Professional Documents

Culture Documents

Unit-4 TTT Diagram PDF

Uploaded by

Shyam PatidarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Unit-4 TTT Diagram PDF

Uploaded by

Shyam PatidarCopyright:

Available Formats

2.

TTT - Diagrams

2. TTT Diagrams

An essential feature of low alloyed ferrous materials is the crystallographic transformation of

the body-centred cubic lattice which is stable at room

-Iron

body-centered

temperature (-iron, ferritic

structure)

to

the

-Iron

face-centered

face-

centred cubic lattice (-iron,

austenitic structure), Figure

2.1. The temperature, where

this transformation occurs, is

not constant but depends on

Lattice constant

0.364 nm

at 900 C

Lattice constant

0.286 nm

at room temperature

factors like alloy content,

br-eI-02-01.cdr

crystalline

structure,

ten-

sional status, heating and

cooling rate, dwell times,

Figure 2.1

etc..

In order to be able to understand the basic processes it is necessary to have a look at the

basic processes occuring in an idealized binary system. Figure 2.2 shows the state of a binary system with complete solubility in the liquid and solid state.

If the melting of the L1 alloy is cooling down, the first crystals of the composition c1 are formed

with reaching the temperature T1. These crystals are depicted as mixed crystal , since they

consist of a compound of the components A (80%) and of B (20%). Further, a melting with

the composition c0 is present at the temperature T1.

L1

L1

With dropping temperature,

S

TsA

riched with component B,

T2

T1

Li (liquidus line, up to point

3

2

4

5

Temperature T

following the course of line

Li

So

TsB

Temperature T

the remaining melt is en-

- ss

4). In parallel, always new

and B richer -mixed crystals are forming along the

A

(Ni)

br-eI-02-02.cdr

connection line So (solidus

line, points 1, 2, 5). The dis-

Figure 2.2

c1

c2

c0

c3

Concentration c

c4

B

(Cu)

Time t

2. TTT Diagrams

10

tribution of the components A and B in the solidified structure is homogeneous since concentration differences of the precipitated mixed crystals are balanced by diffusion processes.

The other basic case of complete solubility of two components in the liquid state and of complete insolubility in the solid state shows Figure 2.3 If two components are completely insoluble in the solid state, no mixed crystal will be formed of A and B. The two liquidus lines Li cut

in point e which is also designated as the eutectic point. The isotherm Te is the eutectic line.

If an alloy of free composition solidifies according to Figure 2.3, the eutectic line must be cut.

This is the temperature (Te) of the eutectic transformation:

S A+B (T = Te = const.).

This means that the melt at a constant temperature Te dissociates in A and B. If an alloy of

the composition L2 solidifies, a purely eutectic structure results. On account of the eutectic

reaction, the temperature of the alloy remains constant up to the completed transformation

(critical point) (Figure 2.2).

Eutectic

L1

L2

L1

TsA

1

TsB

So

Te

Li

Li

S+A

S+B

orientation

Temperature T

are

normally fine-grained and

show

S

2

L2

structures

characteristic

between

the

constituents. The alloy L1

will consist of a compound

3

4

of alloy A and eutectic alloy

A+E

B+E

E in the solid state.

A

c1

ce

Concentration c

Time t

You can find further infor-

br-eI-02-03.cdr

mation on transformation

behaviour in relevant specialist literature.

Figure 2.3

The definite use of the principles occurs in the iron-iron carbide diagram. Transformation behaviour of carbon containing iron in the equilibrium condition is described by the stable phase

diagram iron-graphite (Fe-C). In addition to the stable system Fe-C which is specific for an

equilibrium-close cooling, there is a metastable phase diagram iron cementite (Fe-Fe3C).

