Professional Documents

Culture Documents

Guidance To Prepare WPS-PQR For Welding

Uploaded by

Saran KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Guidance To Prepare WPS-PQR For Welding

Uploaded by

Saran KumarCopyright:

Available Formats

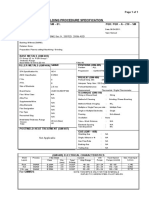

WPSPQR

1 WPS-Welding Procedure is the Procedure, in written format, by the Fabricator/Manufacturer, giving

details about base metal

metal, welding groove

groove, filler metals and instructions that are followed in the

welding, to make good and quality welding, Code: ASME Sec IX, AWS D.1.1, API1104

2 Welding is done, following the Procedure(WPS)

3 The welded piece(originally, in the form of plate or pipe) is cut into test speciments/test coupens.

4 PQR-These test specimens are tested in the Lab(for mechanical and metallurgical tests, visual test) and

the welding parameters (during actual welding, PWHT etc ) and test results are recorded.

Reason to have many WPS: One WPS is made to meet a set of specific welding parameters. If we change the parameters,

then we check, whether the parameter is essential or non essential variable. If it is essential variable, then new WPS is

prepared Each WPS should have their specimen tested and PQR is made for that WPS

prepared.

WPS. So

So, each WPS has its own PQR

PQR. If it

is non essential, variable, then , no need to make a new WPS and qualification(sometime, WPS alone, need amended). ASME

Sec IX, gives the QW-XXX reference numbers, on the sample WPS-PQR, so that we can find whether the data is essential

variable or not.

If the PQR meets the test acceptance criteria, then the WPS is said , as, WPS is qualified.

Steps to make WPS:

Study

y the P.O.,

Product

Prepare list of WPS

Prepare Weld Map

References & Approval Codes to

prepare WPS & PQR:

Prepare WPS

(before welding)

ASME Sec IX (most common)

AWS D1.1 (for Structures)

Welding

Cut the test piece into

Test Specimen/ Test

coupen

Prepare additional

Coupens & test . Or

change the weld

parameters in WPS

and retest.

Lab Testing

API 1104 (for Country Pipelines)

Test is not ok. WPS

Rejected

Prepare PQR

. Evaluate the results.

WPS:

Aim:

To have good and quality weld

To pass the test and to get WPS qualified.

Preparation for WPS:

1 Reporting Forms: Select the code for approval &

select the sample form from the Code

2 Forms can also be selected from Lincon Electric

WPS and from other people who had already

approved WPS

3 Vendors are also preparing detailed step by step

WPS, with good practices to produce quality welds.

4 Collect welding parameter details:

Base metal: Plate or Pipe(for testing), from rolled/

forged/ cast/ extruded form & its spec.

Results are

satisfactory & Test is

Ok and WPS is

qualified

PQR

Welding

1 List/ record the

parameters during

welding, PWHT etc

and record the test

results

2 Evaluate the rest

results and certify

whether the test had

passed and if so,

declare WPS is

qualified

Weld metal: Welding Process(SMAW/GTAW/SAW

etc) /Filler/welding practices

Welder: Already has some basic welding experience

& some qualification

Prepared by: Annamalai-JGC

You might also like

- Quick Guide To Welding Procedure Qualification (WPS & PQR)Document5 pagesQuick Guide To Welding Procedure Qualification (WPS & PQR)Annamalai Ram JGCNo ratings yet

- Presentation Asme Sec Ix Wps PQR WPQDocument177 pagesPresentation Asme Sec Ix Wps PQR WPQsiva92% (26)

- Welder Qualification Procedure PDFDocument13 pagesWelder Qualification Procedure PDFEngineersEDGE Coimbatore0% (1)

- WPS & PQRDocument84 pagesWPS & PQRjoseph.maquez24100% (4)

- Multiple PQR QualificationDocument4 pagesMultiple PQR QualificationKarthikeyan ShanmugavelNo ratings yet

- Steps of Making WPSDocument51 pagesSteps of Making WPSDavid Macatangay100% (7)

- PQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpDocument1 pagePQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpSatish KeskarNo ratings yet

- ASME BPVC.IX performance thickness limitsDocument1 pageASME BPVC.IX performance thickness limitskumar100% (2)

- WPS Asme IxDocument4 pagesWPS Asme Ixjcarlosherrerac7100% (1)

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- Welding Procedure Specification: Page 1 of 1Document2 pagesWelding Procedure Specification: Page 1 of 1Anderson Perez MartinezNo ratings yet

- Visual Weld InspectionDocument7 pagesVisual Weld InspectioninsiderrNo ratings yet

- Wps p91 - BhelDocument2 pagesWps p91 - BhelAshish Gupta100% (4)

- Asme PQRDocument4 pagesAsme PQRHong Dae Yoon100% (2)

