Professional Documents

Culture Documents

752 Handbook

Uploaded by

Abdul Shokor Abd TalibCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

752 Handbook

Uploaded by

Abdul Shokor Abd TalibCopyright:

Available Formats

AIR CONDITIONING AND CLIMATE CONTROL

Course 752

2004 Toyota Motor Sales, U.S.A., Inc.

All rights reserved. This book may not be reproduced or copied, in whole or in part by any means, without the written

permission of Toyota Motor Sales, U.S.A. Inc.

Printed in the U.S.A.

Ver. 1 Jan. 2005

Toyota Motor Sales, U.S.A., Inc.

Course 752 Toyota Air Conditioning and Climate Control

Table of Contents

Introduction Introduction to Toyota Air Conditioning

and Automatic Temperature Control . . . . . . . . . . . . . . . . . . . . . . . v

Section 1 Safety Practices . . . . . . . . . . . ......................... . . . 1-1

Preparation Compressed Gases . . . . ........................ . . . 1-1

Electrical Circuits . . . . . . . ........................ . . . 1-2

SRS/Airbag Systems . . . ........................ . . . 1-2

Tools and Equipment . . . ........................ . . . 1-3

Section 2 The Refrigerant Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

The A/C System Expansion and Evaporation . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Compression and Condensation . . . . . . . . . . . . . . . . . . . . . 2-1

Refrigerant Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Basic A/C System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

System Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Review . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Section 3 Expansion Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

A/C System Evaporator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Expansion Valve/Evaporator Interaction . . . . . . . . . . . . . . . . . . . 3-4

Components

Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Compressor Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Condenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Receiver-Drier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Pressure Relief Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Multipressure Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Lines and Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Cooling Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

A/C Blower Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Review of Refrigeration Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Section 4 Systematic Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Diagnosis and Toyota Six-Step Diagnosis Process . . . . . . . . . . . . . . . . . . . 4-1

Repair System Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Need for Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . .4-3

A/C-Specific Maintenance and Inspection . . . . . . . . . . . . . .4-3

Diagnostic Trouble Codes (DTCs) . . . . . . . . . . . . . . . . . . . . .4-4

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Recovery-Recycling-Recharging Station . . . . . . . . . . . . . . . .4-7

Leak Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Leak-Testing Dyes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

System Sealant (Stop Leak) Products . . . . . . . . . . . . . . . .4-9

Refrigerant Identifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

Drive Belt Tension Gauge . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Miscellaneous Special Tools . . . . . . . . . . . . . . . . . . . . . . . .4-11

Resource Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

Troubleshooting, Service and Repair Tips . . . . . . . . . . . . .4-14

Component Replacement . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

Refrigerant Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

Flushing Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

Evacuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

Refrigerant System Lubrication . . . . . . . . . . . . . . . . . . . . . .4-17

TOYOTA Air Conditioning and Climate Control Course 752 i

Table of Contents

Adding Oil After Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

Inline Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

Performance Checking . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-19

Recovery and Recycling Techniques . . . . . . . . . . . . . . . . . . . . .4-19

Equipment Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-20

Noncondensables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-20

Storage Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-22

Section 5 Temperature Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

A/C System Heater Control Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Air Mix Temperature Control . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Controls

Blower Speed Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Air Distribution Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Air Inlet Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

FRESH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

RECIRC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Typical Mode Position Charts . . . . . . . . . . . . . . . . . . . . . . . .5-10

Dual-Plane Air Distribution . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

Section 6 Introduction to Automatic A/C . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Automatic Automatic A/C Temperature Control . . . . . . . . . . . . . . . . . 6-1

Temperature Automatic A/C Components . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Customized Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

Control A/C Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

Automatic A/C Control Panel . . . . . . . . . . . . . . . . . . . . . . . .6-7

Temperature Sensor Circuits . . . . . . . . . . . . . . . . . . . . . . . . .6-8

Servo-Motor Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

Control of Blend Air Damper . . . . . . . . . . . . . . . . . . . . . . . .6-10

Pressure Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-11

Belt Protection Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-12

Thermistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-14

In-Car Sensor (Thermistor) . . . . . . . . . . . . . . . . . . . . . . . . .6-14

Ambient Temperature Sensor (Thermistor) . . . . . . . . . . . .6-14

Solar Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-15

Sensor (Thermistor) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-16

Maximum Cool Damper . . . . . . . . . . . . . . . . . . . . . . . . . . .6-17

Multimode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-17

Rear Air Conditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-18

Section 7 Diagnosis of Automatic A/C Systems . . . . . . . . . . . . . . . . . . . . .7-1

Automatic Diagnosis Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Temperature Testing Sensor Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Testing the Solar Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Control Testing Servo-Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Diagnosis and Automatic A/C System Repair Techniques . . . . . . . . . . . . . . . . 7-7

Repair A/C System Odors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Diagnosing the Automatic A/C System . . . . . . . . . . . . . . . . 7-9

ii TOYOTA Technical Training

Toyota Air Conditioning and Climate Control

Section 8 A/C Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Air Conditioning: A/C Components Comparison . . . . . . . . . . . . . . . . . . . . . . .8-2

Hybrid Vehicles A/C Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

Refrigerant Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-4

Other Hybrid HVAC Components . . . . . . . . . . . . . . . . . . . . . . . . .8-4

Heater Core . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-4

Water Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-6

Temperature Control System . . . . . . . . . . . . . . . . . . . . . . . . .8-6

Electric Inverter A/C Compressor Control . . . . . . . . . . . . . .8-9

Room Temperature and Humidity Sensor . . . . . . . . . . . . .8-10

Hybrid System Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-11

Troubleshooting/Self-Diagnosis . . . . . . . . . . . . . . . . . . . . . .8-11

Self-Diagnosis Procedure . . . . . . . . . . . . . . . . . . . . . . . . . .8-12

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

TOYOTA Air Conditioning and Climate Control Course 752 iii

Table of Contents

iv TOYOTA Technical Training

Introduction to Toyota Air Conditioning

and Climate Control

Course 752, Toyota Air Conditioning and Climate Control is a technical

training course that covers basic through advanced concepts of mobile

air-conditioning systems, and basic and automatic temperature-control

systems used on Toyota vehicles. This course will familiarize you with

the theory of operation, troubleshooting techniques and repair procedures

necessary to diagnose and repair Toyota air-conditioning systems.

The Technician Handbook presents information in a logical order for use

during the course and for reference in the shop.

A prerequisite to this course is successful completion of Course 623,

Electrical Circuit Diagnosis. You should have completed the Self-Study

Prework Modules before attending this course.

Course 752 uses this Technician Handbook, other Toyota reference

manuals, sample components, integrated worksheets and hands-on

lab activities with vehicles to broaden the air conditioning repair and

diagnosis skills of the technician.

TOYOTA Air Conditioning and Climate Control Course 752 v

Introduction

Course After completing this course, you should be able to meet the following

Objectives objectives:

Effectively diagnose and repair Toyota air-conditioning systems using

approved resources, tools and procedures

Effectively operate Toyota-specified recovery/recycling equipment and

recharge vehicle A/C systems

Demonstrate a working understanding of the principles of the

automatic air-conditioning system

Successfully diagnose and repair Toyota Automatic A/C systems

Note: Federal, state or local regulations may require technicians to receive

additional training or certification prior to working on the refrigerant

circuits of mobile air-conditioning systems. Consult the appropriate

city and state regulations for handling refrigerants and for additional

information.

Information contained in these course materials is subject to change.

Reference should be made to the Technical Information System (TIS) and

to current Toyota Vehicle Repair Manuals, Electrical Wiring Diagrams and

Technical Service Bulletins (TSB) for exact specifications and procedures.

vi TOYOTA Technical Training

Section 1

Preparation

Lesson 1. Demonstrate safe practices for working with compressed gases.

