Professional Documents

Culture Documents

The History and Physics of Magnetic Particle Inspection

Uploaded by

daemsalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The History and Physics of Magnetic Particle Inspection

Uploaded by

daemsalCopyright:

Available Formats

The Welding Institute

1. INTRODUCTION

1.1 History of Magnetic Particle Inspection

The origins of magnetic particle inspection can be traced to the

1920s although the method did not become fully accepted until the

expansion years of World War II. In the early days battery packs and

direct current were the norm and it was some years before

alternating current proved acceptable.

Magnetic particle inspection superseded the oil and chalk method in

the 1930s as it proved far more sensitive to surface breaking flaws.

Today it is still preferred to the penetrant method on ferromagnetic

material.

1.2 Magnetism

The phenomenon called magnetism is said to have been discovered

in the ancient Greek city of Magnesia, where naturally occurring

magnets were found to attract iron.

The use of magnets in navigation goes back to Viking times or

maybe earlier, where it was found that rods of magnetised material,

when freely suspended, would always point in a north-south

direction. The end of the rod which pointed towards the North Pole

star became known as the North Pole and consequently the other

end became the South Pole.

Hans Christian Oersted (1777-1851) discovered the connection

between electricity and magnetism, to be followed by Michael

Faraday (1791-1867) whose experiments revealed that magnetic

and electrical energy could be interchanged.

TWI Training & Examination Services NDT 30M

1

The Welding Institute

2. THE PHYSICS OF MAGNETISM

2.1 DIAMAGNETISM AND PARAMAGNETISM

All materials are affected by magnetic fields, to a greater or lesser

degree. The change or orbital motion of the electrons in the atoms

of the substance concerned relates to the degree of magnetisation.

Those materials which are:

a) Repelled by a magnetic force are called DIAMAGNETIC.

They have a small negative susceptibility to magnetism.

b) Lightly attracted by a magnetic force are called PARAMAGNETIC.

They have a small positive susceptibility to magnetism.

c c) Materials strongly attracted by a magnetic field are termed

FERROMAGNETIC

2.2 FERROMAGNETISM AND DOMAIN THEORY

Ferromagnetic materials are strongly attracted by magnetic fields.

These are the materials which can be magnetised and thus tested by

magnetic particle inspection.

Ferromagnetism can be explained using the idea of the magnetic

domain. Domains can be considered to be minute internal magnets,

each perhaps comprising 1015 to 1020 atoms. In ferromagnetic

atoms, the configuration dictates that more electrons spin one way

than the other. The resultant magnetic moment of a group of atoms

means that an internal polarity is created. Simply, a very small

internal magnet having a north and south pole.

TWI Training & Examination Services NDT 30M

2

The Welding Institute

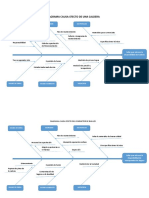

Unmagnetised state.

Domains randomly

orientated.

Field

Magnetised state.

Domains orientated

in external magnetic

field.

Field

Field

Saturated state.

Domains orientated

in strong external

field.

Field

Residual state.

Domains remaining

orientated in

absence of external

field.

Field

Demagnetised

state.

Domains randomly

orientated in

opposing field

Field

Figure 1: Domain Theory

TWI Training & Examination Services NDT 30M

3

The Welding Institute

2.3 PERMANENT MAGNETISM

When the external magnetising force is removed from a

ferromagnetic material the domains will remain in a partial alignment

dependent on a number of factors, such as:

Alloying elements

Carbon content

Heat treatment

Temperature

Strong permanent magnets used in magnetic particle inspection are

commonly made of iron alloyed with aluminium, nickel and cobalt.

Hence such trade names as: Alnico or Alcomax.

If a bar magnet is placed under a flat sheet of paper and iron filings

are sprinkled on to the paper, a visual field is created. This is called

a magnetographThe filings are orientated by the magnetic field

created by the lines of force running between the poles of the bar

magnet.

S N

Figure 2: Permanent Magnet

Shown below are a number of rules relating to lines of force:

1. By convention flow from north to south outside the

material and south to north inside

2. Do not cross

3. Repel each other laterally

4. Are in a constant state of tension

5. Are more numerous where the field intensity is greatest

TWI Training & Examination Services NDT 30M

4

The Welding Institute

2.4 ELECTROMAGNETISM

When an electric current flows through a conductor, a magnetic field

is set up around the conductor in a direction at 90 to the electric

current. This is explained by the 'right hand rule', see Fig.3.

If the thumb of the right hand is extended in the direction in which the

current is flowing, then the direction of the magnetic field is

represented by the fingers.

Figure 3: Right Hand Rule

When the conductor is ferromagnetic, strong magnetic flux lines are

created also in the direction of the fingers. This is called circular

magnetism. Circular magnetism is not polar and cannot be detected

externally on a round symmetrical specimen.

Now, if the original conductor carrying the current is bent into a loop,

the magnetic field around the conductor will pass through the loop in

one direction.

Figure 4: Coiled conductor

TWI Training & Examination Services NDT 30M

5

The Welding Institute

The field within the loop has direction and one side will be a north

pole and the other a south pole. By increasing the number of loops, a

coil, or solenoid, is created and the strength of the field passing

through the coil is proportional to the current passing through the

conductor in amperes multiplied by the number of turns in the

solenoid, see Fig.5a.

When a ferromagnetic specimen is placed in an energised coil, the

magnetic field is concentrated in the specimen. One end of the

specimen is a north pole and the other south pole. This is called

longitudinal magnetism, see Fig.5b.

Longitudinal magnetism has polarity and is therefore readily

detectable. Only one type of field can exist in a material at one time;

the stronger will wipe out the weaker. Normally in magnetic particle

inspection, circular tests are done before longitudinal.

Figure 5a: Coil Magnetisation

Figure 5b: Coil Magnetisation

TWI Training & Examination Services NDT 30M

6

The Welding Institute

2.5 MAGNETIC HYSTERESIS

When a ferromagnetic material is influenced by an alternating

magnetising force (H), the variation of magnetic flux density (B) in it

is related to a phenomena known as magnetic hysteresis.

The word hysteresis is derived from the Greek word for delayed and

is used to describe one quantity lagging behind another. The

variation of B to H follows a hysteresis loop and is characteristic to a

particular ferromagnetic material.

Figure 6 is a typical hysteresis loop whose co-ordinates represent

magnetising force (H) on the horizontal axis and flux density (B) on

the vertical axis.

B a

c f

H

o

e

d

Figure 6: Hysteresis

When an unmagnetised ferromagnetic material is exposed to a

gradually increasing magnetising force the corresponding flux

density can be plotted along the dotted line o - a. The level of flux

density is increased until point a is reached and a further increase

of magnetising force produces no increase in flux density. The

specimen is saturated with flux and indeed, point 'a' is called the

saturation point.

TWI Training & Examination Services NDT 30M

7

The Welding Institute

The dotted line o-a is often referred to as the virgin curve. Point a

towards point b is where the hysteresis loop begins.

As the magnetising force is reduced the flux density does not fall

back to zero but follows the line a-b. So at b there is a zero

magnetising force but a flux density o-b remains. The flux is

lagging behind the force and this is what gives ferromagnetics their

permanent magnetism.

To reduce the flux density to zero, or demagnetise the specimen, a

negative magnetising force c has to be applied and maintained. So

as the force increases to produce this the relationship of B to H

follows the line b to c. The force o to c required to

demagnetise the specimen, is called the coercive force.

Increasing the negative magnetising force still further produces a B

to H relationship along the curve c to d. Point 'd' is exactly

opposite point a and represents negative saturation.

As the negative force is reduced, point 'e' is reached, exactly

opposite point b and reversal to a positive magnetising force

achieves a zero flux density at point f, exactly opposite c.

