Professional Documents

Culture Documents

Jsa For Static Equipment Erection

Uploaded by

Khuda BukshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jsa For Static Equipment Erection

Uploaded by

Khuda BukshCopyright:

Available Formats

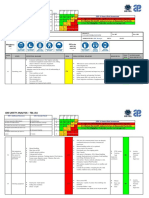

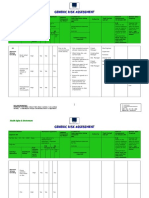

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Description of Activity to be carried out:

Work Location:

METHOD STATEMENT FOR STATIONARY EQUIPMENT

MC3

Corridors of Ras Laffan, Tank form area, B110,

B120, B130, B140, B150, B160, B310, C110, C120,

C130, C140, C160, C300, D100, D200

ERECTION

Risk Assessment Log Section:

1430-601-3-417<01>

JGC approve the use of this MSJSA :

Activity Guidelines used:

RL0-306013-M32-417 <01>

Name:

Position: JGC HSE Manager

Signature:

Date:

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Step

1.0

ACTIVITY

Loading of Equipment at TSF

HAZARDS

Personnel injury due to:

1.1

1.2

Mobilization of equipment to site.

Using crane, trailer and lifting gears /

Appliances.

CONTROL MEASURES

- Tool Box Meeting Shall be conduct.

Improper loading / unloading of

Equipment.

Incorrect position of crane

(Falling material, Personnel Injury)

Vehicle related incident

Property damage

- Experienced rigging lifting supervisor will

Supervise all loading, mobilization and

Unloading activities

- Only third party certified & color coded

Lifting gear will be used.

- All Lifting gears is subjected to visual inspection by

respective riggers.

-

During Operation Position the crane on solid

ground, out Riggers fully extended on approved

pads.

- Barricade loading / unloading areas to avoid any

unauthorized person

- Secure all material with sling / rope as per vendors

specifications.

1430-601-3-417<01>

RL0-306013-M32-417 <01>

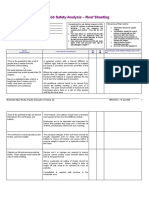

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Step

ACTIVITY

HAZARDS

CONTROL MEASURES

No standing at the edge of the trailer approved route.

Toolbox talk to be conducted.

Install scaffolding barricade on all

Restricted areas i.e. cable trench, under

Ground services etc.

Experienced and trained banksman with

Visible vest will control all movement and

Maneuvering of vehicles / equipment

Follow road and traffic regulations.

All equipment should be inspected

All operators / drivers will be approved &

Authorized by JGC

1430-601-3-417<01>

RL0-306013-M32-417 <01>

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Step

2.0

ACTIVITY

HAZARDS

CONTROL MEASURES

Preparation of foundation & check

Wear & tear in equipment position,

Check all shimming, leveling of

Before installation of equipment.

Leveling & incorrect anchor bolts

Foundation.

Placement of necessary material / tool.. Free movement of nuts on foundation

Bolts.

Position of anchor bolts

Check the weight, orientation of nozzles

& Centre of gravity of the equipment.

Check any wear & tear, damage caused

During the transportation.

Remove loose parts / assemblies from

The equipment

Remove all tripping hazards from the

Equipment erection areas.

Ensure all necessary required materials

1430-601-3-417<01>

RL0-306013-M32-417 <01>

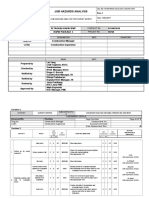

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Step

3.0

ACTIVITY

Preparation of the crane positioning and

HAZARDS

CONTROL MEASURES

Supervisor will inspect all lifting gear and

Personnel injury due to:

Ensure that all gear are inspected and

Attaching Rigging gears

Incorrect position of crane

Approved by Qatar Gas, color coded and

(Slings; shackles; grommets; spreader

Failure of lifting gear.

Capacities are suitable for the load to be

Beams; etc.)

Incorrect Lifting gear.

Working at high elevations.

Lifted.

Re-check weights to be lifted to ensure

That same are within the SWL. Of crane

and Hook block.

Crane operators and riggers will

have proper training, experience and

Qualifications.

Use of safe means of access to detach

Lifting gear.

1430-601-3-417<01>

RL0-306013-M32-417 <01>

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Step

4.0

ACTIVITY

Lifting Equipment as per rigging study

Using crane & lifting gear

HAZARDS

Personnel injury due to:

CONTROL MEASURES

Supervisor will inspect the suitability of

Failure of lifting gear / appliances.

Inexperienced / unqualified / untrained

Rigging crew / operator and supervisor.

