Professional Documents

Culture Documents

EN-DG-746-145-4001 Rev01

Uploaded by

apsCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EN-DG-746-145-4001 Rev01

Uploaded by

apsCopyright:

Available Formats

HMI SYSTEM DESCRIPTION

SD / 404 / 1033

REV NO. 01

PAGE 1 OF 27

PROJECT NAME

3 X 660 MW PRAYAGRAJ STPP, BARA, UP

PRODUCT

MAXDNA BASED HMI SYSTEM

CUSTOMER

PPGCL

CONSULTANT

TCE, BANGALORE

BHEL DRG. NO.

EN DG 746 145 4001

WBS NO.

CE / 0746 SH1 56 01

CE / 0746 SH2 56 01

CE / 0746 SH3 56 01

Prepared by :

Arjun Sundar Raj

Checked by

Reetesh Kumar A

Approved by :

A. K. Sinha

Issued by

CE-ENGG / HMI

Date

14/10/2014

Copyright and Confidential:

The information on this document is the property of BHEL. It must not be used directly or indirectly in anyway detrimental to the

interest of the company.

HMI SYSTEM DESCRIPTION

SD / 404 / 1033

REV NO. 01

PAGE 2 OF 27

INDEX

INTRODUCTION......................................................................................... 4

SYSTEM CHARACTERISTICS .5

SYSTEM .. 6

HMI HARDWARE.. 6

HMI SOFTWARE 8

STANDARD APPLICATION SOFTWARE... 9

SYSTEM SCOPE.. 23

PROJECT ENGINEERING... 26

Copyright and Confidential:

The information on this document is the property of BHEL. It must not be used directly or indirectly in anyway detrimental to the

interest of the company.

HMI SYSTEM DESCRIPTION

SD / 404 / 1033

REV NO. 01

PAGE 3 OF 27

HUMAN MACHINE INTERFACE

IN

maxDNA

DISTRIBUTED DIGITAL CONTROL

MONITORING AND INFORMATION SYSTEM

Copyright and Confidential:

The information on this document is the property of BHEL. It must not be used directly or indirectly in anyway detrimental to the

interest of the company.

HMI SYSTEM DESCRIPTION

SD / 404 / 1033

REV NO. 01

PAGE 4 OF 27

1. INTRODUCTION

The maxDNA Distributed Control System is the latest computer control system to realize

complete power plant automation.

The full maxDNA Distributed Control System consists of one or more maxDNA Remote

Processing Units (RPUs) cabinets containing the following:

maxDPU4F Distributed Processing Units (DPUs), the process controller which provides

control and data acquisition functions.

Input/Output devices (I/Os) for monitoring and controlling the actual process.

One or more maxSTATIONs configured as operator or engineer workstations.

maxNET, a local area network which connects DPUs and maxSTATIONs

Human machine Interface is a system of computers (maxSTATIONs) with associated special

and general hardware components, running real time software. This system of computers is

integrated with the downstream control system, Remote Processing Units (RPUs). Remote

Processing Units are housing Distributed Processing Units (DPU), to maxSTATIONs are

connected through Ethernet switch in a redundant network called maxNET.

An operator may view and manage process control environment through a maxSTATION,

the interface between operator and the maxDNA Distributed Control System. A

maxSTATION may be set up as an Operator's Workstation or an Engineer's Workstation.

HMI runs a set of applications powered by Windows XP Operating system, to realize plant

monitoring and control functions.

The Operators Workstation uses maxVUE graphical interface software to provide a

graphical view of the process. The software uses both standard and custom displays.

The Engineers Workstation is used for creating and maintaining configurations and process

control documentation using the maxDPUTOOLS and maxVUE Graphical Configurator

software. It is also used to create and maintain custom graphic displays using the maxVUE

graphics editor software.

Copyright and Confidential:

The information on this document is the property of BHEL. It must not be used directly or indirectly in anyway detrimental to the

interest of the company.

HMI SYSTEM DESCRIPTION

SD / 404 / 1033

REV NO. 01

PAGE 5 OF 27

HMI provides the following functions:

Engineering of the project

Supervision of Plant Processes

Processing of Plant Information

Presentation of Plant Information

Analysis of Plant Events

Operator Dialogue

Monitor based control of the plant (Video process Control)

Long time storage of data for analysis of plant performance

These functions are realized through a variety of displays and reports, which work around

the Process Database and Historical Data. The operator friendliness and the ergonomic color

displays are important features of this system. The operator is guided through a hierarchical

menu of display set, to select a required function or a required picture.

2. SYSTEM CHARACTERISTICS

The main characteristics of this system are:

High speed modern computer systems are at the heart of the system.

Standard computer systems are used to control plants of varying sizes and

complexity.

Windows XP as Operating system.

A set of structured software products, combination of which meets customer

requirements.

Most of the software components are user configurable to provide a customer

specific environment to work with where he is most comfortable.