Objectives 2. Demonstrate safe practices for working with electricity and

Supplemental Restraint Systems (SRS).

3. Identify tools and equipment necessary to diagnose and repair the

air-conditioning system.

TOYOTA Air Conditioning and Climate Control Course 752

Section 1

Preparation

Safety Throughout this course and during normal A/C service procedures, there

Practices is a possibility for dangerous contact with moving parts, pressurized

gases, high current electrical circuits and accidental deployment of the

supplemental restraint system (airbags). Consider the potential hazards

involved and use the following safe working practices.

Compressed Pressurized gases are present in vehicle air-conditioning systems, recovery/

Gases recycling equipment and even manifold test gauges. All pressurized gases

exhibit two characteristics that can be hazardous:

1. When heated, internal pressure increases (rises).

2. When pressure is suddenly released, the temperature of the gas

decreases (drops).

These properties of a compressed gas can be hazardous in two ways:

1. If heat is applied to a pressurized system (bright sunlight, lack of

ventilation, use of steam cleaner or welder, etc.), system pressure can

quickly increase beyond a safe limit. This could result in an explosion

with the danger of injury from flying metal fragments.

2. If refrigerant gas rapidly escapes, there is a danger of frostbite.

Frostbite is a serious injury that results in tissue damage caused by

localized freezing and requires medical attention. Since the eyes are

made of delicate tissue, they can be damaged by direct contact with

even a small amount of escaping refrigerant. Always wear safety

goggles when working with refrigerant.

Risk of Frostbite

Warning: Refrigerant is a

compressed gas and can

burn skin or eyes.

Fig. 1-1

752f101

TOYOTA Air Conditioning and Climate Control Course 752 1-1

Section 1

Electrical The low voltages used in vehicles generally pose little risk of electrical

Circuits shock. However, many repairs require using equipment powered by

120 volts with high current. Accidental short circuits can damage

components or test equipment. Touching a wire that is shorted to ground

can burn you. Observe the following to reduce the risk of personal injury:

1. Verify all 120-volt equipment line cords are in good condition and

properly grounded.

2. Before making resistance measurements with an ohmmeter, first

confirm the circuit source voltage is OFF by testing the circuit with

a meter set to measure voltage.

3. When bypassing components to test a circuit, use a fused jumper wire

to protect against accidental short circuits.

SRS/Airbag The Supplemental Restraint Systems (SRS) are designed to deploy only

Systems in response to a significant frontal or side impact. To prevent accidental

deployment, disconnect the ground (negative) cable from the battery and

wait for up to 60 seconds before performing any repairs which involve

disconnecting any SRS wiring. SRS-related circuits are identified by bright

yellow wire harnesses and connectors.

Before disconnecting the battery cable, make a note of the radio presets,

Auto A/C panel settings and the display of any system fault codes.

Precautions

for Airbags

Read all precautions

in the Repair Manual

prior to work.

Fig. 1-2

752f102

1-2 TOYOTA Technical Training

Preparation

Tools and Accurate diagnosis and efficient repair depend on using the correct tools

Equipment and information. In addition to Vehicle Repair Manuals, Electrical Wiring

Diagrams, Technical Service Bulletins and a standard technicians tool set,

the following Special Service Tools and other equipment may be needed:

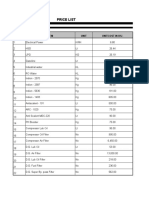

Recommended Tools (or equivalent) Part Number

A/C Recovery/Charge Station

Refrigerant Identifier

Refrigerant Leak Detector

Thermometer Dial Type 0 220 degrees F

DVOM Meter

Dial Indicator with Magnetic Base

Cooling System Pressure Tester

Condenser Fin Straightener

R-134a Valve Core Removers

Magnetic Clutch Remover (SST) 07112-66040

Magnetic Clutch Stopper (SST) 07112-76060

A/C Quick Joint Puller #1 Suction Tube (SST) 09870-00015

A/C Quick Joint Puller #2 Liquid Tube (SST) 09870-00025

Toyota/Lexus Diagnostic Tester

01001270

(SST Hand Held Tester/SCAN Tool)

Belt Tension Gauge (SST) 09216-00021

Eye Protection Goggles/Safety Glasses with Side Panels

Rubbers gloves

TOYOTA Air Conditioning and Climate Control Course 752 1-3

Section 1

Notes

1-4 TOYOTA Technical Training

Section 2

The A/C System

Lesson 1. Identify and demonstrate the function of the basic refrigerant circuit.

Objectives 2. Identify the low- and high-pressure sides of the refrigeration circuit.

3. Identify the major components of the A/C refrigeration circuit.

TOYOTA Air Conditioning and Climate Control Course 752

Section 2

The A/C System

The The basic A/C system contains components to push refrigerant through

Refrigerant a closed system in order to extract heat out of the vehicle interior and

Circuit transfer that heat to the outside air. This cycle continues constantly until

the vehicles interior reaches a set temperature. Inside the A/C system,

the refrigerant changes from a liquid to a gas and then back to a liquid.

As we shall see, this phase change is what helps remove heat from the

air circulating inside the vehicle.

Expansion and If a pressurized liquid is released into an area of lower pressure, it will

Evaporation evaporate into a gas and absorb heat from that area. This is the principle

that causes the spray from an aerosol can to feel cold to your skin.

Likewise, a liquid that changes from liquid to vapor at a low temperature

(e.g. alcohol) will feel cool on the skin as it evaporates (phase change).

This is the situation you feel when you get out of a swimming pool or

shower. The evaporating water on your skin absorbs heat from your body

even though the air temperature is quite high.

Absorb Heat

Vaporization

Vaporization

(Evaporation)

Vapor Liquid

Condensation

Fig. 2-1

Reject Heat

752f201

The device that regulates pressure in an A/C system is the expansion

valve. The area where heat transfer takes place is the evaporator

(heat exchanger).

TOYOTA Air Conditioning and Climate Control Course 752 2-1

Section 2

Compression After the gaseous refrigerant absorbs heat, the system pressurizes it to

and change it back into a liquid. As this happens, the gas gives off much of

Condensation the heat that was absorbed. This is what the compressor and condenser

do in the A/C system. In order for the gas to actually give up heat while

in the condenser (heat exchanger), it must be hotter than the air around

it. The compressor makes this possible by increasing the line pressure,

and therefore, the temperature of the refrigerant gas.

Refrigerant Automotive air conditioning has been widely available since the 1940s.

Properties The refrigerant CFC-12 or R-12 (also known as Freon) was used for many

years due to its relative safety in contact with humans and its low boiling

point of 21 F. In other words, the CFC-12 refrigerant (HFC-134a 17),

and most liquids used as refrigerants, change from a liquid to a gas at a

very low temperature.

For the last decade, another refrigerant, HFC-134a (R-134a), has been

developed for use in automobiles due to its less negative impact on the

environment. Most new vehicles manufactured today use HFC-134a.

Federal laws regulate the use, recycling and recharging of CFC-12 and

HFC-134a refrigerant.

Heat and Matter Using water as an example, we can commonly find water in any of

three states: Ice, water and steam. Its temperature is what determines

the state of water (H20).

Three States

of Matter

212

31

60

Fig. 2-2

752f202

The concept of heat is directly related to the nature of all materials. Some

materials are solid, some are liquid, and some are gaseous. In fact, all

matter can exist in each of these three states depending on its temperature.

2-2 TOYOTA Technical Training

The A/C System

Matter has different characteristics as it exists in each different state.