Un expected movement of the load

Un authorized personnel in work area

Collision with plant equipment

High wind speed

Each lifting gears, color coding &

Approval by QGS.

Crane operator and riggers will have

proper training , experience and

Qualification must be approved by JGC

Position the crane on solid ground, out

Riggers fully extended on approved pads

Banksman with visibility vest & whistle to

give signal and proper co-ordination

Between banksman & operator.

Tag line to be used.

Barricade the lift areas of crane ensuring

1430-601-3-417<01>

RL0-306013-M32-417 <01>

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Step

ACTIVITY

HAZARDS

CONTROL MEASURES

Crane operation will be stopped if the

Wind speed is 25 knots or more, heavy

5.0

Foundation Bolt Tightening

Fall of material, personnel

Use of wrong tool

Slips & trips.

Shower, sand or thunderstorm etc.

Use proper access & approved working

Platform.

Use full body harness if working at height

Use spark proof Color coded, inspected

And approved hammers / tools.

6.0

Fasten the spanner by rope to avoid slip

Detaching lifting gear &tag line

If using Man lift (vehicle entry permit

Required)

Personnel injury due to:

Slip / trip & fall (working at height)

From hand.

Use canvas pouch or bucket to keep

Tools.

Use proper PPEs.

For access to elevated areas use ladder

1430-601-3-417<01>

RL0-306013-M32-417 <01>

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Step

7.0

ACTIVITY

Manhole Opening, Entry into the vessel,

Internal Cleaning

(Permit required)

HAZARDS

Deficiency of Oxygen

CONTROL MEASURES

Toxic clip for each working group

Exposure to Toxic gas

Personnel Injury due to:

Area monitor on standby or as required

By PTW.

Falls / Slips / Trips

Trained hole watcher with vest to

Inhalation of Dust

Maintain and update a tally board.

Insufficient Illumination

24V Lights will be used inside the vessel

Lights will be inspected, approved and

Color coded before use.

Exhaust fans will be installed prior to

start of work to provide proper

Ventilation.

Suitable access at all times.

Confined Space Entry Board / Head

count will be placed outside the boiler.

1430-601-3-417<01>

RL0-306013-M32-417 <01>

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

HSE Information / Requirements

Resources and Competency

Does the Work Team have the necessary capacity, capability, experience & authority to avoid, minimize, monitor and control the risks (Training / Awareness / Equipment, etc.)?

Detail minimum expected requirements:

Experience personnel will execute the job and before start of job, tool box talk will be given.

Communications / Workforce Consultation

Have all members of the Work Party attended the Toolbox Talk, and have they been made fully aware of the risks that they are taking (Residual risks)?

TBT Record No.

Yes, upon commencement of job, tool box talk will be delivered.

External Risk

Has an assessment been conducted to identify all external (to the activity) hazards and potential risks (3rd parties such as other workforce teams or other adjacent parties)? What is the

result?

Risk Assess. No.

Job Safety Analysis has been carried out keeping in view all external Risks / Hazards. No simultaneous activities are carried out by

other Parties

While doing jobs at height, proper barrication will be done to stop the entry of outside personnel

..

H&S Training

Employees should be trained in the proper interaction with equipment, and the proper response to incidents involving this equipment. List the training your employee(s) has received.

All employees attended JGC induction training and DESCON HSE training, Emergency training as is conducted also

Specialist Training

Will the workforce require any specialist training?

1430-601-3-417<01>

YES / NO (IF YES, list the specialist training required for the job):

RL0-306013-M32-417 <01>

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Crane operators and Riggers are trained and certified. A training session on Hazards and precautions of steel structure erection

will be carried out based on JSA and Method statement before start of the job

High Potential Risks

Does the task require special access / egress / heavy lifting / entry into confined spaces or work at height / in excavations?

(IF YES, a separate Risk Assessment needs to be completed).

YES / NO

Risk Assess. No.

No

Where practicable - Attach supporting Risk Assessment

Other Impacts

Are there any other ways in which the work will be affecting and/or protecting the Health and Safety of the team members?

YES / NO (If so, please describe below):

No

PTW / Isolations: Other Certificates / Permits

What other precautions (e.g. electrical isolation, permits to work) are required and who will authorize them?

PTW / Cert. Nos.

No

Contingency / Emergency Response

Should special emergency procedures be instituted, e.g. Emergency Drill, providing Fire Wardens, extra First Aid cover, etc.?

No

Air Emissions

1430-601-3-417<01>

RL0-306013-M32-417 <01>

YES / NO (If so, please describe below):

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Will the work you perform produce or cause the release of any air emissions?

