Professional Documents

Culture Documents

Safety Data Sheet: Identification of The Preparation and of The Company 1

Uploaded by

Rehan SadiqOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Safety Data Sheet: Identification of The Preparation and of The Company 1

Uploaded by

Rehan SadiqCopyright:

Available Formats

Conforms to Regulation (EC) No.

1907/2006 (REACH), Annex II

SAFETY DATA SHEET

Guard Classic D (C052)

1. Identification of the preparation and of the company

Product name : Guard Classic D (C052)

SDS Code : C052

Supplier/Manufacturer : JOTUN POWDER COATINGS PAKISTAN (Pvt) Ltd.

2 KM DEFENCE ROAD, OFF 9 KM RAIWIND RD. NEAR

VALANCIA HOMES GATE, LAHORE

PAKISTAN

Phone : + 92 42 53 20 438

Fax : + 92 42 53 20 468

sdspowder@jotun.com

Emergency telephone : Phone : + 971 4 347 2515

number

Product type : Powder coating.

28000 3 28000

^(ValidationDate) 1

Approved

2. Hazards identification

The product is not classified as dangerous according to Directive 1999/45/EC and its amendments.

This product is not classified according to EU legislation.

Additional hazards : None known.

3. Composition/information on ingredients

Type

[1] Substance classified with a health or environmental hazard

[2] Substance with a workplace exposure limit

[3] Substance meets the criteria for PBT according to Regulation (EC) No. 1907/2006, Annex XIII

[4] Substance meets the criteria for vPvB according to Regulation (EC) No. 1907/2006, Annex XIII

[5] Substance of equivalent concern

4. First-aid measures

First-aid measures

General : In all cases of doubt, or when symptoms persist, seek medical attention. Never give

anything by mouth to an unconscious person. If unconscious, place in recovery

position and seek medical advice.

Inhalation : Remove to fresh air. Keep person warm and at rest. If not breathing, if breathing is

irregular or if respiratory arrest occurs, provide artificial respiration or oxygen by

trained personnel.

Skin contact : Remove contaminated clothing and shoes. Wash skin thoroughly with soap and

water or use recognised skin cleanser. Do NOT use solvents or thinners.

Eye contact : Remove contact lenses, irrigate copiously with clean, fresh water, holding the

eyelids apart for at least 10 minutes and seek immediate medical advice.

Ingestion : If swallowed, seek medical advice immediately and show the container or label.

Keep person warm and at rest. Do NOT induce vomiting.

Date of issue : 11.04.2016 Page: 1/4

Guard Classic D (C052)

5. Fire-fighting measures

Extinguishing media : Recommended: alcohol-resistant foam, CO blanket, water spray or mist.

Extinguishing media not to : Do not use water jet.

be used Do not use inert gas under high pressure (e.g. CO2).

Recommendations : Fire will produce dense black smoke. Exposure to decomposition products may

cause a health hazard. Appropriate breathing apparatus may be required.

Cool closed containers exposed to fire with water. Do not release runoff from fire to

drains or watercourses.

Fire/explosion hazards : Fine dust clouds may form explosive mixtures with air.

6. Accidental release measures

Personal precautions : Exclude sources of ignition and ventilate the area. Avoid breathing dust. Refer to

protective measures listed in sections 7 and 8.

Spill : Contain and collect spillage with an electrically protected vacuum cleaner or by wet-

brushing and place in container for disposal according to local regulations (see

section 13). Do not use a dry brush as dust clouds or static can be created.

Note: see section 8 for personal protective equipment and section 13 for waste disposal.

7. Handling and storage

Advice should be taken from a competent occupational health practitioner on the assessment of employees

with skin or respiratory complaints before the individual is exposed to the uncured product.

Handling : Precautions should be taken to prevent the formation of dusts in concentrations

above flammable, explosive or occupational exposure limits.

Electrical equipment and lighting should be protected to appropriate standards to

prevent dust coming into contact with hot surfaces, sparks or other ignition sources.

Mixture may charge electrostatically: always use earthing leads when transferring

from one container to another.