For example:

1. A solid has a defined shape and cannot flow to fill empty spaces in

a container.

2. A liquid can flow to fill voids in a space, but it cannot be compressed

or made more dense by pressure.

3. A gas (or vapor) also flows easily, and it can be compressed; that is,

its density can be made greater or smaller by applying pressure to a

closed vessel containing the gas.

As heat energy is applied to a solid, the solid absorbs the heat (we could

say it gets hotter) up to a point. If the solid is heated past its freezing

point, it will gradually become a liquid. The heat required for this to

happen is called sensible heat. As heat energy is added to a solid, its

observed temperature will increase. In fact, this relationship is consistent

for each material. However, the process of changing its state requires the

addition of an extra amount of heat.

Latent Heat is the additional energy necessary to cause refrigerant to

change state from a gas to a liquid or from a liquid back into a gas.

Water boils at 212 F and applying additional heat will not raise the water

temperature but will increase vaporization or evaporation rate resulting in

steam vapor. Humidity reduces the absorption of heat into the evaporator

coils until the moisture is condensed on the coils and fins then drained

from the case by the drain hose.

In fact, at the point at which a change of state is about to take place,

a material will absorb a significant amount of heat without getting

noticeably warmer. The additional heat is called latent heat, which

means, unnoticed heat.

TOYOTA Air Conditioning and Climate Control Course 752 2-3

Section 2

Gas

Sensible and

Latent Heat

Liquid

100 C (212 F)

Solid

0 C (32 F)

Sensible Latent Sensible Latent

Heat Heat Heat Heat

79.3 100 539

kcal/kg kcal/kg kcal/kg

Fig. 2-3

(143 BTU/lb) (180 BTU/lb) (790 BTU/lb) 752f203

Pressure and A physical relationship that affects heat transfer is the effect of pressure

Temperature on the boiling point. When water freezes at 32 F (0 C) and boils at 212 F

(100 C), these values only apply with an open container at sea level

where the air pressure is 14.7 psi.

If, for example, the altitude is 5000 above sea level. The atmospheric

pressure is only 512.5 psi and water in an open pot will boil at only

195 F (91 C). In addition, at this altitude, water will freeze at 35 F (2 C).

In an extreme low pressure environment (sometimes called a vacuum),

the boiling point can be further reduced and the freezing point increased

until they meet. At this point, freeze-drying occurs and solid water (ice)

changes state directly into gaseous water (steam).

Pressure, psi

Effect of Pressure 30

on Boiling Point

15

30

(Vacuum, In. Hg)

(7)

(15)

(22)

(30)

0 50 100 150 200 250 Fig. 2-4

Boiling Point of Water, F 752f204

2-4 TOYOTA Technical Training

The A/C System

As pressure is increased the boiling point also increases as in a radiator

with a pressure cap. The increase is approximately three degrees of boiling

point for each one psi of pressure increase, meaning a 15 psi radiator cap

will increase boiling point by 45 degrees F.

Humidity Relative humidity has a great influence on the apparent cooling effectiveness

and A/C of an A/C system. The higher the humidity in the air, the less energy is

Performance available for cooling. A side benefit is that removing humidity from the

interior air is in itself an improvement in comfort since humidity prevents

the body from dissipating heat in its normal manner.

Humidty vs. 72

Performance

68

Between Inlet and Outlet

Temperature Difference

64

61

F

57

54

50

50 60 70

Relative Humidity (%) Fig. 2-5

752f205

Humidity reduces evaporator heat absorption and efficiency due to

humidity condensing on the coils and draining away out the drain tube.

Different

Temperature C

Scales 30 25 20 17.8 15 10 5 0 5 10 15 20 25 30 35 40 50 60 70 80 90 100

22 13 4 0 5 14 23 32 41 50 59 68 77 86 95 104 122 140 158 176 194 212

Centigrade and

Fahrenheit Temperature F

Scales

Fig. 2-6

752f206

TOYOTA Air Conditioning and Climate Control Course 752 2-5

Section 2

Basic A/C A basic A/C system has a high-pressure side and a low-pressure side.

System The high-pressure side (shown in red below) includes the compressor,

condenser and the receiver/drier. The low-pressure side of the system

(shown in blue below) includes the expansion valve and the evaporator.

Refrigeration Cycle

Vehicle

A/C System

Evaporator Cold Air

Expansion

Heat-

Valve

Sensing

Low-Pressure, Tube

Low-Temperature

Gas

Suction Blower Motor

Service Liquid

Valve Refrigerant

Car Interior Air High-

Temperature,

Hot Air High-Pressure

Discharge Gas

Service Engine Cooling Fan

Valve

Compressor Receiver

Condenser (Liquefies)

High-Pressure,

High-Temperature Fig. 2-7

Liquid 752f207

Here is the basic flow through the system. Beginning with the low side,

the expansion valve controls the flow and pressure of liquid refrigerant

into the evaporator (heat exchanger). As the lower pressure liquid

refrigerant turns into a gas inside the evaporator, a tremendous amount

of heat is absorbed from the warm passenger compartment air circulating

over and around the evaporator. The A/C blower motor helps circulate air

throughout the vehicles interior. The still gaseous, but very hot refrigerant

then flows into the compressor.

The compressor pressurizes the gaseous refrigerant. The high-pressure

refrigerant then flows to the condenser (heat exchanger) where the absorbed

heat in the refrigerant transfers to the air outside the vehicle. A condenser

fan helps this heat transfer process. As heat is removed from the refrigerant,

it changes from a gas back to a liquid. The liquid refrigerant is then ready

for another cycle through the system. The receiver-drier acts as a filter

and storage tank for refrigerant before entering the expansion valve.

2-6 TOYOTA Technical Training

The A/C System

System Pressure All automotive A/C systems are now based on HFC-134a refrigerant.

Because of this, all systems have similar characteristics.

Even though current vehicles use less refrigerant or a smaller volume

of refrigerant, system pressure will be about the same under similar

conditions. Therefore, the pressures within a working system will provide

the technician with an accurate measure of the following:

Amount of refrigerant in the system

Operation of the compressor

Degree of pressure regulation provided by the expansion valve

Efficiency of the condenser to dissipate heat (dirt or bugs reduce

efficiency)

For these reasons, the system pressures (high and low) will provide

useful diagnostic information.

TOYOTA Air Conditioning and Climate Control Course 752 2-7

Section 2

The A/C system uses the properties of refrigerant to remove heat from the

passenger interior.

The A/C system contains two pressure zones: low and high pressure.

The low pressure portion of the system contains the expansion valve and

the evaporator.

The high pressure portion of the system contains a compressor,

condenser and a receiver-drier.

There are two heat exchangers in the system: A condenser (gets rid of

heat) and an evaporator (absorbs heat).

Electric fans assist heat transfer: An A/C blower fan for the evaporator

and a fan for the condenser.

The entire system is connected by high and low pressure hoses (hard and

flexible lines).

2-8 TOYOTA Technical Training

Section 3

A/C System Components

Lesson 1. Identify A/C System Components, and their function in the

Objectives refrigeration circuit.

2. Identify and verify the changes in pressures within the A/C refrigeration

circuit during operation.

3. Identify circuit protection devices and their role in the A/C system.

4. Locate and identify front and rear A/C System Components on a

vehicle and vehicle simulator.

TOYOTA Air Conditioning and Climate Control Course 752

Section 3

A/C System Components

In the previous sections, we referred to the functions of the A/C

components. Heres how each one works in closer detail.

