Professional Documents

Culture Documents

JHA For Cable Laying, Cable Glanding and Termination

Uploaded by

Francis Enriquez TanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JHA For Cable Laying, Cable Glanding and Termination

Uploaded by

Francis Enriquez TanCopyright:

Available Formats

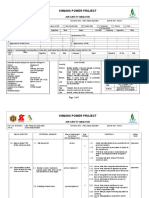

QP Ref.

: IP-OPS-066

JOB HAZARD ANALYSIS Rev.:A1

Date.: Dec. -2014

Page.: 1 of 10

ATTACHMENT C TYPICAL JHA FORM

JHA No.:GC- Revision Area RG PLANT Job Location: 92,93,94,95,96,97 Date:

14113600/0 : & MCR

No.:

Job Ref (Project No. / Work

Hazardous Area Classification: Zone 0 , Zone 1 , Zone 2 , Non

Order No.:

Hazardous

GC-14113600

Job Description : cable laying, cable glanding and termination Permit Type& No.:

Risk

Residu

Rating Action

Activity (Job al Risk

S/N Potential Hazard Before Control Mitigation Measures Party /

Steps) /

Mitigati Remark

Rating

on

1 Work permit from Unauthorized 3 X B= Authorized PTW holder shall ensure 1 X B= Engineer /

QP to be commencement of Medium Low Supervisor

obtaining and maintaining valid work

works may result in

obtained exposing workers permit. and Safety

and or potential to The worksite supervisor responsible for this Officer

harm or danger. activity has to check the PPE of his staff to

ensure that all required items are

available and properly used.

Inform all workers regarding permit

condition before work starts. Worksite

supervisor shall conduct toolbox talks

about nature of works and associated

potential hazards and their essential

precautionary measure.

JHA No. GC-14113600/0 Page 1 of 10

2 Pre-task briefing The work force does 3 X B= Ensure that the pre task briefing is given 1 X B= Engineer /

toolbox talks and not understand the Medium out in a language understood by the work Low Supervisor

pre task briefing

site inspection therefore does not force, have it translated. and Safety

understand the Ask question regarding the briefing to get Officer

potential dangers feedback from the staff, this ensures full

and control comprehension.

measures to be

implemented. Some Issue required appropriate PPE and

of the workers could replace PPE that has signs of defect.

be lacking PPE or PPE must include both hearing protection

using defective PPE as well as dust inhalation protection.

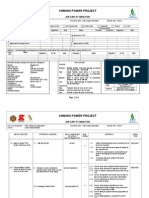

3 Mobilization and Physical injury from 3 X B= Before transporting the loads to the site, 1 X B= Engineer /

demobilization heavy equipment, Medium rest assure that the materials are secured Low Supervisor

heavy lifting, pinch and tight with nylon rope for the safe and Safety

point, slip, trips and transporting. Officer

fall hazards Ensure that a driver is having knowledge to

the hazard while transporting the

materials.

The driver shall not have driving attitude

while using the road.

Driver is driving only in the minimum speed

limit.

Minimize work personnel in the vicinity of

equipment.

Provide ergonomic training, institute good

housekeeping procedure.

Keep feet and hands clear of

moving/suspended materials and

equipment.

Keep a tidy site.

4 Ensure all staff Incorrect PPE given 3 X B= The supervisor responsible for this activity 1 X B= Engineer /

involved in this out or failure to Medium has to check the PPE of his staff to ensure Low Supervisor,

activity has the provide required PPE all required items are available and Safety

correct PPE and

Staffs are not correctly used. Officer,

JHA No. GC-14113600/0 Page 2 of 10

have receive the adequately briefed The supervisor with the assistance of the Technician

pre start on the activity, the safety officer shall give a pre start briefing and Helper

briefing risks or the to all staff involved pointing out the job

emergency steps and how they will be conducted

procedures leading

to increased risk of

incident

If staff is not The supervisor with the assistance of the Engineer /

adequately briefed HSE officer shall give Tool box talk briefing Supervisor,

on the activity, the to all staff involved pointing out the job Safety

risks and the steps and how they will be conducted Officer,

emergency The staff shall be briefed about the Technician

procedures leading emergency procedure, so that they should and Helper

to increased risk of know how to proceed further in case of

incident. any incident during this activity.