YES / NO

(If YES, list air emissions and method for preventing impact to the environment):

No

Water Discharges

Will the work you perform produce or cause the release of any wastewater?

YES / NO (IF YES, how will the wastewater be handled?):

No

Materials

What materials (chemicals, oils, etc.) and/or equipment will you be handling or bringing on-site to perform the contracted work?

No

Environmental Training

Have employees been trained in the proper handling of materials and equipment, and the proper response to incidents involving these materials? List the training your task employees

have received.

Environmental aspects are already covered in Job Safety Analysis training

Waste Generation

Will the work you perform result in any wastes? YES / NO (IF YES, list the disposal location, as well as amounts and types of wastes expected and the proposed disposal method):

No

Energy

Will the work you perform consume energy (electricity, compressed air, natural gas, steam, etc.)? YES / NO (IF YES, explain what type of energy will be consumed, and how you will

minimize consumption):

Yes, Diesel fuel will be used in cranes, generators, air compressors etc. Equipment will be stopped if it is not needed to reduce fuel consumption

1430-601-3-417<01>

RL0-306013-M32-417 <01>

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Other Impacts

Are there any other ways in which the work will be affecting and/or protecting the environment?

YES / NO (If YES, please describe below):

No

Environmental Monitoring

Describe any environmental monitoring to be performed, including sampling methods, frequency, analytical requirements and laboratory to be used:

Not Applicable

Legal requirements

Identify environmental legal requirements applicable to the work that has not already been addressed by the Project.

Not Applicable

1430-601-3-417<01>

RL0-306013-M32-417 <01>

SAFE WORK METHOD STATEMENT (SWMS) Incorporating Job Safety Analysis

Training modules required to complete Activity:

List Codes of Practice, Legislation, Standards which apply to this Activity:

JSA will be used as a training module

Standard

ANSI Z 87.1 1989

ANSIZ89.1 1986

ANSI Z41.1

Codes

List Plant / Equipment / PPE required for this Activity:

Crane, power generator, welding machines,

compressor.

PPEs:

Safety Helmet

List Equipment / Maintenance

Checks required for this Activity:

Pre job equipment check

will be done before starting

the job

Safety Shoes

Engineering Certificates / Permits / Approvals required for this Activity

(e.g. RLC Permit Road closure, Utility isolation, Special Waste license, etc.)

No

Type

Reference/Documents

Safety Goggles

Safety Gloves

Dust Masks

Safety Harness

Coverall

Person(s) Responsible for Supervising / Inspecting Work:

Person(s) responsible for supervising the work, inspecting and approving work areas, work methods, protective measures, plant equipment and power / other tools:

NB: List of qualifications/experience is held in local JGC files see JGC HSE Group for details.

Name: .

Position:

Supervisor (DESCON)

Name: .

Position:

Supervisor (DESCON)

Signature: .................................................................

Signature: .................................................................

For a list of names and signatures of staff instructed in this Safe Work Method Statement and JSA, see JGC training records.

Copy 2 - To be retained by JGC HSE Group (24 months)

Copy 3 - To be held by the subcontractor (24 months)

1430-601-3-417<01>

RL0-306013-M32-417 <01>

SAFE ACTIVITY PRE-CHECK (SAP) SHEET

Company:

Date:

Foreman (print

name):

Location:

Task Description:

MUSTER / ASSEMBLY POINT LOCATION:

IS YOUR DESIGNATED PLACE OF WORK TIDY? - YES or NO (If "NO" housekeeping must be performed prior to work commencing).

PERMIT TO WORK REQUIREMENTS

YES

Key Task Related Hazards

(tick box)

NO

N/A

Excavations

Access Only

Plant & Equipment

Electrical

Key Preventative Control Measures

Confined Spaces

Isolations

Lock Out / Tag Out

Hot work

Instrumentation

Pre / Commissioning / START-UP

EXCAVATION

YES

NO

N/A

HOTWORK (Non PTW controlled)

