Professional Documents

Culture Documents

Demister Design Check Analysis

Uploaded by

shazanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Demister Design Check Analysis

Uploaded by

shazanCopyright:

Available Formats

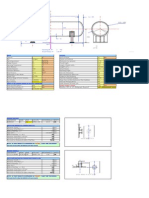

DESIGN CHECK OF DEMISTER

Input:

Shell Inside Diameter

Di = 4000 mm

Demister Pad Diameter

Dp = 1470 mm

Demister pad top support ring thk.

t1 = 12 mm

Demister pad top support ring I.D

D1 = 1496 mm

Demister pad top support ring gusset thk.

t2 = 12 mm

Demister pad top support ring gusset height

h =

213 mm

Demister pad top support ring gusset length

l2 = 1253 mm

Demister pad top support ring gusset qty.

N =

8

Demister pad bottom support plate width

b =

100 mm

Demister pad bottom support plate thk.

t3 = 12 mm

Demister pad bottom support plate length

l3 = 1370 mm

Weight of demister

Wd

=

100 Kg

= 1000 N

Impact Factor

=

1.5

Therefore,

Wd

= 1500 N

Weight of person

Wh

Impact Factor

Therefore,

Wh

=

=

=

=

Fillet size of gusset to shell

F =

Throat size of fillet

Tf= 0.7*F =

150 Kg

1500 N

1.5

2250 N

8 mm

5.60 mm

Demister Bottom support plate design:

Load acting on plate

Pb = Wd =

Bending Moment acting on plate

Section modulus

Bending stress acting on plate

Allowable Bending Stress [p]

1500

Mp =

Z =

p =

N

Wd*l3/8 = 256875 N-mm

b*t3^2/6 =

2400 mm^3

Mp/Z

= 107.0313 N/mm^2

= 0.67*yeild strength

= 0.67 X

220

=

147.40 N/mm^2

Demister bottom support plate is safe

Demister top ring design

Load Acting on demister top ring

Area of top ring

= Pt = Wh = 2250 N

At =

100000

mm^2

( Assuming 150Kg Weight of person occupies 1 Sq. meter of area)

Tensile stress on top ring

Allowable tensile stress [t]

t = Pt/At = 0.023 N/mm^2

=

147.40 N/mm^2

Demister top ring is safe

Demister top plate gusset weld design

max. load acting on demister

Length of weld

P

l

= Pt + Wd =

3750 N

= pi()*Di

= 12566.37 mm

Shear stress on fillet weld

Allowable shear stress on fillet

= P/(l*Tf)

= 0.053 N/mm^2

[] = 88 N/mm^2

Fillet passes in shear

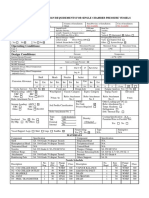

DESIGN CHECK OF DEMISTER

Input:

Shell Inside Diameter

Di = 4000 mm

Demister Pad Diameter

Dp = 1470 mm

Demister pad top support ring thk.

t1 =

6 mm

Demister pad top support ring I.D

D1 = 1496 mm

Demister pad top support ring gusset thk.

t2 =

6 mm

Demister pad top support ring gusset height

h =

213 mm

Demister pad top support ring gusset length

l2 = 1253 mm

Demister pad top support ring gusset qty.

N =

8

Demister pad bottom support plate width

b =

100 mm

Demister pad bottom support plate thk.

t3 =

6 mm

Demister pad bottom support plate length

l3 = 1370 mm

Weight of demister

Wd

=

100 Kg

= 1000 N

Impact Factor

=

1.5

Therefore,

Wd

= 1500 N

Weight of person

Wh

Impact Factor

Therefore,

Wh

=

=

=

=

Fillet size of gusset to shell

F =

Throat size of fillet

Tf= 0.7*F =

150 Kg

1500 N

1.5

2250 N

8 mm

5.60 mm

Demister Bottom support plate design:

Load acting on plate

Pb = Wd =

Bending Moment acting on plate

Section modulus

Bending stress acting on plate

Allowable Bending Stress [p]