The loop is completed by increasing the magnetising force, giving a

B to H ratio along curve f to a. Note that once the virgin curve is

produced the hysteresis loop does not pass through o again.

The specimen will not be demagnetised until special steps are taken

to achieve that state.

As stated earlier, a hysteresis loop is characteristic to a particular

ferromagnetic material.

TWI Training & Examination Services NDT 30M

8

The Welding Institute

Figure 7: 2 Loops Relating to Iron and Steel.

Alloying Hysteresis Permeability Coerciv Remanence Loss

Element e Force of

Power

Silicon

Manganese

with pearlitic

steels

Manganese

with austenitic

steels

Chromium

Nickel

with pearlitic

steels

Nickel

with austenitic

steels

Aluminium

Tungsten

Vanadium

Cobalt

Molybdenum

Copper

Sulphur

Phosphorus

Increase ( the more arrows the more intense the effect )

Decrease

Unknown

Table 1: Effect of Magnetising Elements

TWI Training & Examination Services NDT 30M

9

The Welding Institute

2.6 DEFINITION OF TERMS

A knowledge of some of the physical terms related to magnetisation

is essential. However, the following definitions are not meant to be

exhaustive but only those which are considered relevant to

understanding the practice of magnetic particle inspection.

BS3683:Part 2:1985 provides a comprehensive glossary.

Flux density

The number of magnetic flux lines per unit area

Symbol = B

SI unit = tesla = T

(It has replaced the gauss and 1 tesla = 104 gauss)

Magnetising force

The total force tending to set up a magnetic flux in a magnetic circuit.

Symbol = H

SI unit = ampere per metre = Am-1

(It has replaced the oersted and 1Am-1 = 0.01256 oersted or 1 Oe =

79.58Am-1).

Permeability

The ease with which a magnetic field or flux can be set up in a

magnetic circuit.

Symbol = (mu)

B

H

=

is the absolute magnetic permeability in Henry/metre

B is the magnetic flux density in tesla (T)

H is the magnetic field strength in amperes per metre (A/M)

For air and non-magnetic materials, is constant and denoted by

= 4 x 10-7 Henries/metre

For ferromagnetic materials it varies considerably according to the

value of H. For convenience we use relative permeability r:

TWI Training & Examination Services NDT 30M

10

The Welding Institute

r =

Relative permeability is therefore a dimensionless ratio which relates

the permeability of the material to that of air.

Saturation

The stage at which any increase in the magnetising force H applied

to a specimen, produces no significant gain in flux density B.

Effectively it is at point 'a' on Fig.6. Saturation on a test specimen,

can be recognised by a high ink background caused by clumping,

furring or blushing of the particles.

Coercive force

The reverse magnetising force required to remove residual

magnetism from a material. On Fig. 6 it is represented by 'o-c'.

Remanence

The magnetic flux density remaining in a material after the

magnetising force has been removed. On Fig.6 it can be any value

of B , between b and e, when

H = O.

Residual magnetic field

The magnetic field remaining in a material after the magnetising

force has been reduced to zero.

Reluctance

A measure of the degree of difficulty with which a component can be

magnetised that is analogous to resistance in an electrical circuit. It

is the reciprocal of permeability.

Retentivity

The magnetic flux density remaining in a material after the

magnetising force has been removed (BS3683 Pt.2), synonymous to

remanence. However, McGraw-Hill, "Dictionary of Scientific and

Technical Terms", defines retentivity as, the residual flux density

corresponding to the saturation induction of a magnetic material.

This corresponds to point 'b' in Fig.6, the maximum remanence.

TWI Training & Examination Services NDT 30M

11

The Welding Institute

2.7 FLUX LEAKAGE

A flux leakage is a break or a discontinuity in a magnetic circuit. Any

abrupt change of permeability within a magnetic specimen will

change the number of flux lines which can flow and thus there will be

a diversion of the field.

Magnetic particle inspection relies on flux leakages being seen on

the surface of a ferromagnetic specimen under test. All defects

produce flux leakages but not all flux leakages are created by

defects.

Magnetic particle inspection relies on:

a) Magnetising the specimen to an adequate flux density.

b) Applying fine ferromagnetic particles over the surface of the

specimen.

c) Being able to see clusters of the magnetic particles which

gather at flux leakages.

The magnetic field must run in a direction so that it can be

interrupted by the defect, thus producing a flux leakage field. Also

the degree of distortion at the leakage must allow the magnetic

particles to provide an adequate degree of contrast between the

leakage and the adjacent material surface, so that it is readily visible.

Flux lines will take the path of least reluctance, hence the highest

permeability. Figure 8a shows flux lines flowing in a ferromagnetic

bar but having to divert around an air gap, creating a flux leakage.

However, if ferromagnetic particles are sprinkled on the bar they will

start to form a magnetic bridge across the flux leakage and a highly

preferred path. If the flux leakage is strong, such as a surface

breaking crack in the optimum direction, then the visual indication will

be plain. See Fig.8b.

a. b.

Figure 8: Flux Leakage

TWI Training & Examination Services NDT 30M

12

The Welding Institute

Whether a flux leakage is made into a visual indication depends on a

number of factors, such as:

a) Size of defect

b) Shape of defect

c) Volume of defect

d) Orientation of defect

e) Depth below surface

f) Permeability of material

2.7.1 Indications

Indications are any particle indications which are seen on the

specimen under test. Just as not all flux leakages are defects,

not all indications are flux leakages.

Indications can be further subdivided into:

Relevant

Spurious

Non-Relevant

2.7.1.1 Relevant indications

Relevant indications are discontinuities or flaws, which

in turn are undesigned imperfections.

When it is considered that a relevant indication will

affect the fitness for purpose of a test specimen, then it

is classified as a defect, but not all defects are cracks.

Product and process knowledge (a knowledge of

product technology and the processes that a test

specimen has been through) is necessary to define

and interpret defects more closely. It is perhaps safer,

without that knowledge, to categorise indications by

their:

a) Size

b) Shape

c) Orientation

2.7.1.2 Spurious indications

Indications which are not held on the surface by a flux

leakage are called spurious. Lint, scale, dirt, hairs,

drainage lines, etc. are examples.

TWI Training & Examination Services NDT 30M

13

The Welding Institute

However, there is one spurious indication called

magnetic writing which is a little different. If two pieces

of steel touch when one of them is in a magnetised

condition local poles are created at the areas of

contact. If magnetic particles are then sprinkled on the

surface the local poles become visible as fuzzy lines.

2.7.1.3 Non-relevant indications

Non-relevant indications are true magnetic particle

patterns actually formed and held in place by leakage

fields. However, they are caused by design features

and the structure of the specimen and only

exceptionally will they affect the fitness for purpose of

the specimen.

Below is a non-exhaustive list:

a) Scores and scratches

b) Key ways

c) Internal splines and drillings

d) Abrupt changes of section

e) Fine threads

f) Force fits

g) Dissimilar magnetic material (HAZ or heat treated

material)

h) Forging flow lines

i) Grain boundaries

j) Brazed joints

k) Cold working

2.7.2 LONGITUDINAL FIELD

It has already been said that the magnetic flux lines must run

in a direction so that they can be interrupted at a defect

causing a flux leakage. So, in order to detect defects, the flux

lines should ideally be at 90 to the direction of potential

defects.

In Fig.9 the magnetic lines of force are longitudinal in a bar

and thus the bar has magnetic poles. Transverse flaws will

easily show; but longitudinal defects such as seams, which

are very straight, will not show. However, it is accepted that

flaws up to 45 to the flux lines will also be shown. In fact,

longitudinal flaws having a transverse component, such as

jagged cracks, will almost certainly show.