Operators should wear antistatic footwear and clothing and floors should be of the

conducting type.

Keep away from heat, sparks and flame.

Avoid contact with skin and eyes. Avoid the inhalation of dust, particulates, spray or

mist arising from the application of this mixture. Avoid inhalation of dust from

sanding.

Eating, drinking and smoking should be prohibited in areas where this material is

handled, stored and processed.

Put on appropriate personal protective equipment (see Section 8).

Always keep in containers made from the same material as the original one.

Comply with the health and safety at work laws.

Do not allow to enter drains or watercourses.

Storage : Store in accordance with local regulations.

Additional information on storage conditions

Observe label precautions. Store in a dry, cool and well-ventilated area. Keep away

from heat and direct sunlight.

Keep container tightly closed.

Keep away from sources of ignition. No smoking. Prevent unauthorised access.

Containers that have been opened must be carefully resealed and kept upright to

prevent leakage.

See Technical Data Sheet / packaging for further information.

8. Exposure controls/personal protection

Engineering measures : Avoid breathing dust. Where reasonably practicable, this should be achieved by the

use of local exhaust ventilation and good general extraction. If these are not

sufficient to maintain exposure to dusts below the OEL, suitable respiratory

protection must be worn.

Occupational exposure : Dust Limit : 10 mg/m (TWA of total inhalable dust) and 4 mg/m (TWA of respirable)

limits

No exposure limit value known.

Personal protective equipment

Date of issue : 11.04.2016 Page: 2/4

Guard Classic D (C052)

Respiratory system : If workers are exposed to concentrations above the exposure limit, they must use

appropriate, certified respirators. If dust is generated and ventilation is inadequate,

use respirator that will protect against dust/mist. (FFP2 / N95).

Skin and body : Personnel should wear protective clothing. Care should be taken in the selection of

protective clothing to ensure that inflammation and irritation of the skin at the neck

and wrists through contact with the powder are avoided.

Hands : Wear suitable gloves. Barrier creams may help to protect the exposed areas of the

skin but should not be applied once exposure has occurred.

The user must check that the final choice of type of glove selected for handling this

product is the most appropriate and takes into account the particular conditions of

use, as included in the user's risk assessment.

Eyes : Safety eyewear should be used when there is a likelihood of exposure.

9. Physical and chemical properties

Physical state : Powder.

Odour : Odourless.

Colour : Various

Density : 1.2 to 1.9 g/cm

Not applicable.

Lower explosion limit : 30 g/m

Minimum ignition energy : 10 - 30

(mJ)

Decomposition temperature : 230C (446F)

Auto-ignition temperature : Not applicable.

Melting point/melting range : Not applicable.

10. Stability and reactivity

Stable under recommended storage and handling conditions (see Section 7).

Hazardous decomposition products: carbon monoxide, carbon dioxide, smoke, oxides of nitrogen.

Fine dust clouds may form explosive mixtures with air.

11. Toxicological information

There are no data available on the mixture itself. The mixture is not classified as dangerous according to Directive

1999/45/EC and its amendments.

Coating powders can cause localised skin irritation in folds of the skin or under tight clothing. Handling and/or

processing of this material may generate a dust which can cause mechanical irritation of the eyes, skin, nose and

throat. Repeated inhalation of dust can produce varying degrees of respiratory irritation or lung damage. Swallowing

may cause nausea, diarrhoea, vomiting and gastro-intestinal irritation.

Handling and/or processing of this material may generate a dust which can cause mechanical irritation of the eyes, skin,

nose and throat. Repeated inhalation of dust can produce varying degrees of respiratory irritation or lung damage.

12. Ecological information

There are no data available on the mixture itself.

Coating powder residues should not be allowed to enter drains or watercourses or be deposited where they could

affect ground or surface waters.

The mixture has been assessed following the summation method of the CLP Regulation (EC) No 1272/2008 and is not

classified as hazardous to the environment.

Date of issue : 11.04.2016 Page: 3/4

Guard Classic D (C052)

13. Disposal considerations

Within the present knowledge of the supplier, this product is not regarded as hazardous waste, as defined by EU

Directive 91/689/EEC.

