Professional Documents

Culture Documents

Us 20140231364

Uploaded by

ask101Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Us 20140231364

Uploaded by

ask101Copyright:

Available Formats

US 20140231364A1

(19) United States

(12) Patent Application Publication (10) Pub. N0.: US 2014/0231364 A1

Tanttu et al.

(54)

Aug. 21, 2014

(43) Pub. Date:

METHOD FOR PREPARING A PRECOAT ON

THE SURFACE OF THE FILTER MEDIUM OF

A POLISHING FILTER, POLISHING FILTER

AND USE OF A POLISHING FILTER

(30)

Foreign Application Priority Data

Oct. 11,2011

(Fl) .................................... .. 20116000

Publication Classi?cation

(71) Applicant: OUTOTEC (FILTERS) OY,

Lappeenranta (Fl)

(72)

Inventors: Leena Tanttu, Lappeenranta (Fl); Janne

Kauppi, Lappeenranta (Fl); Yrjo

Oinonen, Kokkola (Fl)

(51)

Int. Cl.

B01D 37/02

B01D 36/04

(52) U.S. Cl.

CPC .............. .. B01D 37/02 (2013.01); B01D 36/04

(2013.01)

(73) Assignee: OUTOTEC (FILTERS) OY,

Lappeenranta (Fl)

(21) Appl. No.:

USPC

(57)

14/351,207

(22)

PCT Filed:

Oct. 10, 2012

(86)

PCT N0.:

PCT/FI2012/050975

371 (0X1)

(2), (4) Date:

Apr. 11, 2014

(2006.01)

(2006.01)

......................................... .. 210/777; 210/193

ABSTRACT

Method for preparing a precoat (3) on the surface of the ?lter

medium (2) of a polishing ?lter (1), polishing ?lter (1) anduse

of a polishing ?lter. The essential feature in the invention is

that in the polishing ?lter (1), the precoat (3) is formed either

exclusively or jointly from the under?ow created in the sepa

ration process.

//

Q

Patent Application Publication

Aug. 21, 2014 Sheet 1 0f 2

US 2014/0231364 A1

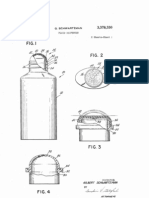

FIG. 1

Patent Application Publication

Aug. 21, 2014 Sheet 2 0f2

US 2014/0231364 A1

FIG. 2

Aug. 21,2014

US 2014/0231364 A1

METHOD FOR PREPARING A PRECOAT ON

THE SURFACE OF THE FILTER MEDIUM OF

A POLISHING FILTER, POLISHING FILTER

AND USE OF A POLISHING FILTER

[0001] The invention relates to a method according to the

preamble of claim 1 for preparing precoat on the surface of

the ?lter medium of a polishing ?lter. The invention also

relates to polishing ?lter equipment according to claim 8 and

to the use according to claim 14.

[0002] Various ?ltering methods are well known. One of

the most demanding methods is polishing ?ltration. There the

basic principle is to reduce the solids content of process

liquids down to an extremely low level, in some applications

even down to fractions of a billionth. Polishing ?lters can be

utilized in many different applications, for example in chemi

cal and process industry. Polishing ?lters can also be utilized

in metallurgy plants that use electrolytic concentration pro

cesses for removing impurities. Gold and zinc plants are well

cess according to the invention is particularly based on the

fact that the process in question is polishing ?ltration where

an autogenous precoat is made use of. Here the term autog

enous means that the precoat is formed of essentially the

same material as the material to be ?ltered. In practice, only

the particle size of the material is different, either completely

or partly. Thus it is particularly essential for the invention to

make use of the under?ow created in the process, with a

particle size larger than in the over?ow, of which under?ow

there is formed, by a rapid ?ltration, a precoat on the surface

of the ?lter medium, to serve as a ?lter aid medium. Said

under?ow, serving as a ?lter aid medium, improves the sepa

ration by ?ltration of the solids contained in the process

over?ow and having a particle size smaller than the under

?ow, without blocking the ?lter medium. The ?lter aid

medium serves as a kind of porous ?lter in which the solids

fed at a low feed rate are ?ltered, possibly also precipitated,

adsorbed or crystallized.

able to make use of polishing ?lters.