- Draft WPSDocument32 pagesDraft WPSAnilkumar G NairNo ratings yet

- WPS PQRDocument23 pagesWPS PQRHashim Khan88% (8)

- Welder Certification ProcedureDocument28 pagesWelder Certification ProcedureAnant Rubade100% (1)

- How To Read PWHTchartDocument10 pagesHow To Read PWHTchartAkhilesh Kumar100% (2)

- Electrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedureDocument2 pagesElectrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedurePrashant Puri100% (1)

- Approved Welding Procedures List RegioDocument2 pagesApproved Welding Procedures List Regiogabriel__regio100% (1)

- WPS-PQR (Er309l Mo)Document4 pagesWPS-PQR (Er309l Mo)Hamza Nouman0% (1)

- Weld Visual ExaminationDocument11 pagesWeld Visual ExaminationAnonymous hBBam1n100% (3)

- WPS, PQR, WPQ (Si007)Document5 pagesWPS, PQR, WPQ (Si007)Suresh RathodNo ratings yet

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Document20 pagesWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- Welder'S Work Record Log Sheet Welder's Name: S.M.W. Membership#Document1 pageWelder'S Work Record Log Sheet Welder's Name: S.M.W. Membership#satnamNo ratings yet

- Welding Procedures and Welders QualificationDocument41 pagesWelding Procedures and Welders QualificationDhayalan Nethiranantham100% (14)

- WPS E6013+e7018Document2 pagesWPS E6013+e7018Anvesh Vaddi100% (1)

- Welding Table WPS & PQR Check List (Sheet, 2 Pages)Document2 pagesWelding Table WPS & PQR Check List (Sheet, 2 Pages)abomanar100486375% (4)

- WPS For Structure Mild Steel Fillet Weld PDFDocument2 pagesWPS For Structure Mild Steel Fillet Weld PDFHarshit AdwaniNo ratings yet

- Welder Qualification Tests WQT DL QC 001 2019Document24 pagesWelder Qualification Tests WQT DL QC 001 2019adelNo ratings yet

- Welding Consumable and Storage ProcedureDocument10 pagesWelding Consumable and Storage Procedurehasan_676489616100% (1)

- WPQT FormatDocument176 pagesWPQT FormatRafiqKu50% (2)

- Guidance To Prepare Wps PQR For WeldingDocument1 pageGuidance To Prepare Wps PQR For WeldingHamid MansouriNo ratings yet

- WpsDocument39 pagesWpsAkhilesh Kumar100% (1)

- Section IX WeldingDocument6 pagesSection IX WeldingAhmedNo ratings yet

- 07 Apr 2020 - WPS PQRDocument17 pages07 Apr 2020 - WPS PQRBrijesh KumarNo ratings yet

- WPS & PQR - 2021Document82 pagesWPS & PQR - 2021Subramanian RNo ratings yet

- Qualification Checklists For WPS PQR - Welding AnswersDocument7 pagesQualification Checklists For WPS PQR - Welding Answersedwin100% (2)

- Qualification Checklists For WPS PQR - Welding AnswersDocument7 pagesQualification Checklists For WPS PQR - Welding AnswersIbe ChinonsoNo ratings yet

- ASME Sec IX Welding Qualification GuideDocument176 pagesASME Sec IX Welding Qualification GuideUtkarsh GautamNo ratings yet

- 1 Qualified Welding Procedure Specifications: GeneralDocument15 pages1 Qualified Welding Procedure Specifications: GeneralAlaaNo ratings yet

- Inspection GuidelinesDocument67 pagesInspection GuidelinesMohammed Amjad Ali67% (3)

- Fab 04 WPS, WPQR, Welder Qualification, Welding Positions, Defect - Repair WeldingDocument39 pagesFab 04 WPS, WPQR, Welder Qualification, Welding Positions, Defect - Repair WeldingRaghu vamshiNo ratings yet

- I Can Do That WPS'S, PQR's and WQ'sDocument93 pagesI Can Do That WPS'S, PQR's and WQ'sKo NSNo ratings yet

- Procedure Qualification Record PQRDocument6 pagesProcedure Qualification Record PQRMR ANo ratings yet

- Welder and Procedure QualificationDocument25 pagesWelder and Procedure QualificationRamón G. Pacheco100% (3)

- 6 Welding Procedure Qualification & Welder QualificationDocument15 pages6 Welding Procedure Qualification & Welder QualificationSampath KumarNo ratings yet

- Introduction Wps and PQRDocument4 pagesIntroduction Wps and PQRdhasdj100% (1)

- Understanding WPS, PQR, WPQRDocument4 pagesUnderstanding WPS, PQR, WPQRYousef Adel HassanenNo ratings yet

