Professional Documents

Culture Documents

A64 PC Datasheet PDF

Uploaded by

Cruzado Vilca AmesquitaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A64 PC Datasheet PDF

Uploaded by

Cruzado Vilca AmesquitaCopyright:

Available Formats

A64 Personnel Carrier

Personnel Transporter

Getman personnel carriers are designed to support underground logistics by moving crews throughout

underground mines safely and efficiently. Built on the reliable A64 Chassis, these carriers protect miner safety

through purpose-built design, including individual seat belts for all passengers, a calculated ROPS/FOPS

structure over the rear passenger area and a certified ROPS/FOPS structure over the driver compartment.

The A64 Personnel Carrier comes in a 16-person capacity and a 23-person capacity, and are available with

either open or enclosed passenger compartments (some exclusions apply). All Getman personnel carriers

come with an emergency horn button located in the rear compartment to notify the machine operator from

inside the operators compartment, and all walking surfaces come with a anti-slip coating to minimize the

likelihood of slip and fall accidents.

Product Datasheet

Updated March 3, 2016

A64 Personnel Carrier

Personnel Transporter

Technical Specifications

Engine

Tier III approved engine - 4-cylinder

Mercedes Benz OM904LA, 129 kW (173 hp) @ 2200 rpm

Cummins QSB4.5, 127 kW (170 hp) @ 2200 rpm

Liquid-cooled, turbocharged

113 L (30 gal) fuel tank with self-closing cap

Exhaust System

Catalytic exhaust conditioner and silencer

Transmission

Dana Clark 32000 powershift transmission

Three speeds forward and reverse

4-wheel drive

Axles

Planetary drive axles

Heavy-duty Carraro 28.43 axle package

Enhanced capacity Carraro 28.60 axle package

Tires

Mine service tires

10.0020-16pr

12.0020-28pr

Brake System

Fully hydraulic wet disc service brakes on each axle

Spring applied, hydraulic pressure release wet disc secondary

brake

Automatic secondary brake application upon loss of brake

accumulator pressure, transmission pressure or electrical

power

Steering

Orbitrol controlled articulated frame steering

Heavy-duty, self-aligning bearings inside replaceable inserts

Two double-acting steer cylinders with replaceable bushings

in cylinder and frame ears

40 articulation each direction

Hydraulic System

Hot side/cold side engine layout

Hydraulic hoses routed to cold side of engine

Open center hydraulic circuits with gear hydraulic pump

Diagnostic test ports with quick couple fittings for: each axle,

service brake application pressure, and hydraulic pumps

10-micron return filter

151 L (40 gal) hydraulic reservoir

Operator Compartment

Three-point contact for entry and exit

ROPS/FOPS certified compartment (SAE J1040C, CSA B-352,

ISO 3471)

Open canopy

Enclosed cabin with heater and air conditioner

Operator and passenger seating

Mechanical suspension operator seat

Retractable lap seat belts

Instrumentation

Engine and transmission gauges

Engine temperature

Engine oil pressure

Voltmeter

Hour meter

Tachometer

Transmission clutch pressure

Converter temperature

Brake accumulator pressure gauge

Brake accumulator low-pressure warning

Park brake applied warning light

Audio/visual alert for high engine temperature

Audio/visual alert for low engine pressure

Electrical System

24 V, 100 A alternator

Lockable electrical master switch (lockout)

Maintenance-free 12 V batteries

LED lighting package (IP69K rated): two 900 lm front

headlights, two 900 lm rear headlights

Sealed and oil resistant wiring

Fully sealed connectors

Fully sealed electrical boxes

Other General Equipment

Variable audio backup alarm (87-112dBA)

2.3 kg (5 lb) fire extinguisher

Wheel chocks

Four nozzle Ansul fire suppression system tied to engine

shutdown (LTA-101-30)

Optional Equipment

Wiggins fill system

Lincoln auto-lubrication package

Ansul Checkfire automatic actuation fire suppression system

with linear detection loop

Product Datasheet

Updated March 3, 2016

A64 Personnel Carrier

Personnel Transporter

Carrier Configuration*

Personnel Transporting Package

Open or enclosed passenger compartment

16-man compartment

23-man compartment (requires enhanced capacity axles)