[0003] The purpose of polishing ?ltration is to separate, as

[0008] The object of the present invention is to achieve a

completely new arrangement for enhancing the ?ltration by a

completely as possible, the extremely small solid particles

polishing ?lter, so that the ?ltering e?iciency is substantially

contained in a liquid. The size of the particles varies. Typi

cally the size is smaller than 1,000 nm, and by average within

improved. Different types of ?lters can be employed as the

polishing ?lter. A particularly advantageous ?lter is a pres

surized polishing ?lter, for instance the Outotec Larox Pol

ishing Filter, i.e. LSF ?lter, or the Outotec Larox Vertical

Polishing Filter, i.e. VPF ?lter, where the operation is based

the range 40-400 nm. Generally particles of this size are in

English called submicrons, i.e. particles having a size of order

of less than one micrometer. In this invention, they are called

nanosize particles, which refers to the same thing. Different

on a pressure vessel and on cloth-coated frames provided

types of equipment can be used for measuring the size of

particles, for example the Hanna Instruments HI 93703 tur

therein, in which frames the ?ltering process is carried out.

Apart from LSF or VPF ?lters, also other types of ?lters can

bidity meter. The device is based on an 825 nm light source,

and the measurement is carried out as a re?ection of 90

be used, for example precoat ?lters, precoat drum ?lters,

degrees for readings below 40 FTU.

[0004] When the solids content of process liquids is

bag polishing ?lters. The essential feature in the invention is

reduced down to a very low level, and the particle size

remains as small as this, there are several problems in the

surface, and equipment for utilizing said method. More pre

cisely, the invention is characterized by what is set forth in the

?ltering process. Especially these nanosize particles, i.e. par

appended claims.

ticles with a size of less than one micrometer, tend to block the

[0009] The invention is described in more detail below,

with reference to the appended drawings, where

?lter medium in a short time. A particular problem is created

by the layer impermeable to liquid that is formed on the

surface and pores of the ?lter medium.

chamber ?lters, pressure leaf ?lters or candle-type ceramic or

the method for forming a pre-coat layer on the ?lter medium

Thus the ?lter medium, such as a ?lter cloth or a

[0010] FIG. 1 is a simpli?ed illustration of a method and

equipment according to an embodiment of the invention.

ceramic medium, is rapidly blocked, which directly affects

the ?ltering e?iciency. This in turn increases the ?ltering

[0011] FIG. 2 is a simpli?ed illustration of how the precoat

surface is formed on top of the ?lter medium.

[0005]

costs, such as costs caused directly by the ?lter material, as

well as maintenance and service costs. Moreover, aid medium

costs as well as waste and post-processing volumes increase.

These are extremely signi?cant aspects considering that in

process industry, particularly ef?ciency and all possible cost

bene?ts are welcome.

[0006]

According to the invention, an arrangement has

[0012]

FIG. 1 illustrates an embodiment of the method

according to the invention, where a precoat layer 3 is formed

on the surface of the ?lter medium 2 of a pressurized polish

ing ?lter 1. Said precoat layer 3 is formed either completely or

partially of an under-?ow, crystals or precipitated solids

obtained from a separation process, and thus the precoat 3

been devised where the above enlisted problems can be

serves as an autogenous ?lter aid medium in the method.

solved. In the arrangement according to the invention, it is

[0013] According to step I of FIG. 2, the precoat 3 is advan

tageously fed to an empty polishing ?lter 1, including a ?lter

essential to make use of an autogenous material created in the

process as a ?lter aid medium comprising a precoat. Here the

term precoat refers to a ?lter aid medium that is formed

essentially on the surface of the ?lter medium, or formed to be

in connection with said medium. This kind of second ?ltering

layer formed on the ?lter, such as the ?lter cloth, substantially

improves the ?ltering e?iciency. At the same time, better use

can be made of the whole process.

[0007] In an arrangement according to the invention, pol

ishing ?ltration is utilized more ef?ciently than in the prior

art, and at the same time, the operation of the whole equip

ment is optimized. The inventive nature of the ?ltering pro

element 4, a ?lter medium 2, such as ?lter cloth, and a ?ltrate

conduit 5. When the pre-coat 3 is fed to the ?lter 1, it forms an

even layer on the surface of the ?lter medium 2, such as a ?lter

cloth. According to step II, liquid is ?ltered through the cloth

into the ?ltrate conduit 5. After forming the precoat layer 3,

the solids to be ?ltered, such as an over?ow 6, are fed to the

?lter 1. Filtering is carried out by means of the precoat layer

3 and the ?lter medium 2, according to step III, so that the

small, nanoparticle-size crystals 7 are ?ltered by the precoat

3 serving as the ?lter aid medium, or by the surface thereof.

