Professional Documents

Culture Documents

Astm Manual

Uploaded by

AashifCairoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Astm Manual

Uploaded by

AashifCairoCopyright:

Available Formats

S TEE L

N T ERe HAN G E

Steel Interchange is an open forum for Modern Steel

Construction readers to exchange useful and practical professional ideas and information on all phases of steel building and

bridge construction. Opinions and suggestions are welcome on

any subject covered in this magazine. If you have a question or

problem that your fellow readers might help you to solve, please

forward it to Modern Steel Construction . At the same time, feel

free to respond to any of the questions that you have read here.

Please send them to:

Steel Interchange

Modern Steel Construction

One East Wacker Dr., Suite 3100

Chicago, IL 60601-2001

****

Answers and/or questions should be typewritten and doublespaced. Submittals that have been prepared by word-processing

are appreciated on computer diskette (either as a Word file or in

ASCII format) .

The opinions expressed in Steel Interchange do not necessarily represent an official position of the American Institute of

Steel Construction, Inc. and have not been reviewed. It is recognized that the design of structures is within the scope and

expertise of a competent licensed structural engineer, architect

or other licensed professional for the application of principals to

a particular structure.

Information on ordering AlSC publications mentioned in

this article can be obtained by calling AlSC at 800/644-2400.

Questions and answers can now be e-mailedto:newman@aiscmail.com

The following responses from previous Steel

Interchange columns have been received:

Should connections involving bolts and

welds used in combination be welded first or

bolted first?

he sharing of load between bolts (both A307

T

and high-strength bolts ) and welds in bearing

type connection is not recommended. However,

high-strength bolts in slip-critical connections can

be used in combination with welds. In this case

bolts should be fully tensioned before the weld is

made. Additional Ih to 1A turn of a nut is recommended to apply after the welding is done.

The combination of bolts and welds is discussed

in LRFD Manual 2nd Edition Vol. I Chapter J1.9.

and Vol. II p.8-211 and in similar chapters in ASD

9th Edition Manual.

Boris S. Fayman, P.E.

Engineered Endeavors, Inc.

Mentor,OH

Another response:

deSigner must consider ease of construction as

A

well as structural integrity when using welded

and bolted connections together. For example,

when I worked as a steel fabricator a typical connection for splicing beams (say at a zero moment

point as in cantilever construction) involved welding and punching holes in the splice plates. These

plates were welded to opposite sides of each beam

flange. In the field, the holes were aligned, bolted,

then the remainder of the plates welded.

Overstressing of the bolts in this situation is not a

problem because the strength of the connection

comes from the welds and not the bolts.

Ray Schork P.E.

Bayer Becker Engineers

Fairfield, Ohio

via email

****

How does one design a stepped column?

designing a

Ithenstepped

column

first task would

be to determine the

IorW12

slenderness "K"

value for the upper

and lower shafts.

AISC

in Steel

Design Guide Series

,..W24

number 7, Industrial Buildings, publishes an excellent

article in appendix

B. This article by

Krishna Agrawal

and Andrew Stafiej

presents tables in which the engineer may determine the following characteristics of the upper and

lower shafts of stepped columns.

1) Ratio of inertia of upper shaft to lower shaft.

2) Ratio of lower shaft length to total length.

3) Ratio of "P" load at column step to total column axial load.

From these ratio the article provides tables for

selection of the "K" values for the upper and lower

shafts. The article provides several conditions in

the stepped column tables ranging from a pinned pinned condition to a fixed -fixed condition. Once

the slenderness ratios are known, the allowable

axial stress may be determined. Step columns are

generally provided for installation of a crane girder

at the step. This will result in a bending moment

which will produce a moment acting on the upper

and lower shafts. The bending moment from the

upper and lower shafts may then be determined by

simple statics. After the bending stress is determined, one could the apply AISC interaction equations for selecting the column size.

Michael A. Morgan, P.E.

BE&K Engineering, Inc.

Birmingham, Alabama

via email

Modern Steel Construction / September 1997/ 9

S TEE L

N T ERe HAN G E

How is a welded double angle connection

designed when the double angles are connected to the flange of the column and welded on the back side of the double angles? See

figure. This may be necessary when the column flange is short.

he design of

T

doubleangle connec-

tions

using

"back-side"

welds is no different

than

',using

" when

conventionally

placed welds .