During a slow cooling, carbon precipitates as graphite in accord with the stable system Fe-C,

2. TTT Diagrams

11

while during accelerated cooling, what corresponds to technical conditions, carbon precipitates as cementite in agreement with the metastable system (Fe-Fe3C). Per definition, iron

carbide is designated as a structure constituent with cementite although its stoichiometric

composition is identical (Fe3C). By definition, cementite and graphite can be present in steel

together or the cementite

melt +

- solid solution

can decompose to iron

solid sol.

and graphite during heat

Fe3C

(cementite)

solid sol.

melt +

austenite

treatment of carbon rich

austenite + graphite

austenite + cementite

formation of cementite is

ledeburite

damentally valid that the

melt +

cementite

austenite

Temperature C

alloys. However, it is fun-

austenite +

ferrite

encouraged with increas-

ferrite

ferrite + graphite

ferrite + cementite

perlite

ing cooling rate and decreasing carbon content.

stable equilibrium

metastable equilibrium

Mass % of Carbon

br-eI-02-04.cdr

In a double diagram, the

Stable and Metastable Iron-Carbon-Diagram

stable system is shown by

a dashed, the metastable

melt +

graphite

melt

Figure 2.4

by a solid line, Figure 2.4.

The metastable phase diagram is limited by the formation of cementite with a carbon content

of 6,67 mass%. The strict stoichiometry of the formed carbide phase can be read off at the

top X-coordinate of the molar carbon content. In accordance with the carbon content of Fe3C,

cementite is formed at a molar content of 25%. The solid solutions in the phase fields are

designated by Greek characters. According to convention, the transition points of pure iron

are marked with the character A - arrt (stop point) and distinguished by subjacent indexes. If

the transition points are determined by cooling curves, the character r = refroidissement is

additionally used. Heat-up curves get the supplement c - chauffage. Important transition

points of the commercially more important metastable phase diagram are:

1536 C: solidification temperature (melting point) -iron,

1392 C: A4- point - iron,

911 C: A3- point non-magnetic - iron,

with carbon containing iron:

-

723 C: A1- point (perlite point).

2. TTT Diagrams

12

The corners of the phase fields are designated by continuous roman capital letters.

As mentioned before, the system iron-iron carbide is a more important phase diagram for

technical use and also for welding techniques. The binary system iron-graphite can be stabilized by an addition of silicon so that a precipitation of graphite also occurs with increased

solidification velocity. Especially iron cast materials solidify due to their increased silicon contents according to the stable system. In the following, the most important terms and transformations should be explained more closely as a case of the metastable system.

The transformation mechanisms explained in the previous sections can be found in the binary system iron-iron carbide almost without exception. There is an eutectic transformation in

point C, a peritectic one in point I, and an eutectoidic transformation in point S. With a temperature of 1147C and a carbon concentration of 4.3 mass%, the eutectic phase called Ledeburite precipitates from cementite with 6,67% C and saturated -solid solutions with 2,06%

C. Alloys with less than 4,3 mass% C coming from primary austenite and Ledeburite are

called hypoeutectic, with more than 4,3 mass% C coming from primary austenite and Ledeburite are called hypereutectic.

If an alloy solidifies with less than 0,51 mass percent of carbon, a -solid solution is formed

below the solidus line A-B (-ferrite). In accordance with the peritectic transformation at

1493C, melt (0,51% C) and -ferrite (0,10% C) decompose to a -solid solution (austenite).

The transformation of the -solid solution takes place at lower temperatures. From -iron with

C-contents below 0.8% (hypoeutectoidic alloys), a low-carbon -iron (pre-eutectoidic ferrite)

and a fine-lamellar solid solution (perlite) precipitate with falling temperature, which consists

of -solid solution and cementite. With carbon contents above 0,8% (hypereutectoidic alloys)

secondary cementite and perlite are formed out of austenite. Below 723C, tertiary cementite

precipitates out of the -iron because of falling carbon solubility.

The most important distinguished feature of the three described phases is their lattice structure. - and -phases are cubic body-centered (CBC lattice) and -phase is cubic facecentered (CFC lattice), Figure 2.1.

2. TTT Diagrams

13

Different carbon solubility of solid solutions also results from lattice structures. The three above mentioned phases dissolve carbon interstitially, i.e. carbon is embedded between the

iron atoms. Therefore, this types of solid solutions are also named interstitial solid solution.

Although the cubic face-centred lattice of austenite has a higher packing density than the cubic body-centred lattice, the void is bigger to disperse the carbon atom. Hence, an about 100

times higher carbon solubility of austenite (max. 2,06% C) in comparison with the ferritic

phase (max. 0,02% C for -iron) is the result. However, diffusion speed in -iron is always at

least 100 times slower than in -iron because of the tighter packing of the -lattice.