Thus the ?lter aid medium comprising the precoat 3 serves as

Aug. 21,2014

US 2014/0231364 A1

a kind of porous ?lter in which the solids 7 fed at a low feed

rate are ?ltered, possibly also precipitated, adsorbed or crys

tallized.

[0014] The use of an autogenous material, i.e. material

obtained from the process, as the ?lter aid medium forming

the precoat 3, is stable in the process and does neither cause

impurity residues in the process liquid nor increase mass

?ows in the plant. Thus said use reduces the process byprod

uct volumes and valuable material losses. The autogenous

precoat and the ?ltered solids can also be returned back to the

process. Moreover, the method enables the ?ltering of nano

particle-size crystals 7, i.e. solids with a particle size of

roughly 40-400 nm by average, from the process liquid. Con

sequently, by means of an arrangement according to the

invention, it is possible to increase ?ltering e?iciency, reduce

process residues or possible waste and minimize the ?ltering

costs.

[0015]

An advantageous example of a method utilizing the

material as the material to be ?ltered, or of material obtained

from the same process as the material to be ?ltered. The

invention makes the separation ?ltering of solids more effec

tive and at the same time improves the recovery of nanopar

ticles. A saturated solution precipitates/crystallizes nearly all

of the calcium in the precoat layer or on the surface thereof

according to the ?rst exemplary embodiment, or manganese

according to the second exemplary embodiment, without,

however, in any way interfering with the polishing ?ltration

process.

[0020] A person skilled in the art appreciates that the inven

tion is not restricted to the above described embodiments, but

the embodiments may vary within the scope of the appended

claims.

1-12. (canceled)

13. A method comprising forming a precoat on the surface

of a ?lter medium of a polishing ?lter, where the precoat is at

least partially formed of the under?ow of at least one of a

invention is the polishing ?ltration of calcium sulfate over

?ow (CaSO4) making use of polishing ?ltration with an

autogenous precoat. In an exemplary ?ltration that was car

thickener and a clari?er, and where the precoat serves as a

ried out, the employed ?lter aid medium forming the precoat

14. A method according to claim 13, where the precoat is a

?lter aid medium in pressurized polishing ?ltration, on the

was under?ow from a gypsum thickener.

[0016]

The arrangement according to the invention was

reached on the basis of various experiments and test runs,

?lter aid medium in polishing ?ltration of the over?ow of said

at least one of a thickener and a clari?er.

surface and/ or in the structure of which there are separated

nanoparticle-size solids from an over?ow that has a smaller

because from earlier experience it was found problematic that

in the course of time, gypsum was crystallized in the ?lter

medium of the polishing ?lter, thus causing it to be blocked.

Therefore the over?ow of the CaSO4 clari?er cannot, in most

particle size than the under?ow.

15. A method according to claim 13, where the under?ow

cases, be directly polishing ?ltered. The over?ow rapidly

that are fed at a slow ?ltering rate and have a smaller particle

size are at least one of ?ltered, precipitated, adsorbed and

crystallizes a layer impermeable to liquid on the surface of the

?lter medium. By means of an arrangement according to the

invention, this can be avoided by using the under?ow of the

CaSO4 clari?er as precoat material on the surface of the ?lter

medium. The method is made even more effective when the

used precoat is recycled back to polishing ?ltration, to be

reused as ?lter aid medium. Advantageously the polishing

?lter used in the method is an LSF ?lter, by means of which

the ?ltering of the CaSO4 over?ow is realized.

[0017] Another advantageous example of a method utiliz

ing the invention is manganese recovery for instance from the

has a larger particle size and serves as a ?lter aid medium

forming a porous precoat in which nanoparticle-size solids

crystallized.

1 6. A method according claim 13, where the particles of the

?lter aid medium created by the precoat formed of the under

?ow serve as seed crystals, and where the particles contained

in the supersaturated solution of the over?ow are crystallized.

17. A method according to claims 13, where the size of the

particles contained in the under?ow and in the particles con

tained in the over?ow is generally less than 1,000 nm, by

average 40-400 nm.