1500

Mp =

Z =

p =

N

Wd*l3/8 =

b*t3^2/6 =

Mp/Z

=

256875 N-mm

600

mm^3

428.125 N/mm^2

= 0.67*yeild strength

= 0.67 X

220

=

147.40 N/mm^2

Demister bottom support plate is not safe

Demister top ring design

Load Acting on demister top ring

Area of top ring

= Pt = Wh = 2250 N

At =

100000

mm^2

( Assuming 150Kg Weight of person occupies 1 Sq. meter of area)

Tensile stress on top ring

Allowable tensile stress [t]

t = Pt/At = 0.023 N/mm^2

=

147.40 N/mm^2

Demister top ring is safe

Demister top plate gusset weld design

max. load acting on demister

Length of weld

P

l

= Pt + Wd =

3750 N

= pi()*Di

= 12566.37 mm

Shear stress on fillet weld

Allowable shear stress on fillet

= P/(l*Tf)

= 0.053 N/mm^2

[] = 88 N/mm^2

Fillet passes in shear

You might also like

- TW 1736 design parametersDocument5 pagesTW 1736 design parametersantonyabirawaNo ratings yet

- Output Summary: SI UnitsDocument42 pagesOutput Summary: SI UnitsAkhil JoseNo ratings yet

- Demister SizingDocument3 pagesDemister SizingD K SNo ratings yet

- Agitator - Xls 0Document2 pagesAgitator - Xls 0Prathmesh Gujarati100% (4)

- Sample FLG CalcDocument6 pagesSample FLG CalcameyyammaiNo ratings yet

- Sizing of The Feed Nozzles For Gas-Liquid Separator - Industrial Professionals - CheresourcesDocument5 pagesSizing of The Feed Nozzles For Gas-Liquid Separator - Industrial Professionals - CheresourcesJavierNo ratings yet

- Tank Volume CalculationDocument9 pagesTank Volume CalculationMangesh MandgeNo ratings yet

- Vdocuments - MX Rectangular Tank CalculationDocument34 pagesVdocuments - MX Rectangular Tank CalculationAtilla TekinNo ratings yet

- Bulk Air Eliminator R1Document1 pageBulk Air Eliminator R1hydrothermsNo ratings yet

- Final Weld Strength CalnsDocument5 pagesFinal Weld Strength CalnsamachmouchiNo ratings yet

- Body Flange DesignDocument3 pagesBody Flange DesignDeepikaNo ratings yet

- Weir Plate or Baffle Plate CalculationDocument2 pagesWeir Plate or Baffle Plate CalculationamaNo ratings yet

- Condensate Line SizingDocument2 pagesCondensate Line SizingAnonymous oVRvsdWzfBNo ratings yet

- Sizing For Vaporiser/Flash Vessel: InputsDocument3 pagesSizing For Vaporiser/Flash Vessel: InputsSaravana ChandranNo ratings yet

- TD HE THE v2020.00Document43 pagesTD HE THE v2020.00Claudia BonocoreNo ratings yet

- Design of AgitatorDocument3 pagesDesign of Agitatorkaps12No ratings yet

- Double Pipe Heat Exchanger Design: Chemical Engineering SpreadsheetsDocument2 pagesDouble Pipe Heat Exchanger Design: Chemical Engineering Spreadsheetsrudy_423522658No ratings yet

- Half Pipe Coil AgitatedDocument1 pageHalf Pipe Coil AgitatedNITINNo ratings yet

- Volume Calculation For Pressure Vessel TankDocument2 pagesVolume Calculation For Pressure Vessel Tanksai srikarNo ratings yet

- 302 - Nozzle Design Tool Ver E4.01Document2 pages302 - Nozzle Design Tool Ver E4.01Honey TiwariNo ratings yet

- PH2-03-PLG-GRS-DS-M-005 Rev.0 Vent StackDocument16 pagesPH2-03-PLG-GRS-DS-M-005 Rev.0 Vent StackRanu JanuarNo ratings yet