Windows for operation of plant, display of status and trends.

Mouse for operation of plant.

Network wide printing.

Copyright and Confidential:

The information on this document is the property of BHEL. It must not be used directly or indirectly in anyway detrimental to the

interest of the company.

HMI SYSTEM DESCRIPTION

SD / 404 / 1033

REV NO. 01

PAGE 6 OF 27

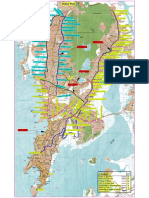

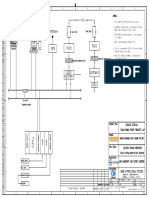

3. SYSTEM ARCHITECTURE

The HMI system for 3 X 660 MW PRAYAGRAJ STPP, BARA, UP project is configured as

shown in overall configuration drawing of SG/TG/BOP & HMI, EN DG 746 145 5001.

It consists of five Operator Stations (maxSTATION), one TG OWS, 1 electrical draw out

console, 1 no. C&I Draw out console, Six No. LVS Screen, two Engineering Station

(maxSTATION), 1 Shift I/C PC, 1 Performance Calculation PC, 2 MIS PC, Two Storian Stations

(maxSTATION), and One Link Station. These maxSTATIONs are connected in an ethernet

based local area network. A set of switches is used to realize redundant communication

network, called maxNET, for communication between maxSTATIONs and DPUs.

Thus we have a distributed configuration of computer system to cater to the modular

growth, logical distribution of tasks, increased reliability and more choice in configuring the

individual Operator Work Stations. These computer systems perform tasks associated with

facilitating the Operator's dialogue with the Control system like picture call up, issue of

control commands, etc.

4. HMI HARDWARE

The hardware components can be classified into following functional groups:

maxSTATION

These are Operator Stations, Engineer Stations, Storian Stations and Link Stations. This

consists of a PC with Windows XP operating system. These maxSTATIONs are connected

among themselves and also to DPUs via maxNET.

OPERATOR WORK STATION

The Operator Work Station performs all tasks associated with the operator's dialogue with

the Control System. All the software components for the acquisition of data from

controllers, generation of reports, application programs and historical trending are

performed here. Display of control graphics, trends, alarms, historical data, diagnostics, and

reports is done from the Operator workstation.

ENGINEER WORK STATION

Any workstation in the system can be designated as Engineers Workstation. An Engineers

Work Station is used to create, download and edit the control configuration, database and

process graphics.

Copyright and Confidential:

The information on this document is the property of BHEL. It must not be used directly or indirectly in anyway detrimental to the

interest of the company.

HMI SYSTEM DESCRIPTION

SD / 404 / 1033

REV NO. 01

PAGE 7 OF 27

Graphics are created and run under a program called maxVUE. maxVUE uses ActiveX

Components for animation.

Control Scheme Generation and database creation is carried out by a configuration software

package called maxDPUTOOLS. It utilizes drag and drop organization, standard graphical

symbols and automatic generation of code.

DATA STORAGE STATION

This station runs a software package called maxSTORIAN. This will collect data for

maintaining history and archiving. Archiving to CDROM is available.

maxLINK STATION

maxLINK runs a software package called maxLINK. This software is used to establish

connectivity with third party systems like PLC over serial link using MODBUS Protocol.

Printers

These are information output devices, used for taking hard copies of data, reports, and

pictures.

maxNET

The maxNET communication system is based on an industry standard open network

architecture providing a 100 Mbps redundant data communications to each drop on the

highway. All the remote processing units and maxSTATIONs connect directly to the

communication network (maxNET).

The maxNET utilizes commercially available standard components, like cables, Ethernet

switches and network interface cards (NICs).

Between the Ethernet switches, the backbone of maxNET communication is 100Mbps, Full

Duplex Fast Ethernet. The bandwidth provided by maxNET exceeds that needed for plant

operation even under the worst case scenario with alarm bursts in few thousands.

Copyright and Confidential:

The information on this document is the property of BHEL. It must not be used directly or indirectly in anyway detrimental to the

interest of the company.

HMI SYSTEM DESCRIPTION

SD / 404 / 1033

REV NO. 01

PAGE 8 OF 27

5. HMI SOFTWARE

A number of software components are executed in the computer system for realizing the

various functions of this subsystem.

Some of the important software applications available in HMI System are as follows:

maxVUE Editor

The maxVUE editor is used by engineers to create and maintain custom graphic displays.

These displays are used by the operator to view and control applications. This software

application can be executed only on the Engineers Workstation.

maxVUE Runtime

maxVUE runtime uses the displays created with maxVUE editor. It can be executed in both

the Operators and the Engineers Workstations.

maxVUE is powerful, intuitive, and visually appealing operator interface to the process.

Dynamic data may be displayed with text, colors, shapes or images. System provides for

multiple security levels, allowing flexible control of operator actions. Online context

sensitive help and tool-tips to help operator and engineers are available.