18. A method according to claim 13, where the precoat is

over?ow of ?nishing neutralization by applying polishing

formed of essentially the same substance as the substance to

?ltration utilizing an autogenous precoat. In a performed

be ?ltered.

19. A method according to claim 13, where the under?ow

and the over?ow comprise those of a CaSO4 clari?er.

exemplary ?ltration, the autogenous pre-coat serving as the

?lter aid medium was formed by utilizing the over?ow from

?nishing neutralization and the under?ow from the gypsum

20. A method according claim 13, where the precoat is

thickener, which is mainly calcium sulfate (CaSO4).

conducted back to polishing ?ltration, and reused as the ?lter

[0018] The aim was to make manganese sulfate, MnSO4, to

either crystallize in the precoat layer or to retain on the pre

coat laycr serving as the ?lter aid mcdium. First there was

formed a precoat layer on the surface of the polishing ?lter

aid medium creating the precoat.

21. A polishing ?lter having a ?lter medium comprising a

prccoat, where the prccoat is at least partially formed of the

neutralization was continued without interruptions after

undertow of at least one of a thickener and a clari?er, and

where the precoat serves as a ?lter aid medium in polishing

?ltration of the over?ow of said at least one of a thickener and

forming the autogenous precoat. On the basis of analysis

clari?er.

results from a test run realized at a low ?ow rate, it was found

22. A polishing ?lter according to claim 21, where the

precoat is a ?lter aid medium of a pressurized polishing ?lter,

cloth, and the ?ltering of the over?ow from the ?nishing

that the retention of manganese sulfate was higher than

99.8%. The method is made even more effective when the

used precoat is recycled back to the process, to be reused as an

on the surface and/or in the structure of which there are

autogenous ?lter aid medium. Advantageously the polishing

smaller particle size than the under?ow.

23. A polishing ?lter according to claim 22, where the

solids from the under?ow that has a larger particle size than

?lter used in the method is an LSF ?lter, by means of which

the ?ltering of the over?ow containing MnSO4 is realized.

[0019] According to the invention, it is essential that by

applying the new autogenous precoat system, there is

achieved an advantageous precoat that is formed of the same

separated nanoparticle-size solids from an over?ow that has a

the over?ow are arranged as a ?lter aid medium comprising

the precoat in connection with the ?lter medium of polishing

?ltration, and boost at least one of the ?ltering, precipitation,

Aug. 21,2014

US 2014/0231364 A1

adsorption and crystallization of nanoparticle-size solids con

tained in the over?ow that have a smaller particle size than the

under?ow.

24. A polishing ?lter according to claim 21, Where the

particles of the ?lter aid medium comprising the precoat and

formed of the undertow serve as seed crystals, in Which the

particles contained in a supersaturated solution of the over

?ow are crystallized.

25. A polishing ?lter according claim 21, Where the ?lter

aid medium arranged in the polishing ?lter enables the ?lter

ing of such nanoparticle-size solids from the process solution

Where the particle size is generally less than 1,000 nm, by

average 40-400 nm.

26. A polishing ?lter according claims 21, including ele

ments for conducting used precoat back to polishing ?ltra

tion, to be reused to form the precoat serving as a ?lter aid

medium.

27. A method comprising using a polishing ?lter for pol

ishing ?ltration of the over?ow of at least one of a thickener

or clari?er, Where a precoat is formed on the surface of a ?lter

medium of the polishing ?lter, and is at least partially formed

of an under?oW of the at least one of a thickener and clari?er.

*

You might also like

- Processes: Novel Technique For Coating of Fine Particles Using Fluidized Bed and Aerosol AtomizerDocument18 pagesProcesses: Novel Technique For Coating of Fine Particles Using Fluidized Bed and Aerosol AtomizerDenis Crispin IrazabalNo ratings yet

- Chee Lab 2 FinalDocument26 pagesChee Lab 2 FinalOLEBOGENG RATLHOGONo ratings yet

- Experimental Techniques in Chemistry: 2.1 FiltrationDocument6 pagesExperimental Techniques in Chemistry: 2.1 FiltrationKhan HaeeNo ratings yet

- Paste Thickening Iron Ore TailingsDocument8 pagesPaste Thickening Iron Ore TailingsAlejandra Vega Avilez100% (1)