European waste catalogue : 08 02 01 08 02 01 waste coating powders

(EWC) If this product is mixed with other wastes, this code may no longer apply. If mixed

with other wastes, the appropriate code should be assigned. For further information,

contact your local waste authority.

14. Transport information

Transport within users premises: always transport in closed containers that are upright and secure. Ensure that

persons transporting the product know what to do in the event of an accident or spillage.

This preparation is not classified as dangerous according to international transport regulations (ADR/RID, IMDG or

ICAO/IATA).

15. Regulatory information

EU regulations : The product is determined as not being dangerous according to the requirements of

the DPD.

Safety phrases : S22- Do not breathe dust.

Additional information : IMO Antifouling System Convention compliant (AFS/CONF/26).

Industrial use : The information contained in this safety data sheet does not constitute the users

own assessment of workplace risks, as required by other health and safety

legislation. The provisions of the national health and safety at work regulations apply

to the use of this product at work.

16. Other information

CEPE Classification : 3

Europe

Full text of abbreviated H : Not applicable.

statements

Full text of abbreviated R : Not applicable.

phrases

This Safety Data Sheet is prepared in accordance with Annex II to Regulation (EC) No 1907/2006.

Date of issue : 11.04.2016

Version : 1.04

Notice to reader

The information in this document is given to the best of Jotun's knowledge, based on laboratory testing and

practical experience. Jotun's products are considered as semi-finished goods and as such, products are

often used under conditions beyond Jotun's control. Jotun cannot guarantee anything but the quality of the

product itself. Minor product variations may be implemented in order to comply with local requirements.

Jotun reserves the right to change the given data without further notice.

Users should always consult Jotun for specific guidance on the general suitability of this product for their

needs and specific application practices.

If there is any inconsistency between different language issues of this document, the English (United

Kingdom) version will prevail.

Date of issue : 11.04.2016 Page: 4/4

You might also like

- Material Safety Data Sheet: Toa Thinner # 21Document5 pagesMaterial Safety Data Sheet: Toa Thinner # 21ชินวิช แสงสักNo ratings yet

- MSDS Hair PermDocument10 pagesMSDS Hair Permsabuyexpress.worldwideNo ratings yet

- Material Safety Data Sheet: Product and Company Identification 1Document16 pagesMaterial Safety Data Sheet: Product and Company Identification 1Safdar JuttNo ratings yet

- Xan PlexDocument6 pagesXan PlexArina Sauki100% (1)

- SDS - Fenomastic Emulsion Primer - English (Uk) - Dubai PDFDocument4 pagesSDS - Fenomastic Emulsion Primer - English (Uk) - Dubai PDFBNo ratings yet

- Safety Data Sheet: Identification of The Substance/preparation and Company/undertaking 1Document3 pagesSafety Data Sheet: Identification of The Substance/preparation and Company/undertaking 1John RamboNo ratings yet

- Material Safety Data Sheet InsightsDocument10 pagesMaterial Safety Data Sheet InsightsDarin WilsonNo ratings yet

- Epocast 1628 BDocument10 pagesEpocast 1628 BNICKYNo ratings yet

- MSDS - 1.120SB.0102Document6 pagesMSDS - 1.120SB.0102Pollo tiktokNo ratings yet

- Safety Data Sheet: Section 1. IdentificationDocument9 pagesSafety Data Sheet: Section 1. IdentificationFleet B Arcadia AegeanNo ratings yet

- Raw Material Safety Data SheetDocument10 pagesRaw Material Safety Data SheetRinal ArnandoNo ratings yet

- Msds Lanco 1890 CDocument9 pagesMsds Lanco 1890 CBryan GavilanezNo ratings yet

- Material Safety Data Sheet: Product and Company Identification 1Document6 pagesMaterial Safety Data Sheet: Product and Company Identification 1zubair1950No ratings yet

- MSDS 0649 Sigma Enamel SA21 Oct 2008Document6 pagesMSDS 0649 Sigma Enamel SA21 Oct 2008mohamed.farouk.takkyNo ratings yet