Although - and -iron show the same lattice structure and properties, there is also a difference between these phases. While -iron develops of a direct decomposition of the melt (S

), -iron forms in the solid phase through an eutectoidic transformation of austenite (

+ Fe3C). For the transformation of non- and low-alloyed steels, is the transformation of ferrite of lower importance, although this -phase has a special importance for weldability of

high alloyed steels.

Unalloyed steels used in industry are multi-component systems of iron and carbon with alloying elements as manganese, chromium, nickel and silicon. Principally the equilibrium diagram Fe-C applies also to such multi-component systems. Figure 2.5 shows a schematic cut

through the three phase system Fe-M-C.

During precipitation, mixed carbides of the general composition M3C develop. In contrast to

the binary system Fe-C, is

the three phase system

Fe-M-C characterised by a

Ac3

temperature interval in the

Ac1e

three-phase field + +

M3C. The beginning of the

transformation of + M3C

to is marked by Aclb, the

end by Acle. The indices b

and e mean the beginning

br-eI-02-05.cdr

Description of the Terms Ac1b, Ac1e, Ac3

and the end of transformation.

Figure 2.5

2. TTT Diagrams

14

The described equilibrium diagrams apply only to low heating and cooling rates. However,

higher heating and cooling rates are present during welding, consequently other structure

types develop in the heat

affected zone (HAZ) and in

the weld metal. The strucC

ture transformations during

heating and cooling are described

by

transformation

diagrams, where a temperature change is not carried

out close to the equilibrium,

s

but

at

different

heating

br-eI-02-06.cdr

and/or cooling rates.

A

representation

transformation

of

TTA Diagram for

Isothermal Austenitization

the

processes

Figure 2.6

during isothermal austenitizing shows Figure

ASTM4; L=80m

2.6. This figure must be read exclusively along

ASTM11; L=7m

the time axis! It can be recognised that several

transformations during isothermal austenitizing

occur with e.g. 800C. Inhomogeneous austen20m

20m

ite means both, low carbon containing austenite is formed in areas, where ferrite was

present before transformation, and carbon-rich

austenite is formed in areas during transforma-

Temperature

tion, where carbon was present before transformation. During sufficiently long annealing

times, the concentration differences are balanced by diffusion, the border to a homogeneous austenite is passed. A growing of the

Time

br-er02-07.cdr

ISF 2002

austenite grain size (to ASTM and/or in m)

can here simultaneously be observed with

longer annealing times.

Figure 2.7

2. TTT Diagrams

15

The influence of heating rate on austenitizing is shown in Figure 2.7. This diagram must only

be read along the sloping lines of the same heating rate. For better readability, a time pattern

was added to the pattern of the heating curves. To elucidate the grain coarsening during austenitizing, two microstructure photographs are shown, both with different grain size classes to

ASTM.

Figure 2.8 shows the relation between the TTA and the Fe-C diagram. It's obvious that the

Fe-C diagram is only valid for infinite long dwell times and that the TTA diagram applies only

for one individual alloy.

Figure 2.9 shows the dif-

Ac3

ferent

time-temperature

passes during austenitizing

Ac1e

and

Ac1b

subsequent

cooling

down.

The heating period is composed of a continuous and

an isothermal section.

br-eI-02-08.cdr

Dependence Between TTA-Diagram

and the Fe-M-C System

During cooling down, two

different ways of heat con-

Figure 2.8

trol can be distinguished:

1. : During continuous

temperature

Ac3

continuous

Ac1e

control

cooling is carried out with a

constant cooling rate out of

Ac1b

the area of the homogeneisothermal

ous and stable austenite

down to room temperature.

2.

During

temperature

isothermal

control

quenching out of the area

br-eI-02-09.cdr

Heating and Cooling Behaviour With

Several Heat Treatments

of the austenite is carried

out into the area of the me-

Figure 2.9

2. TTT Diagrams

16

the area of the homogeneous and stable austenite down to room temperature.

2. : During isothermal temperature control a quenching out of the area of the austenite is

carried out into the area of the metastable austenite (and/or into the area of martensite), followed by an isothermal holding until all transformation processes are completed. After transformation will be cooled down to room temperature.

Figure

2.10

shows

the

time-temperature diagram

of a isothermal transformation of the mild steel Ck 45.

Read such diagrams only

along the time-axis! Below

the Ac1b line in this figure,

there is the area of the metastable austenite, marked

with

an

A.