- Plate and Frame FiltrationDocument30 pagesPlate and Frame FiltrationRays Shearer100% (2)

- Drilling Lab Experiment on Mud Cake Thickness and Water LossDocument7 pagesDrilling Lab Experiment on Mud Cake Thickness and Water LossAbdullwahid AhmedNo ratings yet

- Sistema Filament WindingDocument8 pagesSistema Filament WindingFrancisco CarrascoNo ratings yet

- Production of Rigid PU and PIR SlabstockDocument9 pagesProduction of Rigid PU and PIR Slabstockvitapur1No ratings yet

- Doctor Blade TechniqueDocument4 pagesDoctor Blade Techniquearunbalaji86No ratings yet

- Us 3378330Document5 pagesUs 3378330James LindonNo ratings yet

- European Patent ApplicationDocument9 pagesEuropean Patent Applicationdryele.sassoNo ratings yet

- Experiment 4 Plate and Frame FiltrationDocument22 pagesExperiment 4 Plate and Frame FiltrationMadel Isidro100% (1)

- SPE 144098 A New Technique To Characterize Drilling Fluid Filter CakeDocument14 pagesSPE 144098 A New Technique To Characterize Drilling Fluid Filter CakeJorge FernandoNo ratings yet

- Experiment 1: Dust Removal From Gas Using Cyclone Separator: ObjectiveDocument16 pagesExperiment 1: Dust Removal From Gas Using Cyclone Separator: ObjectivenaquiahoNo ratings yet

- United States Patent (19) : Crane (45) Aug. 23, 1977Document4 pagesUnited States Patent (19) : Crane (45) Aug. 23, 1977hosseinnaNo ratings yet

- FILTRATION PROCESS GUIDE: FACTORS, TYPES, MEDIADocument41 pagesFILTRATION PROCESS GUIDE: FACTORS, TYPES, MEDIAKonesi RonaldNo ratings yet

- Applying Label On Tubes Machine - US2007084556A1 - Description - 20240304 - 1240Document2 pagesApplying Label On Tubes Machine - US2007084556A1 - Description - 20240304 - 1240hana.hovorkovaNo ratings yet

- Flotation of Cleaner Rejects Removes High Density StickiesDocument16 pagesFlotation of Cleaner Rejects Removes High Density Stickiespaperravi2000No ratings yet

- Lost Circulation Material With A Multi-Modal Large Particle Size DistributionDocument21 pagesLost Circulation Material With A Multi-Modal Large Particle Size DistributionThura AungNo ratings yet

- Sample Preparation of XpsDocument5 pagesSample Preparation of XpsnajwaizzatiNo ratings yet

- Formulation of Highly Concentrated Suspensions For Spray Drying in A Fluidized BedDocument12 pagesFormulation of Highly Concentrated Suspensions For Spray Drying in A Fluidized BedVishnupriya RamalingamNo ratings yet

- FiltrationDocument77 pagesFiltrationmeet2abhayNo ratings yet

- Recent Innovations in Paper Recycling Flotation)Document4 pagesRecent Innovations in Paper Recycling Flotation)kayee516No ratings yet

- Solid-Liquid Filtration: A User’s Guide to Minimizing Cost and Environmental Impact, Maximizing Quality and ProductivityFrom EverandSolid-Liquid Filtration: A User’s Guide to Minimizing Cost and Environmental Impact, Maximizing Quality and ProductivityRating: 5 out of 5 stars5/5 (2)

- Us 4925562Document7 pagesUs 4925562César Fernando Melquiades BravoNo ratings yet

- Liquid Penetrant Testing Theory and InterpretationDocument44 pagesLiquid Penetrant Testing Theory and InterpretationCRISTIAN SILVIU IANUCNo ratings yet

- Inkjet-Printed Tio Nanoparticles From Aqueous Solutions For Dye-Sensitized Solar Cells (DSSCS)Document6 pagesInkjet-Printed Tio Nanoparticles From Aqueous Solutions For Dye-Sensitized Solar Cells (DSSCS)Wendy PhNo ratings yet

- Organic Solvent and Surfactant Resistant Paper-Fluidic Devices Fabricated by One-Step Embossing of Nonwoven Polypropylene SheetDocument8 pagesOrganic Solvent and Surfactant Resistant Paper-Fluidic Devices Fabricated by One-Step Embossing of Nonwoven Polypropylene SheettreedeNo ratings yet