TWI Training & Examination Services NDT 30M

14

The Welding Institute

Magnetic Lines 45o Defect

of Force may show

Longitudinal Transverse

Magnetising Defect will Defect will

Current not show show

Figure 9: Longitudinal Field

2.7.3 CIRCULAR FIELD

The longitudinal magnetising field in the bar is now replaced

by a longitudinal current, which creates a magnetic field at 90

to itself. In fact, the current has produced a circular non-polar

field around the bar. Under normal circumstances the circular

field is not detected, due to it having no external poles, but a

longitudinal surface flaw at 90 creates a flux leakage,

creating miniature poles and is thus detectable with magnetic

particles. Fig.10 shows the effect of flaw orientation in

circularly magnetised bar.

Magnetic Lines 45o Defect

of Force may show

Longitudinal Transverse

Magnetising Defect will Defect will

Current show not show

Figure 10: Circular Magnetism

TWI Training & Examination Services NDT 30M

15

The Welding Institute

3. EQUIPMENT

The equipment used for magnetic particle inspection can be divided up

according to size and purpose. The magnetising force may be supplied by

anything from a small permanent magnet to a highly sophisticated fixed

installation, utilising high values of rectified current and finely calibrated

meters.

When electricity is introduced into a specimen in order to magnetise, it is

usually transformed into a low voltage, high amperage supply. Therefore

there is no danger from electrocution, however, specimens do get hot due

toS electrical resistance if the supply is applied for more than a couple of

N seconds.

3.1 Permanent magnets

Permanent magnets produce a longitudinal magnetic field between

the poles. Modern variants of the horseshoe magnet have

adjustable arms, and may have variable geometry removable pole

ends. Optimum defect detectability is at 90 to the poles. Modern

opinion tends not to favour permanent magnets.

Figure 11: Permanent Magnets

Advantages Disadvantages

No power supply needed Direct field only

Cling to vertical surfaces Deteriorate with wear

No electrical contact Have to be pulled from test surface

problems

Inexpensive No control over field strength

No damage to test piece Magnetic particles attracted to poles

Lightweight

TWI Training & Examination Services NDT 30M

16

The Welding Institute

3.2 Electromagnets

Electromagnets are made from soft iron laminates to reduce eddy

current losses, if powered by alternating current (AC).

The yoke laminates are encased in a multi-turn coil, usually powered

by mains electricity.

The legs of modern equipments are normally articulated to allow

area contact on uneven surfaces.

Figure 12: Electromagnet

Electromagnets produce a longitudinal field. Defect orientation is the

same as when using a permanent magnet. Rectified AC current or

DC current from a battery may be used. DC is not favoured as a

magnetising method, due to the possibility of not achieving an

adequate flux density within the specimen.

Advantages Disadvantages

AC, rectified or DC operation Needs power supply

Controllable magnetic field Longitudinal field only

strength

Run direct from mains Carry mains voltage

electricity supply

Can be switched on and off Poles attract magnetic

allowing particles

Easy removal Legs must have area contact

No harm to test piece

Lightweight

Can be used to

demagnetise on AC

TWI Training & Examination Services NDT 30M

17

The Welding Institute

3.3 Prods

Prods induce a circular magnetic field by sending a high amperage

(1000A typically) current through the test piece. The high amperage

can cause arcing between the electrodes and test surface. Contact

points must be carefully cleaned, and electrode materials chosen to

prevent contamination of the test piece.

Figure 13: Prods

Advantages Disadvantages

Variable field strength Danger of arcing

AC or DC fields Danger of overheating

Useful in confined spaces Heavy transformer required

Low voltages Possible to switch on without creating

field

No poles to attract Possible contamination of

particles the test piece by the electrode

Control of amperage

TWI Training & Examination Services NDT 30M

18

The Welding Institute

3.4 Flexible coil

In this technique the current-carrying cable is wound tightly around

the component. It is a longitudinal magnetisation method and will

find defects lying parallel to the cable. If possible the turns should be

spaced so that inspection is possible between them.

Split coils with quick release fasteners are commercially available to

allow coils to be fixed and removed more quickly.

Advantages Disadvantages

Simple to operate Difficult to keep turns apart

No danger of burning Limited inspection cover

AC and rectified current High current capacity

sometimes

Magnetising force is the

product of amps needed

multiplied by turns

Current is adjustable

3.5 Flexible cable and close loop

Working from the basic principle that a current must create a

magnetic field around the conductor, the flexible cable is a useful

means of testing welded constructions, large casting and forgings.

The cable may be laid on to a job, perhaps parallel to a weld and

defects will be found in the direction of current flow, adjacent to the

cable.

When used as a single or a multi-turn threading cable, the conductor

is passed through openings of interest and defects will be found

radially around the hole or longitudinally in the bore. When used on

a pipe, defects will be found parallel to the cable internally and

externally, as well as radially on the ends.

The parallel closed loop is a novel variation which has found some

favour in underwater inspection and the gas industry.

a) The cables or conductors are kept apart by insulators

b) The direction of current in each cable must be complementary,

not opposing

c) Defects will be found within the grid, parallel to the conductors.

TWI Training & Examination Services NDT 30M

19

The Welding Institute

Advantages Disadvantages

Simple application May require long cables

Variable field strength High current draw sometimes

Can cover large areas Difficult to keep cable in position

3.6 Clamps and leeches

Where prods are not suitable because heat damage may be caused,

or the item is too large and awkward, it is often still possible to pass a

current into a specimen. Special 'crocodile' clips with copper woven

braiding on them are one alternative. Another possibility is to use

permanent magnets as leeches to clamp on the job so that the

operator's hands are free to apply the ink or powder. The current is

passed through the leeches and does not affect the permanent

magnetism.

3.7 Mobile Equipment

As the name implies, mobile equipment is too bulky and heavy to

carry and yet needs to be moved to the work. Some mobile units are

capable of supplying output currents up to 20,000A, although 5000A

is a more normal figure.

The current required to test a job may be quite low but losses due to

cable length or bulk of specimen may mean that a portable set

cannot produce enough. Paragraphs 3.3 to 3.6 are relevant to

mobile units as well as portables.

In addition to the normal features on a portable unit, the mobile is

likely to have better current control and a step control to allow

demagnetising.

TWI Training & Examination Services NDT 30M

20

The Welding Institute

3.8 Bench Units

Bench units are fixed installations used to test large numbers of

manufactured specimens. They range in size and output from those

able to test small components at no more than a few amperes to

large cranks and gun barrels capable of 10-20,000A. Essentially, the

electrical components of the mobile are incorporated in the bench

unit together with handling and operating features that make testing

more rapid, convenient and efficient. Among the features normally

found on a bench unit are:

a) Adjustable head and tail stocks on a fixed bed.

Manually, electrically or air operated.

b) Agitated ink trough or reservoir.

c) Recirculating ink supply from reservoir to spray gun.

d) AC and rectified current facilities.

e) Large area copper gauze covered electrodes on head

and tail stock to allow current flow, for circular

magnetisation.

f) Magnetic flow solenoids on head and tail stocks and/or

rigid coil on the bed, for longitudinal magnetisation.

g) Calibrated meters.

h) Controls to vary magnetising force values.

i) Foot switches and hand switches to operate controls.

j) UV-A (black light) lamp (optional).

k) White light lamp (optional).

l) Timers, to adjust operating duty cycle (optional).

3.8.1 Current Flow

The component is fixed firmly between contact heads which

have a soft conductive surface, such as copper braiding. A

low voltage, high amperage current is passed through the

component creating a circular magnetic field around it. The

method favours detection of defects lying in line with the

contact heads and not more than 45 from the ideal.

Field

Current

Figure 14: Current Flow

TWI Training & Examination Services NDT 30M

21

The Welding Institute

3.8.2 Threading Bar

Magnetisation by the threading bar technique is induced by

passing current through an insulated non-magnetic conductor

(aluminium, copper or brass are usual) which is placed in a

bore or aperture in the component. Hollow components such

as tubes and rings, are normally tested by the threading bar

technique. In practice a number of small parts, such as rings,

can be tested at the same time, providing they are not allowed

to touch each other.