5 Travelling Driver without proper 3 X B= Ensure driver has a proper document 1 X B= Engineer /

without documents & gate Medium before travelling with the materials Low Supervisor,

necessary and pass. Apply the proper gate pass for the driver to Safety

essential enter in the Client premises to prevent Officer,

Documents any delay or any discrepancies while Technician

entering to the site. and Helper

6 Transportation Traffic accident, 3 X B= Ensure driver has valid driving license, 1 X B= Engineer /

of cable drums fatalities, serious Medium follow road regulations and courtesy Low Supervisor,

and material to personnel injury, Ensure load material are properly Safety

the site property damage, fastened Officer,

unsecured materials Compliance to the requirements of Technician

on the truck, critical national infrastructure authority and Helper

overloading Drive carefully and within the speed

limit

Be aware of other road users and drive

defensively

Driver and helper have to check loading

of Materials and ensure materials are

JHA No. GC-14113600/0 Page 3 of 10

tired down and secured correct and safe

to travel going to site

Ensure that the truck or equipment is

not over to its capacity

7 Offloading of Failure of lifting 3 X B= Ensure that all lifting appliance and 1 X B= Engineer /

materials at the equipment and Medium accessories have a valid 3rd party Low Supervisor,

site using heavy accessories that will inspection certificate. Safety

equipment. cause of injury to All lifting operation shall be planned in Officer,

the workers and prior to the operation. Technician

property damage. Ensure that lifting accessories are well and Helper

maintained and inspected prior to used.

Use proper tag-lines to guide the heavy

loads.

Use appropriate PPE

Ensure operator and lifting supervisor

have a valid 3rd party certificate and

approved by QP.

8 Cable pulling Serious injury by 3 X B= Be sure that the cable stands are 1 X B= Engineer /

while falling cable drums Medium properly balanced & surface level is Low Supervisor,

the cable places or stud shaft verified by proper and good magnetic Safety

in the cable Injury to hand due of spirit level. Officer,

drums wooden sharp or Prohibit anyone posting nearby cable Technician

sharp nails drums and Helper

Damage of cable Wear appropriate cut resistant gloves

while pulling. Be sure that the cable pulling person

have knowledge or train to pull the

cable

Use proper cable rollers

Exercise proper looping of cables if

necessary

Ensure workers are aware of looping

cables while pulling

JHA No. GC-14113600/0 Page 4 of 10

Take proper precaution to pull cable in

duct.

9 Cable pulling on Inhalation of harmful 3 X B= Use appropriate mask or other required 1 X B= Engineer /

dusty cable tray dust and fumes and Medium PPE. Low Supervisor,

area skin contact. Spray with water to minimize blown Safety

materials (dust suppression) Officer,

Stop work when the weather condition is Technician

not good. and Helper

10 Cable Pulling Falls from ladder or 3 X B= Be sure that the ladders are in proper 1 X B= Engineer /

using ladders or mobile scaffolding Medium position and at least 70 parallel. Low Supervisor,

mobile While working on the 2nd rung, keep 3 Safety

scaffolding as points of contact on the ladder at all Officer,

working times. Technician

platform Ladder should be proper tying by rope or and Helper

properly hold by the workers with buddy

system.

Before use the ladders make sure it is in

good condition.

Take a moment to check a ladder, not a fall.

Check the stiles, rungs, rivets and welding

to make sure that the ladder is not liable

to collapse or twist.

Check the feet, make sure they are clean

and not worn. They must be able to give a

good grip on the surface that is set up on.

Be sure that they inspect by the qualified

scaffolder inspector and green tag should

be attached in the scaffolding itself.

Ensure that a worker has wearing fall body

arrest system.

Ensure that a worker has a 100% tie off the

fall arrest system in a proper anchorage

JHA No. GC-14113600/0 Page 5 of 10

to prevent fall from heights

Check first the fall body arrest system and

dont used defective fall body arrest.

Dont use scaffolding if the scaff tag is red

(DONT USED)

11 Manual Handling Back and shoulder 3 X B= Avoid improper positioning during cable 1 X B= Engineer /

of cable injuries due to Medium pulling/laying works. Low Supervisor,

twisting or lifting Avoid lifting until you have warmed up and Safety

things too far from stretched Officer,

the body. If manual handling is unavoidable, ensure Technician

Shoulder injuries occur operatives involved are trained in basic and Helper

due to lifting things lifting techniques. Selection may be

above the head or required of suitable, fit individuals

moving things depending upon the nature of the task.

repeatedly. Use more than one person if greater than

Lower back and 40 lbs or greater than your capability, or

shoulder strains due the load is awkward

to twisting or over Use your legs to lift not your back

excursion while Use your feet to turn not your waist

pulling or pushing

Keep weight close to the body

things that are too

Use wheel borrow where available and it

heavy or to stuck in

makes sense

place to move easily.