- MSDS Jotun Thinner No 2Document8 pagesMSDS Jotun Thinner No 2willhansen kamarga100% (1)

- Dupont™ Vertak® Dba2220: Safety Data SheetDocument11 pagesDupont™ Vertak® Dba2220: Safety Data SheetJose Antonio Montoya Gonzalez TayniNo ratings yet

- BFL5818 MSDSDocument7 pagesBFL5818 MSDSRamdhan ShalehNo ratings yet

- Sikagard 703W MSDS 1Document5 pagesSikagard 703W MSDS 1lir mNo ratings yet

- Dade Actin FS PDFDocument5 pagesDade Actin FS PDFIto SukirnaNo ratings yet

- Material Safety Data Sheet: Pilot IIDocument7 pagesMaterial Safety Data Sheet: Pilot IIBeyar. ShNo ratings yet

- Material Safety Data Sheet: Version No.01 - Revision Date 12/07/2010Document10 pagesMaterial Safety Data Sheet: Version No.01 - Revision Date 12/07/2010shulhan nstNo ratings yet

- MSDS Castrol Perfecto XPG 32Document4 pagesMSDS Castrol Perfecto XPG 32Teguh SNo ratings yet

- Safety Data Sheet: 1. IdentificationDocument10 pagesSafety Data Sheet: 1. IdentificationzaighumNo ratings yet

- Chlorine Based Sanitiser MSDSDocument9 pagesChlorine Based Sanitiser MSDSFerguson MushanduriNo ratings yet

- Safety Data Sheet Sanitizer: Section 1. Product and Company IdentificationDocument8 pagesSafety Data Sheet Sanitizer: Section 1. Product and Company IdentificationcasildogonzalesNo ratings yet

- Safety Data Sheet Energol THB 46Document4 pagesSafety Data Sheet Energol THB 46zaidan hadiNo ratings yet

- MSDS - Reagent ModuleDocument8 pagesMSDS - Reagent ModuleEdwin AgustianNo ratings yet

- Ecolab Alkali BoosterDocument8 pagesEcolab Alkali BoosterRND HEAVENCHEMICALNo ratings yet

- Safety Data Sheet NALCO® 7330: Section 1. Product and Company IdentificationDocument11 pagesSafety Data Sheet NALCO® 7330: Section 1. Product and Company IdentificationFSAAVEDRAFNo ratings yet

- DEDM0431 - Siemens AUS MSDS - Australia - EukDocument8 pagesDEDM0431 - Siemens AUS MSDS - Australia - Eukheru ramadhanNo ratings yet

- UV Ink MSDS Safety Hazards CompositionDocument4 pagesUV Ink MSDS Safety Hazards Compositionnorbertscribd0% (1)

- Corena Oil PDocument5 pagesCorena Oil Pmingyu parkNo ratings yet

- Cleaning Product MSDSDocument10 pagesCleaning Product MSDSElzubair EljaaliNo ratings yet

- Medline Fresh Odor Eliminators SprayDocument7 pagesMedline Fresh Odor Eliminators SprayB4nt3nNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingDocument4 pagesSafety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingBNo ratings yet

- Msds Energol THB 46Document5 pagesMsds Energol THB 46Teguh SNo ratings yet

- SikaGrout 215M.MSDSDocument5 pagesSikaGrout 215M.MSDSMuhammad Akbar AriantoNo ratings yet

- Safety Data Sheet: 30275 / Dichlorodifluoromethane Standard Page 1 of 6Document6 pagesSafety Data Sheet: 30275 / Dichlorodifluoromethane Standard Page 1 of 6Andy TariganNo ratings yet

- ASHWAGANDHA OIL (Winter Cherry) - MSDSDocument7 pagesASHWAGANDHA OIL (Winter Cherry) - MSDSnkrotkovNo ratings yet

- Complement Super: Safety Data SheetDocument7 pagesComplement Super: Safety Data SheetANDRE AURELLIONo ratings yet

- THV-5102019-03-28 ThifeDocument7 pagesTHV-5102019-03-28 Thifejason KlangNo ratings yet