In fact, "backside"

flare

bevel welds are

quite common

_~v

in HSS (hollow

structural section) construction. The AISC connection tables can be used as

these take into account weld eccentricities on the

angle legs connected to the column. But, do not

attempt to make top returns on the vertical welds

as this may result in notches in the column flange

edges.

If one needs to avoid a "back-side" weld, one can

use angles with shorter legs such as a 3-112 x 2-112

and use the normal weld placement. If this won't

work, another connection such as a shear plate

could be used.

David T. Ricker, P.E.

Payson,AZ

....

or wide flange beam, with padeyes top and

bottom at both ends. The lifting wire rope

bridle with two legs at about a 45 degree

angel attaches to the top padeyes and the

supported weight attaches to the bottom

padeyes. (see sketch)

,.

New Questions

Listed below are questions that we would like the

readers to answer or discuss.

If you have an answer or suggestion please send it to

the Steel Interchange Editor, Modern Steel Construction,

One East Wacker Dr., Suite 3100, Chicago, IL

60601-2001. Questions can also be sent via e-mail to newman@aiscmail.com.

Questions and responses will be printed in future editions of Steel Interchange. Also, if you have a question or

problem that readers might help solve, send these to the

Steel Interchange Editor.

A variation of the lifting beam question.

A typical lifting beam or strongback in the

materials handling, crane and rigging industry take the form of either a horizontal pipe

10 / Modern Steel Construction / September 1997

The wire rope bridle induces both compression and bending moment in the lifting

beam. Again there is no lateral support.

What analysis would be used to solve for

the safe lifting capacity of this form of lifting

beam?

R. McCardell

Harbor Design Engineers

What is the procedure for designing a hole

for piping in a simply supported steel beam?

Are there special details?

Charles J. Collins, Jr.

Charles J. Collins, Jr./Architect

Medford,NJ

How does the AISC Code of Standard

Practice address the possible tolerance for

vertical and horizontal alignment of crane

rail in a mill type building?

Dan A. Torrence

United Steel Erectors

Houston, TX

What size mig wire is considered structurally acceptable or comparable to an E70XX

specification? Is there a solid wire that is

acceptable? With what gas? Can the penetration and weld properties be equivalent to

arc welding with, say, an E7018 rod?

Tim Quinn

Quinn Steel Services

E. Stroudsburg, PA

via email

You might also like

- Tee L Nterc A G: Ses Evio SDocument2 pagesTee L Nterc A G: Ses Evio Sfarhadmrt6923No ratings yet

- Penetration Into The Base Metal: If You'Ve Ever Asked Yourself "Why?"Document2 pagesPenetration Into The Base Metal: If You'Ve Ever Asked Yourself "Why?"Ganesh AdityaNo ratings yet

- July11 Si Web PDFDocument2 pagesJuly11 Si Web PDFmaxeytm_839061685No ratings yet

- Silicon Steel Coatings For Faying Surfaces: WWW - Maine.gov/mdot/nepcoatDocument2 pagesSilicon Steel Coatings For Faying Surfaces: WWW - Maine.gov/mdot/nepcoatdongxiaoNo ratings yet

- Si 12 2011 PDFDocument2 pagesSi 12 2011 PDFHectorNo ratings yet

- Dec11 Si PDFDocument2 pagesDec11 Si PDFspaceheaterNo ratings yet

- Steel Interchange: How To Specify AESS Gusset Plate DesignDocument2 pagesSteel Interchange: How To Specify AESS Gusset Plate Designhector diazNo ratings yet

- Extended End-Plate Stiffener Torsional and Flexural-Torsional BucklingDocument2 pagesExtended End-Plate Stiffener Torsional and Flexural-Torsional BucklingsteelageNo ratings yet

- Selecting Steel Joists and Joist GirdersDocument5 pagesSelecting Steel Joists and Joist GirdersHyunkyoun JinNo ratings yet

- Meet The Experts - Steel JoistsDocument2 pagesMeet The Experts - Steel Joistsseth_gzbNo ratings yet

- Steel Interchange: Stability of Beams During Erection Fire Rating of Concrete-Filled HSS MembersDocument2 pagesSteel Interchange: Stability of Beams During Erection Fire Rating of Concrete-Filled HSS Membershector diazNo ratings yet