SHORED / SLOPED / BENCHED

FIRE EXTINGUISHER

LADDERS PROVIDED

FIRE BLANKET

BURIED SERVICES IDENTIFIED

CYLINDERS UPRIGHT & SECURED

VEHICLE STOP BARRIERS / BOARDS

COMBUSTIBLES REMOVED

EXCAVATION INSPECTED

CONFINED SPACES

NO

N/A

EMERGENCY COMMUNICATIONS

WORK BELOW RESTRICTED

PERMIT to WORK

BARRIERS / SIGNS POSTED

GAS TEST COMPLETED

FLAME ARRESTORS FITTED

TALLY BOARD or similar

WELDING CABLES IN GOOD CONDITION

EMERGENCY ACCESS

CHEMICALS

COMMUNICATIONS

MSDS REVIEWED / AVAILABLE

SAFETY HARNESSES

SKIN / EYE / THROAT IRRITANT

SUITABLE (Ex.) LIGHTING

SHOWER or EYEWASH AVAILABLE

YES

NO

N/A

YES

NO

N/A

YES

NO

N/A

SPECIAL PPE AVAILABLE AS PER MSDS

SCAFFOLD INSPECTED

CONTAINERS LABELLED PROPERLY

INSPECTION SCAFTAG POSITIONED & IN DATE

SIGNS POSTED

SAFE ACCESS / EGRESS PROVIDED

RISK ASSESSMENT CONDUCTED

TOEBOARDS, KICKPLATES IN ORDER

HAZARDS COMMUNICATED

HANDRAILS SECURED

GROUNDING

HARNESS & LANYARDS INSPECTED

CONTAINMENT REQUIRED / PROVIDED

STATIC LINES - TIE OFF POINTS

ABSORBENT AVAILABLE IN SITU.

YES

NO

N/A

PORTABLE TOOLS

PLANT & EQUIPMENT INSPECTED

TOOLS, APPLIANCES INSPECTED

LIFTING GEAR, RIGGING INSPECTED & CERTS.

BANKSMAN / COMPETENT PERSON

IDENTIFIED

LIFTING PLAN / CALCS & M/S CHECKED

DEFECTS REPORTED

OPERATOR CERTIFIED

OPERATORS CERTIFIED

CABLES, HOSES INSPECTED

PPE REQUIREMENTS IDENTIFIED

FLAGMEN TRAINED / POSITIONED

GUARDS POSITIONED

1430-601-3-417<01>

N/A

SPECIAL PPE (VISORS, GLOVES, etc)

VENTILATION

PLANT & EQUIPMENT

NO

FIRE WATCH (Safety Passport check)

YES

STANDBY MAN

SCAFFOLDING

YES

PORTABLE APPLIANCES INSPECTED

EXTENSION CABLE CHECKED & TAGGED

RL0-306013-M32-417 <01>

SAFE ACTIVITY PRE-CHECK (SAP) SHEET

OCCUPATIONAL HEALTH

YES

NO

N/A

PPE

FIRST AIDER / FIRST AID KIT

HARD HAT

HEAT STRESS

BOOTS

DUST

GLASSES

HYGIENE (FOOD / WATER) CONTAINERS

COVERALLS / HIGH-VISIBILITY VESTS

NOISE

FACE MASKS

VIBRATION

YES

NO

N/A

YES

NO

N/A

YES

NO

N/A

YES

NO

N/A

GENERAL WORK GLOVES

YES

ELECTRICITY

NO

N/A

SPECIALIST PPE

PTW REVIEWED (COMPETENT PERSON)

WELDERS, FIRE RETARDANT GLOVES

SYSTEM LOCK OUT

ELECTRICAL RUBBER GLOVES

SYSTEM TAGGED OUT

EAR DEFENDERS / PLUGS

JSA / METHOD STATEMENT IN PLACE

HARNESSES / LANYARDS

SYSTEM DISCONNECTED

WELDERS SCREEN

SYSTEM TESTED

FACE MASK (DUST - FUMES)

MANUAL HANDLING

YES

NO

N/A

RESPIRATORS

WORKER(S) TRAINED (Safety Passport check)

SELF CONTAINED BREATHING APPARATUS

LIFTING, PULLING

FIRE RETARDENT CLOTHING

STRETCHING

ENVIRONMENTAL CONSTRAINTS

SHARP OBJECTS, PINCH POINTS

ENV. STUDY REPORT COMPLETED

(TROLLEYS, FORKLIFTS, etc) available

ENV. HAZARDS IDENTIFIED IN MS

SOUND GROUND / UNDERFOOT CONDITIONS

GENERAL

WORK AREA CHECKED (R&E SPECIES)

YES

NO

N/A

WASTE CONTAINERS / AREA IDENTIFIED

FLYING PARTICLES

SPILL CONTAINMENT

CABLES SECURED ABOVE HEAD HEIGHT

ENV. MONITOR INFORMED / AVAILABLE

VOIDS / HOLES COVERED & SECURED

SITE PLANT & VEHICLES

BARRIERS & TAPE PROVIDED

SAFE DISTANCE - VEHICLES & PEDESTRIANS

ALL HAZARDS COMMUNICATED

SIGNS ERECTED AND VISIBLE

OTHER WORKERS SAFETY CONSIDERED

NOISE / EXHAUST HAZARDS IDENTIFIED

Foreman / Supervisor: I have discussed the above potential hazards involved in the task, reviewed the SAP Card with

the employees under my control, and implemented suitable and sufficient controls to minimize the risks involved.