Using maxVUE operator perform following functions

Monitor plant process status

Initiate control actions

Respond to alarm and initiate corrective actions

Monitor system status

Start, Stop and switch to other windows applications.

maxDPUTOOLS

maxDPUTOOLS provides the system engineer with a comprehensive set of advanced

engineering and configuration tools. It allows offline simulation and verification. Selfdocumentation, on line monitoring, and help are inbuilt features in maxDPUTOOLS.

This configuration software package utilizes drag and drop organization, standard graphical

symbols and automatic generation of code.

Point data is stored in MS Access compatible database format. The user may add, delete,

edit, define I/O and their location with regard to DPU, card rack, data highway, plant area

etc. The Database point builder provides for automatic documentation and generation of

code. It also has an extensive library of standard algorithms or objects.

Copyright and Confidential:

The information on this document is the property of BHEL. It must not be used directly or indirectly in anyway detrimental to the

interest of the company.

HMI SYSTEM DESCRIPTION

SD / 404 / 1033

REV NO. 01

PAGE 9 OF 27

maxDPUTOOLS can run in Engineers workstation (EWS). It can also be run off line in other

PC and then can be transferred to the EWS.

Software Backplane

The software backplane is the maxDNA distributed communications infrastructure software.

This API, residing on each maxSTATION, is responsible for transferring client data requests

to the provider, which, in turn, provides the data to the client.

The software backplane includes the Real-Time Gateway, the interface to the DPU Module

used to send and receive data from the DPUs in the RPU.

The software backplane also includes the local status server, an application which keeps and

provides information about relevant processes (including reporting any identified alarm

conditions) using the software backplane.

maxSTORIAN

maxSTORIAN supports a historical storage and retrieval system located within Windows XP

workstation. Access to maxSTORIAN is through any of the operator console.

Selected data from the real-time database is periodically stored at a fixed rate in the process

history buffer.

6. STANDARD APPLICATION SOFTWARE

Integrated application in Max Control system is designed to perform the following:

Display functions

Monitoring and Alarming of inputs

Reports and Logs

Historical storage and archiving of selected points

Plant performance calculation

Historical trending

Sequence of Event recording

DISPLAY FUNCTIONS

This function is concerned with concerned with the display and output of

information on the Color Monitors used by the operator.

Copyright and Confidential:

The information on this document is the property of BHEL. It must not be used directly or indirectly in anyway detrimental to the

interest of the company.

HMI SYSTEM DESCRIPTION

SD / 404 / 1033

REV NO. 01

PAGE 10 OF 27

Displays are of various types like:

Main Menu

This display provides access to other standard and user created displays.

The Main Menu that comes with the maxVUE Runtime package is really a starting

point for creating custom main menu.

The main menu consists of horizontal and vertical toolbars containing buttons that

open standard displays, such as the System Status display and the Alarm Summary

display. The vertical toolbar also includes an alarm list area. The horizontal toolbar

provides an area for user-defined buttons.

Point data pop-up

This is standard faceplate for each point in the configuration, which allows the

operator to take control actions (mode changes, output and set point changes)

Point Detail pop-up

Copyright and Confidential:

The information on this document is the property of BHEL. It must not be used directly or indirectly in anyway detrimental to the

interest of the company.

HMI SYSTEM DESCRIPTION

SD / 404 / 1033

REV NO. 01

PAGE 11 OF 27

The point detail pop-up shows the point configuration data for each point type in the

system.

Alarm Summary

The Alarm Summary lists all active alarms and allows you to filter alarms based on

hierarchical group or point.

System Status Display

The System Status displays show the current condition of networks and the

hardware connected to them.

Copyright and Confidential:

The information on this document is the property of BHEL. It must not be used directly or indirectly in anyway detrimental to the

interest of the company.

HMI SYSTEM DESCRIPTION

SD / 404 / 1033

REV NO. 01

PAGE 12 OF 27

Network status Displays

Network status displays show the current status of both maxNET networks.

Copyright and Confidential:

The information on this document is the property of BHEL. It must not be used directly or indirectly in anyway detrimental to the

interest of the company.

HMI SYSTEM DESCRIPTION

SD / 404 / 1033

REV NO. 01

PAGE 13 OF 27

Horizontal & Vertical Toolbars

Horizontal and Vertical toolbars provide the alarm list, alarm defeat and restore,

display navigation to standard display, buttons to callup custom displays.

Copyright and Confidential:

The information on this document is the property of BHEL. It must not be used directly or indirectly in anyway detrimental to the

interest of the company.

HMI SYSTEM DESCRIPTION

SD / 404 / 1033

REV NO. 01

PAGE 14 OF 27

Main Live display features

Dynamic graphic objects color fills, conditional color change indicators

Bitmap import for static backgrounds and under dynamic program controls

Trend display with on line color change, cursor readout of point data.

User data entry fields and dialog box prompts.

Start, stop and switch to other windows.