- Steel Interchange: Design tips for cantilever beamsDocument2 pagesSteel Interchange: Design tips for cantilever beamsapirakqNo ratings yet

- Anchor Rods and Base Plates ExplainedDocument3 pagesAnchor Rods and Base Plates Explainedpenneng0% (2)

- Design Guide For Cold-Formed Steel TrussesDocument22 pagesDesign Guide For Cold-Formed Steel Trusseseng_ali_khalafNo ratings yet

- Galvanized Slip-Critical ConnectionsDocument2 pagesGalvanized Slip-Critical Connectionsaams_sNo ratings yet

- Unit 3Document29 pagesUnit 3ashok Pradhan100% (1)

- 2010v06 Interchange PDFDocument2 pages2010v06 Interchange PDFspaceheaterNo ratings yet

- QuizDocument2 pagesQuizMamu ToothNo ratings yet

- Anchor Rod Edge DistanceDocument2 pagesAnchor Rod Edge Distancewudongxiao3953No ratings yet

- Unit - Iii: Srividya College of Engineering and Technology Question BankDocument8 pagesUnit - Iii: Srividya College of Engineering and Technology Question BankAravindNo ratings yet

- Chapter I of The LRFD SpecificationDocument6 pagesChapter I of The LRFD Specificationmn4webNo ratings yet

- Si 08 2012 PDFDocument2 pagesSi 08 2012 PDFhector diazNo ratings yet

- Shear Wall - Seismic Provisions-To BSSC May 29, 2002Document9 pagesShear Wall - Seismic Provisions-To BSSC May 29, 2002Tear Drops WomackNo ratings yet

- MSC Web Sidesway BucklingDocument2 pagesMSC Web Sidesway BucklingAlaym AguilarNo ratings yet

- Deep Xcav Waler Beams Theory ManDocument30 pagesDeep Xcav Waler Beams Theory Manharicv019100% (1)

- HSS Article LimitState Plastification 0718 060120Document3 pagesHSS Article LimitState Plastification 0718 060120clam2014No ratings yet

- Steel Interchange: Drift LimitsDocument2 pagesSteel Interchange: Drift Limitsmaxeytm_839061685No ratings yet

- EFFICIENT USE OF STEEL JOISTSDocument9 pagesEFFICIENT USE OF STEEL JOISTSinsane88No ratings yet

- CRSI The Designer's ResponsibilityDocument16 pagesCRSI The Designer's ResponsibilityAdam Jones100% (1)

- Felxural Strength of A Box Section PDFDocument2 pagesFelxural Strength of A Box Section PDFaams_sNo ratings yet

- CE/CS/CR/CV Steel Structure Design CourseDocument5 pagesCE/CS/CR/CV Steel Structure Design CourseShajit Kumar0% (1)

- Biaxial Bending of Steel Angle Section PDFDocument3 pagesBiaxial Bending of Steel Angle Section PDFImam NakhrowiNo ratings yet

- Soi Etionscenfer: From AssociationDocument2 pagesSoi Etionscenfer: From AssociationLleiLleiNo ratings yet

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Document2 pagesSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Andres CasadoNo ratings yet

- Axial Capacities of Eccentrically Loaded Equal-Leg Single Angles - Comparisons of Various Design MethodsDocument38 pagesAxial Capacities of Eccentrically Loaded Equal-Leg Single Angles - Comparisons of Various Design MethodsAnonymous 7MdZQn1100% (1)

- Restrained Beam Astm A307 Bolts: If You'Ve Ever Asked Yourself "Why?"Document2 pagesRestrained Beam Astm A307 Bolts: If You'Ve Ever Asked Yourself "Why?"gv Sathishkumar KumarNo ratings yet

- RC Column Confinement Reinforcement DesignDocument9 pagesRC Column Confinement Reinforcement DesignfdafaNo ratings yet

- Cantilevered Hung FramesDocument43 pagesCantilevered Hung FramesG-off Robson100% (1)

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Document2 pagesSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Andres CasadoNo ratings yet

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Document2 pagesSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Andres CasadoNo ratings yet

- Steel Interchange: Welding Steel Deck Fatigue DesignDocument2 pagesSteel Interchange: Welding Steel Deck Fatigue Designhector diazNo ratings yet

- Base-Plate Calculation Under Tension.: ArticleDocument24 pagesBase-Plate Calculation Under Tension.: ArticlePanos SpNo ratings yet