Padded bench seats with individual passenger seat belts

Slip-resistance matted floors

Emergency horn button to alert machine operator

*Consult Getman for special configurations

Product Datasheet

Updated March 3, 2016

A64 Personnel Carrier

Personnel Transporter

Design Features and Layout

Open or enclosed

passenger compartment

Padded bench seat

with individual seat belts

All filters and lubrication

points accessible from

ground level

Emergency

horn button to

alert operator

Fluid levels easily

checked using groundlevel sight gauges

Built on the reliable

Getman A64 Chassis

Product Datasheet

Updated March 3, 2016

A64 Personnel Carrier

Personnel Transporter

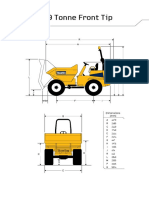

Dimensions and Maneuverability

16-Man

2292

[7-6]

2211

[7-3]

18

GRND

311

[12.25] CLRN

12.0020 TIRES

7563

[24-10]

3659

[12]

23-Man

2215

[7-3]

2276

[7-6]

2286

[7-6]

3686

7

311 GRND

[12.25] CLRN

[12-1]

18

40

12.0020 TIRES

3656

[12]

8755

[28-2]

1000

7563[3-3]

mm

298 in

Machine Length (23-Man)

8755 mm

338 in

Wheelbase Length

3656 mm

144 in

311 mm

12.25 in

2292 mm

90 in

Machine Length (16-Man)

Ground Clearance

2832

[9-4]

Machine Height (Canopy)

2000

[6-7]

40

2085

[6-10]

R6351

[R20-10]

3974

[13]

R3769

[R12-4]

3686

Product Datasheet

[12-1]Updated March 3, 2016

A64 Personnel Carrier

Personnel Transporter

2292

[7-6]

2211

[7-3]

Dimensions and Maneuverability

18

GRND

311

[12.25] CLRN

12.0020 TIRES

7563

[24-10]

3659

[12]

16-Man

2286

[7-6]

40

3686

[12-1]

2085

[6-10]

1000

[3-3]

2000

[6-7]

2215

[7-3]

2276

[7-6]

R6351

[R20-10]

18

R3769

311 GRND

[R12-4]

[12.25] CLRN

12.0020 TIRES

3686

[12-1]

3656

[12]

8755

[28-2]

23-Man

2832

[9-4]

40

3974

[13]

2085

[82]

1000

[3-3]

2000

[6-7]

R6478

[R21-3]

R3542

[R11-7]

3974

[13]

Machine Width (16-Man)

2286 mm

90 in

Inner Turning Radius (16-Man)

3769 mm

148 in

Outer Turning Radius (16-Man)

6351 mm

250 in

Machine Width (23-Man)

2832 mm

112 in

Inner Turning Radius (23-Man)

3542 mm

139 in

Outer Turning Radius (23-Man)

6478 mm

255 in

Product Datasheet

Updated March 3, 2016

A64 Personnel Carrier

Personnel Transporter

Engine and Performance

Mercedes Benz OM904 Engine Package

Cummins QSB4.5 Engine Package

Manufacturer

Mercedes

Manufacturer

Cummins

Model

OM904

Model

QSB4.5

Stage

Tier III

Stage

Tier III

Design

4 Cylinders in line, water cooled

Design

4 Cylinders in line, water cooled

Max Power

129 kW (173 hp) @ 2200 rpm

Max Power

127 kW (170 hp) @ 2200 rpm

Exhaust System

Catalytic exhaust conditioner and silencer

Exhaust System

Catalytic exhaust conditioner and silencer

Aspiration

50.0

Aspiration

50.0

Turbocharged

Fuel Consumption

Fuel Consumption

220 g/kW-hr (0.361 lb/hp-hr)

Speed Chart with Estimated GVW: 10,900 kg (24,000 lb)

Dana Clark 32000 Transmission

Standard Heavy-Duty Carraro 28.43 Axles

1020-16pr Mine-Duty tires

10.0

% Incline

30.0

0.0

243 g/kW-hr (0.399 lb/hp-hr)

40.0

1st Gear

2nd Gear

0.0

40.0

30.0

20.0

3rd Gear

Speed Chart with Estimated GVW: 10,900 kg (24,000 lb)

Dana Clark 32000 Transmission

Standard Heavy-Duty Carraro 28.43 Axles

1020-16pr Mine-Duty tires

10.0

50.0

5.0

10.0

15.0

20.0

0.0

25.0

2nd Gear

3rd Gear

0.0

40.0

5.0

10.0

15.0

20.0

25.0

KPH

% Incline

30.0

20.0

10.0

0.0

1st Gear

50.0

KPH

% Incline

% Incline

40.0

20.0

Turbocharged

30.0

20.0

10.0

0.0

5.0

10.0

15.0

20.0

25.0

0.0

0.0

5.0

KPH

10.0

15.0

20.0

25.0

KPH

20%

9%

Maximum Recommended

Longitudinal Tramming Gradient

0%

Maximum Recommended

Transverse Tramming Gradient

0%

Product Datasheet

Updated March 3, 2016

A64 Personnel Carrier

Personnel Transporter

About Getman Corporation

Getman Corporation is a global supplier of mobile equipment

to the mining industry, offering customer-specific solutions to

underground mines in the production and production support

classes of equipment. All Getman equipment is designed with

extensive research and development and is supported by over fifty

years of experience in serving the underground mining industry.