- KIRK KWM Mist EliminatorsDocument3 pagesKIRK KWM Mist EliminatorsperrychemNo ratings yet

- Sample Design Calculation - Vessel Supported On LugsDocument4 pagesSample Design Calculation - Vessel Supported On LugsAbhay Upadhyay0% (1)

- Vessel Weight CheckDocument8 pagesVessel Weight ChecknileshNo ratings yet

- Flange Pad CalcsDocument4 pagesFlange Pad CalcstomNo ratings yet

- Skirt Support Analysis Per en 13445Document13 pagesSkirt Support Analysis Per en 13445karthik1amarNo ratings yet

- Tank Venting Requirements (API 2000) 2Document3 pagesTank Venting Requirements (API 2000) 2RubensBoerngenNo ratings yet

- U-V-673 - Manual Flange and GussetDocument8 pagesU-V-673 - Manual Flange and GussetDarshan PanchalNo ratings yet

- API 650 STORAGE TANK DESIGN CALCULATIONDocument14 pagesAPI 650 STORAGE TANK DESIGN CALCULATIONhgagselim2012No ratings yet

- Double Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterDocument3 pagesDouble Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterBagusRekaNo ratings yet

- Elliptical Head Design ToolDocument1 pageElliptical Head Design ToolSudjono BroNo ratings yet

- Studding Outlet Calculation - PV Elite 2016Document8 pagesStudding Outlet Calculation - PV Elite 2016Liu YangtzeNo ratings yet

- 8.0 Torispherical Head Design Calculation Asme Sec. Viii Div. 1Document42 pages8.0 Torispherical Head Design Calculation Asme Sec. Viii Div. 1Muhamad Amar Hakimmie Suhaimi100% (1)

- Calculation of Heat and Mass BalanceDocument16 pagesCalculation of Heat and Mass BalanceHEMANTNo ratings yet

- Maz - Design - Separator Capacity EvaluationDocument5 pagesMaz - Design - Separator Capacity EvaluationNaeem HussainNo ratings yet

- Flat HeadsDocument11 pagesFlat HeadsToniNo ratings yet

- Storage Vessel DesignDocument4 pagesStorage Vessel DesignArpit ThumarNo ratings yet

- Pressure Vessel Calculation ReportDocument82 pagesPressure Vessel Calculation ReporteeghbaliNo ratings yet

- Cone Weight CalculationDocument10 pagesCone Weight CalculationRajesh OwaiyarNo ratings yet

- Air Coolers HeadsDocument30 pagesAir Coolers HeadsSergio PluchinskyNo ratings yet

- Nozzle and ReinforcementDocument23 pagesNozzle and ReinforcementAzharyanto Fadhli100% (1)

- Heat Exchanger Design 1Document9 pagesHeat Exchanger Design 1Rajeev SaxenaNo ratings yet

- Etank Full ReportDocument108 pagesEtank Full ReportFaizal SattuNo ratings yet

- Gravity Line Calculations Flow AnalysisDocument7 pagesGravity Line Calculations Flow AnalysisAnshuman ChoudhuryNo ratings yet

- Locking Ring Calculator OD2700Document10 pagesLocking Ring Calculator OD2700muscleglassesNo ratings yet

- Perancangan Plate Adn Frame HEDocument36 pagesPerancangan Plate Adn Frame HEDavid LambertNo ratings yet

- Unstiffened Cylinders EN 13445-3 - 8.5.2 PDFDocument4 pagesUnstiffened Cylinders EN 13445-3 - 8.5.2 PDFfrlamontNo ratings yet

- Burner specification document summaryDocument6 pagesBurner specification document summaryHafiz Muhammad AbubakarNo ratings yet

- Internal CoilDocument2 pagesInternal CoilwhngomjNo ratings yet

- Thermal Insulation Thickness Calculation (By James)Document1 pageThermal Insulation Thickness Calculation (By James)Ah BengNo ratings yet