- Houghton 1998Document15 pagesHoughton 1998_meiantiNo ratings yet

- Plate and Frame Filter PressDocument6 pagesPlate and Frame Filter PressLissa Hannah100% (2)

- 1 PBDocument7 pages1 PBanandhra2010No ratings yet

- Non-woven fabric and method for preventing dye migrationDocument5 pagesNon-woven fabric and method for preventing dye migrationReza MoshiriNo ratings yet

- Microgranulation of fine cornstarch powders in a novel rotating fluidized bed granulatorDocument6 pagesMicrogranulation of fine cornstarch powders in a novel rotating fluidized bed granulatorBlagojeNo ratings yet

- Raw Material E-Glass FibberDocument7 pagesRaw Material E-Glass Fibberpramo_dassNo ratings yet

- Plate and Frambhhe LAB REPORTDocument10 pagesPlate and Frambhhe LAB REPORTrossangel35No ratings yet

- Kenny's Solid Bench FileDocument24 pagesKenny's Solid Bench Fileotaken6No ratings yet

- Assignment (Plate and Frame Filter Press) Group A-8)Document22 pagesAssignment (Plate and Frame Filter Press) Group A-8)Sajjad Rasool Chaudhry0% (4)

- Experiment On Sand ContentDocument15 pagesExperiment On Sand ContentAnsell EwemeNo ratings yet

- Mud Filtraion 1Document5 pagesMud Filtraion 1ايمن القنونيNo ratings yet

- FILTRATIONDocument4 pagesFILTRATIONFatima AminNo ratings yet

- United States Patent Office: Patented Apr. 6, 1971Document3 pagesUnited States Patent Office: Patented Apr. 6, 1971Alexander Franco CastrillonNo ratings yet

- Jan. 1, 1963 W. E. Kaskel 3,071.498: 77oawaDocument8 pagesJan. 1, 1963 W. E. Kaskel 3,071.498: 77oawaricva_rjNo ratings yet

- Process for Spray-Drying Acrylic Polymer SolutionsDocument5 pagesProcess for Spray-Drying Acrylic Polymer SolutionslauraNo ratings yet

- BS 3424-18 1986 Wicking TestDocument12 pagesBS 3424-18 1986 Wicking TestJakariya NugrahaNo ratings yet

- European Patent Application C11D 17/00: Production Process For Detergent TabletDocument19 pagesEuropean Patent Application C11D 17/00: Production Process For Detergent Tabletshadi elhagNo ratings yet

- Spraydrying PDFDocument4 pagesSpraydrying PDFagrocel_bhv5591No ratings yet

- Bsaics of FilterDocument9 pagesBsaics of FilterVigneshwaranPalanivelNo ratings yet

- Page 14-15Document25 pagesPage 14-15Saurabh ChoudharyNo ratings yet

- Lab 9 Almost DoneDocument21 pagesLab 9 Almost DoneAIDYNo ratings yet

- CentrifugationDocument5 pagesCentrifugationNoreen Arshad100% (1)

- Single Screw ExtrusionDocument5 pagesSingle Screw ExtrusionAli RazuNo ratings yet

- ?nite States Tent n91: AssigneeDocument3 pages?nite States Tent n91: AssigneeererNo ratings yet

- Pre Wetting in SizingDocument3 pagesPre Wetting in SizingKhubab Shaker100% (2)

- TEPZZ - 6 48B - T: European Patent SpecificationDocument13 pagesTEPZZ - 6 48B - T: European Patent SpecificationshamsNo ratings yet

- United States Patent (191 (111 4,379,197: Cipriani Et A1. (45) Apr. 5, 1983Document3 pagesUnited States Patent (191 (111 4,379,197: Cipriani Et A1. (45) Apr. 5, 1983Siswand BIn Mohd AliNo ratings yet

- Wet Chemical Synthesis of NanoparticlesDocument4 pagesWet Chemical Synthesis of NanoparticlesAnonymous Oa7AeX1n5hNo ratings yet

- Deinking of Waste Paper - FlotationDocument8 pagesDeinking of Waste Paper - FlotationMiko Still SpeedinNo ratings yet

- University of Zawia Faculty of Oil & Gas Engineering: Mud FiltrationDocument5 pagesUniversity of Zawia Faculty of Oil & Gas Engineering: Mud Filtrationايمن القنونيNo ratings yet