Through our network of distributors we sell and support our

products on six continents, offering exceptional product solutions

and following up with world class aftermarket support. At Getman Corporation, designing and building trucks for the underground mining

industry is what we do. We take pride in being the preferred supplier of underground production and production support equipment to

miners globally by offering customer-specific, value-driven and long-lasting solutions.

For more information contact your Getman distributor or email us at info@getman.com, or visit our website at www.getman.com.

For parts or service support, email us at parts@getman.com or service@getman.com.

Getman Corporation assembled this datasheet with the intention of passing along the most accurate information possible, however this document shall not be binding in any way and

shall be considered informational only. All values stated herein are theoretical in nature. All orders are accepted based on the terms and conditions set forth in the individual purchase

or sales agreement. Getman reserves the right to make changes to the specification herein at any time and without further notification.

Pictured machines in this document may contain optional and additional equipment.

Getman Corporation

59750 34th Avenue

Bangor, MI 49013 USA

Tel +1 (269) 427-5611

Fax +1 (269) 427-8781

www.getman.com

Product Datasheet

Updated March 3, 2016

You might also like

- A64 ExC Transporter S PDFDocument8 pagesA64 ExC Transporter S PDFCruzado Vilca AmesquitaNo ratings yet

- A64 HD Pallet Handler Datasheet PDFDocument8 pagesA64 HD Pallet Handler Datasheet PDFCruzado Vilca AmesquitaNo ratings yet

- A64 Boom 2 1300 Datasheet PDFDocument9 pagesA64 Boom 2 1300 Datasheet PDFCruzado Vilca AmesquitaNo ratings yet

- A64 Service Lube Datasheet PDFDocument8 pagesA64 Service Lube Datasheet PDFCruzado Vilca AmesquitaNo ratings yet

- Atlas Copco Utilitary Vehicles - FamilyBrochure - ENGDocument12 pagesAtlas Copco Utilitary Vehicles - FamilyBrochure - ENGmasterandreis100% (2)

- 89E303 Touareg - ManualDocument67 pages89E303 Touareg - Manualeduardorojas00767% (3)

- 216 BrochureDocument12 pages216 Brochureleotiger123No ratings yet

- A64 ExC 3000 Datasheet PDFDocument10 pagesA64 ExC 3000 Datasheet PDFCruzado Vilca AmesquitaNo ratings yet

- Hoja Tecnica Dumper AtlasDocument4 pagesHoja Tecnica Dumper AtlasRoferq Fernandez QuichuaNo ratings yet

- A64 HD A 70 PDFDocument8 pagesA64 HD A 70 PDFCruzado Vilca AmesquitaNo ratings yet

- ATEGO - SpecificationsDocument18 pagesATEGO - SpecificationsKovács Áron100% (3)

- He Ma End Us TriDocument57 pagesHe Ma End Us TriPratik PanchalNo ratings yet

- P17500 P33000 PDFDocument14 pagesP17500 P33000 PDFAdrian GonzalezNo ratings yet

- Cryostar Process Machinery PDFDocument0 pagesCryostar Process Machinery PDFJavad AmnianNo ratings yet

- A64 Service Fuel PDFDocument8 pagesA64 Service Fuel PDFCruzado Vilca AmesquitaNo ratings yet

- Caterpillar r1600g LHDDocument53 pagesCaterpillar r1600g LHDCarlos Abel Conza LopezNo ratings yet

- Axor WebDocument14 pagesAxor Webkremoso100% (1)

- Carlisle Aftermarket Catalog 070115 SM - CompressedDocument65 pagesCarlisle Aftermarket Catalog 070115 SM - CompressedAgus Yulfizar100% (1)

- Kosan Crisplant LPG Equipment PDFDocument110 pagesKosan Crisplant LPG Equipment PDFAssis Gomes0% (1)

- Rodcraft Workshop2012Document28 pagesRodcraft Workshop2012Ralph WamaeNo ratings yet

- R1600G LHDDocument53 pagesR1600G LHDIvan ColqueNo ratings yet

- R1600H - R1600G Comparison - 13 - Feb - 2013Document42 pagesR1600H - R1600G Comparison - 13 - Feb - 2013Percy CheroNo ratings yet