MONITORING AND ALARMING OF INPUTS

INPUT PROCESSING

All inputs in maxDNA system have a unique 16 alphanumeric tag. Each tag has an associated

32 character descriptions.

Inputs for data acquisition are normally processed as Data Points, which are configured in

DPU. Each DPU processes Analog and Digital Inputs.

Each point in the database is classified and configured as a data point. Each input to be

monitored is assigned by configuration to a Data Point. The type is configured depending

upon the operation to be performed and the type of input.

Data points have the following configurable alarm settings

Low and High alarms

Significant change

Alarm based on reaching a value once or on repetitive basis

Return to normal alarm

Individual alarm cutout

Following Hardware Alarms are provided.

Open thermocouple

Instrument High

Instrument Low

Link fail

The status of raw input is provided for each of the above type of inputs. When any of these

alarms arise the data point value is no longer updated because these alarm indicate that no

better value are available.

Copyright and Confidential:

The information on this document is the property of BHEL. It must not be used directly or indirectly in anyway detrimental to the

interest of the company.

HMI SYSTEM DESCRIPTION

SD / 404 / 1033

REV NO. 01

PAGE 15 OF 27

Quality

Every calculated variable and data point can have one of four quality coding descriptions:

Good, Bad, Doubtful and substitute. The code can be displayed on any operator station

graphic screen. These quality codes denote are explained below:

Bad The data source has an instrument alarm (link fail, open thermocouple,

instrument high, instrument low or a calculation is using bad value.

Substitute Operator entered value in manual mode or a calculation is using a

substituted value.

Doubtful Transformations using a bad value over part or full time period, data

point is in manual mode and its value is not being updated, or a calculation is using

doubtful value

Good None of the above

Data Reduction

Data points can perform comparisons, arithmetic calculations and similar data reduction

functions. All data point types perform comparisons, generally for alarm limits. They also

perform calculations, transforms and Boolean functions

Display Format

Data point displays contain value and an engineering unit with units of measure and a single

yellow bar representing percent of span. This bar is not necessarily zero based, but indicates

0% when the engineering unit value equals the RANGE LOW value and 100% when the

engineering unit value equals the RANGE HIGH value. Digital data points (contact closures)

are represented by a message or message pairs such as ON/OFF. Data points can appear in

any graphic in the system. Data points have a 12-character tag, a 12 character short title and

a 32 character long title.

Alarm Display

Alarms and events are received over the data highway from the DPUs where they are time

stamped. These include process alarms, operator actions and digital events. Upto 5000

alarms/events are maintained in the history buffer.

An Alarm summary display is provided which lists the latest 18 alarms. Paging backward will

reveal more alarms with the maximum number being 5000 active alarms. The latest five

alarms in an abbreviated form appear on the bottom right hand side of every graphic.

Copyright and Confidential:

The information on this document is the property of BHEL. It must not be used directly or indirectly in anyway detrimental to the

interest of the company.

HMI SYSTEM DESCRIPTION

SD / 404 / 1033

REV NO. 01

PAGE 16 OF 27

The Alarms are displayed in chronological order. The newest alarm is on the top and the

oldest alarm is at the bottom of the alarm summary display. The background flashes for

unacknowledged alarms. Alarms are displayed in order of priority with the time indicated in

a different color designating the priority. There are 5 levels of priority.

Returns to normal alarms are also indicated. They are removed from the screen when

acknowledged by the operator. Alarms can also be printed.

REPORTS AND LOGS

Reports can be triggered by process events, manually by operator or can be scheduled for

example at the end of shift, day or month.

Process history can be represented in two ways, as summaries or as trends, the periods may

vary. Summary reports list data over an extended period. Typical standard periods include

an hour, a shift, a day, a week or a month. Trend reports list more detailed information

collected at relatively high resolution, such as one second interval during a 24 hour period.

Standard History Report package is provided as a part of HMI Software to create

professional looking printed reports containing historic trending data. Historic Trending data

consists of point attribute values, specified in the project.

Copyright and Confidential:

The information on this document is the property of BHEL. It must not be used directly or indirectly in anyway detrimental to the

interest of the company.

HMI SYSTEM DESCRIPTION

SD / 404 / 1033

REV NO. 01

PAGE 17 OF 27

HMI in the maxDNA System can collect, store, and display trend history of any selected

attribute for analog or discrete points.

Data may be viewed in real time via maxVUE displays, can be archived in a maxSTATION, or

be printed in preformatted reports using the History Reports software.

The report software allows Configuration and scheduling of reports using any one of four

preformatted report types:

Trend

Summary

Trip

Shift

This software also allows definition of point groups, independent entities, containing point,

attribute statistics and algebraic expressions etc.

Copyright and Confidential:

The information on this document is the property of BHEL. It must not be used directly or indirectly in anyway detrimental to the

interest of the company.