Think through how you are going to lift

Straining a muscle in

the leg, back, or Do not jerk the load

shoulder by being Use your core muscles as much as

thrown off balance. practicable

Injuring knee joints by Keep your fingers and toes out of the way

trying to recover to prevent injuring them

your balance. Maintain good footing and good gripping to

Turning an ankle while prevent un-intended shifts or slips

recovering. Pushing is preferable to pulling

Scrapes and bruises Inspect the travel path or work area for

JHA No. GC-14113600/0 Page 6 of 10

from the fall as a potential tripping hazards

result of a missed Remove tripping hazards whenever possible

tripping hazard. Maintain a clean and uncluttered work area

Pay close attention to where you are

walking, do not take anything for granted

Pay extra attention when carrying bulky

items

When laying down tent floors remove any

potential tripping hazards

12 Cable glanding Damage of cable 3 X B= Ensure that the hand tools to be use is 1 X B= Engineer /

gland due to Medium appropriate or exactly only to the size of Low Supervisor,

improper use of cable gland. Safety

hand tools Ensure that the person work for cable Officer,

glanding is proper trained for the job and Technician

competent. and Helper

Hand tools injury 3 X B= Ensure to check visually a hand tools prior 1 X B= Engineer /

(pinch point) Medium to use. Low Supervisor,

Use hand tools for their intended purpose. Safety

Ensure to have the correct tools before Officer,

starting a task. Technician

Clean the hand tools before and after use. and Helper

Place and keep hand tools in the correct

container or rack.

Discontinue using worn out hand tools.

Replace them.

Ensure to used appropriate gloves be worn

when operating or handling hand tools

Special precautions must be taken to avoid

placing hands or fingers in pinch points,

especially around the torque arms of the

wrenches and is reaction points.

Do pre-work inspection to Identify potential

pinch points before starting work

Hand tools have been designed with a

special purpose; use these tools as they

JHA No. GC-14113600/0 Page 7 of 10

have been designed, if the job requires a

specific tool use that tool do not

improvise.

Disturbance to live 3 X B= Take extra care and keep away from live 1 X B= Engineer /

panel due to short Medium panel to avoid tripping or shutdown the Low Supervisor,

circuit/ tripping any system. Safety

loop/system Ensure the work site supervisor is properly Officer,

monitoring the work task and barricading Technician

the area and Helper

Do not touch any connection to avoid

tripping the system or plant.

Take time and paying attention to where

you are going for the walking surface and

the tasks you are doing.

Ensure with a presence of QP personnel

before starting the work activities.

Slips, trips and fall 3 X B= Take time and paying attention to where 1 X B= Engineer /

near the equipment Medium you are going for the walking surface and Low Supervisor,

the tasks you are doing. Safety

Adjusting yours stride to a pace that is Officer,

suitable for the walking surface and the Technician

tasks youre doing.

and Helper

Ensuring that things you are carrying or

pushing do not prevent you from seeing

any obstructions.

Ensure that a workers going to site have

properly instructed to the working area.

13 Cable wiring Short circuit on wiring 3 X B= Use insulated terminal screw while 1 X B= Engineer /

termination connection that will Medium removing the wire connection Low Supervisor,

cause of Ensure that the power supply is shutting Safety

electrocution off before will proceed to disconnect the Officer,

wire Technician

Keep tape isolation for the terminal wiring and Helper

after removing to the connection

JHA No. GC-14113600/0 Page 8 of 10

Hand, finger, eye 3 X B= Be alert to potential hazards before an 1 X B= Engineer /

injury cause during Medium accident happens. Low Supervisor,

wiring termination Use hand tools, do not use your HAND as Safety

the TOOL. Officer,

Wear appropriate gloves to give adequate Technician

protection and gloves should be and Helper

appropriate to the jobs, fit properly and

comfortable.

Ensure to wear proper safety glass for the

unwanted small particles during wiring

termination

Disturbance to live 3 X B= Take extra care and keep away from live 1 X B= Engineer /

panel due to short Medium panel to avoid tripping or shutdown the Low Supervisor,

circuit/ tripping any system. Safety

loop/system Ensure the work site supervisor is properly Officer,

monitoring the work task and barricading Technician

the area and Helper

Do not touch any connection to avoid

tripping the system or plant.

Take time and paying attention to where

you are going for the walking surface and

the tasks you are doing.

Ensure with a presence of QP personnel

before starting the work activities.