- Kalmar Dce 120-12Document10 pagesKalmar Dce 120-12kerasus100% (2)

- Wesc 1350Document4 pagesWesc 1350diosmio111No ratings yet

- GMK3050 1 Product Guide MetricDocument24 pagesGMK3050 1 Product Guide MetricSzakács CsillaNo ratings yet

- Jornada de Actualización de Máquinas Caterpillar: Cabina CAT frente a cabina VolvoDocument53 pagesJornada de Actualización de Máquinas Caterpillar: Cabina CAT frente a cabina VolvoJean Carlos Zapata Rumay75% (4)

- Linde ReachstackersDocument8 pagesLinde ReachstackersRanolf Lavtern100% (1)

- Komatsu PC200-8M0 Excavator Specifications and FeaturesDocument16 pagesKomatsu PC200-8M0 Excavator Specifications and FeaturesfijriNo ratings yet

- A64 Service Lube S PDFDocument8 pagesA64 Service Lube S PDFCruzado Vilca AmesquitaNo ratings yet

- Isb PDFDocument6 pagesIsb PDFDiego Ledesma50% (2)

- 7FGU8 17500SpecSheetDocument6 pages7FGU8 17500SpecSheetEdwin NgNo ratings yet

- Sandvik QA451 PDFDocument2 pagesSandvik QA451 PDFAnonymous P0ePHjNo ratings yet

- Versatile A64 ExC 2-500ER Explosives ChargerDocument10 pagesVersatile A64 ExC 2-500ER Explosives ChargerCruzado Vilca AmesquitaNo ratings yet

- Minetruck MT436B 9851 2249 01N tcm835-1540890 PDFDocument4 pagesMinetruck MT436B 9851 2249 01N tcm835-1540890 PDFCristian Cabrera0% (1)

- 3492 0022 01 - LDocument16 pages3492 0022 01 - LJoe SmithNo ratings yet

- 2010 Cryostar LNGDocument16 pages2010 Cryostar LNGproscokeNo ratings yet

- Sprinter Tyre Performance Characteristics. The New SprinterDocument24 pagesSprinter Tyre Performance Characteristics. The New SprinterTetsunari KodaNo ratings yet

- Minetruck MT5020Document4 pagesMinetruck MT5020Michael de la BarraNo ratings yet

- A64 HD R 60 Datasheet PDFDocument8 pagesA64 HD R 60 Datasheet PDFCruzado Vilca AmesquitaNo ratings yet

- D6K2Document20 pagesD6K2ivanamanticNo ratings yet

- Cat Ad22 Dump TruckDocument24 pagesCat Ad22 Dump TruckGeorge AdamsNo ratings yet

- 1000 MaxtrackDocument6 pages1000 MaxtrackJaimeAguilar0% (1)

- Estandar Instuctor de Motoniveladoras Carlos Hernan Rodriguez BedoyaDocument105 pagesEstandar Instuctor de Motoniveladoras Carlos Hernan Rodriguez BedoyaJorgeAMoralesNo ratings yet

- Cat. 262CDocument2 pagesCat. 262CPedro Aponte CamposNo ratings yet

- Eicher Pro 1049 - Sales Advisory - Application FITDocument13 pagesEicher Pro 1049 - Sales Advisory - Application FITKarunesh MathurNo ratings yet

- Unimog Techdata u4000 Euro5 1209 en PDF Unimog_techdata_u4000_euro5_1209_en_pdf.pdf Unimog_techdata_u4000_euro5_1209_en_pdf.pdf Unimog_techdata_u4000_euro5_1209_en_pdf.pdfDocument2 pagesUnimog Techdata u4000 Euro5 1209 en PDF Unimog_techdata_u4000_euro5_1209_en_pdf.pdf Unimog_techdata_u4000_euro5_1209_en_pdf.pdf Unimog_techdata_u4000_euro5_1209_en_pdf.pdfIvana Ilic67% (3)

- 40 T Crawler PDFDocument16 pages40 T Crawler PDFBharathyNo ratings yet

- "Big Red": Empty Container Handler Preliminary SpecificationsDocument4 pages"Big Red": Empty Container Handler Preliminary SpecificationsNeil DesaiNo ratings yet

- Workshop Layout SampleDocument44 pagesWorkshop Layout Sampleautocarewin83% (6)

- Team Terasvin Supra Virtuals Ppt1Document21 pagesTeam Terasvin Supra Virtuals Ppt1Mohamed Arief M100% (2)