Current

Figure 15: Threading Bar

The threading bar technique induces circular magnetisation

and defects in the same direction as the current will be found,

externally, internally, and on end faces. Defects deviating up

to 45 from the ideal will also be found.

3.8.3 Magnetic Flow

Energised solenoids in the bench heads create a longitudinal

magnetic field in a component, which is clamped between the

heads, completing the magnetic circle. Defects, where the

major axes lie transverse to a line joining the heads, are found

best and the method is most applicable for short simple

shapes. The solenoids on bench equipment are energised by

full wave rectified current.

Magnetism

Figure 16: Magnetic Flow

TWI Training & Examination Services NDT 30M

22

The Welding Institute

Where there are large differences between the size of the

bench heads and the ends of the component, shaped

extenders may have to be used to ensure that the flux is

smoothed into the ends of the component. If this is not done,

clumping of magnetic particles on the component will prevent

defect detection.

3.8.4 RIGID COIL

The component is placed in a current-carrying rigid coil with

its longitudinal axis at 90 to the direction of the windings on

the coil. Four to eight turn coils are usual and the specimen is

placed in the bottom of the coil wherever possible.

Longitudinal magnetism is induced into the component, so the

method favours basically transverse defects. Long and

slender components are best tested in coils, although a long

component may have to be re-tested along its length. 300mm

is about the longest that one can expect to inspect at any one

time. Pole extenders should be used on short components,

having a length/diameter ratio less than 5:1.

Current

Figure 17: Rigid Coil

TWI Training & Examination Services NDT 30M

23

The Welding Institute

3.8.5 Induced Current

The induced current technique is not normally a feature of

standard bench equipment but is applicable to particular

components, such as high quality finish bearing races, where

arcing would ruin the part.

The technique induces a circumferential current flow in a ring

specimen by making it the secondary winding of a

transformer. Therefore only alternating current may be used

and only surface defects are revealed.

It is a novel but extremely useful technique, as it eliminates

the possibility of overheating the component under test.

There are many variations, as often the technique has to be

tailored to suit a specific component's inspection need.

TWI Training & Examination Services NDT 30M

24

The Welding Institute

4. CURRENT WAVEFORMS

It is the value of peak current which creates the maximum magnetising

force and therefore the most drive to the magnetic particles to migrate to a

flux leakage. However, few ammeters are calibrated in peak values. In fact

they read some other quantity such as root mean square (rms), mean or

average.

The apparently simple ampere can be read by a meter in many different

ways and it is necessary to be aware of this. It is intended to look at the

more common current waveforms and the more usual ways of reading their

outputs. In view of the many ammeter variations, the safest thing for

operators to do is to check with the equipment manufacturer as to what type

of ammeter is fitted. Then print the peak to actual readout ratio on the

meter scale.

4.1 DIRECT CURRENT

An electrical current flowing in one direction only and effectively free

from pulsation. Therefore, after a small build-up period the current is

at a constant peak value and this is what the meter reads.

-

Figure 18: Direct Current

Direct current is either supplied from a battery pack or a DC

generator. In the early days of MPI, DC was almost universally used.

This is not so today.

Advantages Disadvantages

Sub-surface defects No agitation

Availability from batteries Less sensitive to surface defects

TWI Training & Examination Services NDT 30M

25

The Welding Institute

4.2 Alternating Current

Alternating current is a form of electricity which, after reaching a

maximum value in one direction, decreases, reverses direction and

reaches a maximum in the opposite direction before returning to

zero. It is cyclic and the cycle is repeated continuously.

-

Figure 19: Alternating Current

It is of course, the peak current which creates the maximum

magnetising force, but in reality the meter reads the root mean

square (rms) value as the current is reversing between equal but

opposite peak values it is therefore impossible to measure the mean

value.

By plotting the squares of the current values we can find an average,

since negative as well as positive values become positive. To

measure the square of the current we use a moving iron ammeter.

This type of ammeter consists of two iron rods which are forced apart

as they are magnetised. Their level of magnetisation is proportional

to the current and therefore the force between them is roughly

proportional to the square of the current. The meter is calibrated to

read the root of the mean of the square values and is therefore non-

linear.

Advantages Disadvantages

Availability Will not detect sub-surface defects

Sensitivity to surface defects

Agitation of particles

Demagnetisation

The phenomenon that causes the magnetisation produced by

alternating current to be contained near the surface of a

ferromagnetic component is called skin effect. Therefore if the

TWI Training & Examination Services NDT 30M

26

The Welding Institute

magnetic field produced by AC only exists at or just under the

surface of the component and only surface defects will be revealed

by AC.

If subsurface defects are of interest, rectified or DC current must be

used because they produce an even flux density through the cross

section of the component.

4.3 Half wave rectified (HWR)

This is a pulsed unidirectional current produced by clipping a half

cycle from single phase alternating current. As a result there are

intervals when no current is flowing.

It is the least expensive form of rectification, used on cars and

motorcycles. In the UK it is common in portable, mobile and bench

units.

+

-

Figure 20: Half Wave Rectified Current

Advantages Disadvantages

Penetration like DC Lower sensitivity to surface defects

than AC

Agitation

TWI Training & Examination Services NDT 30M

27

The Welding Institute

4.4 Full wave rectified current (single phase)

This is a form of current where the negative half wave of an

alternating current is converted into a positive wave, so that both

halves of the swing are able to deliver unidirectional current.

Full wave rectified equipment is unlikely to be even nominally

portable, due to the weight of electrical equipment within them.

Bench units using this waveform are most likely to be found where

codes from the USA prevail.

+

-

Figure 21: Direct Current

Advantages Disadvantages

Penetration like DC Lower sensitivity to surface defects

than AC

Agitation

TWI Training & Examination Services NDT 30M

28

The Welding Institute

5. MAGNETISING VALUES

United Kingdom magnetic particle inspection practice is based on research

which recommends that a minimum flux density of 0.72T must be achieved.

Since most engineering steels have a permeability greater than 240 then an

applied field greater than 2400A/m is required. The magnetising values

quoted in this test are therefore derived with the above parameters in mind.

It has been explained that different current wave terms are used in MPI, but

not why. Alternating current is simple to transform, when taken from the

electrical mains, and employ. Because the polarity is changing fifty times a

second the magnetic particles are constantly reversing their direction and

this causes them to migrate or 'walk' to flux leakages. This is excellent

because it gives bright clear indications.

However, because of the skin effect phenomenon the magnetism is

concentrated near to the surface of a component. Therefore only surface

defects can be found using alternating current.

It is considered that subsurface defects are critical and it is believed that

they are likely to be orientated in a way that makes detection possible, then

DC or rectified current must be used. Good HWR circuits will give full depth

magnetic penetration with a pulse effect to help the particles migrate.

Complicated machined specimens with fine threads or key ways might be

difficult to interpret due to flux leakage across changes of section. It is often

possible to use the residual magnetism to produce fine line indications and

reduce the incidence of non-relevant indications. This is called the residual

technique and when employed, rectified current or DC must be used.

Thus, before selecting a magnetising value and wave form for a job, the

type, orientation and depth of likely defects must be deduced.

5.1 Permanent magnets and dc electromagnets

Permanent magnets and dc electromagnets should be able to lift at

least 18kg of ferritic steel with the poles between 75 and 150mm

apart. For pole spacing less than or equal to 75mm the magnet shall

be capable of lifting not less than 0.24Kg/mm.

Each pole should pull off at more than 9kg.