Slips, trips and fall 3 X B= Take time and paying attention to where 1 X B= Engineer /

near the equipment Medium you are going for the walking surface and Low Supervisor,

the tasks you are doing. Safety

Adjusting yours stride to a pace that is Officer,

suitable for the walking surface and the Technician

tasks youre doing. and Helper

Ensuring that things you are carrying or

pushing do not prevent you from seeing

any obstructions.

Ensure that a workers going to site have

JHA No. GC-14113600/0 Page 9 of 10

properly instructed to the working area.

14 Cable dressing/ Persons are possible 3 X B= 1 X B= Engineer /

Cable Tagging for back pain Medium Low Supervisor,

Dissemination information for proper Safety

ergonomic maneuver in cable dressing Officer,

Technician

and Helper

Cable tagging 3 X B= 1 X B= Engineer /

materials may cause Medium Low Supervisor,

Person must wear proper hand gloves.

hand injury Safety

And observe suitable tools intended for

Officer,

the cable

Technician

and Helper

15 In case of Personnel doesnt 3 X B= All worksite supervisors must aware to 1 X B= Engineer /

emergency know what they will Medium the nearest assembly point area and Low Supervisor,

do Emergency exit gates. Safety

Brief all personnel about the emergency Officer,

evacuation procedure. Technician

Go to the nearest muster point area or and Helper

Emergency exit gates.

Call Emergency Control Room 44716999

and 44717999

Presence of H2s or any 3 X B= Ensure that all personnel are trained by 3rd 1 X B= Engineer /

hazardous gas in the Medium party H2s awareness training. Low Supervisor,

area All individuals personnel should have Safety

portable H2s monitor. Officer,

If any suspicious gas smells, inform all Technician

personnel to check the wind direction and and Helper

approach QP plant operator to check

atmospheric testing.

16 Housekeeping Trips, stumble or 3 X B= Place equipment in orderly manner. 1 X B= Engineer /

foot puncture Medium Keep work location and access safe. Low Supervisor,

Keep area clean daily & weekly basis, Safety

JHA No. GC-14113600/0 Page 10 of 10

remove debris and store material tidily Officer,

safely. Technician

and Helper

TEAM MEMBER AND ENDORSEMENT

Position Position

S/ Name Site Supervisor & / Ref S/ Name Site Supervisor & / Ref

Sign Sign

N Safety Officer Indicato N Safety Officer Indicato

r r

JHA Team Leader Authorization: Ref. Indicator: Sign:

JHA Approval (Permit Authority / Asset Holder): Ref. Indicator: Sign:

Risk Assessment Matrix (RAM)

JHA No. GC-14113600/0 Page 11 of 10

INCREASING LIKELIHOOD/PROBABILITY

CONSEQUENCES A B C D E

Poten Asset Never

Reputati Occurrence Occurrence several

tial damage & Environmen heard of Occurred Occurred

People on several times a year at this

Severi business tal Effect in in industry in QP

Impact times in QP site

ty losses industry

0 No Injury No Damage No Effect No Impact No Risk Low Low Low Low

Slight injury or Slight damage

INCREASING SEVERITY

1 Slight effect Slight impact Low Low Low Low Low

health effects (<QR35,000)

Minordamage

Minor injury

(between QR

2 or health Minor effect Minor impact Low Low Medium Medium Medium

35,000 and

effects

350,000)

Moderate

damage

Major injuryor Moderate

3 (between QR Moderate Effect Low Medium Medium Medium High

healtheffects impact

350,000 and

3.5 Million)

Major damage

Single fatality

(between QR

4 orpermanent Major effect Major Impact Low Medium Medium High High

3.5 Million and

totaldisability

35 Million)

Massive

Multiple Massive

5 damage (> QR Massive Effect Medium Medium High High High

fatalities impact

35 Million)

JHA No. GC-14113600/0 Page 12 of 10

You might also like

- DOCUMENT Loop Checking Activities JHADocument8 pagesDOCUMENT Loop Checking Activities JHAFrancis Enriquez Tan83% (6)

- 5.19 JSP Electrical Power InstallationDocument4 pages5.19 JSP Electrical Power InstallationDarius DsouzaNo ratings yet

- JSA Cable LayingDocument2 pagesJSA Cable Layingnishanth100% (2)

- JSA Cable Pulling and Laying WorksDocument6 pagesJSA Cable Pulling and Laying Workskabir100% (1)

- JHA For Electrical Works - Rev. 01.Document16 pagesJHA For Electrical Works - Rev. 01.SreekumarNo ratings yet

- Cable Laying Safety AnalysisDocument6 pagesCable Laying Safety AnalysisLuqman Osman100% (6)