- WPS Understanding: By: Eng. Mohamed Farouk BayomiDocument11 pagesWPS Understanding: By: Eng. Mohamed Farouk BayominwohaNo ratings yet

- Lloyd's Register Welding Procedure & Welder Qualification Review RP - tcm240-236457 PDFDocument30 pagesLloyd's Register Welding Procedure & Welder Qualification Review RP - tcm240-236457 PDFjos22231No ratings yet

- Lloyd's Register Welding Procedure & Welder Qualification Review RP - tcm240-236457Document30 pagesLloyd's Register Welding Procedure & Welder Qualification Review RP - tcm240-236457Navneet Singh100% (2)

- Shortcut To A WPSDocument18 pagesShortcut To A WPSCepi Sindang Kamulan100% (1)

- Welding Procedure SpecificationDocument1 pageWelding Procedure Specificationfallalovaldes100% (1)

- Welding Procedure: Job KnowledgeDocument4 pagesWelding Procedure: Job KnowledgeMuhammed SulfeekNo ratings yet

- Differences between Welding Procedure Specification and Welder Performance QualificationDocument1 pageDifferences between Welding Procedure Specification and Welder Performance QualificationFazeel Rick MohammedNo ratings yet

- TÜV SÜD South Asia Training Program on ASME Sec IX Welding Procedures and Welder QualificationDocument177 pagesTÜV SÜD South Asia Training Program on ASME Sec IX Welding Procedures and Welder QualificationM A67% (3)

- 1.1 Welding Procedure Specification (WPS)Document35 pages1.1 Welding Procedure Specification (WPS)Mohamed WahidNo ratings yet

- Welding QDocument33 pagesWelding QBurapha Malutphanth100% (1)

- Summary Sheet On FlexipayDocument1 pageSummary Sheet On FlexipaySaran KumarNo ratings yet

- Benefit Booklet - FinalDocument18 pagesBenefit Booklet - FinalSaran KumarNo ratings yet

- AustenDocument2 pagesAustenSaran KumarNo ratings yet

- Anatomic Therapy English NewDocument364 pagesAnatomic Therapy English Newrupesh1000No ratings yet

- Damage Mechanisms For API 653Document10 pagesDamage Mechanisms For API 653Saran KumarNo ratings yet

- ASNT Announcement PDFDocument4 pagesASNT Announcement PDFSaran KumarNo ratings yet

- HerbocareDocument1 pageHerbocareSaran KumarNo ratings yet

- WPS Variables for SMAW, SAW, GTAWDocument12 pagesWPS Variables for SMAW, SAW, GTAWSaran KumarNo ratings yet

- Bcpl-Detailed Advt 4 2010Document12 pagesBcpl-Detailed Advt 4 2010karthik_iitNo ratings yet

- Announcement Level 3Document4 pagesAnnouncement Level 3Saran KumarNo ratings yet

- US Wall Chart REV 06 2011Document2 pagesUS Wall Chart REV 06 20111DB7Li51Q2cZMNo ratings yet

- Anatomic Therapy English NewDocument364 pagesAnatomic Therapy English Newrupesh1000No ratings yet

- Defects in WeldsDocument6 pagesDefects in WeldsSaran KumarNo ratings yet

- Summary ISO TR 15608 Metallic Materials Grouping SystemDocument4 pagesSummary ISO TR 15608 Metallic Materials Grouping SystemV SwamiNo ratings yet

- QC EnggDocument4 pagesQC EnggSaran KumarNo ratings yet

- TPM How It Can WorkDocument55 pagesTPM How It Can WorkBathuka ChukaNo ratings yet

- Keyboard SettingDocument10 pagesKeyboard SettingDiayana Amirah Mohd RadinNo ratings yet

- Asme Sec Ix, Wps-Welding Variables and Data (Smaw-Saw-Gtaw)Document7 pagesAsme Sec Ix, Wps-Welding Variables and Data (Smaw-Saw-Gtaw)Saran Kumar100% (1)

- Steel Welding PDFDocument21 pagesSteel Welding PDFcharzreeNo ratings yet

- Defect PercentageDocument4 pagesDefect PercentageSaran KumarNo ratings yet

- Introduction To Stainless SteelDocument2 pagesIntroduction To Stainless SteelSushil KumarNo ratings yet

- Keyboard SettingDocument10 pagesKeyboard SettingDiayana Amirah Mohd RadinNo ratings yet

- SSDocument4 pagesSSSaran KumarNo ratings yet

- Basic Metallurgy Guide for Non-MetallurgistsDocument9 pagesBasic Metallurgy Guide for Non-MetallurgistsSaran KumarNo ratings yet

- Basic Metallurgy Guide for Non-MetallurgistsDocument9 pagesBasic Metallurgy Guide for Non-MetallurgistsSaran KumarNo ratings yet