5.2 AC electromagnets

An AC powered electromagnet must be able to lift 4.5kg with the

poles 300mm or less apart. Each pole must pull off at more than

2.5kg. The test area is a circle inscribed by the poles.

TWI Training & Examination Services NDT 30M

29

The Welding Institute

5.3 Prods

If a flat area is to be tested then a pattern similar to that in Fig.22 is

used. The peak current values must be not less than 7.5A/mm of

prod spacing, equivalent to 5.3A/mm AC rms.

When a simple check of a narrow region, such as a weld is required

then the current value can be reduced to 3.75A/mm peak (2.7A/mm

AC rms).

Practically, on a weld, to cover both USA and UK requirements, a

current of 100A/in. (4 A/mm) is adequate, with a maximum prod

spacing of 200mm (8in.).

CF1 CF1 CF2 CF2

CF3 CF3

Figure 22: Prod Test Pattern

5.4 Flexible coil

British Standard 6072 gives two formulae to be used when testing

with a flexible coil. These are shown as follows:

Y2

1 7.5 T

4T a) Using direct or rectified current,

the peak value of the current flowing in a cable shall have a

minimum value of:

where

I = peak current

T = wall thickness (in mm) or radius of component if round

Y = the spacing (in mm) between adjacent windings in the coil.

TWI Training & Examination Services NDT 30M

30

The Welding Institute

b) Using alternating current, the peak value of the current

flowing in the cable shall have a minimum value of:

Y2

I 7.5 10

40

where

I = peak current

Y = the spacing (in mm) between adjacent windings in the coil

K

N x I

L

2

D The UK system requires the cable

windings to be spaced. But in the USA it is accepted that

spacing the windings is extremely difficult and thus the

formula in ASME V shown below applies to flexible close

turn coils:

where:

I = coil current

N = number of turns in the coil or cable wrap

L = part length

D = part diameter

K = 35000

Note: The maximum L/D ratio for calculations is limited to

15:1. The effective field extends on either side of the coil to a

distance approximately equal to its radius.

5.5 Flexible cable

TWI Training & Examination Services NDT 30M

31

The Welding Institute

To achieve most efficient magnetisation the cable should be mounted

at a distance from the test surface (d), see Fig. 23. The width of the

effective inspection area on each side of the cable centreline is then

also d and is related to the peak current value (I) in the cable by:

I = 30d

d2

d1 d1

Figure 23: Flexible Cable

r = radius of influence

d1 = distance from surface

d2 = distance of effective cover

This formula can be extended to give a simple close wrapped flexible

coil formula, where

N x I = 30d

N being the number of turns.

Figure 24: Flexible Coil

5.6 Current flow

TWI Training & Examination Services NDT 30M

32

The Welding Institute

The values for current flow applications are given in Tables 2 and 3.

When components having varying cross section are tested, a single

current value can be used if the diameters of the larger and small

sections are within a ratio of 1.5:1. The large diameter governs the

value.

If the cross section variation is greater than 1.5:1 then each section

is tested in turn, starting with the smallest.

Current Peak or AC Single Single

Waveform DC Source Phase Phase

Source Full Wave Half Wave

Rectified Rectified

Type of A B A B

ammeter

Current for 7.5 5.3 4.8 2.4

Basically

Round

components

per mm of

diameter

Current for 2.4 1.7 1.5 0.75

Non-Round

components

per mm of

perimeter

Table 2: General Engineering Current Values

Current Peak or AC Single Single

Waveform DC Source Phase Phase

Source Full Wave Half Wave

Rectified Rectified

Type of A B A B

ammeter

Current for 28 20 18 9

Basically

Round

components

per mm of

diameter

Current for 9 6.4 5.7 2.9

Non-Round

components

per mm of

perimeter

Table 3: Aerospace Current Values

5.7 Threading bar

TWI Training & Examination Services NDT 30M

33

The Welding Institute

When the threading bar is placed centrally the current values given

in Tables 2 and 3 may be used.

Alternatively, and when the threading bar is offset from the centre,

the surface under test shall lie totally within a circle centred on the

threading bar. The radius (in mm) (r) of this circle is given by:

1

r

15

general engineering

1

r

56

aerospace application

where

I = peak current value

and where I = AC rms current value this becomes

1

r

11

general engineering applications

1

r

40

aerospace applications

When large rings, etc. have to be tested a number of shots, equidistant

around the circumference may be necessary, see Fig. 25.

Test 1

Test 2

Test 5

Test 3

TWI Training & Examination Services NDT 30M

Test 4

34

The Welding Institute

Figure 26: Threading Bar Test Coverage

5.8 Magnetic flow

There are no formulae applicable to the magnetic flow technique. It

is recommended that the magnetic field strength should lie between

the value which will just saturate the material under test and not less

than one third of the saturation value.

Alternatively, flux indicators are used.

5.9 Rigid coil

32000 22000

Ip or Irms

L L

xN xN

D D The formulae given by

BS6072 is:

Where

Ip is the current peak value

Irms is the rms current value

N is the number of coil turns

L is the testpiece length

D is the testpiece diameter

22000

N x Irms

L/ D This can be usefully transposed to read:

To use the formula, the following conditions apply:

1. The cross-sectional area of the testpiece must be less than

10% of the cross-sectional area of the coil aperture.

2. The test piece should lie against the side or bottom of the coil.

3. L/D ratio of the part must be greater than 5:1 if not, pole

extenders can be clamped to the ends of the testpiece.

TWI Training & Examination Services NDT 30M

35

The Welding Institute

4. If the L/D ratio exceeds 20 then the ampere turn value for a

20:1 ratio should be used. The test should be repeated at coil

length intervals.

5. The major axis of the test piece should be parallel with the axis

of the coil.

6. When using rigid coils of helical form the pitch of the helix

shall be less than 25% of the coil diameter.

7. BS6072 implies that only the section in the coil is tested and

the test must be repeated at coil length intervals. In US

instructions the test area extends 6" beyond the coil on each

side.

Formula:

N= number of turns

I= amperage

D= diameter of specimen

L= length of specimen

X= 32 000 for peak

22 000 for AC rms and FWR

11 000 for HWR

L/D ratio Ampere turns

Peak AC and FWR HWR

4 8000 5500 2750

5 6400 4400 2200

6 5333 3667 1833

7 4571 3143 1692

8 4000 2750 1571

9 3556 2444 1467

10 3200 2200 1100

11 2909 2000 1000

12 2667 1833 917

13 2462 1692 846

14 2286 1571 786

15 2133 1467 733

TWI Training & Examination Services NDT 30M

36

The Welding Institute

Table 5. Fixed coil current for known L/D ratios

5.10 Induced current

A clamp meter is required to find out the value of current induced into

a component. If one is available then the current values used for

current flow apply. However, if the correct type of ammeter is not to

hand, a flux indicator is the alternative.

5.11 Flux Indicators

Field strength meters based on the Hall effect are the best way of

ascertaining adequate field strength at the surface of a test

component. However, they are expensive and the probes used tend

to be fragile. Portable flux indicators are an acceptable alternative.

They:

a) are simple to use

b) provide a clear visual indication of the direction of the surface

field

c c) are a rough guide to the magnitude of the surface field.

This is

only true if the flux indicator abuts intimately with the test

specimen.

Flux indicators consist of a magnetic material which is interrupted by

non-magnetic spacers. When the flux indicator is placed on the

surface of a magnetised specimen, flux is induced in it. The non-

magnetic spacers behave as artificial flaws. If the magnetic field at

the surface of the specimen is sufficiently high, leakage flux above

the artificial flaws can be detected by the application of a magnetic

particle ink or powder.

Flux indicators are made with high permeability magnetic materials

with low coercivity and low remanence so that a flux can be easily

induced into them, yet without permanently magnetising them.