- Installation of Earthing System JSADocument4 pagesInstallation of Earthing System JSAAkash Shukla75% (4)

- Jsa - Cable TerminationDocument4 pagesJsa - Cable TerminationSantos Rex73% (15)

- Job Safety Analysis: Cable Jointing & Termination in Wind TurbinesDocument1 pageJob Safety Analysis: Cable Jointing & Termination in Wind TurbinesPerwez2186% (7)

- JSA For Cable Tray Installation-Reviewed by CBREDocument10 pagesJSA For Cable Tray Installation-Reviewed by CBREPrakash Tiwari86% (7)

- JSA SplicingDocument3 pagesJSA Splicingluis100% (4)

- MV, HV LV Transformer Installation SafetyDocument6 pagesMV, HV LV Transformer Installation SafetyKiran Bhatt75% (4)

- Civil JSA Form Block WorkDocument3 pagesCivil JSA Form Block Workdrmuhsin86% (7)

- JSA Cable Laying PDFDocument2 pagesJSA Cable Laying PDFManoj WaskelNo ratings yet

- Electrical Isolation JSA SheetDocument1 pageElectrical Isolation JSA SheetLal Dhwoj100% (2)

- JSA Cable Glanding & Wiring Termination Works 112Document5 pagesJSA Cable Glanding & Wiring Termination Works 112Francis Enriquez Tan83% (6)

- Job Safety Analysis (14) For Cable Laying and PullingDocument4 pagesJob Safety Analysis (14) For Cable Laying and Pullingnasar_mahsood79% (34)

- Jha - Transformer Installation PDFDocument6 pagesJha - Transformer Installation PDFperquino oasan0% (1)

- JSA Fitting and Welding Work For Pipe Trench InstalationDocument6 pagesJSA Fitting and Welding Work For Pipe Trench InstalationAzmi Fauzi78% (9)

- Mie-Hse-Jha-007 - Cable Pulling, Laying, Dressing Work, TerminationDocument6 pagesMie-Hse-Jha-007 - Cable Pulling, Laying, Dressing Work, TerminationLuqman Osman100% (3)

- JSA - CABLE TERMINATION TITLEDocument4 pagesJSA - CABLE TERMINATION TITLESyed Yousuf Ali100% (1)

- Jsa For Drilling.Document3 pagesJsa For Drilling.Belsyah Nofriyan75% (4)

- JSA - Fire Proofing WorksDocument5 pagesJSA - Fire Proofing WorksAnis Uddin100% (3)

- Safely erect and install electrical equipmentDocument3 pagesSafely erect and install electrical equipmentMon Trang Nguyễn100% (5)

- Jsa For Piping and Erection RevisedDocument1 pageJsa For Piping and Erection RevisedAlvin Smith77% (26)

- Earthing and Lightning Protection MaintenanceDocument2 pagesEarthing and Lightning Protection Maintenancemartins7367% (3)

- JSA FOR Shakthi ElectricalDocument8 pagesJSA FOR Shakthi Electricalwahyu nugroho100% (1)

- Mie Hse Jha 004 - Installation of TransformerDocument5 pagesMie Hse Jha 004 - Installation of TransformerLuqman Osman67% (6)

- JSA-049 Valves & Support Installation and DismantlingDocument4 pagesJSA-049 Valves & Support Installation and DismantlingMoaatazz Nouisri100% (3)

- JSA For Installation of Fire PumpsDocument2 pagesJSA For Installation of Fire Pumpsperquino oasan100% (3)

- 004 Annexure D Job Safety SAnalysis JSADocument3 pages004 Annexure D Job Safety SAnalysis JSAAvoor Khan75% (4)

- JHA-011 (Power Brush & Touch-Up Painting Activities 1)Document1 pageJHA-011 (Power Brush & Touch-Up Painting Activities 1)shaiful annuar50% (2)

- JSA Template 2017-05-31 Cable Tray InstallationDocument19 pagesJSA Template 2017-05-31 Cable Tray InstallationJayvee Baradas ValdezNo ratings yet

- Jha Energize Distribution DBDocument1 pageJha Energize Distribution DBAhmad Zahir100% (2)

- Jsa For Civil Confined Space EntryDocument11 pagesJsa For Civil Confined Space EntryKhuda BukshNo ratings yet

- HARADH AND HAWIYAH FIELD GAS COMPRESSION PROJECT SAFETY ANALYSISDocument8 pagesHARADH AND HAWIYAH FIELD GAS COMPRESSION PROJECT SAFETY ANALYSISsathakathulla100% (3)