- Presentation Now Prepare A Perfect Presentation in Less Than 3 Hours PDFDocument201 pagesPresentation Now Prepare A Perfect Presentation in Less Than 3 Hours PDFask101No ratings yet

- Pipe Schedule PDFDocument1 pagePipe Schedule PDFSrinivasan SeenuNo ratings yet

- Presentation Now Prepare A Perfect Presentation in Less Than 3 Hours PDFDocument201 pagesPresentation Now Prepare A Perfect Presentation in Less Than 3 Hours PDFask101No ratings yet

- Presentation Now Prepare A Perfect Presentation in Less Than 3 Hours PDFDocument201 pagesPresentation Now Prepare A Perfect Presentation in Less Than 3 Hours PDFask101No ratings yet

- The Rules For Being Amazing PDFDocument1 pageThe Rules For Being Amazing PDFAkshay PrasathNo ratings yet

- Twist drill bit nomenclature guideDocument3 pagesTwist drill bit nomenclature guideask101No ratings yet

- Sgs Ind NDT TC MT A4 en 11Document2 pagesSgs Ind NDT TC MT A4 en 11musaismail8863No ratings yet

- Air Pump Supplier ListDocument1 pageAir Pump Supplier Listask101No ratings yet

- Operating Instructions for the HSTL-880 Hydraulic Punching Press with Two-Hand ControlDocument29 pagesOperating Instructions for the HSTL-880 Hydraulic Punching Press with Two-Hand Controlask101No ratings yet

- Duraband PDFDocument1 pageDuraband PDFrobertNo ratings yet

- Cameron Land BOP Control SystemDocument1 pageCameron Land BOP Control Systemask101No ratings yet

- The Rules For Being Amazing PDFDocument1 pageThe Rules For Being Amazing PDFAkshay PrasathNo ratings yet

- Surface Preparation Standards Comparison ChartDocument2 pagesSurface Preparation Standards Comparison ChartajuhaseenNo ratings yet

- CatalogueDocument62 pagesCatalogueask101No ratings yet

- 3.1-16 10K Choke Manifold COC and DWGDocument3 pages3.1-16 10K Choke Manifold COC and DWGask101No ratings yet

- T3 Energy 4-1/16'' 10000 PSI choke manifold componentsDocument2 pagesT3 Energy 4-1/16'' 10000 PSI choke manifold componentsask101No ratings yet

- ReadmeDocument1 pageReadmeask101No ratings yet

- 250-350 CFM (100-150 PSI) Kubota Engine Diesel Portable Air Compressor - tcm795-3586101Document2 pages250-350 CFM (100-150 PSI) Kubota Engine Diesel Portable Air Compressor - tcm795-3586101ask101No ratings yet

- Welding Electrode Classifications Wallchart PDFDocument1 pageWelding Electrode Classifications Wallchart PDFask101No ratings yet

- InstalacjaDocument92 pagesInstalacjaAntonio B GuzamanNo ratings yet

- Photoshop CS5 Extended 3D & Motion Editing Trial InstallDocument2 pagesPhotoshop CS5 Extended 3D & Motion Editing Trial InstallFaisal MohammedNo ratings yet

- Kemper Catalog StndDist Aug2013Document12 pagesKemper Catalog StndDist Aug2013ask101No ratings yet

- Time Magazine - August 3, 2015 USADocument62 pagesTime Magazine - August 3, 2015 USAHatef Ghanei100% (3)

- AS3041Document1 pageAS3041ask101No ratings yet

- Fluid Management Selection GuideDocument8 pagesFluid Management Selection Guideask101No ratings yet

- FMC Flowline Product CatalogDocument80 pagesFMC Flowline Product CatalogRodrigo França100% (2)

- Api 6a PDFDocument422 pagesApi 6a PDFask101No ratings yet

- Structural Optimization of A Thin-Shell Bridge Structure: Evrard Fauche Sigrid Adriaenssens Jean H. PrevostDocument8 pagesStructural Optimization of A Thin-Shell Bridge Structure: Evrard Fauche Sigrid Adriaenssens Jean H. Prevostask101No ratings yet