Opinion differs on their efficacy when used with permanent magnets

and DC electromagnets. In every case when a permanent magnet

or electromagnet is used, good area contact of the poles is

imperative or the flux indicator is useless. Results may be

misleading when indicators are used in a coil.

Flux indicators may be divided into two main types:

segment type

foil type

TWI Training & Examination Services NDT 30M

37

The Welding Institute

5.11.1 Segment type

Four or eight identical segments of ferrous metal are joined

with non-magnetic

compound of even thickness into the shape of a flat disc.

One surface of the disc is covered with non-magnetic foil to

prevent magnetic particles getting to the surface and prevent

them giving misleading indications.

The eight segment type, with a fixed foil is popular in the

USA. A four section indicator

with an adjustable foil, giving a varying air gap between them

is called a Berthold penetrameter.

5.11.2 Foil type

The most common foil type indicator is the Burmah Castrol

strip. These indicators consist of a magnetic foil containing

slots to simulate discontinuities, sandwiched between non-

magnetic foils.

Non-magnetic foils are either brass or stainless steel

depending on whether they are for general or

aerospace use.

The simulated discontinuities in a Burmah Castrol strip are

arranged in three parallel lines. These foils are less than

0.2mm thick and flexible, which gives them a significant

advantage over the segment type.

TWI Training & Examination Services NDT 30M

38

The Welding Institute

6. TEST METHODS

The magnetic particle test method may be classified as

Wet or Dry (based upon the detecting media used)

Continuous or Residual (according to when the detecting media is

applied with relation to the magnetising force)

Visible or Fluorescent (according to the nature of the viewing

conditions)

6.1 Dry Powders

Powders comprise finely ground ferromagnetic particles, often iron,

coated or heated to a temperature which will give a distinctive colour.

British Standard 4069, magnetic flaw detection inks and powders,

lays down that the particle size must be less than 200 microns.

However, manufactures quote values well below this size.

Ideally the particle shape should be elongated. However, to allow

dry powders to flow from the dispenser, a mixture of rod shaped

particles and globular ones is used. Typical colours for powders are:

Black

Red

Grey

Yellow

Dry powders are dispersed on to the test component either through a

puffer or a dry spray can. The chosen colour is the one which gives

the best contrast against the specimen background. To enhance the

contrast a white strippable contrast paint may be sprayed or painted

on the specimen. If this is applied lightly, not more than 50 micron

thick, there will be minimal effect on defect sensitivity.

Powders are usually applicable to site work such as welds and

castings, often as an initial check on a weld root pass, where wet

materials would cause contamination. PD6513 states that dry

powders can be used for testing hot components up to 300c but

fluorescent powders may lose their brightness if heated, so should

be used at ambient temperature. We advise that manufacturers'

recommendations should be followed. Invariably powders are

treated as disposable and should not be re-used, due to the danger

of contamination by dirt and moisture.

TWI Training & Examination Services NDT 30M

39

The Welding Institute

6.2 Inks

Magnetic inks are further sub-divided into:

Contrast or fluorescent

Kerosene or water-based

The ink comprises finely ground oxides of iron, having high

permeability and low retentivity, suspended in a liquid. British

Standard 4069 requires the maximum particle size to be no more

than 100 micron, however, contrast particles are typically less than 1

micron and fluorescent less than 10 micron. The reason for the

difference is that the fluorescent particle is dye coated, whereas the

contrast particle is a natural colour of red or black.

Water-based inks are becoming more popular because of:

1. price

2. odour reduction

3. health and safety implications

Inks are usually sprayed, flooded or ladled on to the specimen.

Kerosene based materials are also sold in aerosols. Water-based

inks when used on site are often sprayed from garden dispensers

and when used in bench machines the tanks should be stainless

steel. Although a wetting agent and corrosion inhibitor is added to

the concentrate, the effects of contamination of the ink by corrosion

products cannot be ignored. Water-based inks are sold as a

concentrate and then mixed.

Kerosene based inks are supplied in bulk but to maintain the solid

content at the correct level a small amount of concentrate is added at

intervals. It is not recommended that magnetic inks are made up

with normal kerosene, especially fluorescent inks since:

The fire risk is greater. BS4069 states a minimum flash

point of 65C

There will be a higher odour level

Almost certainly there will be a high background

fluorescence under UV/A light.

Of paramount importance is the maintenance of the ink strength. The

solid content must be constantly monitored as detailed in Control

Checks, Section 9, and the ink must be constantly agitated to keep

the solid content in suspension. The appropriate solid content levels

are 0.1 to 0.3% for fluorescent ink and 1.25 to 3.5% for visible (black)

ink.

TWI Training & Examination Services NDT 30M

40

The Welding Institute

6.3 Continuous technique

The continuous technique implies that the detecting media is applied

before the magnetising force, to a component and continued during

the period of magnetisation. However, ink or powder application

should be stopped before magnetisation is stopped.

Indeed, on low retentivity components it is important to inspect at the

same time as magnetisation and ink application. A classic case of

reporting a spurious indication as a defect is where ink is allowed to

run down the toe of a weld after a test. The solid content forms a

visible line, exactly conforming to the shape of the toe and this line is

often enhanced by the residual magnetism of the heat affected zone.

What is worse is that the inspector notes the indication as spurious

but fails to see small toe defects which are now masked by that

spurious indication.

To avoid overheating the component and the equipment,

magnetisation times should be limited to 2-3 seconds. In fact some

equipment has shot timers on them to avoid the duty cycle being

exceeded.

Table 5 lists the steps in a one shot continuous technique. It should

be pointed out that if full cover of a component is envisaged, a

number of shots will be required.

1. Demagnetise if specified

2. Clean

3. Affix magnetising contacts

4. Apply detecting media

5. Apply magnetising force, 2-3 sec duration

6. Stop detecting media

7. Stop magnetising force

8. Inspect - this should start at operation 5 and

end at 8

9. Demagnetise, if specified

10. Clean

11. Protect

Table 5. Continuous technique

TWI Training & Examination Services NDT 30M

41

The Welding Institute

If demagnetisation is called for, circular magnetising tests are done

first followed by longitudinal. This is so because it is probable that

a residual circular field is not detectable but that residual field will

be removed by longitudinal test applied later. Therefore, the final

residual field to be removed is a longitudinal one, which is

detectable with a field indicator. All current waveforms are

applicable to continuous techniques, depending on the defect

morphology.

6.4 Residual technique

The residual technique uses only DC or rectified forms of AC to

magnetise a component because it is the residual flux density which

is relied upon to attract magnetic particles to the flux leakages

created by defects. Direct current and rectified AC produce a full

cross section magnetisation, whereas AC will only create an effective

flux density in the skin, hence skin effect. Thus, the residual field

from AC is not considered adequate for the residual technique.

Also the residual technique is only applicable on components

which have high retentivity, that is high carbon equivalent steels. It

usually follows that components suitable for the residual technique

are high tensile machine parts, often when we are looking for flaws

in corners or thread roots etc. If the continuous technique is used

on these parts there will be a high build up of detecting media

across such features and these non-relevant indications are likely to

mask an actual defect beneath them. For best defect sensitivity the

detecting media is applied after magnetisation and to allow time for

the particles to migrate. Inspection takes place a short time after

that.

Table 6 lists the steps in a one shot residual technique. The

magnetising values should be the higher ones recommended for

aerospace, using the appropriate electrical current waveform. Again,

circular magnetism shots should be done before longitudinal, as

invariably demagnetisation will be necessary.

TWI Training & Examination Services NDT 30M

42

The Welding Institute

1. Demagnetise

2. Clean

3. Affix magnetising contacts

4. Apply magnetising force, not AC, 2-3 sec

5. Apply detecting media, spray or dip

6. Wait, 30 sec-1 min

7. Inspect

8. Demagnetise

9. Clean

10. Protect

Table 6. Residual technique

6.5 Fluorescence and the Electromagnetic Spectrum

Fluorescence is the property of some materials to absorb

electromagnetic energy of one wavelength and re-emit the energy at

another . The ultraviolet and visible light section of the spectrum,

which is of interest in MPI, lies between 100 and 800 nm, see Fig.27.