Name (print)

Signature

Employees: I / WE ACCEPT THE RESPONSIBILITY FOR THE SAFE BEHAVIOUR OF MYSELF AND MY CO-WORKERS

DURING THE TASKS IDENTIFIED ABOVE:

EMPLOYEE NAME

SIGNATURE

EMPLOYEE NAME

1.

10.

2.

11.

3.

12.

4.

13.

5.

14.

6.

15.

7.

16.

8.

17.

9.

18.

1430-601-3-417<01>

SIGNATURE

RL0-306013-M32-417 <01>

You might also like

- Safe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisDocument15 pagesSafe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisKhuda BukshNo ratings yet

- Column Lifting & Erection JSADocument7 pagesColumn Lifting & Erection JSAAli Mohsin100% (3)

- GRP PIPING INSTALLATION SWMSDocument13 pagesGRP PIPING INSTALLATION SWMSKhuda Buksh100% (1)

- JSA Confined Sapce EntryDocument1 pageJSA Confined Sapce EntryprasongNo ratings yet

- JSA For HDPE SLEEVING DEL 89Document3 pagesJSA For HDPE SLEEVING DEL 89Mohammed Minhaj100% (1)

- Jsa For Erection of Pipes Welding Cutting Grinding-Imtiaz SBDocument6 pagesJsa For Erection of Pipes Welding Cutting Grinding-Imtiaz SBMohammed MinhajNo ratings yet

- Jsa For Tie in of Fuel Gas LineDocument3 pagesJsa For Tie in of Fuel Gas LineMohammed Minhaj100% (1)

- Job Safety Analysis - Cone ErectionDocument7 pagesJob Safety Analysis - Cone ErectionMohammed MinhajNo ratings yet

- Ast Jsa - Piping FabricationDocument3 pagesAst Jsa - Piping Fabricationmd_rehan_2No ratings yet

- JSA-049 Valves & Support Installation and DismantlingDocument4 pagesJSA-049 Valves & Support Installation and DismantlingMoaatazz Nouisri100% (3)

- Jsa For Intallation of Sub Pipe Rack Incuding Grinding Cutting and Welding Near Condensate DrumsDocument6 pagesJsa For Intallation of Sub Pipe Rack Incuding Grinding Cutting and Welding Near Condensate DrumsMohammed MinhajNo ratings yet

- 008 JSA - Manual BoringDocument3 pages008 JSA - Manual BoringMohammed MinhajNo ratings yet

- JSA For DuctDocument13 pagesJSA For DuctRakeshkasarlaNo ratings yet

- PTA-JSA-005-Material Handling by Farhana F-15 CraneDocument6 pagesPTA-JSA-005-Material Handling by Farhana F-15 CraneSaiyad RiyazaliNo ratings yet

- JSA For WrappingDocument6 pagesJSA For WrappingMohammed Minhaj100% (2)

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7Document4 pagesThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7abhijit janaNo ratings yet

- Column Erection JSA AnalysisDocument6 pagesColumn Erection JSA AnalysisRaghava Richhu100% (2)

- Jsa For HydrotestDocument10 pagesJsa For HydrotestAnonymous CcGYhZb080% (5)

- Area Hard Barrication JsaDocument4 pagesArea Hard Barrication JsanishantNo ratings yet

- JSA For Erection and Repair Work of TanksDocument19 pagesJSA For Erection and Repair Work of TanksMohamed Farouk100% (2)

- JS A Excavation Work For Electrical CableDocument3 pagesJS A Excavation Work For Electrical CableMohammed MinhajNo ratings yet

- JSA Installation of PumpsDocument6 pagesJSA Installation of Pumpsyc safety100% (2)

- 4-JSA - Unloading Under Inert - F9030 B NewDocument6 pages4-JSA - Unloading Under Inert - F9030 B NewAde RahmadiNo ratings yet

- Draft JSA Levelling & GradingDocument9 pagesDraft JSA Levelling & GradingAzeem Khan33% (3)

- Hydro Testing On Piping System Utility and Plant Piping Jsa 2012Document4 pagesHydro Testing On Piping System Utility and Plant Piping Jsa 2012AldrinNo ratings yet

- 12-JSA Pipe Erection Work - Existing Pipe RackDocument4 pages12-JSA Pipe Erection Work - Existing Pipe RackSwaminathan ThayumanavanNo ratings yet