- Risk Assessment - Distribution Board (DB) & Junction Box (JB) InstallationDocument6 pagesRisk Assessment - Distribution Board (DB) & Junction Box (JB) Installationnsadnan91% (11)

- JSA for Holiday TestingDocument4 pagesJSA for Holiday TestingMohammed Minhaj67% (3)

- Risk Assessment - Cable Pulling Laying, Glanding and Termination From RT Bay Outdoor Enclosure To RT Control BuildingDocument14 pagesRisk Assessment - Cable Pulling Laying, Glanding and Termination From RT Bay Outdoor Enclosure To RT Control Buildingnsadnan91% (82)

- Jsa - Electrical WorksDocument2 pagesJsa - Electrical WorksaneshseNo ratings yet

- JSA Installation of Equipment For Electrical and InstrumentDocument3 pagesJSA Installation of Equipment For Electrical and InstrumentHong Hai Pham75% (4)

- Column Erection JSA AnalysisDocument6 pagesColumn Erection JSA AnalysisRaghava Richhu100% (2)

- Nghi Son Refinery Manual Bolt Tightening JSADocument5 pagesNghi Son Refinery Manual Bolt Tightening JSAHưởng Phạm100% (1)

- Format for JHA WorksheetDocument4 pagesFormat for JHA WorksheetWaseem Ahmad100% (1)

- 1installation of Steel Structures JHA 1 (06!06!2015)Document33 pages1installation of Steel Structures JHA 1 (06!06!2015)Karthik babu100% (2)

- Jsa Pipe Cutting at Fire PumpDocument5 pagesJsa Pipe Cutting at Fire PumpHow Chin Engineering Sdn BhdNo ratings yet

- Job Hazard Analysis FormDocument10 pagesJob Hazard Analysis FormJayson Escamillan100% (1)

- JSA Electrical Maintenance LCSDocument8 pagesJSA Electrical Maintenance LCSmohamed yasinNo ratings yet

- JSA - Electrical Testing - Circuit Breaker Field TestDocument4 pagesJSA - Electrical Testing - Circuit Breaker Field TestTawfik Mohamed Abu Zaid0% (1)

- 2.JSA-Electrical Work Installation of Fire Alarm SystemDocument5 pages2.JSA-Electrical Work Installation of Fire Alarm SystemMuhammad Umar Gondal80% (5)

- Jsa-Jha For Using of Hand ToolsDocument2 pagesJsa-Jha For Using of Hand ToolsKamran Khan50% (2)

- JSA For Hydrotesting PDFDocument6 pagesJSA For Hydrotesting PDFMohammed Minhaj100% (1)

- Job Hazard Assessment For Cable TestingDocument4 pagesJob Hazard Assessment For Cable TestingSamuel Carlos100% (2)

- 03 Jha For Cable Laying Cable Glanding and Terminationdocx - CompressDocument16 pages03 Jha For Cable Laying Cable Glanding and Terminationdocx - CompressSavio SunnyNo ratings yet

- JHA For Manual Excavation Near On Control RoomDocument9 pagesJHA For Manual Excavation Near On Control RoomFrancis Enriquez Tan100% (1)

- DOCUMENT Job Hazard AnalysisDocument11 pagesDOCUMENT Job Hazard AnalysisFrancis Enriquez Tan0% (1)

- JHA ISO Container Lifting Point MPI InspectionDocument7 pagesJHA ISO Container Lifting Point MPI InspectionMohamedNo ratings yet

- RA Pump TemoraryDocument12 pagesRA Pump TemoraryCarlos ImmanuelNo ratings yet

- Al-Nafay Engeenering Solution Co. BSPM Kasur: Description: Risk Assessment of General Maintenance Work On Bio MassDocument11 pagesAl-Nafay Engeenering Solution Co. BSPM Kasur: Description: Risk Assessment of General Maintenance Work On Bio MassMuhammad Muneeb Naeem NaeemNo ratings yet

- NEW Form JHA-Assembling & Dismatling of Crawler Crane-FinalDocument15 pagesNEW Form JHA-Assembling & Dismatling of Crawler Crane-FinalKarthik babuNo ratings yet

- Risk Assessment - 1059Document3 pagesRisk Assessment - 1059Francis Enriquez TanNo ratings yet

- Risk Assessment - 1106Document2 pagesRisk Assessment - 1106Francis Enriquez TanNo ratings yet

- Oct-Nov-WSO Newsletter-2022Document18 pagesOct-Nov-WSO Newsletter-2022Francis Enriquez TanNo ratings yet