The

areas

marked with F, P, B, und M

represent areas where ferFigure 2.10

rite, perlite, Bainite and

martensite are formed. The

lines which limit the area to the left mark the beginning of the formation of the respective

structure. The lines which limit the area to the right mark the completion of the formation of

the respective structure. Because the ferrite formation is followed by the perlite formation, the

completion of the ferrite formation is not determined, but the start of the perlite formation.

Transformations to ferrite and perlite, which are diffusion controlled, take place with elevated

temperatures, as diffusion is easier. Such structures have a lower hardness and strength, but

an increased toughness.

Diffusion is impeded under lower temperature, resulting in formation of bainitic and martensitic structures with hardness and strength values which are much higher than those of ferrite

and perlite. The proportion of the formed martensite does not depend on time. During

quenching to holding temperature, the corresponding share of martensite is spontanically

formed. The present rest austenite transforms to Bainite with sufficient holding time. The right

2. TTT Diagrams

17

detail of the figure shows the present structure components after completed transformation

and the resulting hardness at room temperature.

Figure 2.11 depicts the graphic representation of the TTT diagram, which is more important

for welding techniques. This is the TTT diagram for continuous cooling of the steel Ck 15.

The diagram must be read along the drawn cooling passes. The lines, which are limiting the

individual areas, also depict the beginning and the end of the respective transformation.

Close to the cooling curves, the amount of the formed structure is indicated in per cent, at the

end of each curve, there is the hardness value of the structure at room temperature.

Figure 2.12 shows the TTT

diagram of an alloyed steel

containing

approximately

the same content of carbon

as the steel Ck 15. Here

you can see that all transformation

processes

are

strongly postponed in relation to the mild steel. A

Figure 2.11

completely

marte nsitic

transformation

is

carried

out up to a cooling time of

about 1.5 seconds, compared with 0.4 seconds of

Ck 15. In addition, the

completely diffusion controlled transformation processes of the perlite area

are postponed to clearly

longer times.

The hypereutectoid steel C

100

behaves completely

different, Figure 2.13. With

Figure 2.12

this carbon content, a pre-

2. TTT Diagrams

18

eutectoid ferrite formation cannot still be carried out (see also Figure 2.3).

The term of the figures 2.9 to 2.11 "austeniti zing temperature means the temperature,

where the workpiece transforms to an auste nitic microstructure in the course of a heat

treatment. Dont mix up this temperature with

the AC3 temperature, where above it there is

only pure auste nite. In addition you can see

that only martensite is formed from the austenite, provided that the cooling rate is sufficiently

high,

formation

of

any

other

microstructure is completely depressed. With

this type of transformation, the steel gains the

highest hardness and strength, but loses its

toughness, it embrittles. The slowest cooling

rate where such a transformation happens, is

Figure 2.13

Figure 2.14

called critical cooling rate.

Figure 2.15

2. TTT Diagrams

19

Figure 2.14 shows schematically how the TTT diagram is modified by the chemical composition of the steel.

The influence of an increased austenitizing temperature on transformation beha viour shows

Figure 2.15. Due to the higher hardening temperature, the grain size of the austenite is

higher (see Figure 2.6 and 2.7).

This grain growth leads to

an extension of the diffusion lengths which must be

passed during the transformation. As a result, the

"noses" in the TTT diagram

are shifted to longer times.

The lower part of the figure

shows the proportion of

formed

martensite

and

Bainite depending on cooling time. You can see that

Figure 2.16

with

higher

austenitizing

temperature the start of

Bainite formation together

with the drop of the martensite proportion is clearly

shifted to longer times.

As Bainite formation is not

so much impeded by the

coarse austenite grain as

with the completely diffusion controlled processes

of ferrite and perlite formation, the maximum Bainite

Figure 2.17

proportion

is

increased

from about 45 to 75%.

2. TTT Diagrams

20

Due to the strong influence of the austenitizing temperature to the transformation behaviour

of steel, the welding technique uses special diagrams, the so called Welding -TTT-diagrams.

They are recorded following the welding temperature cycle with both, higher austenitizing

temperatures (basically between 950 and 1350C) and shorter a usteniti zing times.

You find two examples in Figures 2.16 and 2.17.

Figure 2.18 proves that the

iron-carbon diagram was

developed as an equilibrium diagram for infinite

long cooling time and that

a TTT diagram applies always only for one alloy.

