per manufacturers

requirements

3.6.3.3 Pavement

Table 3-4 Design life criteria for Pavement

Item

Design Life

Maintenance Interval

Structure

20 years

20 years

Pavement

n/a

10 years

43

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

3.6.3.4 Bulk storage facilities and equipment

Table 3-5 Design life criteria for Bulk storage facilities and equipment

Item

Design Life

Maintenance Interval

Palm Oil storage and

un/loading facilities

30 years

As per manufacturers

requirements, 5 years at

least

Hydrocarbon storage and

un/loading facilities

30 years

As per manufacturers

requirements, 5 years at

least

3.6.3.5 Networks

Table 3-6 Design life criteria for networks

Item

Design Life

Maintenance Interval

Stormwater Drainage

Network

30 years

5 years

Sewage Network

30 years

5 years

Water supply and

firefighting Network

50 years

Equipment such as valves,

traps, etc. every year

Floodlighting

25 years

Lighting replacement every

2 years

Sodium light bulbs clean up

every year

Voice and data

50 years

Power Supply system

network and back-up

system

50 years

3.6.4 Standards and Codes of Practice

The design shall comply with the latest versions of Eurocodes for the design,

European Standards, (such as EN 206 for concrete works) and internationally

recognized codes of practice (PIANC, CIRIA - Rock Manual)

3.6.4.1 Marine structures

Structural works shall follow the Eurocodes standards, listed as below:

Eurocodes 0: Basis of Structural design

Eurocodes 1: Actions on Structures

Eurocodes 2: Design of Concrete structures

Eurocodes 3: Design of Steel structures

Eurocodes 4: Design of Composite Steel and Concrete structures

Eurocodes 6: Design of Masonry structures

Eurocodes 7: Geotechnical Design

Eurocodes 8: Design of structures for earthquake resistance

44

Construction of Liquid Storage

Yard Facility at Owendo

Tender Documents

Volume-3

Eurocodes 9: Design of aluminium structures

In case of cohesive soil, seismic design shall follow Japanese Standard, for

the issue not covered by the Eurocodes.

3.6.4.2 Filling works

The reclamation works shall follow the following codes or manuals:

Hydraulic Fill Manual For Dredging and Reclamation Works Edited by

Jan van 't Hoff, Art Nooy van der Kolff

Eurocodes 7: Geotechnical Design

3.6.4.3 Earthworks

Earthworks shall be performed using Eurocodes and the Technical guide

"Fills and roadbed realization GTR - September 1992).

3.6.4.4 Pavements

Design of pavements shall be carried out in accordance with guidelines from