- Risk Assessment For External Façade & Canopies CleaningDocument8 pagesRisk Assessment For External Façade & Canopies CleaningFrancis Enriquez Tan100% (1)

- Daily Observation Report: Health, Safety & EnvironmentDocument3 pagesDaily Observation Report: Health, Safety & EnvironmentFrancis Enriquez TanNo ratings yet

- 2021 - 10 - 04 - Ddab-Hse-Dor-Contraco - JJJDocument3 pages2021 - 10 - 04 - Ddab-Hse-Dor-Contraco - JJJFrancis Enriquez TanNo ratings yet

- 2021-10-02 - Ddab-Hse-Dor-Contraco - RBLDocument3 pages2021-10-02 - Ddab-Hse-Dor-Contraco - RBLFrancis Enriquez TanNo ratings yet

- Defensive DrivingDocument54 pagesDefensive DrivingFrancis Enriquez TanNo ratings yet

- Method Statement For Scaffolding WorksDocument17 pagesMethod Statement For Scaffolding WorksFrancis Enriquez TanNo ratings yet

- Cleaning Window Risk AssessmentDocument3 pagesCleaning Window Risk AssessmentFrancis Enriquez TanNo ratings yet

- 2021-10-02 - Ddab-Hse-Dor-Contraco - RBLDocument3 pages2021-10-02 - Ddab-Hse-Dor-Contraco - RBLFrancis Enriquez TanNo ratings yet

- 2021.10.2 - Ddab-Hse-Dor-Contraco - JJJDocument3 pages2021.10.2 - Ddab-Hse-Dor-Contraco - JJJFrancis Enriquez TanNo ratings yet

- Guidelines for LPG plan submissionsDocument7 pagesGuidelines for LPG plan submissionsPrathamesh ShevaleNo ratings yet

- Daily HSE report observationsDocument2 pagesDaily HSE report observationsFrancis Enriquez Tan100% (1)

- Daily Observation Report: Health, Safety & EnvironmentDocument3 pagesDaily Observation Report: Health, Safety & EnvironmentFrancis Enriquez TanNo ratings yet

- 2021.10.02 - Ddab-Hse-Dor-Contraco - VNDocument2 pages2021.10.02 - Ddab-Hse-Dor-Contraco - VNFrancis Enriquez TanNo ratings yet

- 2021.10.02 - Ddab-Hse-Dor-Contraco - RFMDocument2 pages2021.10.02 - Ddab-Hse-Dor-Contraco - RFMFrancis Enriquez TanNo ratings yet

- Daily Observation Report: Health, Safety & EnvironmentDocument3 pagesDaily Observation Report: Health, Safety & EnvironmentFrancis Enriquez TanNo ratings yet

- Daily HSE ReportsDocument3 pagesDaily HSE ReportsFrancis Enriquez TanNo ratings yet

- Daily Observation Report: Health, Safety & EnvironmentDocument3 pagesDaily Observation Report: Health, Safety & EnvironmentFrancis Enriquez TanNo ratings yet

- 2021.10.02 - Ddab-Hse-Dor-Contraco - AmpDocument2 pages2021.10.02 - Ddab-Hse-Dor-Contraco - AmpFrancis Enriquez TanNo ratings yet

- 2021.10.02 - Ddab-Hse-Dor-Contraco - MNLDocument3 pages2021.10.02 - Ddab-Hse-Dor-Contraco - MNLFrancis Enriquez TanNo ratings yet

- Additional Guidance Unit 1Document5 pagesAdditional Guidance Unit 1Francis Enriquez TanNo ratings yet

- Daily Observation Report: Health, Safety & EnvironmentDocument3 pagesDaily Observation Report: Health, Safety & EnvironmentFrancis Enriquez TanNo ratings yet

- Ev01 - Hse Induction Attendance SheetDocument5 pagesEv01 - Hse Induction Attendance SheetFrancis Enriquez TanNo ratings yet

- Ev02 - Brief Program For New Work at Height CampaignDocument2 pagesEv02 - Brief Program For New Work at Height CampaignFrancis Enriquez TanNo ratings yet

- Ev05 - Safety Task Analysis Reduction - Star Card in Different LanguageDocument3 pagesEv05 - Safety Task Analysis Reduction - Star Card in Different LanguageFrancis Enriquez TanNo ratings yet

- Ev04 - Behavioral Based Safety Training SlidesDocument21 pagesEv04 - Behavioral Based Safety Training SlidesFrancis Enriquez TanNo ratings yet