Figure 2.18

You might also like

- ERP Roll Lisst AuDocument2 pagesERP Roll Lisst AuShyam PatidarNo ratings yet

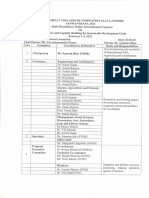

- Ci:on: Shri Vaishnav Vidyapeeth Vishwavidyalaya, IndoreDocument2 pagesCi:on: Shri Vaishnav Vidyapeeth Vishwavidyalaya, IndoreShyam PatidarNo ratings yet

- Committee - Sanmantrana 2021Document4 pagesCommittee - Sanmantrana 2021Shyam PatidarNo ratings yet

- MP-PET-2009-physics 455Document7 pagesMP-PET-2009-physics 455Shyam PatidarNo ratings yet

- Scheme of Mechanical Diploma 4 SemDocument1 pageScheme of Mechanical Diploma 4 SemShyam PatidarNo ratings yet

- MP PET 2008 Classes PDFDocument7 pagesMP PET 2008 Classes PDFShyam PatidarNo ratings yet

- Admission jULY 2019 PDFDocument1 pageAdmission jULY 2019 PDFShyam PatidarNo ratings yet

- Online International Conference Sanmantrana-Feb 1-3, 2021Document4 pagesOnline International Conference Sanmantrana-Feb 1-3, 2021Shyam PatidarNo ratings yet

- MP-PET-2009-physics 455Document7 pagesMP-PET-2009-physics 455Shyam PatidarNo ratings yet

- Physics Objective Questions Part 8Document10 pagesPhysics Objective Questions Part 8hamayaunNo ratings yet

- Att 6146 PDFDocument76 pagesAtt 6146 PDFranaNo ratings yet

- Marks Feeding Notice For RGPVDocument1 pageMarks Feeding Notice For RGPVShyam PatidarNo ratings yet

- National Project Implementation UnitDocument5 pagesNational Project Implementation UnitabhiNo ratings yet

- Subject Distribution For July - Dec 2017 OldDocument1 pageSubject Distribution For July - Dec 2017 OldShyam PatidarNo ratings yet

- Debit Account Details: Account No. Account Type Branch Amount Commission Amount Transaction Type UTR NumberDocument1 pageDebit Account Details: Account No. Account Type Branch Amount Commission Amount Transaction Type UTR NumberShyam PatidarNo ratings yet

- Heat Treatment Processes GuideDocument18 pagesHeat Treatment Processes GuideShyam PatidarNo ratings yet

- Important For B.techDocument15 pagesImportant For B.techShyam PatidarNo ratings yet

- Ci EnginesDocument32 pagesCi EnginesammuvarshNo ratings yet

- Fluid Dynamics - The Navier-Stokes EquationsDocument7 pagesFluid Dynamics - The Navier-Stokes EquationsShyam PatidarNo ratings yet

- Course Content of IEDocument4 pagesCourse Content of IEShyam PatidarNo ratings yet

- 01 LoadsDocument80 pages01 LoadsWan RidsNo ratings yet

- Mechatronics & AutomationDocument2 pagesMechatronics & AutomationShyam PatidarNo ratings yet

- Industrial Engineering PDFDocument35 pagesIndustrial Engineering PDFShyam PatidarNo ratings yet

- Ajay's MoviesDocument4 pagesAjay's MoviesShyam PatidarNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Microstructure of Rapidly Solidified Cu-Al-Ni Shape Memory Alloy RibbonsDocument10 pagesMicrostructure of Rapidly Solidified Cu-Al-Ni Shape Memory Alloy RibbonsMarité MalachevskyNo ratings yet

- The New 200-Series: An Alternative Answer To Ni. Surcharge ? Dream or Nightmare?Document9 pagesThe New 200-Series: An Alternative Answer To Ni. Surcharge ? Dream or Nightmare?alban500100% (1)

- Article - Stress Relieving Heat Treatments For Austenitic Stainless SteelsDocument2 pagesArticle - Stress Relieving Heat Treatments For Austenitic Stainless Steelsabhishek198327No ratings yet