A/C System Evaporator

Components

Expansion

Valve

Receiver-Drier*

Condenser *Built into

sub-cool condenser

on some models Fig. 3-1

Compressor

752f301

Expansion The expansion valve receives liquid refrigerant from the high-pressure

Valve components (compressor and receiver/drier). In order for the system to

develop pressure, the flow of refrigerant must be met with a restriction.

The expansion valve provides the needed restriction in the system. It

creates the difference between the high-pressure side of the system and

the low-pressure side.

Capillary Tube

Traditional

Expansion Valve Diaphragm

Chamber

Controls amount of

refrigerant into Equalizer Circuit

evaporator core. Diaphragm (for Internal

Equalizer Type)

Heat-

Valve Sensing

Outlet Tube

Inlet

Pressure

Spring

Fig. 3-2

752f302

TOYOTA Air Conditioning and Climate Control Course 752 3-1

Section 3

Most Toyota models now use a block-type expansion valve where both the

evaporator inlet and outlet pass through the valve assembly. The capillary

tube is located inside the stream of refrigerant leaving the evaporator.

Due to the low temperature at this point, the valve is subject to blockage

by microscopic debris or internal ice if any water is present in the

refrigerant. Because of this, every system has some method to filter

out these elements.

Block-Type

Expansion Valve

Releases high

pressure refrigerant into

evaporator.

Valve

Fig. 3-3

752f303

Not all vehicles use an expansion valve like the one described above. Some

have a pressure-regulator at the outlet end of the evaporator. Other

manufacturers use a fixed-opening orifice tube to create the pressure

drop at the entry to the evaporator. This type of expansion valve relies on

the cycling of the compressor clutch to vary the flow and prevent icing.

The expansion valve is located at the inlet of the evaporator. A small

passage creates a pressure drop as the refrigerant enters the evaporator.

The pressure drop occurs as the small spray of refrigerant expands to fill

the large volume inside the tubes of the evaporator. Here is the sequence

of events:

Warm, high-pressure liquid refrigerant flows to the expansion valve

A low-pressure spray of cold refrigerant droplets pass through the

expansion valve into the evaporator

As the cold spray contacts the relatively warm tubing of the evaporator,

the refrigerant vaporizes (becomes a gas) and absorbs heat from

the evaporator and the air surrounding the evaporator

3-2 TOYOTA Technical Training

A/C System Components

Evaporator The action between the expansion valve and the evaporator is the key to

heat transfer in the system. The evaporator is the heat exchanger for the

low-pressure side of the system. It is the key heat exchanger in the A/C

system. All incoming or recirculated air passes through the evaporator. In

doing so, the evaporator absorbs heat from the cabin air (car interior) or

incoming fresh air so this heat can be carried to the condenser.

Evaporator

Removes heat from

interior as refrigerant is

released into the core.

Dehumidifies air by

condensing moisture on

the fins.

Fig. 3-4

752f304

Evaporators are typically multiple-flow designs and made from aluminum.

Since the surface fins or plates of the evaporator are usually colder than

the air flowing past them, any moisture (water vapor) in the air tends to

condense and form liquid droplets on the fins. The moisture eventually

drains from the evaporator case through a drain hose to the ground. This

process is called dehumidification.

This process of dehumidifying is not only important to passenger

comfort, but can also be used in cold or humid climates to reduce

windshield fogging. However, a large amount of heat must be removed

from water vapor in order to condense it, so extreme humidity reduces the

ability of the evaporator to lower the temperature of the incoming air.

TOYOTA Air Conditioning and Climate Control Course 752 3-3

Section 3

Expansion Since the evaporator surface temperature can be close to 32 F (0 C),

Valve/ there could be a problem in high humidity conditions when moisture

Evaporator vapor condenses on the evaporator and freezes. This frozen water forms

Interaction an insulating layer that prevents air from reaching the evaporator to

exchange heat.

In order to prevent icing, the expansion valve can change the size of

the spray orifice (opening). The size of the orifice is controlled by a

spring-loaded diaphragm that moves according to a heat-sensing tube

(bulb). This bulb, called the capillary tube is located at the outlet of the

evaporator. A thin, hollow tube connects the sensing tube to the

diaphragm chamber. The sensing tube contains refrigerant and senses the

evaporator temperature which changes the pressure inside the tube. The

capillary tube transfers this pressure to the diaphragm to push against

the spring and open the expansion valve to control refrigerant flow to the

evaporator. Less flow = less heat transfer; more flow = more heat transfer.

For example, if there is a high heat load in the vehicle, the evaporator

temperature will be relatively high (more heat transfer). The refrigerant

in the sensing tube will therefore expand and the increased pressure will

tend to open the expansion valve more. This increases refrigerant flow

and heat transfer in the evaporator. When the system stabilizes, the

evaporator surface temperature should remain constant at about

32 F (0 C) in order to provide the greatest heat-removing capacity.

The traditional expansion valve has external equalization. The block-type

expansion valve is internally vented. This helps prevent flooding the

evaporator during operation with a high heat load.

Compressor The compressor is driven by a drive belt and is a type of pump which

moves a compressible gas, as opposed to a pump that moves a liquid

(e.g. water pump). The air compressor in your repair shop and the intake

and compression strokes in a 4-stroke cycle engine are two other examples

of compressors.

In order for the refrigerant to exchange heat at the condenser, it must be

hotter than the air outside the vehicle. The compressor accomplishes this

by raising the pressure, and therefore, the temperature of the refrigerant.

3-4 TOYOTA Technical Training

A/C System Components

An important difference between a compressor and a pump is that a

compressor cannot pump liquids. Since liquids cannot be compressed,

a compressor filled with liquid will either lock up or break depending on

the amount of torque applied to its pulley by the engine crankshaft. More

commonly, the reed valve assembly that controls gas flow inside will be

destroyed when a compressor hydraulically locks.

Most compressors have a bolt-on fitting block to provide connections to

the low-pressure side of the system (suction side) and high-pressure side

of the system (discharge port). There may also be fittings on or near the

compressor to connect pressure gauges.

Reed Valve Control Discharge Reed Valve

of Refrigerant Flow

Reed valves control

both suction and

discharge flow.

Discharge Reed Valve

Fig. 3-5

Suction Reed Valve 752f305

Various Toyota vehicles use or have used one of the following types of A/C

compressors:

Piston

Through-Vane

Swash-plate

Variable Capacity

Scroll-type

Piston-type compressors have valves to control the flow of intake and

exhaust gases. For simplicity, A/C compressors use spring-tensioned

stainless steel reed valves which allow gas flow in one direction and only

when a significant pressure difference exists between the chamber of the

compressor and the intake or outlet passages. The earliest compressors

were belt-driven using two- or three-pistons with connecting rods and a

TOYOTA Air Conditioning and Climate Control Course 752 3-5

Section 3

crankshaft supported by ball bearings. Lubrication is provided by a

splash from a sump in the compressor base. Construction of reciprocating

compressors are very similar to a four-stroke cycle lawn mower engine.

Suction Discharge

Piston-type A/C

Compressor

Reed Valve Construction.

Down-Stroke Up-Stroke

Fig. 3-6

752f306

Through-Vane (TV) compressors replaced reciprocating, piston-type

compressors. Through-vane compressors reduce rotating mass by

eliminating pistons in favor of sliding vanes which seal against the

compressor housing at both ends. These compressors are lubricated by

oil from a pressurized chamber in the rear of the compressor.

Discharge Reed Valve

Through-Vane

Compressor Discharge Valve

Exhaust Port

Rotor

Sludging Valve

Vane

Through-Vane

Rotor Housing Fig. 3-7

Intake Port 752f307

With four pulses per revolution, TV compressors provide high efficiency

and minimal vibration. However, unlike conventional compressors that

build pressure against a reed valve until it opens, TV compressors

perform compression internally. Because of this, they tend to run hotter

than conventional compressor designs. In addition, for this reason, they

are equipped with an internal pressure release called a sludging valve.