- 98 Tips: For DesigningDocument6 pages98 Tips: For DesigningKarthikeyan KrishNo ratings yet

- Steel Interchange: Stiffened Seated Connection Strength Eccentrically Loaded Bolt GroupsDocument2 pagesSteel Interchange: Stiffened Seated Connection Strength Eccentrically Loaded Bolt GroupsHectorNo ratings yet

- Analytical Approach of Anchor Rod Stiffness and Steel Base-Plate Calculation Under TensionDocument24 pagesAnalytical Approach of Anchor Rod Stiffness and Steel Base-Plate Calculation Under TensionAmin AskariNo ratings yet

- Multistoreyed BLDGDocument89 pagesMultistoreyed BLDGsohanpmeharwadeNo ratings yet

- Bolted Beam Column ConnectionsDocument16 pagesBolted Beam Column Connectionslael00No ratings yet

- 2012 10 Application of Axial Loads in Connection DesignsDocument7 pages2012 10 Application of Axial Loads in Connection DesignsDak KaizNo ratings yet

- Pipe Rack DesignDocument3 pagesPipe Rack DesignBalamuruganNo ratings yet

- Clase Dise o Anclajes PDFDocument59 pagesClase Dise o Anclajes PDFFran Barrera AlbornozNo ratings yet

- Design and Detailing of Seismic Connections For Braced Frame StructuresDocument19 pagesDesign and Detailing of Seismic Connections For Braced Frame StructuresDavid SantiagoNo ratings yet

- SH Wall ProvisionsDocument8 pagesSH Wall Provisionsgifofic219No ratings yet

- Steel QuizDocument2 pagesSteel Quizmuh2006No ratings yet

- A Practical Method of Design of Concrete Pedestals For Columns For Anchor Rod Tension BreakoutDocument17 pagesA Practical Method of Design of Concrete Pedestals For Columns For Anchor Rod Tension Breakoutjohn blackNo ratings yet

- REINFORCING STEEL FOR CONCRETEDocument8 pagesREINFORCING STEEL FOR CONCRETEPrittam Kumar JenaNo ratings yet

- AISC Steel Construction Manual 6th Edition.Document780 pagesAISC Steel Construction Manual 6th Edition.Ayk Altuntopian83% (6)

- BrowseDocument133 pagesBrowseyared destaNo ratings yet

- SESOC AnchorBolts PDFDocument33 pagesSESOC AnchorBolts PDFDivesh rahulNo ratings yet

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Some Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910From EverandSome Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910No ratings yet

- 1999v03 Si WebDocument2 pages1999v03 Si WebAashifCairoNo ratings yet

- 2001v10 Si Web PDFDocument2 pages2001v10 Si Web PDFAashifCairoNo ratings yet

- Compression MembersDocument2 pagesCompression MemberssarahbstNo ratings yet

- Astm A992Document2 pagesAstm A992Harley Ilave IlaveNo ratings yet

- SWDocument1 pageSWAashifCairoNo ratings yet

- Yoga FullDocument33 pagesYoga FullAashifCairoNo ratings yet

- UTK Elevator Design CriteriaDocument60 pagesUTK Elevator Design Criteriamishraengg100% (1)

- Astm A992Document2 pagesAstm A992Harley Ilave IlaveNo ratings yet

- Astm A992Document2 pagesAstm A992Harley Ilave IlaveNo ratings yet

- Structural Engineering 2Document31 pagesStructural Engineering 2sm_jdsNo ratings yet

- Gate Paper Last YearDocument19 pagesGate Paper Last YearSandeep VermaNo ratings yet

- Aptitude FormulasDocument16 pagesAptitude FormulasAashifCairoNo ratings yet

- CPWD Manual 2014Document480 pagesCPWD Manual 2014Kiran N S Gowda100% (1)

- Form 6 TamilDocument7 pagesForm 6 Tamilapi-276452640No ratings yet

- Delhi Schedule of Rates Civil - 2014Document452 pagesDelhi Schedule of Rates Civil - 2014Jaisree Balu Pydi83% (12)

- Pipe Stress Engineering (PDFDrive) 3Document1 pagePipe Stress Engineering (PDFDrive) 3Darshan PanchalNo ratings yet