- UHX CalcsDocument5 pagesUHX CalcsRajesh Panchal100% (1)

- Design of Limpet Coil as per Appendix EEDocument10 pagesDesign of Limpet Coil as per Appendix EEmaheshspawar0% (1)

- Methanol Tank Wall ThicknessDocument4 pagesMethanol Tank Wall ThicknesshaidirNo ratings yet

- DESIGN COLUMN WALL THICKNESS AND VESSEL SUPPORTDocument12 pagesDESIGN COLUMN WALL THICKNESS AND VESSEL SUPPORTfarahanisiliasNo ratings yet

- 26 Pressure Vessel.Document21 pages26 Pressure Vessel.mishtinil93% (14)

- 26 Pressure VesselDocument21 pages26 Pressure VesseljnmanivannanmechNo ratings yet

- Pile Cap Design US Code (ACI 318-05) : Colum N D Im EnsionsDocument19 pagesPile Cap Design US Code (ACI 318-05) : Colum N D Im EnsionsEdilberto ContrerasNo ratings yet

- 1 Design of Lifting Plate: Ref. L&T Engineers DigestDocument1 page1 Design of Lifting Plate: Ref. L&T Engineers DigestChandra MouliNo ratings yet

- Mechanical Design Details for Reactor R-4 and Associated EquipmentDocument37 pagesMechanical Design Details for Reactor R-4 and Associated EquipmentPDPPPMAT0621 Ruhilin Binti NasserNo ratings yet

- Pilecap DesignDocument23 pagesPilecap DesignwaikenNo ratings yet

- Checking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumberDocument1 pageChecking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumbershazanNo ratings yet

- Clearance Calculation For Skirt OpeningDocument3 pagesClearance Calculation For Skirt OpeningshazanNo ratings yet

- Flange Details & DrawingsDocument338 pagesFlange Details & DrawingsshazanNo ratings yet

- Cleat Summary Excel SheetDocument4 pagesCleat Summary Excel SheetshazanNo ratings yet

- Welding EngineeringDocument1 pageWelding EngineeringshazanNo ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Clearance CalculationDocument12 pagesClearance CalculationshazanNo ratings yet

- Weld CalculationsDocument12 pagesWeld Calculationshakr5100% (1)

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Static Equipment A Look Inside The How and Why of SpecificationDocument19 pagesStatic Equipment A Look Inside The How and Why of SpecificationshazanNo ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Manhole MH PDFDocument1 pageManhole MH PDFshazanNo ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Flange GeometryDocument1 pageFlange GeometryshazanNo ratings yet

- Test Flange TypeDocument1 pageTest Flange TypeshazanNo ratings yet

- U Stamp - KK Form - SampleDocument5 pagesU Stamp - KK Form - SampleshazanNo ratings yet

- Gasket Selection GuideDocument6 pagesGasket Selection GuiderezaNo ratings yet

- Seismic Calculation IS 1893 - RSMDocument3 pagesSeismic Calculation IS 1893 - RSMshazanNo ratings yet

- Midrex Case StudyDocument1 pageMidrex Case StudyshazanNo ratings yet

- MN-V-02 Sump - NozDocument1 pageMN-V-02 Sump - NozshazanNo ratings yet

- Lecture2 (Petrochemical)Document12 pagesLecture2 (Petrochemical)ToniAndiwijaya100% (1)

- MN-V-02 M-01 - NozDocument1 pageMN-V-02 M-01 - NozshazanNo ratings yet

- Saddle DrawingDocument1 pageSaddle DrawingshazanNo ratings yet

- Test Ring1 ModelDocument1 pageTest Ring1 ModelshazanNo ratings yet

- ASME BPVC Latest Edition Design and FabricationDocument2 pagesASME BPVC Latest Edition Design and Fabricationshazan100% (1)

- ROM Magazine V1i6Document64 pagesROM Magazine V1i6Mao AriasNo ratings yet

- The Patient Self-Determination ActDocument2 pagesThe Patient Self-Determination Actmarlon marlon JuniorNo ratings yet