- Kra 12-13Document9 pagesKra 12-13Saran KumarNo ratings yet

- CHBE 213 CH 9 Phase Diagrams - 6Document12 pagesCHBE 213 CH 9 Phase Diagrams - 6Saran KumarNo ratings yet

- Aws ChartDocument3 pagesAws ChartSaran KumarNo ratings yet

- Basic Functions QCDocument6 pagesBasic Functions QCSaran KumarNo ratings yet

- 7 1 CarrefourDocument4 pages7 1 CarrefourRoxana RobuNo ratings yet

- Fire Brick - Wikipedia, The Free EncyclopediaDocument2 pagesFire Brick - Wikipedia, The Free EncyclopediareaktorenergiNo ratings yet

- PMBOK Chapter 7 - QualityDocument30 pagesPMBOK Chapter 7 - QualitylatehoursNo ratings yet

- ZARA PresentationDocument17 pagesZARA PresentationMuhammad NaveedNo ratings yet

- Grungeboard Surfaces: by Sue BleiweissDocument2 pagesGrungeboard Surfaces: by Sue BleiweissLogan MckeeNo ratings yet

- Cladding Report-Version 3 (Print Out)Document31 pagesCladding Report-Version 3 (Print Out)Henry NgNo ratings yet

- CONCRETE TECHNOLOGY DEVELOPMENTSDocument20 pagesCONCRETE TECHNOLOGY DEVELOPMENTSvpmohammed100% (1)

- Book of Spindles Part 2 PDFDocument44 pagesBook of Spindles Part 2 PDFnirmalmthp100% (1)

- Rittal Drawing Format Criteria for Quoting and ManufacturingDocument1 pageRittal Drawing Format Criteria for Quoting and ManufacturingsamoweidaNo ratings yet

- PB Uddeholm Sverker 21 EnglishDocument12 pagesPB Uddeholm Sverker 21 EnglishulfwisenNo ratings yet

- Material Handling and Storage Safety GuideDocument21 pagesMaterial Handling and Storage Safety Guideabdullah amanullahNo ratings yet

- Analysis of Short Run Cost of ProductionDocument12 pagesAnalysis of Short Run Cost of ProductionPrince KumarNo ratings yet

- The Defence Industry BlueprintDocument95 pagesThe Defence Industry BlueprintKhairol Nizam80% (5)

- Flux Cored Wires (Elga) PDFDocument15 pagesFlux Cored Wires (Elga) PDFVladan TimotijevicNo ratings yet

- Cutting Force of End Cutting Tool Milling MachiningDocument24 pagesCutting Force of End Cutting Tool Milling MachiningGabryel BogdanNo ratings yet

- Welding Process Work InstructionDocument6 pagesWelding Process Work InstructionmkcsekarNo ratings yet

- 3 Bumax Inox Classe 88 Et 109Document4 pages3 Bumax Inox Classe 88 Et 109grouhNo ratings yet

- Project On Logistics Management: Name: Suresh Marimuthu Roll No.: 520964937 LC Code: 3078Document147 pagesProject On Logistics Management: Name: Suresh Marimuthu Roll No.: 520964937 LC Code: 3078awaisjinnahNo ratings yet

- FMEA Arc WeldingDocument4 pagesFMEA Arc WeldingGODHOT_69No ratings yet

- Project Management for Construction: Understanding the Owners' PerspectiveDocument21 pagesProject Management for Construction: Understanding the Owners' PerspectivePrem Kumar DharmarajNo ratings yet

- Quality Risk Management PharmDocument9 pagesQuality Risk Management Pharmagarciah15891No ratings yet

- Destin Brass Costing ProjectDocument2 pagesDestin Brass Costing ProjectNitish Bhardwaj100% (1)

- Case example: Inventory control system automates trading company operationsDocument2 pagesCase example: Inventory control system automates trading company operationslekhanh_y2kNo ratings yet

- Nandan Petrochem LTD - Company ProfileDocument12 pagesNandan Petrochem LTD - Company ProfileNandan Petrochem LtdNo ratings yet

- Lathe MachineDocument34 pagesLathe MachineVaibhav Vithoba Naik100% (1)

- 01 SAP OverviewDocument41 pages01 SAP OverviewKushal Varshney50% (2)

- ASA LI941 Injection Molding Grade for Automotive Radiator GrillsDocument2 pagesASA LI941 Injection Molding Grade for Automotive Radiator Grillsjitendertalwar1603No ratings yet

- Walworth Safety Steel Catalog2012 1Document76 pagesWalworth Safety Steel Catalog2012 1rasko65No ratings yet

- BeoSound 1 Service GuideDocument89 pagesBeoSound 1 Service GuideOmar Contreras NavaNo ratings yet

- Wire AbbreviationsDocument6 pagesWire Abbreviationssarat chandNo ratings yet