- A DessertationDocument74 pagesA DessertationChandan SrivastavaNo ratings yet

- Metals 10 00505Document14 pagesMetals 10 00505qwerty fkvorkcjdkNo ratings yet

- CALPHAD 36 (2012) 16-22: Critical Assessment: Martensite-Start Temperature for the γ → ε TransformationDocument17 pagesCALPHAD 36 (2012) 16-22: Critical Assessment: Martensite-Start Temperature for the γ → ε TransformationGanesh PMNo ratings yet

- Nickel Titanium Alloys / Orthodontic Courses by Indian Dental AcademyDocument182 pagesNickel Titanium Alloys / Orthodontic Courses by Indian Dental Academyindian dental academyNo ratings yet

- 06 Strengthening MechanismsDocument63 pages06 Strengthening Mechanismspranavkumarparit100% (2)

- Heat Treatment Effects on Low Carbon SteelDocument9 pagesHeat Treatment Effects on Low Carbon SteelAhmad Farhan F1120No ratings yet

- Sutures Types GoodDocument76 pagesSutures Types Goodkirank_11100% (1)

- MAM College of Engineering: Two Mark Questions and AnswersDocument31 pagesMAM College of Engineering: Two Mark Questions and Answersashok pradhanNo ratings yet

- 1.6580 Heat Treatment (Q and T)Document12 pages1.6580 Heat Treatment (Q and T)Ali AlyaniNo ratings yet

- Welding Martensitic Stainless SteelsDocument4 pagesWelding Martensitic Stainless SteelsBabar Manzoor GhauriNo ratings yet

- Iron Carbon Diagram Form The Basis of Heat TreatmentsDocument41 pagesIron Carbon Diagram Form The Basis of Heat TreatmentsMuhammad TalhaNo ratings yet

- Wang 2019Document13 pagesWang 2019Cesar CortesNo ratings yet

- William F Hosford-Iron and Steel-Cambridge University Press (2012) PDFDocument310 pagesWilliam F Hosford-Iron and Steel-Cambridge University Press (2012) PDFJulian Sihombing50% (2)

- The Measurement and Interpretation of Transformation Temperatures in NitinolDocument14 pagesThe Measurement and Interpretation of Transformation Temperatures in NitinolNihar VsNo ratings yet

- (Engineering Materials) High Nitrogen Steels - Structure, Properties, Manufacture, ApplicationsDocument385 pages(Engineering Materials) High Nitrogen Steels - Structure, Properties, Manufacture, ApplicationsJasmin Halilovic100% (3)

- Austenite Reversion in Cold Formed 18 Wt-%Ni 350 Grade Maraging SteelDocument5 pagesAustenite Reversion in Cold Formed 18 Wt-%Ni 350 Grade Maraging SteelSimone Izabel VieiraNo ratings yet

- Heat Treatment ProcessesDocument44 pagesHeat Treatment Processesmesa142No ratings yet

- Advanced Shape Memory Alloy Material Models For ANSYSDocument12 pagesAdvanced Shape Memory Alloy Material Models For ANSYSSlava SlesarenkoNo ratings yet

- Stainless SteelDocument201 pagesStainless SteelKishore KumarNo ratings yet

- HEAT TREATMENT OF TOOL STEELDocument20 pagesHEAT TREATMENT OF TOOL STEELعزت عبد المنعمNo ratings yet

- WJ 1995 05 s153 PDFDocument7 pagesWJ 1995 05 s153 PDFVijayakumar SamyNo ratings yet

- Comparative Analysis of Hardenability of Steel Using Jominy End Quench TestDocument3 pagesComparative Analysis of Hardenability of Steel Using Jominy End Quench TestInternational Journal of Innovations in Engineering and ScienceNo ratings yet

- Finite Element Modeling of Hot Stamping: Metal FormingDocument7 pagesFinite Element Modeling of Hot Stamping: Metal FormingsharenterNo ratings yet

- Additive Manufacturing of Titanium ThesisDocument98 pagesAdditive Manufacturing of Titanium ThesisHassan HabibNo ratings yet

- AgronomyResearch Vol 13 Number 3Document235 pagesAgronomyResearch Vol 13 Number 3Tetti ManikNo ratings yet

- Conditions Leading To Quench Cracking Other Than Severity of QuenchDocument11 pagesConditions Leading To Quench Cracking Other Than Severity of QuenchalsgoodNo ratings yet

- Avesta Welding Manual - 2008Document312 pagesAvesta Welding Manual - 2008jswldeep100% (1)