- Jsa For Manual Backfiling Usin Hand Roller CompactorDocument5 pagesJsa For Manual Backfiling Usin Hand Roller CompactorAbdus SamadNo ratings yet

- Job Safety Analysis for Pipeline LoadingDocument8 pagesJob Safety Analysis for Pipeline LoadingMoaatazz NouisriNo ratings yet

- Environmental Change Steel Structure Dismantling and Erection JSADocument1 pageEnvironmental Change Steel Structure Dismantling and Erection JSASamuel Hugos100% (4)

- Loading and Unloading Pile Pipes SafelyDocument4 pagesLoading and Unloading Pile Pipes SafelyOsiobe Ewomazino100% (1)

- JSA For Insulation of VesselDocument6 pagesJSA For Insulation of Vesselyc safetyNo ratings yet

- JSA For Operation of Jack Hammer, Dimantalling Batching Plant Fountdation Near Waste Water TreatmentDocument4 pagesJSA For Operation of Jack Hammer, Dimantalling Batching Plant Fountdation Near Waste Water TreatmentMohammed Minhaj100% (1)

- Job Safety Analysis for Hydro-TestingDocument1 pageJob Safety Analysis for Hydro-TestingZeyad RezkNo ratings yet

- JSA Ladders Working at Heights 001Document2 pagesJSA Ladders Working at Heights 001Raman SawNo ratings yet

- Copy (4) of JSA For HDPE Liner Fusion Welding Includes Night WorksDocument7 pagesCopy (4) of JSA For HDPE Liner Fusion Welding Includes Night WorksMohammed Minhaj75% (4)

- JSA for TIE in of Utility water with fire water line near train 1 areaDocument4 pagesJSA for TIE in of Utility water with fire water line near train 1 areaMohammed Minhaj100% (1)

- Installation JSADocument4 pagesInstallation JSAMohammed Minhaj100% (1)

- DOCUMENT Loop Checking Activities JHADocument8 pagesDOCUMENT Loop Checking Activities JHAFrancis Enriquez Tan83% (6)

- Jsa For Civil WorkDocument6 pagesJsa For Civil WorkMuhammad Umar GondalNo ratings yet

- 1.SW-JSA - Piping-1 - Fabrication and Erection of Piping ActivityDocument5 pages1.SW-JSA - Piping-1 - Fabrication and Erection of Piping ActivityAnwar AliNo ratings yet

- JSA For Hydrotesting PDFDocument6 pagesJSA For Hydrotesting PDFMohammed Minhaj100% (1)

- JSA Mechanical Activity Risk AssessmentDocument1 pageJSA Mechanical Activity Risk Assessmentjithin shankarNo ratings yet

- JSA Hot Work and ModificationDocument19 pagesJSA Hot Work and ModificationBrings MotoVlogNo ratings yet

- Boring & Cone Penetration test-JSA-01Document3 pagesBoring & Cone Penetration test-JSA-01Akash Shukla67% (3)

- RETAIL PERMIT WORK HAZARDDocument7 pagesRETAIL PERMIT WORK HAZARDSanthosh Kumar100% (1)

- PVCMS-BMV-HSE-JSA-001 InsulationDocument6 pagesPVCMS-BMV-HSE-JSA-001 InsulationBkdn DungNo ratings yet

- Electrical Works Safety AnalysisDocument6 pagesElectrical Works Safety AnalysisShaikh Abu bakarNo ratings yet

- Catalyst Filling & SeggregationDocument3 pagesCatalyst Filling & SeggregationMohammed MinhajNo ratings yet

- Pipe Fabrication and Erection JSADocument8 pagesPipe Fabrication and Erection JSAjithin shankarNo ratings yet

- Jsa For Mobilization of Crane, Erection of Spools and Welding Cutting and Grinding and Tie in On Existing SpoolsDocument7 pagesJsa For Mobilization of Crane, Erection of Spools and Welding Cutting and Grinding and Tie in On Existing SpoolsMohammed Minhaj100% (1)

- ARK JSA 0 Rev 00 Crane LiftingDocument6 pagesARK JSA 0 Rev 00 Crane LiftingREMYANo ratings yet

- Roof Sheeting SafetyDocument6 pagesRoof Sheeting SafetyMomo XxxxNo ratings yet

- JHA - Survey WorksDocument3 pagesJHA - Survey WorksNazirul Syazwan100% (3)

- JSA-Construction Right of WayDocument3 pagesJSA-Construction Right of Wayfrancis_e_tan100% (5)