HMI SYSTEM DESCRIPTION

SD / 404 / 1033

REV NO. 01

PAGE 18 OF 27

The History Reports package consists of two major components, the Reports Editor and the

Reports Server. The Reports Editor component is used to configure the report in offline

mode. This component usually resides in a maxSTATION set up as an Engineer's workstation.

The Reports Server generates reports already configured in the Reports Editor.

The History Reports Package allows the various controls such as

Print reports on demand,

Preview reports before printing

Export, print, archive, or delete generated reports.

TREND REPORT

Of all the report types a trend report is the most basic, presenting trending data for

specified coverage periods. You may specify standard report coverage periods of an hour, a

shift, a day, a week, a month, or a year in addition to custom intervals.

SUMMARY REPORT

A Summary Report is similar to a trend report, but features summary rows to provide an

aggregate statistic at the end of each point column. The supported summary operations are

Average, Minimum, Maximum, Total, and No summary.

Copyright and Confidential:

The information on this document is the property of BHEL. It must not be used directly or indirectly in anyway detrimental to the

interest of the company.

HMI SYSTEM DESCRIPTION

SD / 404 / 1033

REV NO. 01

PAGE 19 OF 27

TRIP REPORT

A trip report is generated in response to a specific event or combination of two events. An

event occurs when a state change is detected. A specified digital value may change from off

to on or false to true and vice-versa. In an actual situation, a device that was on may go to

an off state, triggering an event. This in turn, triggers a report.

When you specify scheduling based on two events, the second event (also based on a

specified digital value), must occur within a stated time period after the first event for a

report to be triggered. If the second event does not occur within the specified time, the first

event is ignored and no report is triggered.

The resulting report typically records the event, the name of the digital point triggering the

event and the state change, from on too off or off to on. The report shows similar

information for the second event, if the report is based on two-event scheduling.

The report shows events and sampling data before the event occurred and after. If the

report uses two events, it also shows samples for the period between the occurrences of

the two events.

You may specify a sampling period and sampling rate (row intervals) for a period before the

occurrence of the event and after.

Copyright and Confidential:

The information on this document is the property of BHEL. It must not be used directly or indirectly in anyway detrimental to the

interest of the company.

HMI SYSTEM DESCRIPTION

SD / 404 / 1033

REV NO. 01

PAGE 20 OF 27

Copyright and Confidential:

The information on this document is the property of BHEL. It must not be used directly or indirectly in anyway detrimental to the

interest of the company.

HMI SYSTEM DESCRIPTION

SD / 404 / 1033

REV NO. 01

PAGE 21 OF 27

SHIFT REPORT

A shift report groups data by daily shift coverage periods, such as four hours, eight hours,

etc. The report may list data for one to four shifts within a 24-hour period. The report will

include hourly time intervals with a shift summary row and an aggregate statistic for

multiple shifts.

Copyright and Confidential:

The information on this document is the property of BHEL. It must not be used directly or indirectly in anyway detrimental to the

interest of the company.

HMI SYSTEM DESCRIPTION

SD / 404 / 1033

REV NO. 01

PAGE 22 OF 27

Similar to a summary report, when you configure a shift report you may select from the

following supported summary operations: Average, Minimum, Maximum, Total, and No

summary.

Historical storage and archiving

The maxDNA system maintains and supports a historical storage and retrieval system

located in a maxSTATION, referred to as maxSTORIAN. Any maxSTORIAN instance can be

executed on a single, standalone maxSTATION.

The maxSTORIAN runs the long-term history system software and makes use of the disk

space in the maxSTATION.

Selected data from real time database is periodically stored at a fixed rate in the process

history buffer. It uses historic trending package is designed to collect and store trend data

for extended historic periods. The maxSTORIAN collects data using a delta-save style storage

and compression algorithm.

Using this approach, much more data may be retained and accessible online since not all

values are saved. Instead a delta from the last time the value changed is saved.

Copyright and Confidential:

The information on this document is the property of BHEL. It must not be used directly or indirectly in anyway detrimental to the

interest of the company.

HMI SYSTEM DESCRIPTION

SD / 404 / 1033

REV NO. 01

PAGE 23 OF 27

On the History Storage display configuration, a sampling rate is configured in seconds, a

statistical rate in minutes or hours.

Permissible sampling rates for historical trending are:

1, 5, 30 seconds

Statistical data for storage is selectable for each analog point over the period selected.

Statistical points are collected at any one of the following rates:

1, 10 minutes, 1 hour

The data management software package enables the operators to use natural queries to

extract information. It is possible to sort data by time, date, points, area, functions, events

etc. The information is displayed in tabular format on the screen and can be printed as a log

on demand

HISTORICAL TRENDING

maxSTORIAN Trend allows the user to present historical data as a graphical trend on a CRT.

The package supports real time trending and historical trending. Users can change trending

tags, time spans of trends and resolution of trended data on-line. The flexibility of the

maxSTORIAN makes it a powerful process analysis tool in addition to being an easy-to-use

trending package. maxSTORIAN Trend is integrated together with maxDNA operators users

interface, maxVUE.