(A nanometre (nm) is 1 millionth of a mm.) In MPI long wavelength

ultraviolet (black light) light sources are used having a waveband

between 315 and 400nm. This is UV-A radiation. Fluorescent inks

absorb energy at approximately 365nm and re-emit at about 550nm.

Industrial radiography

Microwaves Electric Waves

Ultra violet

Infra red TV

10-10 10-8 10-6 10-4 10-2 1cm 102 104 106 108

Wavelength

Figure 27 : Ultraviolet spectrum

TWI Training & Examination Services NDT 30M

43

The Welding Institute

6.5.1 Types of UV-A Lamp

By far the most common type of light source used to inspect

components tested with fluorescent ink is the mercury vapour

arc lamp. In fact, the mercury arc lamp is a street or

workshop lamp which has a filter over it to reduce the visible

light to a minimum but allow the UV-A to be transmitted.

The filter is called a Woods in the UK and a Kopp in the USA.

On the Philips type of lamp the filter is integral with the outer

envelope but on the Magnaflux unit, using either a GE or

Westinghouse lamp, it is separate.

The mercury arc is drawn between electrodes enclosed in a

quartz tube. The resistor limits the amount of current in the

starting electrode. The quartz tube is mounted and enclosed

in the outer glass envelope which serves to protect it and filter

out any possible hazardous radiations.

400W mercury vapour arc flood-lamps can be used where

very large components are tested or to give a background

illumination in an inspection area. However, background light

in a darkened area can be more economically provided by UV

strip lights.

6.5.2 Safety Precautions and Operating Instructions

Under normal working conditions, there are no known long

term harmful effects arising from the use of UV-A (black light)

sources, providing simple safety precautions and operating

instructions are observed. The precautions and instructions in

these notes are general. For full advice the manufacturers'

data on a particular light should be followed.

Safety precautions when using a UV-A mercury vapour arc

lamp

a) Avoid looking directly at the light source

b) The light must not be used without a correctly fitted filter

c) Do not operate the light with a chipped or cracked filter

d) Avoid contact with the lamp housing as it becomes hot

e) Keep the light cables away from liquids, to avoid

contamination or shorting

f) Ensure that regular electrical earth continuity checks are

carried out on the lamp unit

TWI Training & Examination Services NDT 30M

44

The Welding Institute

6.5.3 Operating instructions for a UV-A lamp

a) Allow 5 minutes warm up period after switch on, before

inspecting with the lamp

b) If the lamp is switched off and then immediately

switched on again, allow a minimum of 10 minutes

before recommencing inspection. The bulb will not re-

light until its temperature reduces.

c) Avoid repeated switching on and off, as this will reduce

bulb life significantly

d) Angle the light with respect to the specimen being

inspected, to avoid reflections which reduce inspection

efficiency

e) Clean the lamp filter regularly, with lint-free material

moistened with a mild detergent/water solution

f) Check the light output of the lamp regularly. This

should be done in accordance with paragraph 6.1 of

BS4489. The lamp must achieve a UV-A irradiance

level of 0.8mW/cm2 at the testing surface.

TWI Training & Examination Services NDT 30M

45

The Welding Institute

7. DEMAGNETISATION

British Standard 6072 recommends that demagnetisation should only be

carried out if specifically requested. In certain industries the consequences

of not demagnetising can be catastrophic.

Demagnetisation should be carried out:

1. before testing, if residual fields could affect test results

2. between tests except for when a similar shot is to be applied

but at a higher amperage. An exception can be made if a

subsequent shot is to be applied at 90 to the original and the

original field strength is to be exceeded

3. after testing, when applicable

Post demagnetising must be done:

1. on aircraft parts, where magnetic compasses and electronic

equipment may be affected

2. on rotating parts, where magnetic debris might adhere and

cause excess wear

3. where automatic arc or electron beam welding is to be carried

out and arc wander may be caused by residual magnetic

fields

4. if residual magnetic fields may affect subsequent machining

processes. Reamers and taps become magnetic as well and

thus can break in use, if swarf is not cleared from flutes.

5. when a high quality finish, such as electro-plating is to be

applied. The particles attracted will prevent or reduce

adhesion.

It is not usually necessary to demagnetise specimens which are to be heat

treated. This is provided that the heat treatment is beyond the Curie point,

about 700c. At and above the Curie point, ferromagnetic materials

become paramagnetic.

Often it is not possible or practical to demagnetise a specimen completely,

therefore a maximum residual field level must be agreed. An agreed

deflection on a calibrated or uncalibrated magnetic field indicator is the most

common.

For critical situations a compass test is recommended. The component

under test is positioned at an agreed distance from a suitable compass and

rotated through 360. The compass needle must deflect by less than 1.

TWI Training & Examination Services NDT 30M

46

The Welding Institute

7.1 Principle of Demagnetisation

Looking at a typical hysteresis loop for a ferromagnetic material

Fig.6, after the initial magnetising force is applied and then removed,

it is well nigh impossible to end the test with a zero flux density.

Even if a negative coercive force is applied it will only keep the flux

density at zero, as long as it continues to be applied.

Figure 28 shows that the key to demagnetisation is that a reversing

and reducing magnetising force must be applied, so that the

hysteresis loop reduces until all the parameters achieve zero. There

are a number of ways to achieve this.

Field

Strength

Figure 28: Demagnetisation Process

7.2 Methods of Demagnetisation

7.2.1 Aperture coil, removal

The component is passed through an aperture type coil,

whose major axis is aligned in an east-west direction and

which is carrying AC. The component is removed from the

coil to a minimum distance of 1.5m before the current is

switched off.

Special demagnetisers of this type are usually multi-turn coil,

working directly from a single phase AC supply. However, a

hand held coil made from a portable unit cable may be

adequate for site use. If the component cannot be passed

through the demagnetising coil there is no reason why the coil

should not be passed over the component to achieve the

same result.

TWI Training & Examination Services NDT 30M

47

The Welding Institute

7.2.2 Aperture coil, reducing AC

Where it is not possible to remove either the component or

the coil from the vicinity of each other, then the AC can be

reduced to zero to achieve the same demagnetising effect.

Modern units use a capacitor discharging to achieve an

almost instantaneous result.

7.2.3 Aperture coil, reversing DC

Sometimes if a component has been magnetised using DC or

rectified AC, it is nearly impossible to reduce the residual flux

density to a satisfactory level using AC. This is especially true

if the component is a complex shape.

Therefore, a reversing and reducing DC, or more usually full

wave rectified and smoothed AC, is used. The component is

usually left in the coil but with long components the operation

is carried out several times along its length.

Each reduction of current should be 50% of the preceding

one, down to a reasonable minimum.

7.2.4 Electromagnet, reversing DC

The same principles apply as with the reversing DC aperture

coil method, but in this case the component is clamped

between the poles of an electromagnet in a field strong

enough to saturate it magnetically. The field is then reduced

and reversed in 50% increments to near zero.

7.2.5 Electromagnet, AC yoke

A most useful way to remove local residual fields on

components in situ, on a structure than cannot easily be

moved or removed, is by means of a portable AC powered

electromagnet. The energised yoke is pulled over and off the

component, to a distance of about 450mm and then switched

off. If the level achieved is not adequate, the operation is

repeated in the same way and direction until the residual field

is removed.

TWI Training & Examination Services NDT 30M

48

The Welding Institute

8. CONTROL AND MAINTENANCE CHECKS

In order to ensure that the equipment ancillaries and materials are up to

standard it is necessary to carry out a number of control checks. It is also

important to make sure that the system performs consistently each day.