- Jsa For Installation of Fence & Area GradingDocument11 pagesJsa For Installation of Fence & Area GradingKhuda Buksh80% (10)

- Jsa For Steel Structure For Off PlotDocument13 pagesJsa For Steel Structure For Off PlotKhuda BukshNo ratings yet

- Crane Mobile SpecificationDocument13 pagesCrane Mobile Specificationsancakemre100% (2)

- JSA G17 Lift Container With CraneDocument4 pagesJSA G17 Lift Container With CraneYosep Sapto Rahyudi100% (2)

- SAFE LIFTING WITH SCISSOR LIFTDocument6 pagesSAFE LIFTING WITH SCISSOR LIFTjokerseri100% (3)

- JSA G20 Scaffolding (Erection, Dismantling)Document4 pagesJSA G20 Scaffolding (Erection, Dismantling)Kanchalida Champathong92% (12)

- Work at Heigh at Night SafetyDocument49 pagesWork at Heigh at Night SafetyKhuda BukshNo ratings yet

- 1691582034614Document16 pages1691582034614Joseph NNo ratings yet

- Toxic Gas Fact SheetDocument15 pagesToxic Gas Fact SheetKhuda BukshNo ratings yet

- Monthly HSE Performance ReportDocument17 pagesMonthly HSE Performance ReportKhuda BukshNo ratings yet

- HSE Docs 186 HSE Checklists Hseprof ComDocument57 pagesHSE Docs 186 HSE Checklists Hseprof ComMansoor BabbarNo ratings yet

- Checklist For Heavy Equipment - 1Document15 pagesChecklist For Heavy Equipment - 1Katita ChascaNo ratings yet

- Permit To Work ProcedureDocument42 pagesPermit To Work ProcedureKhuda Buksh100% (1)

- Short Note For Safety OfficerDocument24 pagesShort Note For Safety OfficerKhuda BukshNo ratings yet

- Work at Height Safety Question & AnswersDocument34 pagesWork at Height Safety Question & AnswersKhuda BukshNo ratings yet

- HSE PLAN by HTTPSDocument52 pagesHSE PLAN by HTTPSKhuda BukshNo ratings yet

- Safety GuideDocument53 pagesSafety GuideKhuda BukshNo ratings yet

- Stamp: Copy No. HolderDocument266 pagesStamp: Copy No. HolderMd EnaamAzharNo ratings yet

- 3S Technical Proposal OHSAS ISO Implementation PDFDocument38 pages3S Technical Proposal OHSAS ISO Implementation PDFKhuda BukshNo ratings yet

- HSE-BMS-010 Permit To WorkDocument24 pagesHSE-BMS-010 Permit To WorkKhuda BukshNo ratings yet

- HSE Procedure For Planning & AuditingDocument4 pagesHSE Procedure For Planning & AuditingKhuda Buksh100% (1)

- ISO 45001 Gap Analysis ChecklistDocument7 pagesISO 45001 Gap Analysis ChecklistKhuda Buksh73% (11)

- 500 Technical Questions Safety&Fire-1Document26 pages500 Technical Questions Safety&Fire-1Saad GhouriNo ratings yet

- NFPAP Member Registration Form - WordDocument1 pageNFPAP Member Registration Form - WordKhuda BukshNo ratings yet

- HSE Procedure For Garbage DisposalDocument4 pagesHSE Procedure For Garbage DisposalKhuda BukshNo ratings yet

- HSE Drilling and Well Control ProcedureDocument5 pagesHSE Drilling and Well Control ProcedureKhuda Buksh100% (1)

- HSE (Trainor Et Al) - 2006 - HSE Report No 426 ACUTEXDocument106 pagesHSE (Trainor Et Al) - 2006 - HSE Report No 426 ACUTEXKhuda Buksh100% (1)

- 02 Abrasive WheelsDocument2 pages02 Abrasive WheelsKhuda BukshNo ratings yet

- 03 Wood CuttingDocument1 page03 Wood CuttingKhuda BukshNo ratings yet

- 06 Power Tools OperationDocument2 pages06 Power Tools OperationKhuda BukshNo ratings yet

- Weekly Safety InspDocument4 pagesWeekly Safety InspKhuda BukshNo ratings yet

- PPE PROTECTIONDocument3 pagesPPE PROTECTIONKhuda BukshNo ratings yet

- Quality PlanDocument21 pagesQuality PlanTAHER AMMAR86% (7)

- Emergency ProceduresDocument23 pagesEmergency ProceduresKhuda BukshNo ratings yet