- Sika Grout 212 215 212hp - MsdsDocument5 pagesSika Grout 212 215 212hp - MsdsMohd MustafhaNo ratings yet

- MSDS ST70Document11 pagesMSDS ST70Multazam KamaludinNo ratings yet

- DEDM0429 - Siemens AUS MSDS - Australia - EukDocument6 pagesDEDM0429 - Siemens AUS MSDS - Australia - Eukheru ramadhanNo ratings yet

- FDS-jotamastic 87 ALU Comp ADocument7 pagesFDS-jotamastic 87 ALU Comp Amahmoud_allam3No ratings yet

- PPD 2 - Champion X Para19304aDocument9 pagesPPD 2 - Champion X Para19304aJeevanNo ratings yet

- Safety Data Sheet for Acetanilide, Tech GradeDocument7 pagesSafety Data Sheet for Acetanilide, Tech GradeSuad QasimovNo ratings yet

- MSDS Nalco 3935Document9 pagesMSDS Nalco 3935zainudin simonNo ratings yet

- Ally 20DFDocument6 pagesAlly 20DFGUDANG BIENo ratings yet

- Florgard Epu SL Part A - MSDSDocument5 pagesFlorgard Epu SL Part A - MSDSGabriel GabeNo ratings yet

- Sigma Thinner 21-06 PDFDocument6 pagesSigma Thinner 21-06 PDFusman khalidNo ratings yet

- Solisep MPT150Document8 pagesSolisep MPT150huyNo ratings yet

- Safety Data Sheet for Optigard Ant BaitDocument8 pagesSafety Data Sheet for Optigard Ant Baitrei estacioNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingDocument4 pagesSafety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingBalasubramanian AnanthNo ratings yet

- PF-XC: Product Trade NameDocument5 pagesPF-XC: Product Trade NameSupanca Ade PutriNo ratings yet

- Durathane Matt - Comp ADocument4 pagesDurathane Matt - Comp ABalasubramanian AnanthNo ratings yet

- 2023 SDS N3935 EngDocument9 pages2023 SDS N3935 Enganthony tiensunNo ratings yet

- MSDS Sika - 4a - 1010Document7 pagesMSDS Sika - 4a - 1010Allan AlagerNo ratings yet

- ANA Hardener 90150 SG6NDocument11 pagesANA Hardener 90150 SG6NAgung Wahyu WidodoNo ratings yet

- Survival Skills: How to Survive Anything and Anywhere in the World (A Comprehensive Guide to Preparing for and Overcoming Challenges of Earthquakes)From EverandSurvival Skills: How to Survive Anything and Anywhere in the World (A Comprehensive Guide to Preparing for and Overcoming Challenges of Earthquakes)No ratings yet

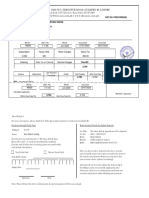

- Tianjin Grewin Technology Co.,Ltd. Electric Power Inductor/Bar Inductor /chokeDocument4 pagesTianjin Grewin Technology Co.,Ltd. Electric Power Inductor/Bar Inductor /chokeRehan SadiqNo ratings yet

- Notice AGM 2021Document3 pagesNotice AGM 2021Rehan SadiqNo ratings yet

- KE Electric Tenders Spare Parts for Flowserve Positioners, Load Break SwitchesDocument2 pagesKE Electric Tenders Spare Parts for Flowserve Positioners, Load Break SwitchesRehan SadiqNo ratings yet

- London Metal Exchange - LME CopperDocument1 pageLondon Metal Exchange - LME CopperRehan SadiqNo ratings yet

- Solutions For Electrical Installation in Buildings - Catalogue - 2017Document8 pagesSolutions For Electrical Installation in Buildings - Catalogue - 2017BojanNo ratings yet

- Voestalpine Range of Supply Electrical Steel EN 030720Document11 pagesVoestalpine Range of Supply Electrical Steel EN 030720Rehan SadiqNo ratings yet