- Method Statement - ASPHALT CONCRETE WORKS PDFDocument10 pagesMethod Statement - ASPHALT CONCRETE WORKS PDFTAHER AMMAR100% (6)

- Mat UrbanismDocument11 pagesMat UrbanismBadr ZeinaNo ratings yet

- Fly OverDocument29 pagesFly OverUrvisha Butani100% (1)

- Technobond Insulation BRANZ Appraisl No 693 Ceiling and Wall PDFDocument5 pagesTechnobond Insulation BRANZ Appraisl No 693 Ceiling and Wall PDFJohn SmithNo ratings yet

- Yanmar - 3tna72lDocument194 pagesYanmar - 3tna72lTiago Campos100% (1)

- Summary of Changes ASME BPVC - Ii.dDocument16 pagesSummary of Changes ASME BPVC - Ii.dAnonymous xr4GVHNo ratings yet

- Shaft and Raise Boring MachinesDocument13 pagesShaft and Raise Boring MachineshidayahNo ratings yet

- Structural Notes and DetailsDocument1 pageStructural Notes and DetailsMohammad AlkahteebNo ratings yet

- T-ZED Homes, Whitefield, BengaluruDocument5 pagesT-ZED Homes, Whitefield, BengaluruHello ShraaNo ratings yet

- VIBR.ROLLER DRUM PARTS LIST BW 212-2Document9 pagesVIBR.ROLLER DRUM PARTS LIST BW 212-2Nidya Wardah JuhanaNo ratings yet

- 4 Design of Slab Bridges PDFDocument6 pages4 Design of Slab Bridges PDFsohanpmeharwadeNo ratings yet

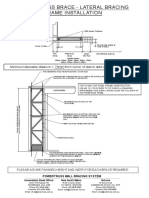

- PT Brace Installation 1Document1 pagePT Brace Installation 1Tony PedaNo ratings yet

- PDS - SikaWrap FX-50 C-En PDFDocument3 pagesPDS - SikaWrap FX-50 C-En PDFjohanes b mudaNo ratings yet

- VILLA 430: Hyderabad, TelanganaDocument27 pagesVILLA 430: Hyderabad, TelanganaH A I K U S T U D I ONo ratings yet

- Ots GRSH 250 00Document6 pagesOts GRSH 250 00ABC - Angela GomezNo ratings yet

- Piping HandbookDocument78 pagesPiping HandbookAurinho9292% (12)

- 04.new Liquid Overflow Handling System To Prevent Process Tank FiresDocument14 pages04.new Liquid Overflow Handling System To Prevent Process Tank FiresHerry SuhartomoNo ratings yet

- Iec 60287 Grouping TableDocument2 pagesIec 60287 Grouping TableAnas Yousuf100% (1)

- Bike Camper Plans by DrewBuildsStuff v2 5-30-22Document6 pagesBike Camper Plans by DrewBuildsStuff v2 5-30-22Márcio GhrollNo ratings yet

- BARE COPPER CONDUCTOR SPECIFICATIONSDocument1 pageBARE COPPER CONDUCTOR SPECIFICATIONSIan de GaliciaNo ratings yet

- Piping Layout: Philosophy of Yard PipingDocument11 pagesPiping Layout: Philosophy of Yard PipingdasubhaiNo ratings yet

- Mahaweli Water Security Investment Program Site EstablishmentDocument26 pagesMahaweli Water Security Investment Program Site EstablishmentAmila Priyadarshana DissanayakeNo ratings yet

- Silt Control GuideDocument32 pagesSilt Control GuidePcEngNo ratings yet

- h06962 Chemical Injection SystemDocument1 pageh06962 Chemical Injection SystemkirankirkNo ratings yet

- Plaxis: Computational Geotechnics Course (2D Plaxis Course)Document2 pagesPlaxis: Computational Geotechnics Course (2D Plaxis Course)Fajar Adi NugrohoNo ratings yet

- Repair Concrete StructuresDocument3 pagesRepair Concrete StructuresSindhe SwethaNo ratings yet

- NBC107 Fire SafetyDocument10 pagesNBC107 Fire SafetyManoj Paudel0% (1)

- 0.12 M, 0.36 M, and The Depth of The FoundationDocument1 page0.12 M, 0.36 M, and The Depth of The FoundationMomen AdilNo ratings yet

- Portfolio 2013Document29 pagesPortfolio 2013mucupNo ratings yet