Common sense dictates that the equipment, etc is maintained properly.

The checks covered in this section are meant to be guides to proper

practice. In different organisations there will obviously be variations and

therefore the code or standard specified for a particular job must be the

overriding factor.

8.1 Ink settlement test

This test is carried out daily or at each shift. Additionally, it is carried

out whenever the ink is changed in a bench unit or a new batch is

made up. A 100ml settlement flask, sometimes called a centrifuge

tube, is used.

The ink is agitated for 5 min and then a 100ml sample is poured into

the settlement flask. The sample is allowed to settle for 60 min and

the volume of solid is then read off the flask scale.

Section 6.2 mentions the recommended concentration maxima and

minima.

8.2 Fluorescent ink intensity

Fluorescent inks should be discarded if there is evidence of

fluorescence in the carrier fluid (supernatant liquid). This can

happen due to over-vigorous agitation, causing the fluorescent dye

to break off the magnetic particles.

Also, a sample of unused agitated ink should be compared with a

similar sample of in-use material under UV/A light. If there is any

significant loss of brightness of the used material, it must be

discarded.

9.3 Equipment performance check

This test is carried out to find any changes that may have occurred

during the day to day use of the equipment or materials. The test is

carried out at the start of work or at shift change.

British Standard 4069, Figures 2, 3 and 4 show detailed views of

these test pieces, although the magnetic flow/coil often has five

holes drilled transverse to the major axis at varying depths.

To carry out the test the appropriate test piece is processed and the

minimum ammeter readings which give satisfactory build-up of

TWI Training & Examination Services NDT 30M

49

The Welding Institute

particles at each hole, are established and noted. This is normally

first done when everything else about the unit is in total control, e.g.

ink renewed, ammeters calibrated, etc and is repeated for each

current waveform.

At each successive check the relevant hole should be visible at the

appropriate amperage.

There are variations on this method but the principle is followed in

BS4069, Appendix B, paragraphs B2 and B4 and BS6072, Appendix

C.

9.4 Viewing efficiency

The output of the ultraviolet (UV-A) lamps used in magnetic particle

inspection will deteriorate with age. In addition, the output can vary

due to:

a) Displacement and tarnishing of the reflector

b) Dirt and other contaminants on the filter

c) Variations of the voltage to the lamp

It is therefore necessary to check the output of all UV-A lamps

regularly. This check involves the use of a radiometer which will

respond to radiation in the UV-A range (400nm-315nm) (nm = 1

nano metre = 10-9m). The test procedure is as follows. Position the

radiometer with the detector at a distance of 400mm, or working

distance, from the front surface of the lamp. If the reading at this

distance exceeds the full scale of the meter, use such longer

distances as will bring the reading to approximately 2/3 scale. Move

the detector in a plane normal to the axis of the beam from the lamp

until a maximum reading is obtained. Record on the lamp calibration

label the radiometer reading, the distance of the lamp from the

radiometer if greater than 400mm and the date. This test, repeated

at regular intervals, will reveal any deterioration in performance or

the need for maintenance of the lamp.

Ultraviolet, UV-A, lamps should be changed if the output at working

distance falls below 0.8mW/cm2 or 800 W/cm2 (mW = milli watt,

W = micro watt) at test surface.

The background light in an inspection area should be darker than 10

lux. If black ink is being used in white light conditions, the level of

light at the work face should exceed 500 lux. This is equivalent to an

80W strip light at 1 metre.

TWI Training & Examination Services NDT 30M

50

The Welding Institute

9.5 Magnetising units

This is a general check for wear, abuse and general cleanliness.

9.6 Tank levels

A surprising amount of ink, including solid particles, is carried off on

components during testing. Ink level and strength checks are

underrated items and are ignored at the inspector's peril.

9.7 Ultraviolet lamp maintenance

A considerable loss of light output can be experienced because of

dirty filters. Before condemning a lamp, clean it and the filter in a

detergent solution.

9.8 Ammeters

Must be checked and calibrated regularly with a meter traceable to

national standards. Most major manufacturers will provide a service

if ownership of a master meter is not considered economic.

9.9 Demagnetiser

Often forgotten until something goes wrong. There does not seem to

be a national standard but a major aerospace manufacturer

recommends that demagnetisers should have a minimum internal

field strength of 5.57kA/m. As with ammeters, the major MPI

equipment manufacturers will provide a service when requested.

TWI Training & Examination Services NDT 30M

51

You might also like

- MT Level III QB Magnetism Test QuestionsDocument2 pagesMT Level III QB Magnetism Test QuestionskingstonNo ratings yet

- Eddy Current Testing LevelII Questions and AnswersDocument6 pagesEddy Current Testing LevelII Questions and AnswersStu Sutcliffe67% (3)

- MT Level I 08-12Document87 pagesMT Level I 08-12R A Bismil100% (1)

- PT Q&aDocument40 pagesPT Q&aJoe BetkerNo ratings yet

- MT Level II 08-12Document208 pagesMT Level II 08-12Tapan Kumar Nayak100% (5)

- Eddy Current Inspection: Detect Flaws in Metals Using Electromagnetic InductionDocument73 pagesEddy Current Inspection: Detect Flaws in Metals Using Electromagnetic InductionSuraj B SNo ratings yet

- MT - GenDocument8 pagesMT - GenkanchanabalajiNo ratings yet

- NDT MT nds1Document41 pagesNDT MT nds1sathi11189No ratings yet

- ASNT - Materials & Process For NDT Technology ASNT Specific Questions - LavenderDocument39 pagesASNT - Materials & Process For NDT Technology ASNT Specific Questions - LavenderMiguel Angel Aguilar Mena100% (1)

- About Magnetic Particle TestingDocument2 pagesAbout Magnetic Particle TestingRaoFarhanNo ratings yet

- Level II Question PaperDocument16 pagesLevel II Question PaperMuhammad HannanNo ratings yet

- Navy NDT - Magnetic ParticleDocument5 pagesNavy NDT - Magnetic Particlebesmindo012345No ratings yet

- PT Level III NoteDocument3 pagesPT Level III NoteAllen Situ80% (5)

- NDT4 - L2 Final Review (EOC) 020219Document13 pagesNDT4 - L2 Final Review (EOC) 020219Ibnu Hamdun100% (1)

- MPT TEST LEVEL-III MAGNETIC PARTICLE TESTING REVIEWDocument24 pagesMPT TEST LEVEL-III MAGNETIC PARTICLE TESTING REVIEWAnu AnoopNo ratings yet

- VT For NDT - 2017Document29 pagesVT For NDT - 2017Selvakpm06No ratings yet

- Magnetic Particle TestingDocument3 pagesMagnetic Particle TestingAnu AnoopNo ratings yet

- MT Level III QuestionsDocument12 pagesMT Level III QuestionsAnu Anoop100% (2)

- Name: - DateDocument7 pagesName: - Datekarioke mohaNo ratings yet

- Level II Questions - MT - Ver - EngDocument6 pagesLevel II Questions - MT - Ver - EngJulio Cesar Fernadez EstelaNo ratings yet

- Eddy Current Testing for Tube InspectionDocument23 pagesEddy Current Testing for Tube InspectionvibinkumarsNo ratings yet

- PT Quiz & Ans 2Document6 pagesPT Quiz & Ans 2Goutam Kumar Deb100% (1)

- Ultrasonic TestingDocument52 pagesUltrasonic TestingSatheenaThiruvenkadamNo ratings yet

- CBIP Magnetic Particle Level 2 Exam QuestionsDocument3 pagesCBIP Magnetic Particle Level 2 Exam QuestionsRohit JosephNo ratings yet

- MT Self-Study NoteDocument153 pagesMT Self-Study Notenewdao100% (5)