- Tianjin Grewin Technology Co.,Ltd. Electric Power Inductor/Bar Inductor /chokeDocument4 pagesTianjin Grewin Technology Co.,Ltd. Electric Power Inductor/Bar Inductor /chokeRehan SadiqNo ratings yet

- Standard Procedure and Formula for Price AdjustmentDocument13 pagesStandard Procedure and Formula for Price AdjustmentAbhinav Goel100% (3)

- Field Studies Using the Cantilever Beam TestDocument5 pagesField Studies Using the Cantilever Beam TestRehan SadiqNo ratings yet

- Export Price List for Wooden ProductsDocument8 pagesExport Price List for Wooden ProductsRehan SadiqNo ratings yet

- Student Counselling ProfileDocument2 pagesStudent Counselling ProfileRehan SadiqNo ratings yet

- T-1155 Mr. Rehan Sadiq: 17 Old FCC, Ferozpur Road, Gulberg Iii, LahoreDocument1 pageT-1155 Mr. Rehan Sadiq: 17 Old FCC, Ferozpur Road, Gulberg Iii, LahoreRehan SadiqNo ratings yet

- 7th National ISMO Class 6 Question PaperDocument10 pages7th National ISMO Class 6 Question PaperRehan SadiqNo ratings yet

- General Terms of Sales & DeliveryDocument1 pageGeneral Terms of Sales & DeliveryRehan SadiqNo ratings yet

- P263e BASFs Ultra-Light Polyurethane Utility Pole Helps Improve ResilienceDocument3 pagesP263e BASFs Ultra-Light Polyurethane Utility Pole Helps Improve ResilienceRehan SadiqNo ratings yet

- Dev Prof Test Gust PDFDocument8 pagesDev Prof Test Gust PDFjonalserNo ratings yet

- Dev Prof Test Gust PDFDocument8 pagesDev Prof Test Gust PDFjonalserNo ratings yet

- DDS 50-2007-MinDocument46 pagesDDS 50-2007-MinRehan SadiqNo ratings yet

- Computer Science 2210: The City SchoolDocument10 pagesComputer Science 2210: The City SchoolRehan SadiqNo ratings yet

- Final English SBP Guidelines Edited24 MARCH2020 PDFDocument13 pagesFinal English SBP Guidelines Edited24 MARCH2020 PDFRehan SadiqNo ratings yet

- Car Ij Appfrm PDFDocument4 pagesCar Ij Appfrm PDFNajeeb KhanNo ratings yet

- Bogo Lahore Brands - 2018-2019 - Sheet3Document24 pagesBogo Lahore Brands - 2018-2019 - Sheet3Rehan SadiqNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Soc Changes PDFDocument1 pageSoc Changes PDFAisha ShahabNo ratings yet

- Busbar SpecificationsDocument2 pagesBusbar SpecificationsFathi MusaNo ratings yet

- Car Ij Appfrm PDFDocument4 pagesCar Ij Appfrm PDFNajeeb KhanNo ratings yet

- National TransmissionDocument236 pagesNational Transmissionhammadriaz1No ratings yet

- Car Ij Appfrm PDFDocument4 pagesCar Ij Appfrm PDFNajeeb KhanNo ratings yet

- DR Sania Nishtar Assets NewDocument4 pagesDR Sania Nishtar Assets NewRehan SadiqNo ratings yet

- Perry Johnson Laboratory Accreditation, Inc.: Proficiency Testing RequirementsDocument22 pagesPerry Johnson Laboratory Accreditation, Inc.: Proficiency Testing Requirementscalibrator1No ratings yet

- Illustrated Microsoft Office 365 and Office 2016 Fundamentals 1st Edition Hunt Test BankDocument19 pagesIllustrated Microsoft Office 365 and Office 2016 Fundamentals 1st Edition Hunt Test BankJenniferAguilardswnp100% (17)

- CVD - Deployment Guide For Cisco HyperFlex 2.5 For Virtual Server InfrastructureDocument234 pagesCVD - Deployment Guide For Cisco HyperFlex 2.5 For Virtual Server Infrastructurekinan_kazuki104100% (1)

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument4 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagyaNo ratings yet