3-6 TOYOTA Technical Training

A/C System Components

This valve prevents damaging the through-vanes or the reed valve (which

should see only refrigerant gas) by allowing liquid oil to escape from the

compression area into an oil chamber.

Some Toyota vehicles use a swash-plate (also called wobble plate) type

compressor. Some models use multiple, opposed pistons arranged around

a single swash-plate with two compression chambers for each cylinder.

The cylinders connect to reed valves and common inlet and outlet passages

at each end. The swash-plate converts the rotary motion of the shaft into

smooth back and forth motions of the pistons. This design provides

reduced vibration and allows more pulses per revolution than a two-piston

reciprocating compressor.

TOYOTA Air Conditioning and Climate Control Course 752 3-7

Section 3

The Variable Capacity swash-plate compressor uses a solenoid control

valve that opens and closes to adjust the low-pressure inlet to the

compressor. Controlling the suction side of the compressor changes the

volume capacity according to the cooling load of the A/C system. This

change in pressure affects the swash-plate angle. It also changes the piston

stroke and thus the amount of refrigerant discharged to the condenser.

Controlling the compressor volume in this manner improves A/C

performance and energy savings.

Variable Capacity Shoe

Compressor and Crank Chamber

Solenoid Valve Piston

Variable stroke of pistons.

Shaft

Solenoid

Control Valve

Piston

Lug Plate Fig. 3-8

Cylinder

Swash-Plate 752f308

Heat Load: Large Heat Load: Small

Solenoid Control Valve Solenoid Control Valve

Low Pressure: High Low Pressure: Low

Internal Pressure Internal Pressure

of Swash-Plate of Swash-Plate

Chamber: Low Chamber: High

Swash-Plate Angle: Large Swash-Plate Angle: Small

Piston Stroke: Large Piston Stroke: Small

Cooling Performance: Large Cooling Performance: Small

Fig. 3-9

752f309

3-8 TOYOTA Technical Training

A/C System Components

A Scroll Compressor is a spirally wound, fixed scroll and variable scroll

that form a pair. The fixed scroll is integrated with the housing. The

rotation of the shaft causes the variable scroll to rotate while maintaining

in the same space. Thus, the volume of the space that is created by both

scrolls varies. This changing volume creates the suction, compression and

discharge forces needed for refrigerant gas flow through the compressor.

Note: Some hybrid models use an electrical motor drive scroll-type compressor

to continue operation even when engine stops (refer to page 3-10).

Shaft Intake

Scroll Compressor Port Oil Separator

Magnetic

Clutch

Scroll-type A/C

Compressor

Discharge

Port

Pins

Variable Fixed Fixed Scroll

Scroll Scroll Discharge

Port Fig. 3-10 Fig. 3-11

752f310 752f311

Operation Suction:

As the capacity of the compression chamber which is created between the

variable scroll and the fixed scroll increases with the revolution of the

variable scroll, refrigerant gas is drawn in from the intake port.

Compression:

As the variable scroll revolves, the capacity of the compression chamber

gradually decreases. As a result, the refrigerant gases drawn in become

compressed and are sent to the center of the fixed scroll. The refrigerant is

completely compressed when the variable scroll completes approximately

2 revolutions.

Discharge:

After the refrigerant is compressed (refrigerant gas pressure high), the

refrigerant gas exits through the discharge port in the center of the fixed

scroll via the discharge valve.

TOYOTA Air Conditioning and Climate Control Course 752 3-9

Section 3

Scroll Compressor

Cycle

Suction

Discharge Intake

Port Port

Fixed

Scroll

Variable

Scroll

Compression

Discharge

Fig. 3-12

752f312

Some scroll compressors in Toyota vehicles contain a built-in oil separator.

This chamber helps separate the compressor oil from the refrigerant that

circulates in the refrigeration system. Excess oil in the scroll section of

the compressor can lower compressor efficiency and in some cases,

damage it.

3-10 TOYOTA Technical Training

A/C System Components

Compressor A drive belt from the crankshaft pulley drives the compressor. Some

Clutch systems use V-belts and some use a flat, multirib belt to help reduce

frictional loss and noise. On some models, a single serpentine V-belt

drives all the engine accessories including the A/C compressor. In this

kind of system, an automatic tensioner maintains the correct serpentine

belt tension.

Idler Pulley

Serpentine Belt

System

Some models have A/C

a single belt that drives Compressor

multiple components. Pulley

Fig. 3-13

Crankshaft Pulley 752f313

The compressor clutch engages and disengages the compressor as needed.

With the clutch disengaged (not energized), there is no refrigerant flow

and the compressor pulley spins freely.

Compressor Clutch

Stator Coil

Engages compressor by

electromagnetic action. Rotor

Shim

Bearing

Pressure Plate

Fig. 3-14

752f314

The single-plate clutch has an electromagnetic pressure plate to allow

the compressor pulley to freewheel or drive the compressor as conditions

demand. The clutch is normally disengaged. When a relay is energized,

the electromagnetic coil pulls the spring-loaded pressure plate into

the clutch.

TOYOTA Air Conditioning and Climate Control Course 752 3-11

Section 3

The electromagnet allows A/C operation to be controlled by an electric

circuit. The compressor clutch relay is also controlled by a temperature

signal from the evaporator and a pressure switch in the refrigerant line.

In most systems, the compressor clutch cycles ON and OFF periodically to

allow the evaporator to warm up (defrost) during periods of high cooling

demand. An evaporator cold enough to freeze moisture around it does not

transfer heat as well.

Some variable capacity compressors dont use a magnetic clutch. Instead

they use a Damper Limiter (DL)-type drive pulley. This pulley uses a

damper to absorb torque fluctuations of the engine and a limiter

mechanism. In case the compressor locks, the limiter mechanism causes

the spoke portion of the pulley to break. This separates the pulley from

the compressor shaft and prevents the drive belt from breaking. To

reduce pulley weight, the pulley portion is made of plastic.

Damper

Limiter Pulley Pulley Portion

Rotate Direction (Plastic)

Spoke

Absorbs torque Portions

fluctuations.

Protects drive belt if

compressor locks.

Damper

Damper

Limiter Mechanism

Fig. 3-15

752f315

3-12 TOYOTA Technical Training

A/C System Components

Condenser In order to condense hot refrigerant gas (vapor) from the compressor

discharge port into a liquid, heat must transfer out of the refrigerant into

the outside air. To do this, the condenser is located in front of the radiator

in the air stream so the maximum temperature differential exists to

transfer the heat. Condensers are typically made of aluminum and have a

single flow or serpentine path (as shown) which increase the time available

for heat transfer. Some systems now use multiple-path condensers with

two or three shorter serpentine sections connected in parallel. This

maximizes the time the refrigerant stays in the condenser for increased

heat transfer.

Condenser

Condenses hot,

high pressure gases

into a liquid.

Heat dissipates to

outside air.

Tube

Gaseous

Refrigerant Liquid

Refrigerant

Fin

Fig. 3-16

752f316

TOYOTA Air Conditioning and Climate Control Course 752 3-13

Section 3

Many Toyota vehicles now use a sub-cool condenser that helps separate

the liquid from the gaseous refrigerant. In this design, the condenser

redirects gaseous refrigerant to the top for further cooling (gas-to-liquid)

while the liquid refrigerant exits from the bottom. This ensures all

refrigerant sent to the evaporator is in a liquid state.