- CV Zafar Ul Haq KhokharDocument1 pageCV Zafar Ul Haq KhokharKhuda BukshNo ratings yet

- Carbon MonoxideDocument17 pagesCarbon MonoxideKhuda BukshNo ratings yet

- Bored Cast In-Situ Pile Method StatementDocument10 pagesBored Cast In-Situ Pile Method StatementVijay JamadarNo ratings yet

- Network Automation: Efficiency, Resilience, and The Pathway To 5GDocument18 pagesNetwork Automation: Efficiency, Resilience, and The Pathway To 5GkarthickNo ratings yet

- High Entropy AlloysDocument24 pagesHigh Entropy AlloysDevangGandhi7100% (1)

- Configure Enterprise Structure in SAPDocument8 pagesConfigure Enterprise Structure in SAPRamesh Balaji100% (1)

- Vertical Hollow Shaft (VHS), WPIDocument21 pagesVertical Hollow Shaft (VHS), WPIeliahudNo ratings yet

- Amortiguador Pala 7495Document2 pagesAmortiguador Pala 7495milenko Cortes100% (1)

- JAR 66 Module 1 Propeller Exam PracticeDocument43 pagesJAR 66 Module 1 Propeller Exam Practicerobija1No ratings yet

- Onshore Wind Potential in GermanyDocument6 pagesOnshore Wind Potential in GermanyRoman BugajNo ratings yet

- CV Indah Dita Oktaviani PDFDocument1 pageCV Indah Dita Oktaviani PDFLovely KittyNo ratings yet

- Week 6 (Study Guide Exercise) - Lukita Yuviananda - 02411840000064Document8 pagesWeek 6 (Study Guide Exercise) - Lukita Yuviananda - 02411840000064Lukita YuvianandaNo ratings yet

- Section R6 Selected Granular Material-Sub-Base CourseDocument21 pagesSection R6 Selected Granular Material-Sub-Base CourseBALEN KAKLNo ratings yet

- Freno Del Motor c12Document3 pagesFreno Del Motor c12Ramón José Aponte FrancoNo ratings yet

- REINFORCED CONCRETE SLAB DESIGNDocument23 pagesREINFORCED CONCRETE SLAB DESIGNMohamed AbdNo ratings yet

- DmesgDocument71 pagesDmesgAnonymous d1kyvAsNo ratings yet

- Hydraulic Fracturing ReferencesDocument1 pageHydraulic Fracturing ReferencesMaulin GogriNo ratings yet

- Landirezon Rail EVODocument2 pagesLandirezon Rail EVOFabio LourençoNo ratings yet

- Water ChemistryDocument14 pagesWater ChemistryJosé Luis Nava RebollarNo ratings yet

- SDMX Reference Architecture v1Document20 pagesSDMX Reference Architecture v1Vishal BiseswarNo ratings yet

- Types 1098-EGR and 1098H-EGR Pressure Reducing RegulatorsDocument44 pagesTypes 1098-EGR and 1098H-EGR Pressure Reducing RegulatorsToto TotoroNo ratings yet

- Chapter 8 Ionic Chain PolymerizationDocument34 pagesChapter 8 Ionic Chain PolymerizationelnurorucluNo ratings yet

- Performance Task in 21st Century LiteratureDocument12 pagesPerformance Task in 21st Century LiteratureRay Iverson100% (4)

- Pipe Data: Mason Industries, IncDocument1 pagePipe Data: Mason Industries, IncselisenNo ratings yet

- MCS-011 Problem Solving and Programming AssignmentDocument8 pagesMCS-011 Problem Solving and Programming AssignmentSumit RanjanNo ratings yet

- Hydronic Systems Specialties For Plumbing PDFDocument3 pagesHydronic Systems Specialties For Plumbing PDFabdullah sahibNo ratings yet

- Security PostDocument2 pagesSecurity PostAdesina OladayoNo ratings yet

- Ruta de Cancun A Mexico MexicanaDocument20 pagesRuta de Cancun A Mexico MexicanaJesus MorenoNo ratings yet

- Icf Exam G7 Q3 2015Document3 pagesIcf Exam G7 Q3 2015patrickkayeNo ratings yet

- IcarusPIDV7 3 1-RefDocument222 pagesIcarusPIDV7 3 1-RefOmar MokhtarNo ratings yet

- Creating a VHDL-Based Component for Multisim Using the VHDL ModuleDocument7 pagesCreating a VHDL-Based Component for Multisim Using the VHDL ModuleedenofknowledgeNo ratings yet

- Managing Design Services for Construction ProjectsDocument22 pagesManaging Design Services for Construction ProjectsAnwarNo ratings yet