- Heat IndexDocument2 pagesHeat IndexFrancis Enriquez TanNo ratings yet

- Assignment Nos. 3 - Scaffolding Risk AssessmentDocument11 pagesAssignment Nos. 3 - Scaffolding Risk AssessmentFrancis Enriquez Tan100% (1)

- The Bondage of Sin Edward WelchDocument8 pagesThe Bondage of Sin Edward Welchandrés_torres_58No ratings yet

- Type I Diabetes Mellitus Management in The Athletic PopulationDocument22 pagesType I Diabetes Mellitus Management in The Athletic PopulationRitesh NetamNo ratings yet

- Mini ProjectDocument16 pagesMini ProjectMr. Y. RajeshNo ratings yet

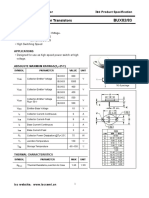

- Isc BUX82/83: Isc Silicon NPN Power TransistorsDocument2 pagesIsc BUX82/83: Isc Silicon NPN Power TransistorsCarlos HCNo ratings yet

- Uco Bank Final (Simple Charts)Document40 pagesUco Bank Final (Simple Charts)gopal8726No ratings yet

- APA Style Guide For StudentsDocument18 pagesAPA Style Guide For StudentsTeacher Jorge Omar NievesNo ratings yet

- Yuken pvr50 FF 45 Raa 3180 Hydraulic Vane PumpDocument4 pagesYuken pvr50 FF 45 Raa 3180 Hydraulic Vane Pumpnelson nadarNo ratings yet

- Installation and Operation Manual: SCR DC Motor ControlDocument32 pagesInstallation and Operation Manual: SCR DC Motor ControlAndres GarcíaNo ratings yet

- Dum Aloo Recipe - How To Make Punjabi Dum Aloo, Restaurant StyleDocument14 pagesDum Aloo Recipe - How To Make Punjabi Dum Aloo, Restaurant Styleabhishek.mishrajiNo ratings yet

- Cell Membrane TransportDocument37 pagesCell Membrane TransportMaya AwadNo ratings yet

- Sterilization and DisinfectionDocument41 pagesSterilization and DisinfectionqiotenseiNo ratings yet

- Narcos 1x01 - DescensoDocument53 pagesNarcos 1x01 - DescensoBirdy NumnumsNo ratings yet

- Case StudyDocument15 pagesCase StudyGaurav Kumar0% (1)

- ANGLICISMSDocument14 pagesANGLICISMSManuel Jorquera100% (1)

- Mass XL Workout Plan by Guru Mann PDFDocument4 pagesMass XL Workout Plan by Guru Mann PDFSaptarshi BiswasNo ratings yet

- 7 HO Clearance Consent FormDocument2 pages7 HO Clearance Consent FormzanehfncbusinessNo ratings yet

- Extent of Compliance on Waste Disposal PracticesDocument13 pagesExtent of Compliance on Waste Disposal PracticesEzza Jean Paypa100% (3)

- CWU Psychiatry 1.1Document8 pagesCWU Psychiatry 1.1Codillia CheongNo ratings yet

- Construction Safety Plan GuideDocument13 pagesConstruction Safety Plan Guideemmanueloboh92% (24)

- Water Plant SOPDocument6 pagesWater Plant SOPIndrie AgustinaNo ratings yet

- Tinnitus Causes and TreatmentDocument3 pagesTinnitus Causes and TreatmentTinnituscausesandtreatment Tinnituscausesandtreatment100% (1)

- Children Education - PPTMONDocument26 pagesChildren Education - PPTMONisna sari kelimagunNo ratings yet

- Aafreen Project Report SIPDocument19 pagesAafreen Project Report SIPshubham moonNo ratings yet

- X1jet MX Manual PDFDocument97 pagesX1jet MX Manual PDFrithik srivastavaNo ratings yet

- Categories of AnalysisDocument4 pagesCategories of AnalysisTee JackNo ratings yet

- Machine Design Document SummaryDocument14 pagesMachine Design Document SummaryJeevanandam ShanmugaNo ratings yet

- Demeclocycline Effective for Treating SIADHDocument4 pagesDemeclocycline Effective for Treating SIADHSally TareqNo ratings yet

- 150W MP3 Car AmplifierDocument5 pages150W MP3 Car AmplifiermanosipritirekhaNo ratings yet

- Green Destination (HR Analytics)Document16 pagesGreen Destination (HR Analytics)snehal patilNo ratings yet

- Importance of WaterDocument3 pagesImportance of WaternicNo ratings yet