Multiflow Condenser Condensing Portion

Sub-Cool

Condenser

Modulator

Current models use Gaseous

sub-cool type. Refrigerant

Super cooling portion

more efficiently

changes gaseous

bubbles into liquid. Liquid

Refrigerant

Fig. 3-17

Super-Cooling Portion 752f317

Receiver- The amount of refrigerant flowing through the system varies depending on

Drier heat load and ambient (outside) temperature. Because of this,

extra refrigerant must be available for these different conditions. The

receiver-drier acts as a storage tank for extra refrigerant. It also contains

a filter and a desiccant material in an internal sack to help remove

moisture in the system.

Receiver-Drier Sight Glass

Removes moisture IN

from refrigerant.

Stores liquid refrigerant.

Filters refrigerant. OUT

Receiver Drier

Tube

Desiccant

Receiver Filter

Body

Fig. 3-18

752f318

3-14 TOYOTA Technical Training

A/C System Components

The outlet of the receiver-drier connects to a siphon tube that goes to the

bottom of the container. This acts as a liquid/vapor separator and ensures

only liquid refrigerant is supplied to the expansion valve. In addition,

the end of the siphon tube has a very fine mesh screen to filter debris from

the refrigerant and oil. This protects the expansion valve and the

compressor from mechanical damage.

To protect the expansion valve from being blocked by ice, any moisture

in the refrigerant is removed as it passes through a desiccant in the

receiver-drier. A desiccant is a chemical that bonds water (H2O) with other

molecules to form a different molecule. There is a limit to the amount of

moisture the desiccant can hold. After the desiccant becomes saturated,

any additional moisture will pass through the system. A receiver-drier left

open (fittings removed) on the shelf or in the vehicle for about 10 minutes

(80% humidity) will become fully saturated and unusable.

The receiver-drier desiccant material is different in HFC134a and older

CFC-12 systems. Do not interchange them. Moisture inside the system

is absorbed by the desiccant and is not fully removed during system

evacuation or the vacuum process prior to recharging. Moisture remaining

inside the system or receiver-drier can result in internal icing of the

expansion valve and cause erratic system operation.

Note: The receiver-drier is a service part and should be replaced any time

the system has leaked, or been left open (even for a short time), or when a

component such as a compressor or reed valve has failed.

In some systems, the receiver-drier contains a sight glass that allows you

to visually confirm that only liquid refrigerant is passing on to the

expansion valve. This may be useful during preliminary diagnosis, but it

is not accurate in determining if the system has the proper amount of

refrigerant. Some models use a modulator-drier that is part of the

condenser. On some Toyota models, the functions of a receiver-drier are

built into the sub-cool condenser; desiccant is stored in the modulator

portion of the sub-cool. On other models, the receiver-drier is separate

from the sub-cool condenser.

TOYOTA Air Conditioning and Climate Control Course 752 3-15

Section 3

Pressure For safety, every pressurized system must have some sort of pressure-relief

Relief system to reduce excess system pressure before it can become a hazard.

Devices In an A/C system, a fusible plug was one type of safety device. A fusible

plug is a hollow bolt filled with a soft, low-temperature solder. The plug

then threads into the top of the receiver-drier. If the pressure in the high

side of the system exceeds a predetermined limit (400 psig or 30 bar) or if

the temperature exceeds 220 F (110 C), the solder melts out of the bolt

and the pressurized gas escapes. On current models, a pressure switch

de-energizes the compressor when system pressure becomes excessive.

Possible causes of excessive pressure or temperature:

Restriction in the high side of the system

Overheating condenser due to restricted airflow or fan failure

System overcharged with refrigerant

Abnormal heat source (e.g. steam cleaner)

After the system is repaired replace the receiver-drier.

On some other vehicles, a pressure relief valve performed the function

of the fuse plug. Threaded into the compressor valve assembly, the relief

valve opened when the system pressure exceeded 400 psig (30 bar). It

only stayed open until the pressure fell below a lower limit. That avoided

a total loss of refrigerant. A/C systems using a relief valve may also have

a pressure switch to de-energize the compressor as described above.

Although effective, this type of safety device vents refrigerant to the

atmosphere, which is no longer allowable.

Note: The pressure relief valve was not designed to reseal after it opened. If you

suspect the valve has opened, replace it after recovering the remaining

refrigerant in the system and repairing the cause of the malfunction.

3-16 TOYOTA Technical Training

A/C System Components

Multipressure There may be one or more pressure switches in the refrigerant lines.

Switch Current models use a Multipressure Switch that contains two or even

three pressure-sensing circuits. It is located in the high-pressure line of

the system (between the compressor and expansion valve).

Low pressure The low-pressure sensing circuit switches the compressor

OFF. This prevents system damage due to the reduced amount of

lubricant as a result of low system pressure. An external leak will also

be detected by this sensing circuit.

Medium pressure The A/C control unit monitors pressures within

this range to control the operation of the high-speed condenser fan.

High pressure Excessively high system pressure indicates a malfunction.

This sensing circuit switches OFF the compressor clutch to prevent

system damage.

Note: The term psig indicates gauge pressure that takes into consideration

atmospheric pressure of 14.5 pounds per square inch and displays it as 0

on a pressure gauge.

Multipressure Magnetic Clutch Control

Switch Source Voltage Source Voltage

Low

Pressure

(NC)

Medium

Pressure

(NC) High

Pressure

(NC)

4 Pins Condenser Fan Compressor

Fig. 3-19 (High Speed) Clutch

Fig. 3-20

3 Pressures

752f319 752f320

During normal operation, the amplifier cycles the compressor clutch

ON and OFF to maintain an evaporator temperature of approximately

32 F (0 C). When the amplifier detects a malfunction in the system, it

will de-energize the compressor clutch and flash the A/C signal lamp.

A Diagnostic Trouble Code will generate and will stay in memory until

the ignition switches OFF.

Lines and Refrigerant flows through the system in rigid metal lines and flexible

Hoses rubber hoses. Connections at each component and between lines provide

convenient installation in the vehicle as well as to service and repair

system components. The volume of refrigerant is always the same at

any point in the system (since it is a closed system). However, since the

high-pressure side has a high-density liquid, it uses much smaller

diameter lines than the low side. As a rule:

TOYOTA Air Conditioning and Climate Control Course 752 3-17

Section 3

The high-pressure lines are smallest in diameter.

The low-pressure lines have the largest diameter.

Hose Fittings On

Receiver-Drier

Block-type fittings

help position and

secure piping.

Fig. 3-21

752f321

Unlike stationary refrigeration systems (appliance or building), mobile

A/C systems must operate under high levels of vibration and motion. For

this reason, all joint fittings use a gasket or O-ring to help seal the system.

O-rings are made of various materials; each selected to deal with the

particular refrigerant and lubricating oil used.

Fittings are typically one of three types: threaded tube-type, block-type or

quick-disconnect. Threaded fittings are used between hoses and lines. The

more rigid block fittings are used at system component. Block fittings

provide more accurate positioning of the sealing surfaces, and they reduce

the risk of tearing an O-ring due to rotation during assembly.

Older vehicles equipped with CFC-12 refrigerant have threaded metric

fittings. Other vehicles may use metric or SAE (inch unit) threads for

CFC-12. Fittings in a HFC-134a system are always metric and do not have

notched corners on the hex nuts for identification.

Thread-Type

Fittings

HFC-134a O ring

slip-type fit.

CFC-12 O ring was

crush-type fit.

CFC-12 fittings have

notch in nut position.