- Drop BoxDocument77 pagesDrop BoxBetty Elizabeth Moreno CarrascoNo ratings yet

- Servo - Magazine.7.03.mar.2009. .EggBotDocument84 pagesServo - Magazine.7.03.mar.2009. .EggBotimpactusjr100% (1)

- SRM Digest 2011Document559 pagesSRM Digest 2011sogatNo ratings yet

- Sustainability Reporting - What, Why and How PDFDocument2 pagesSustainability Reporting - What, Why and How PDFanon_291955230No ratings yet

- ? @abcd E FG? HI JE Gbi? KLM JGJD E FGC? HBCD ? NDocument54 pages? @abcd E FG? HI JE Gbi? KLM JGJD E FGC? HBCD ? Nrhymes2uNo ratings yet

- LNL Iklcqd /: Grand Total 11,109 7,230 5,621 1,379 6,893Document2 pagesLNL Iklcqd /: Grand Total 11,109 7,230 5,621 1,379 6,893Dawood KhanNo ratings yet

- Indian Construction Company Email ListxlsDocument66 pagesIndian Construction Company Email Listxlstaksh.vadaNo ratings yet

- Tổng mạch điện ECU PRO-NEW-3 PDFDocument260 pagesTổng mạch điện ECU PRO-NEW-3 PDFNhật ĐặngNo ratings yet

- Haroon AssignmentDocument3 pagesHaroon AssignmentHaroon KhanNo ratings yet

- Adding Fling Effects To Processed Ground-Motion Time HistoriesDocument17 pagesAdding Fling Effects To Processed Ground-Motion Time HistoriesPatrick CanceranNo ratings yet

- TOCSIN 750 - Datasheet NEWDocument7 pagesTOCSIN 750 - Datasheet NEWabcd8482No ratings yet

- SAD Unit 4 Distributed Database DesignDocument30 pagesSAD Unit 4 Distributed Database DesignonesnoneNo ratings yet

- Air Handling Units Functional Sections and DesignationsDocument44 pagesAir Handling Units Functional Sections and Designationsdiagnoz7auto7carsvanNo ratings yet

- Kaplan Turbine Is A Type ofDocument12 pagesKaplan Turbine Is A Type ofRaunak PrustyNo ratings yet

- 7.module Giam Sat - MAD-401-IDocument2 pages7.module Giam Sat - MAD-401-IsonNo ratings yet

- Nursing Aid ExamDocument144 pagesNursing Aid Examamulan_a93% (15)

- Experiment 6: Projectile MotionDocument4 pagesExperiment 6: Projectile MotionllllllNo ratings yet

- National Junkanoo Museum Preserves Bahamian IdentityDocument105 pagesNational Junkanoo Museum Preserves Bahamian IdentityBen AkobenNo ratings yet

- CBI Vs Mastery LearningDocument3 pagesCBI Vs Mastery LearningleinhuynhNo ratings yet

- Dynamic and Static Ropes: ManualDocument34 pagesDynamic and Static Ropes: ManualKhomeini AchmadNo ratings yet

- Sustainability Report 2020 ToyotaDocument36 pagesSustainability Report 2020 ToyotaMonicaNo ratings yet

- Tacit Knowledge and Knowledge ConversionDocument19 pagesTacit Knowledge and Knowledge ConversionFrancesco CassinaNo ratings yet

- Delhi Public School, Warangal: Enrichment Worksheet-2Document3 pagesDelhi Public School, Warangal: Enrichment Worksheet-2drpNo ratings yet

- END - Report GRP 4 PDFDocument169 pagesEND - Report GRP 4 PDFAmsathvany KanagasuntharasuwamyNo ratings yet

- Led Tube HF Ballast Compatibility List Q4 2021Document34 pagesLed Tube HF Ballast Compatibility List Q4 2021Iñaki Prego RamosNo ratings yet

- English 8Document8 pagesEnglish 8John Philip PatuñganNo ratings yet

- BeowulfDocument13 pagesBeowulfJingky MarzanPurisima Lumauig SallicopNo ratings yet