- 1 20《经济学家》读译参考Document62 pages1 20《经济学家》读译参考xinying94No ratings yet

- Gavrila Eduard 2Document6 pagesGavrila Eduard 2Eduard Gabriel GavrilăNo ratings yet

- Module 5 Communication & Change MGT - HS Planning & Policy Making ToolkitDocument62 pagesModule 5 Communication & Change MGT - HS Planning & Policy Making ToolkitKristine De Luna TomananNo ratings yet

- Yamaha RX-A3000 - V3067Document197 pagesYamaha RX-A3000 - V3067jaysonNo ratings yet

- List of StateDocument5 pagesList of StatedrpauliNo ratings yet

- ASCP User GuideDocument1,566 pagesASCP User GuideThillai GaneshNo ratings yet

- After EffectsDocument56 pagesAfter EffectsRodrigo ArgentoNo ratings yet

- ĐỀ CƯƠNG ANH 9 - CK2 (23-24)Document7 pagesĐỀ CƯƠNG ANH 9 - CK2 (23-24)thuyhagl2710No ratings yet

- Spiral Granny Square PatternDocument1 pageSpiral Granny Square PatternghionulNo ratings yet

- Project On International BusinessDocument18 pagesProject On International BusinessAmrita Bharaj100% (1)

- KS4 Higher Book 1 ContentsDocument2 pagesKS4 Higher Book 1 ContentsSonam KhuranaNo ratings yet

- What Is Inventory Management?Document31 pagesWhat Is Inventory Management?Naina SobtiNo ratings yet

- APLI - Annual Report - 2016Document122 pagesAPLI - Annual Report - 2016tugas noviaindraNo ratings yet

- Cost Systems: TermsDocument19 pagesCost Systems: TermsJames BarzoNo ratings yet

- SWOT AnalysisDocument6 pagesSWOT Analysishananshahid96No ratings yet

- 7 React Redux React Router Es6 m7 SlidesDocument19 pages7 React Redux React Router Es6 m7 Slidesaishas11No ratings yet

- Online Music Courses With NifaDocument5 pagesOnline Music Courses With NifagksamuraiNo ratings yet

- Hollywood Game Plan 20 Page Sample PDFDocument20 pagesHollywood Game Plan 20 Page Sample PDFMichael Wiese Productions0% (1)

- Lending Tree PDFDocument14 pagesLending Tree PDFAlex OanonoNo ratings yet

- DJDocument907 pagesDJDeepak BhawsarNo ratings yet

- FRABA - Absolute - Encoder / PLC - 1 (CPU 314C-2 PN/DP) / Program BlocksDocument3 pagesFRABA - Absolute - Encoder / PLC - 1 (CPU 314C-2 PN/DP) / Program BlocksAhmed YacoubNo ratings yet

- Table of Contents and Executive SummaryDocument38 pagesTable of Contents and Executive SummarySourav Ojha0% (1)

- Country Profile - NigerDocument1 pageCountry Profile - Nigernana kayNo ratings yet

- Solution of Introduction To Many-Body Quantum Theory in Condensed Matter Physics (H.Bruus & K. Flensberg)Document54 pagesSolution of Introduction To Many-Body Quantum Theory in Condensed Matter Physics (H.Bruus & K. Flensberg)Calamanciuc Mihai MadalinNo ratings yet

- Ds 3805Document4 pagesDs 3805sparky2017No ratings yet

- Optimum Work Methods in The Nursery Potting ProcessDocument107 pagesOptimum Work Methods in The Nursery Potting ProcessFöldi Béla100% (1)

- Theatre Arts I 9 - 12 Grade Beginning Theatre Students: TH THDocument18 pagesTheatre Arts I 9 - 12 Grade Beginning Theatre Students: TH THAppleSamsonNo ratings yet

- What Is Chemical EngineeringDocument4 pagesWhat Is Chemical EngineeringgersonNo ratings yet