Fig. 3-22

HFC-134a CFC-12

752f322

3-18 TOYOTA Technical Training

A/C System Components

A quick-disconnect type fitting uses a plastic clamp lock to connect the

tube endings. This type of fitting has no threads. One tube end has

an O-ring that fits into a mating tube end. The plastic clamp keeps the

tube ends together to create a leak-free seal. To service the system

(e.g. evacuating the system the system must be empty), a special

remover tool is used to release the clamp.

Quick-Disconnect Clamp

Fitting

Clamp holds tubes A/C Tube

in place.

See removal SST

page 4-11.

A/C Tube

Note: When assembled,

clamp can still rotate.

Fig. 3-23

752f323

With threaded or threadless tube fittings, in order to ensure the proper

seal under high system pressures and temperatures, A/C O-rings rest

within a machined area instead of just being compressed between two

surfaces like a common gasket. In order to ensure a correct seal, the

O-ring must be the correct one. An O-ring that looks about right may

make a joint impossible to assemble without damage or may result in a

leak. O-rings should be lubricated with the correct system refrigerant oil

to prevent nicks or scratches during assembly.

With threaded fittings, the correct tightening torque is important for a

Note:

proper seal. Too little torque will not provide enough pressure on the

O-ring to seal and may allow the fitting to move. Too much torque may

distort the fitting and make it difficult to disassemble later. Torque

specifications for the different types and sizes of fittings are described in

the Vehicle Repair Manual.

In order to apply the right tightening torque, the threads must be

lubricated with oil. To prevent twisting and to relieve tension on rigid and

flexible lines, hold one fitting stationary with an open-end or flare-nut

wrench while tightening the other fitting. In the case of a threaded tube

fitting, the male end should be held while tightening the female threaded

nut.

TOYOTA Air Conditioning and Climate Control Course 752 3-19

Section 3

Cooling The effectiveness of the A/C system depends on removing heat as the hot

Fans refrigerant flows through the condenser. Because of this, cooling fans

become more critical when the A/C system is ON. There are two fans that

contribute toward heat transfer in the engine compartment:

A/C Condenser Fan

Engine Cooling Fan

A/C Condenser Fans are driven either manually from the engine or

electrically. Some Toyota vehicles use a belt-driven fan. Most current

vehicles use electric fans. A fan circuit contains the following components:

Coolant Temperature Switch (thermo-switch) located in the water jacket

of the cylinder head. The coolant temperature switch is normally closed

(NC). When the coolant temperature is cold/cool, the circuit path

through the switch is complete (ON). The switch opens (OFF) when

the coolant temperature exceeds a specified value, typically around

190 F (90 C).

Cooling Fans

Two types:

Mechanically or

Electrically driven.

Pulley

Fluid Fan Bracket

Coupling

Cooling Fan

Engine Cooling Fan

Condenser Fans Fig. 3-24

752f324

3-20 TOYOTA Technical Training

A/C System Components

Electric Cooling

Fan Circuit

1 2F

Fan relays activate

cooling fans at low or 1 5

high speed depending Engine

3 30A 30A

Main

on coolant temperature RDI CDS

Relay

FAN FAN

or system pressure. 2 4

10 2A

1

2D

W

1 3

Radiator 2

Fan Relay A1

M A/C Condenser

Fan Motor

L

2 4 1

R

3 2E 3 2A 8 2A 2 2D 4 2A 6 2D

5 5

4 5

Radiator 3

B-R

L-B

B

L

Fan Relay 5

No. 2

2 1

2 5 5

From Magnetic

<26-4><27-5>

B-R

Clutch Relay

A2

A/C High

Pressure SW

W-R

W-B

1

B-R

2

R1

1 EA1

B-w

Radiator M

Fan Motor

1 5

B-R

5

W-B

1 3

2

Radiator

W3 Fan Relay

Water Temp. No. 3

SW

1 2

1

5 5

W-B

W-B

B W-B

2 EA1

W-B

W-B

EB Front Left Fender Front Left Fender EB

Fig. 3-25

752f325

Electric cooling fan systems were first used in transverse-mounted

engines in front-wheel drive vehicles (the drive belt is not near the

radiator). Since the fan(s) is electrically powered, various sensors can

control fan operation.

TOYOTA Air Conditioning and Climate Control Course 752 3-21

Section 3

Refrigerant Pressure Switch. This switch normally monitors refrigerant

pressure in the high-pressure side of the system (between the

compressor and the expansion valve). If the pressure is too high or

too low, the pressure switch opens to stop the compressor (via the

compressor clutch). A mid-pressure setting on many cars also controls

the high speed operation of the electric condenser fans.

Normally Open Relays control the condenser fan(s) when the

thermo-switch and pressure switches are closed. However, when either

switch opens (sensing excessive pressure or temperature), the relays

are connected in the circuit to energize the fans. The wiring diagram

on the previous page shows a typical system that uses two fans that

may rotate at different speeds. With this circuit, three relays are used

to connect each fan to power or ground. This means that the two fans

can each be connected to power and ground for high speed operation

(parallel circuits) or they can be connected in series so each fan sees

about half of battery voltage (about 6 volts) for low speed operation.

In the circuit, if either sensor shows high resistance (caused by a loose

wire or corroded terminal) the fans will always run at high speed.

A fail-safe circuit in the cooling fan ECU protects the system in case of a

component failure.

A/C A multispeed fan motor in the air conditioning ductwork circulates cabin

Blower (interior) air or fresh exterior air through the evaporator. In early Toyota

Motor vehicles, a multi-position switch and resistor assembly in the circuit

changes the source voltage to the fan motor. The resistor block contains

multiple outlet terminals to introduce different resistance values into the

circuit to create the multiple speeds. At its highest speed, a full 12 volts

is supplied to the blower motor. To reduce blower speed, the switch

introduces a different resistance to create each of the lower blower speeds.

In current Toyota vehicles, the blower speed is controlled electronically

by the A/C controller.

Resistor-Type 12V

Blower Switch

Current passes through

some or all portions Lo

of resistor depending on M

blower switch speed Fan Motor

position.

Blower Switch

Hi

Resistor Block

Fig. 3-26

752f326

3-22 TOYOTA Technical Training

A/C System Components

Review of Based on the physics of heat transfer, an automotive A/C system works

Refrigeration on these principles:

Circuit Heat is absorbed from the passenger compartment by the evaporator.

This happens because the expansion valve restricts the flow of liquid

refrigerant and increases pressure. However, when the expansion valve

opens, there is a drop in pressure which causes the refrigerant to

evaporate and absorb heat. Dehumidification occurs as the interior air

is drawn across the cool surface of the evaporator.

The gas coming out of the evaporator has its pressure and temperature

raised by the compressor.

The hot gas releases heat to the outside air at the condenser and

changes (condenses) back into a liquid before being filtered and stored

at the receiver-drier.

A/C Refrigerant

Cycle

Fig. 3-27

752f327

TOYOTA Air Conditioning and Climate Control Course 752 3-23

Section 3

Notes

3-24 TOYOTA Technical Training

TOYOTA AIR CONDITIONING AND CLIMATE CONTROL

WORKSHEET 3-1 (IN-CLASS)

A/C Principles

Vehicle: Year/Prod. Date: Engine: Transmission:

Worksheet Objectives:

Describe and identify basic terms, properties and information about vehicle refrigerants.

Background:

Servicing mobile refrigerant systems require a knowledge of service procedures as well as the properties of

different refrigerants.

Tools and Equipment:

This worksheet

1. Compliance in handling refrigerants is covered by what law?

________________________________________________________

2. The release of refrigerant into the atmosphere can damage the ____________________ layer that protects the

earth from excessive __________________________________________ and skin cancer.