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualRating: 2.5 out of 5 stars2.5/5 (2)

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualNo ratings yet

- How Are Supercars Made? Technology Book for Kids 4th Grade | Children's How Things Work BooksFrom EverandHow Are Supercars Made? Technology Book for Kids 4th Grade | Children's How Things Work BooksNo ratings yet

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorFrom EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNo ratings yet

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Motor Truck Logging Methods Engineering Experiment Station Series, Bulletin No. 12From EverandMotor Truck Logging Methods Engineering Experiment Station Series, Bulletin No. 12No ratings yet

- A64 Service Lube S PDFDocument8 pagesA64 Service Lube S PDFCruzado Vilca AmesquitaNo ratings yet

- A64 Service Fuel PDFDocument8 pagesA64 Service Fuel PDFCruzado Vilca AmesquitaNo ratings yet

- A64 Pallet Handler Datasheet PDFDocument10 pagesA64 Pallet Handler Datasheet PDFCruzado Vilca AmesquitaNo ratings yet

- A64 HD R 50 Datasheet PDFDocument9 pagesA64 HD R 50 Datasheet PDFCruzado Vilca AmesquitaNo ratings yet

- A64 Product Catalog: Features - Configurations - SpecificationsDocument26 pagesA64 Product Catalog: Features - Configurations - SpecificationsCruzado Vilca AmesquitaNo ratings yet

- A64 ExC 3000 Datasheet PDFDocument10 pagesA64 ExC 3000 Datasheet PDFCruzado Vilca AmesquitaNo ratings yet

- A64 HD R 60 Datasheet PDFDocument8 pagesA64 HD R 60 Datasheet PDFCruzado Vilca AmesquitaNo ratings yet

- A64 HD A 70 PDFDocument8 pagesA64 HD A 70 PDFCruzado Vilca AmesquitaNo ratings yet

- Versatile A64 ExC 2-500ER Explosives ChargerDocument10 pagesVersatile A64 ExC 2-500ER Explosives ChargerCruzado Vilca AmesquitaNo ratings yet

- Versatile A64 ExC 2-500ER Explosives ChargerDocument10 pagesVersatile A64 ExC 2-500ER Explosives ChargerCruzado Vilca AmesquitaNo ratings yet

- A64 PC Datasheet PDFDocument8 pagesA64 PC Datasheet PDFCruzado Vilca AmesquitaNo ratings yet

- Versatile A64 ExC 2-500ER Explosives ChargerDocument10 pagesVersatile A64 ExC 2-500ER Explosives ChargerCruzado Vilca AmesquitaNo ratings yet

- A64 Crane Datasheet PDFDocument9 pagesA64 Crane Datasheet PDFCruzado Vilca AmesquitaNo ratings yet

- Versatile A64 ExC 2-500ER Explosives ChargerDocument10 pagesVersatile A64 ExC 2-500ER Explosives ChargerCruzado Vilca AmesquitaNo ratings yet

- Versatile A64 ExC 2-500ER Explosives ChargerDocument10 pagesVersatile A64 ExC 2-500ER Explosives ChargerCruzado Vilca AmesquitaNo ratings yet

- A64 Crane-S PDFDocument9 pagesA64 Crane-S PDFCruzado Vilca AmesquitaNo ratings yet

- A64 Product Catalog: Features - Configurations - SpecificationsDocument26 pagesA64 Product Catalog: Features - Configurations - SpecificationsCruzado Vilca AmesquitaNo ratings yet

- A64 Product Catalog: Features - Configurations - SpecificationsDocument26 pagesA64 Product Catalog: Features - Configurations - SpecificationsCruzado Vilca AmesquitaNo ratings yet

- Versatile A64 ExC 2-500ER Explosives ChargerDocument10 pagesVersatile A64 ExC 2-500ER Explosives ChargerCruzado Vilca AmesquitaNo ratings yet

- A64 Cable Stringer DatasheetDocument9 pagesA64 Cable Stringer DatasheetCruzado Vilca AmesquitaNo ratings yet

- A64 Product Catalog: Features - Configurations - SpecificationsDocument26 pagesA64 Product Catalog: Features - Configurations - SpecificationsCruzado Vilca AmesquitaNo ratings yet

- A64 Cable Stringer S DatasheetDocument9 pagesA64 Cable Stringer S DatasheetCruzado Vilca AmesquitaNo ratings yet

- Alldrive 9 Tonne Front Tip SpecsDocument2 pagesAlldrive 9 Tonne Front Tip SpecsQuelmis De La Cruz Vilca AmesquitaNo ratings yet