Up to eight values trended per monitor screen

Shading between points and to a fixed position in time

Add or change points or change ranges on-line

Users can create customized scales and trend borders

SEQUENCE OF EVENT RECORDING

Point configured for SOE will be recorded in two of the OWS (1&2) where Event

Recording server software is running. Point recording resolution will be 1 ms.

7. SYSTEM SCOPE

Scope of Supply

This section gives an overview of the equipments proposed for the Human Machine

Interface. These equipments are ideally configured to meet the plant requirements.

Copyright and Confidential:

The information on this document is the property of BHEL. It must not be used directly or indirectly in anyway detrimental to the

interest of the company.

HMI SYSTEM DESCRIPTION

SD / 404 / 1033

REV NO. 01

PAGE 24 OF 27

The scope of supply of the HMI system hardware for the plant can be sub - divided into

following parts:

PC Compatible computer system.

Computer peripherals.

Network Components.

Included in the scope of supply is the internal power distribution between computer and the

peripherals as well as the cables for all data connections between the central computer and

the peripherals.

Copyright and Confidential:

The information on this document is the property of BHEL. It must not be used directly or indirectly in anyway detrimental to the

interest of the company.

HMI SYSTEM DESCRIPTION

SD / 404 / 1033

REV NO. 01

PAGE 25 OF 27

HARDWARE COMPONENTS

1. maxSTATION comprising of the following:

Intel Core 2 Duo Processor running at 2.0 GHZ Frequency with 2 GB RAM. Operating

system used here is Windows XP

maxSTATION PC consists of the following main components:

Intel Xeon Processor, min 3 GHz

4 GB RAM

Hard disk drive, 320 GB

DVD ROM drive

Graphics I/F

Ethernet I/F (2 nos.)

ASCII keyboard

Optical Mouse

Serial port

USB Port

24 TFT Monitor

Windows XP Operating System (Licensed)

Additionally, engineer stations and maxSTORIAN stations will have a DVD WRITER.

2. Printers:

These are standard Dot Matrix printers for printing SOE and standard LaserJet

printers for printing alarms & logs.

3. Network components:

Ethernet switches and associated interfaces in PC and Remote Processing units and

interconnecting cables constitute network components.

Copyright and Confidential:

The information on this document is the property of BHEL. It must not be used directly or indirectly in anyway detrimental to the

interest of the company.

HMI SYSTEM DESCRIPTION

SD / 404 / 1033

REV NO. 01

PAGE 26 OF 27

SOFTWARE COMPONENTS

SYSTEM SOFTWARE

System Software is an integrated package consisting of maxVUE, maxDPUTOOLS and

maxSTORIAN.

APPLICATION SOFTWARE

These are programs designed to execute along with the system software. These include

Process Database Configuration files, Plant Schematics and assignment of reports etc.

8. PROJECT ENGINEERING

Project Engineering consists of the following:

1. Creation of Database files.

Using maxDPUTOOLS, one configuration database file for each DPU is created and

function blocks are defined within the configuration representing an individual DPUs

associated I/O hardware, along with control and data acquisition processing. These

configuration files are downloaded to respective DPUs.

maxDPUTOOLS is a software utility that allows the engineer to create a configuration

database in offline mode. To configure points in an online environment, the maxVUE

Graphical Configurator, a separate software product available with the maxVUE

Editor software is to be used.

2. Creations of graphical Configurations

Using the Graphical Configuration tool, available through the maxVUE Editor, a point

database is represented graphically in the form of logic diagrams. Graphical

Configurator is used to create graphical representations of point databases, make

online edits to a configuration and document and print graphical representations of

configurations.

Logic diagrams appearing on sheets consist of a collection of boxes representing

atomic blocks [basic building blocks for example and, or, add etc] or elements of a

Custom Block [ex PID etc].

3. Creation of Graphics displays

Using maxVUE, the graphics displays are built which are used to view and control the

process. The maxVUE is used to create high-resolution, multi-colored process

graphics and trend presentations to control continuous or batch processes.

Copyright and Confidential:

The information on this document is the property of BHEL. It must not be used directly or indirectly in anyway detrimental to the

interest of the company.

HMI SYSTEM DESCRIPTION

SD / 404 / 1033

REV NO. 01

PAGE 27 OF 27

The graphics displays are connected to the remote hardware devices. These graphics

displays model a given process and designate what is to be monitored or controlled.

Key processes in the plant such as generators, turbines, distributions etc are

represented in a number of displays.

The Editor is used interactively to create displays. Typical displays may represent

conditions or values, such as valve states and dam levels. Such displays may use

numerical data, and incorporate bar charts, trend graphs, and other MAXVUE

elements.