3. CFC-12 is a _________________________________________ and HFC-134a is a

______________________________________.

4. It is unlawful to release ____________________ or ____________________ refrigerant into the atmosphere.

5. Refrigerant must be ___________________________ from the A/C system before ________________________

the A/C system.

6. What test should be done before recovering refrigerant from a vehicle? _______________________________

7. Recovered refrigerant can be reused if it is _________________________ and service equipment that recycle

the refrigerant during recovery are known as _________________________ machines.

8. Placing a vacuum on the A/C system with a vacuum pump for __________________________ to remove

__________________________ is known as _____________________________.

TOYOTA Technical Training 3W1-1

Worksheet 3-1

9. What does it mean if, following recovery and evacuation, the pressure gauge raises when the vacuum is

removed?

___________________ or _______________________________________________________________________,

which should be _______________________________.

10. When should the evacuation be done?

_______________________________________________________________________________

11. A/C service fittings for HFC-134a have _______________________________________ for low and high sides

and also have _________________________________ within ___________________________________.

12. There is a difference between CFC-12 and HFC-134a service fittings. The CFC-12 service fittings are

_____________________________________ type, while the HFC-134a service fittings are the

_____________________________________ type.

13. A/C service hoses are color-coded. Low-pressure side hoses are _____________________ in color, while

high-pressure hoses are _____________________ in color.

14. CFC-12 containers are _____________________ in color, while HFC-134a containers are

_____________________ in color.

15. Halogen leak-detectors can detect refrigerant leaks of __________________________________ leakage or

more per year.

16. HFC-134a refrigerant is ________________________ than air, which means the leak-detector sensing probe

should be held ________________________ suspected leak points.

17. Detecting leaks on the low side is often more effective with the A/C turned __________________. High-side

leaks are more easily detectable with the system __________________to increase pressures.

18. The location to check for evaporator leaks is at the evaporator case ______________________________.

19. Suspected leak areas such as the compressor seal will often have ______________________________.

20. Refrigerant dyes are generally ___________________ recommended?

3W1-2 TOYOTA Technical Training

A/C PRINCIPLES

21. Refrigerant dyes can ___________________________________________ or if added with PAG oil can cause

______________________________ when looking for leaks.

22. Debris in the A/C system following a compressor failure is _____________________________________ from

components and lines.

23. If debris is trapped in a condenser or evaporator it should be ___________________________.

24. Flushing is not recommended due to ____________________________________________________.

25. PAG oil is used with _________________________ type refrigerant.

26. Mineral compressor oils are used with ________________________ refrigerants.

27. What is the application for Denso oils numbered ND-6 _________________________,

ND-7_________________________, ND-8 _________________________, ND-9 _________________________

28. The A/C works very well to __________________________ windows in rainy weather.

29. When using the A/C in cold weather, remember the ________________________________ may be

__________________________.

30. Unusual A/C clutch noises during engagement could be related to _________________.

31. The A/C compressor clutch gap is adjusted using _______________________.

32. When installing a REMAN compressor, it is important to check for _______________________ in the system.

33. Whenever the A/C system has been opened to the atmosphere, or a component is replaced, you should also

replace the __________________________________, then ___________________________ the system.

34. A/C odors are caused by _______________________ on the __________________________________.

Instructor Sign Off: ______________________________________

TOYOTA Technical Training 3W1-3

Worksheet 3-1

Notes

3W1-4 TOYOTA Technical Training

A/C PRINCIPLES

A/C Principles

Name: ___________________________________________________________ Date: _________________________

Check each category after participating in the classroom discussion and complete this sheet as you are

completing Worksheet 3-1 using the A/C Principles worksheet in the classroom. Ask the instructor if you have

any questions regarding the topics provided below:

I have questions I know I can

Topic Comment

A/C technician certification requirements

Refrigerant recovery requirements

A/C recovery and charge station

requirements

Refrigerant containers and cross

contamination issues

Noncondensable gas (air) purging

TOYOTA Technical Training 3W1-5

Worksheet 3-1

Notes

3W1-6 TOYOTA Technical Training

TOYOTA AIR CONDITIONING AND CLIMATE CONTROL

WORKSHEET 3-2 (ON-CAR)

A/C Component Identification

Vehicle: Year/Prod. Date: Engine: Transmission:

Worksheet Objectives:

Locate and identify system components in both front and rear A/C units.

Background:

Successful diagnosis and troubleshooting requires identifying and knowing where the various A/C components

are located.

Tools and Equipment:

Vehicle Repair Manual

TIS Machine

Toyota vehicle with Auto A/C and rear A/C if available

Section 1

Identify Basic A/C Components

1. Using the Vehicle Repair Manual and NCF Manual, locate and identify the following basic A/C components:

Component Vehicle General Location

Compressor

Multipressure switch

Expansion valve

High-pressure A/C service fitting

Sight Glass

Low-pressure A/C service fitting

Heater water valve and water

valve control cable servo-motor

Sub-cool condenser and modulator

Sub-cool condenser dryer access

Evaporator assembly

Heater unit

Blower assembly

Instructor Sign Off: ______________________________________

Stop: Do not proceed without Instructors approval

TOYOTA Technical Training 3W2-1

Worksheet 3-2

Section 2

Identify Auto A/C Components

2. Using the Vehicle Repair Manual and NCF Manual, locate and identify the following auto A/C components:

Component Vehicle General Location

Ambient temperature sensor

Air mix servo-motors

Room (interior) temperature sensor

A/C ECU

Solar sensor

Clean air filter

Instructor Sign Off: ______________________________________

3W2-2 TOYOTA Technical Training

A/C COMPONENT IDENTIFICATION

A/C Component Identification

Name: ___________________________________________________________ Date: _________________________

Check each category after participating in the classroom discussion and complete this sheet as you are

completing Worksheet 3-2 using the A/C Component Identification worksheet in the shop. Ask the instructor if

you have any questions regarding the topics provided below:

I have questions I know I can

Topic Comment

Location and type of compressor

Location and type of condenser

Location of filter-drier (receiver-drier)

Location and purpose of sight glass

Low-side and high-side A/C Fittings

Hot water (heater) valve

Fresh air filter (cabin filter)

A/C controls and sensor locations

A/C evaporator and servo-motors

TOYOTA Technical Training 3W2-3

Worksheet 3-2

Notes

3W2-4 TOYOTA Technical Training

Section 4

Diagnosis and Repair

Lesson 1. Demonstrate systematic diagnosis and the six-step process.

Objectives 2. Demonstrate leak detection techniques and proper use of a leak detector.

3. Demonstrate refrigerant identification, recovery, recycling, evacuation

and recharging.

4. Successfully operate a refrigerant recovery/recharging machine.

5. Successfully remove and replace the clutch on an A/C compressor.

6. Operate a tester to identify refrigerant contaminants.

7. Locate the leak detector TSB using the TIS, then perform a refrigerant

leak test.

8. Evaluate proper A/C operation using the Touch and Feel procedure.

9. Evaluate proper A/C operation by interpreting manifold gauge

pressures.

TOYOTA Air Conditioning and Climate Control Course 752

Section 4

Diagnosis and Repair

Systematic As with any mechanical system, you should conduct a Systematic

Diagnosis Diagnosis of the complaint to repair a nonfunctioning A/C system.

Systematic Diagnosis is:

Based on a clear understanding of how the system works or should

work.

A logical, systematic approach to the process of finding the malfunction.

Toyota 1. Verify the complaint

Six-Step

Diagnosis 2. Determine the related symptoms

Process 3. Analyze the symptoms

4. Isolate the cause

5. Correct the cause

6. Check for proper operation

System Checks A complete check of the mechanics and performance of the A/C system

will quickly reveal areas in need of attention. You can perform simple