- Filt Rex BrochureDocument8 pagesFilt Rex Brochureask101No ratings yet

- InstalacjaDocument92 pagesInstalacjaAntonio B GuzamanNo ratings yet

- 6 14D 13 PDFDocument17 pages6 14D 13 PDFRiyon Sanjaya IrmalNo ratings yet

- High Speed CastingDocument7 pagesHigh Speed Castingferdlh9No ratings yet

- Community Radio User GuideDocument285 pagesCommunity Radio User GuideHarish KumarNo ratings yet

- Metals and AlloysDocument34 pagesMetals and AlloyszenrockNo ratings yet

- Development of Xbloc Concrete Breakwater Armour Units Canada 2003Document12 pagesDevelopment of Xbloc Concrete Breakwater Armour Units Canada 2003r_anzarNo ratings yet

- 22 - Muhammad Rifky Hasan - 172112238Document4 pages22 - Muhammad Rifky Hasan - 172112238Rifky hasanNo ratings yet

- Tidal CalculationsDocument6 pagesTidal CalculationsSandipanBiswasNo ratings yet

- Coanda Effect Air-LiftDocument19 pagesCoanda Effect Air-LiftJúlio Cesar RodriguesNo ratings yet

- Demolition of BuildingDocument6 pagesDemolition of BuildingMAITRI ADUGENo ratings yet

- Boiler Water ChemistryDocument63 pagesBoiler Water ChemistryDeepak JayNo ratings yet

- Circle TheoryDocument8 pagesCircle Theoryapi-278074538100% (3)

- Week 1 ScienceDocument38 pagesWeek 1 ScienceEyphrille UmandapNo ratings yet

- 5th Sem Mech Diploma OdishaDocument14 pages5th Sem Mech Diploma OdishaBIBEKANANDA SAHOONo ratings yet

- CBSE Class 12 Chemistry Sample Paper-15: Material Downloaded From - 1 / 14Document14 pagesCBSE Class 12 Chemistry Sample Paper-15: Material Downloaded From - 1 / 14Allen Neal JonesNo ratings yet

- The PA Bible Addn 13 The Electric Guitar Loudspeaker PDFDocument3 pagesThe PA Bible Addn 13 The Electric Guitar Loudspeaker PDFjosiasns5257No ratings yet

- Radiochromic Film Dosimetry-1Document47 pagesRadiochromic Film Dosimetry-1Piotr JankowskiNo ratings yet

- H 103 - ISO - Rev10 - INGDocument1 pageH 103 - ISO - Rev10 - INGandersmorais86No ratings yet

- GPS100 Data SheetDocument2 pagesGPS100 Data SheetCaptainNo ratings yet

- Unit 4Document76 pagesUnit 4raghuram67No ratings yet

- .Fraunhofer - Diffraction.at - The.slit.Document6 pages.Fraunhofer - Diffraction.at - The.slit.NCHE BORISNo ratings yet

- Convolution and Frequency Response For LTI Systems: HapterDocument9 pagesConvolution and Frequency Response For LTI Systems: HapterJ. SamNo ratings yet

- Module 1 - 2D FlowDocument18 pagesModule 1 - 2D FlowRizal Irnandi HidayatNo ratings yet

- Reinforced Concrete Structures Analysis and DesignDocument4 pagesReinforced Concrete Structures Analysis and DesignJulio Cesar ValdiviesoNo ratings yet

- Fibre Reinforced ConcreteDocument288 pagesFibre Reinforced ConcreteDinesh Babu100% (1)

- Lecture 3Document10 pagesLecture 3Abhishek SinhaNo ratings yet

- Reserves Estimation For A Coal Bed Methane Well PETSOC-03-11-01-PDocument6 pagesReserves Estimation For A Coal Bed Methane Well PETSOC-03-11-01-Psaladinayubi1234No ratings yet

- Implementing A Virtual TrackballDocument4 pagesImplementing A Virtual Trackballkinny1974No ratings yet

- Injection Molding SOP for Mini-Jector #55.1 MachineDocument12 pagesInjection Molding SOP for Mini-Jector #55.1 MachineYusuf SethNo ratings yet

- Ageing of Zinc Alloys: January 2011Document23 pagesAgeing of Zinc Alloys: January 2011Alicia Jara ChavezNo ratings yet

- Lesson 1.3: General Properties of Indefinite IntegralsDocument6 pagesLesson 1.3: General Properties of Indefinite IntegralsMarkNo ratings yet