4. Configuring maxSTORIAN

The Configuration Editor available with maxSTORIAN is used to configure the points

to be collected by the maxSTORIAN instance

The Reports Package are used to retrieve data from the system over scheduled

intervals and to place this information on either a predefined formatted report or a

custom formatted report. Once created, the data used to create a report is saved in

a format allowing data to be extracted for use by Microsoft Access or custom

programs.

Reports Package is also used to archive the data saved for any generated report.

Copyright and Confidential:

The information on this document is the property of BHEL. It must not be used directly or indirectly in anyway detrimental to the

interest of the company.

You might also like

- DC Power Systems GuideDocument12 pagesDC Power Systems GuideapsNo ratings yet

- SREX POWER INDIA CONTROL CABLE SCHEDULEDocument161 pagesSREX POWER INDIA CONTROL CABLE SCHEDULEaaditya singhNo ratings yet

- 6a Revised 25.03.2015Document2 pages6a Revised 25.03.2015aaditya singhNo ratings yet

- RECOMMENDED SETTINGS FOR 765kV 3*63 MVAR BUS REACTOR PROTECTIONDocument9 pagesRECOMMENDED SETTINGS FOR 765kV 3*63 MVAR BUS REACTOR PROTECTIONapsNo ratings yet

- Commissioning Test Report For Differential Relay: 7SR242 Page 1/5Document5 pagesCommissioning Test Report For Differential Relay: 7SR242 Page 1/5apsNo ratings yet

- Drawing Moose Zebra Panther PDFDocument27 pagesDrawing Moose Zebra Panther PDFapsNo ratings yet

- Item Rate Boq: Validate Print HelpDocument24 pagesItem Rate Boq: Validate Print HelpapsNo ratings yet

- Index Plan PDFDocument1 pageIndex Plan PDFapsNo ratings yet

- Contract:-Medd-01R: Appendix ADocument33 pagesContract:-Medd-01R: Appendix AapsNo ratings yet

- Volume-I BDSDocument4 pagesVolume-I BDSaaditya singhNo ratings yet

- NJHDocument6 pagesNJHapsNo ratings yet

- Item Rate Boq: Validate Print HelpDocument24 pagesItem Rate Boq: Validate Print HelpapsNo ratings yet

- Battery Charging PDFDocument7 pagesBattery Charging PDFapsNo ratings yet

- OBWPL PSS E X 304 D013 Scada System Artitechture Rev. 00 ModelDocument1 pageOBWPL PSS E X 304 D013 Scada System Artitechture Rev. 00 ModelapsNo ratings yet

- Type of TenderDocument1 pageType of TenderapsNo ratings yet

- City Gas Distribution Project FOR Bengaluru: Under International Competitive BiddingDocument55 pagesCity Gas Distribution Project FOR Bengaluru: Under International Competitive BiddingapsNo ratings yet

- City Gas Distribution Project FOR Bengaluru: Under International Competitive BiddingDocument55 pagesCity Gas Distribution Project FOR Bengaluru: Under International Competitive BiddingapsNo ratings yet

- Contract:-Medd-01R: Appendix ADocument33 pagesContract:-Medd-01R: Appendix AapsNo ratings yet

- NKNDocument35 pagesNKNapsNo ratings yet

- NJBDocument5 pagesNJBapsNo ratings yet

- GVFDocument24 pagesGVFapsNo ratings yet

- Product KeyDocument1 pageProduct KeyapsNo ratings yet

- Srex Power India Pvt. LTD.: Pre-Commissioning Report of Ac Distribution BoxDocument8 pagesSrex Power India Pvt. LTD.: Pre-Commissioning Report of Ac Distribution BoxapsNo ratings yet

- Srex Power India Pvt. LTD.: Pre-Commissioning Report of Potential TransformerDocument12 pagesSrex Power India Pvt. LTD.: Pre-Commissioning Report of Potential TransformerapsNo ratings yet

- JNBDocument18 pagesJNBapsNo ratings yet

- May2017/zip/22853383 TD 034517124516scada - Price Schedule - Foreign BiddersDocument12 pagesMay2017/zip/22853383 TD 034517124516scada - Price Schedule - Foreign BiddersapsNo ratings yet

- Srex Power India Pvt. LTD.: Pre-Commissioning Report of IsolatorDocument18 pagesSrex Power India Pvt. LTD.: Pre-Commissioning Report of IsolatorapsNo ratings yet

- Srex Power India Pvt. LTD.: Pre-Commissioning Report of Potential TransformerDocument12 pagesSrex Power India Pvt. LTD.: Pre-Commissioning Report of Potential TransformerapsNo ratings yet

- 5-2017 Tender SetDocument27 pages5-2017 Tender Setaaditya singhNo ratings yet

- City Gas Distribution Project FOR Bengaluru: Under International Competitive BiddingDocument55 pagesCity Gas Distribution Project FOR Bengaluru: Under International Competitive BiddingapsNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Manuel Oracle C#Document154 pagesManuel Oracle C#Luis Claudinei de MoraesNo ratings yet

- Dokumen - Tips - Af SDK 29 Getting Started Guide Pi Datalink Pi Datalink Server Pi DeveloperasDocument54 pagesDokumen - Tips - Af SDK 29 Getting Started Guide Pi Datalink Pi Datalink Server Pi DeveloperasDnyDnyNo ratings yet

- OBIEE Linux Start UpDocument2 pagesOBIEE Linux Start Upvamsi.prasadNo ratings yet

- TTERRDocument498 pagesTTERRerrr33No ratings yet

- OrangeApps - UserLogonIO KRC2 KRC4.User - en V1.0Document28 pagesOrangeApps - UserLogonIO KRC2 KRC4.User - en V1.0Berkay DoganNo ratings yet

- SAA-C03 Dumps with 100% Valid AWS Certified Solutions Architect - Associate (SAA-C03) QuestionsDocument24 pagesSAA-C03 Dumps with 100% Valid AWS Certified Solutions Architect - Associate (SAA-C03) QuestionsThasleem NazeerNo ratings yet

- SPDB - Azure Stack Hci Poc Sow v1.0 (20210416 - Clear)Document16 pagesSPDB - Azure Stack Hci Poc Sow v1.0 (20210416 - Clear)abidouNo ratings yet

- Everything About Purchase Requisition - 1Document13 pagesEverything About Purchase Requisition - 1Raghu SharmaNo ratings yet

- AMX 4-ARM Tool Guide: First Printing: August 1, 1997 Last Printing: November 1, 2007Document62 pagesAMX 4-ARM Tool Guide: First Printing: August 1, 1997 Last Printing: November 1, 2007Faheem SaleemiNo ratings yet

- Installation GuideDocument3 pagesInstallation GuideTara PillayNo ratings yet

- LogDocument548 pagesLogRegine CalipayNo ratings yet

- Control & Monitoring Systems: Admin To Log inDocument2 pagesControl & Monitoring Systems: Admin To Log inSher Bahadur VermaNo ratings yet

- QA Analyst Resume TitleDocument7 pagesQA Analyst Resume TitleMadhav GarikapatiNo ratings yet

- Django Web Development With Python 1787121380 SAMPLEDocument19 pagesDjango Web Development With Python 1787121380 SAMPLEkkisNo ratings yet

- EDU170 Soultions 10Document4 pagesEDU170 Soultions 10Samantha BallesterosNo ratings yet

- C MCQDocument12 pagesC MCQmrunalshinde422No ratings yet

- bin/rm: Argument List Too Long (Find's Delete Flag!)Document3 pagesbin/rm: Argument List Too Long (Find's Delete Flag!)stevetherrienBNo ratings yet

- Gate Pass Management System Using Android (App) : Prerana Khandekar, Vaishnavi Patil, Vikas SolankeDocument6 pagesGate Pass Management System Using Android (App) : Prerana Khandekar, Vaishnavi Patil, Vikas SolankeWowskinNo ratings yet

- Import - SAP2000 MS Excel Spreadsheet .Xls File: New ModelDocument1 pageImport - SAP2000 MS Excel Spreadsheet .Xls File: New ModelBunkun15No ratings yet

- Ms SQL Server 2012 Serial NumberDocument1 pageMs SQL Server 2012 Serial NumberAngga Bayu AlamNo ratings yet

- Cadstar Schematic DiyDocument36 pagesCadstar Schematic DiyAvk SanjeevanNo ratings yet

- PE 612 IT Software Quality & Testing (SQT) : Faculty of Engineering, OU With Effect From The Academic Year 2018-2019Document2 pagesPE 612 IT Software Quality & Testing (SQT) : Faculty of Engineering, OU With Effect From The Academic Year 2018-2019syedazaraliNo ratings yet

- String Functions in ABAP CDS Views - Known Limitations and Workarounds - Visual BI SolutionsDocument5 pagesString Functions in ABAP CDS Views - Known Limitations and Workarounds - Visual BI Solutionssmith kumar0% (1)

- INT402 Quiz (Unit 1 To 6)Document143 pagesINT402 Quiz (Unit 1 To 6)Hancy NixonNo ratings yet

- A10 User GuideDocument22 pagesA10 User GuidemohsinmohamedmaqboolNo ratings yet

- IIB & IHS High AvailabilityDocument12 pagesIIB & IHS High AvailabilitydbaltorNo ratings yet

- Informatica Data Services: Deliver New, Trusted, Critical Data and Reports in Days vs. MonthsDocument4 pagesInformatica Data Services: Deliver New, Trusted, Critical Data and Reports in Days vs. MonthsElaya PerumalNo ratings yet

- Solid APIDocument11 pagesSolid APISmart SridharNo ratings yet

- Read MeDocument12 pagesRead Mecopoz_copozNo ratings yet

- VSphere Troubleshooting and TricksDocument46 pagesVSphere Troubleshooting and TricksManoj KumarNo ratings yet