Professional Documents

Culture Documents

Locktitie 222

Uploaded by

Senthil KumarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Locktitie 222

Uploaded by

Senthil KumarCopyright:

Available Formats

Technical Data Sheet

Product 222

Worldwide Version, October 1995

PRODUCT DESCRIPTION 100

LOCTITE Product 222 is a single component anaerobic

% of Full Strength on Steel

m

5m

threadlocking material, which is thixotropic and develops low 0.1

strength for easy disassembly. The product cures when 75

confined in the absence of air between close fitting metal m

5m

surfaces. 0.2

m

50

5m

0.0

TYPICAL APPLICATIONS

25

Prevents loosening through vibration and leakage of threaded

fasteners. Particularly suitable for applications such as

adjustment of set screws, small diameter or long engagement 0

length fasteners where easy disassembly is required without 5min 10min 30min 1hr 3hr 6hr 24hr 72hr

shearing the screw. Cure Time, Hours

PROPERTIES OF UNCURED MATERIAL Cure speed vs. temperature

The rate of cure will depend on the ambient temperature.

Typical Graph below shows the breakaway strength developed with time

Value Range at different temperatures on M10 steel nuts and bolts and

Chemical Type Dimethacrylate ester tested according to ISO 10964.

Appearance Opaque Purple,

Fluorescent Liquid

% of Full Strength on Steel

1.05 100

Specific Gravity @ 25C

Viscosity @ 25C, mPa.s (cP)

Brookfield RVF 75

C

Spindle 3 @ 2 rpm 5,000 2,500 to 7,500

40

@ 20 rpm 1200 800 to 1,600

DIN 54453, MV 50

D = 277 s-1 after t=180secs 135 90 to 180

C

Flash Point (TCC), C

5

>93

22

25

TYPICAL CURING PERFORMANCE

0

Cure speed vs. substrate 5min10min 30min 1hr 3hr 6hr 24hr 72hr

The rate of cure will depend on substrate used. The graph below Cure Time, Hours

shows the breakaway strength developed with time on M10

steel nuts and bolts compared to different materials and tested Cure speed vs. activator

according to ISO 10964. Where cure speed is unacceptably long, or large gaps are

present, applying activator to the surface will improve cure

speed. The graph below shows breakaway strength developed

% of Full Strength on Steel

100

l with time using ACTIVATOR N and T on M10 Zinc Dichromate

ee ate

St m steel nuts & bolts and tested according to ISO 10964.

75 hro

c Dic

Zin

100

% of Full Strength on Steel

50

or

l at

tee 75 No

ctiv

25 ssS A

e

as

s inl t T

Br Sta Ac

50

0

5min 10min 30min 1hr 3hr 6hr 24hr 72hr tN

Ac

Cure Time, Hours 25

Cure speed vs. bond gap 0

The rate of cure will depend on the bondline gap. Gaps in 5min10min 30min 1hr 3hr 6hr 24hr 72hr

threaded fasteners depend on thread type, quality and size. The Cure Time, Hours

following graph shows shear strength developed with time on

steel pins and collars at different controlled gaps and tested TYPICAL PROPERTIES OF CURED MATERIAL

according to ISO 10123. Physical Properties

Coefficient of thermal expansion, ASTM D696, K-1 80 x10-6

Coefficient of thermal conductivity, ASTM C177, W.m-1 K- 0.1

1

Specific Heat , kJ.kg-1 K-1 0.3

NOT FOR PRODUCT SPECIFICATIONS.

THE TECHNICAL DATA CONTAINED HEREIN ARE INTENDED AS REFERENCE ONLY.

PLEASE CONTACT LOCTITE CORPORATION QUALITY DEPARTMENT FOR ASSISTANCE AND RECOMMENDATIONS ON SPECIFICATIONS FOR THIS PRODUCT.

ROCKY HILL, CT FAX: +1 (860)-571-5473 DUBLIN, IRELAND FAX: +353-(1)-451 - 9959

TDS 222, October 1995

PERFORMANCE OF CURED MATERIAL For safe handling information on this product, consult the

(After 24 hr at 22C on M10 steel nuts & bolts) Material Safety Data Sheet, (MSDS).

Typical

Value Range Where aqueous washing systems are used to clean the

Breakaway Torque, ISO 10964, N.m 6 3 to 9 surfaces before bonding, it is important to check for compatibility

(lb.in) (53) (25 to 80)

of the washing solution with the adhesive. In some cases these

Prevail Torque, ISO 10964, N.m 4 1 to 6

(lb.in) (30) (10 to 50) aqueous washes can affect the cure and performance of the

Breakloose Torque, DIN 54454, N.m 14 8 to 20 adhesive.

(lb.in) (120) (71 to 180)

Max. Prevail Torque, DIN 54454, N.m 14 8 to 20 This product is not normally recommended for use on plastics

(lb.in) (120) (71 to 180) (particularly thermoplastic materials where stress cracking of

the plastic could result). Users are recommended to confirm

TYPICAL ENVIRONMENTAL RESISTANCE compatibility of the product with such substrates.

Test Procedure : Breakloose Torque, DIN 54454

Substrate: M10 Zinc Phosphate Nuts & Bolts Directions for use

Cure procedure: 1 week at 22C For best performance surfaces should be clean and free of

grease. Product should be applied to the bolt in sufficient

Hot Strength quantity to fill all engaged threads. This product performs best in

Tested at temperature. thin bond gaps, (0.05mm). Very large thread sizes may create

100 large gaps which will affect cure speed and strength. This

product is designed to give controlled friction, (torque/tension

ratio), during assembly. In critical tightening applications this

% RT Strength

75 ratio should be confirmed.

Storage

50

Product shall be ideally stored in a cool, dry location in

unopened containers at a temperature between 8C to 28C

25 (46F to 82F) unless otherwise labelled. Optimal storage is at

the lower half of this temperature range. To prevent

contamination of unused product, do not return any material to

0

0 50 100 150

its original container. For further specific shelf life information,

Temperature, C contact your local Technical Service Centre.

Heat Aging Data Ranges

Aged at temperature indicated and tested at 22C. The data contained herein may be reported as a typical value

125 and/or range (based on the mean value 2 standard deviations).

Values are based on actual test data and are verified on a

% Initial Strength at RT

100

periodic basis.

120C

75

Note

The data contained herein are furnished for information only and

are believed to be reliable. We cannot assume responsibility for

50

the results obtained by others over whose methods we have no

150C

control. It is the user's responsibility to determine suitability for

25

the user's purpose of any production methods mentioned herein

and to adopt such precautions as may be advisable for the

0

0 1,000 2,000 3,000 4,000 5,000 protection of property and of persons against any hazards that

Hours may be involved in the handling and use thereof. In light of the

foregoing, Loctite Corporation specifically disclaims all

Chemical / Solvent Resistance warranties expressed or implied, including warranties of

Aged under conditions indicated and tested at 22C. merchantability or fitness for a particular purpose, arising from

sale or use of Loctite Corporations products. Loctite

Solvent Temp % Initial Strength retained at Corporation specifically disclaims any liability for consequential

. or incidental damages of any kind, including lost profits. The

100 500 1000 hr 5000 hr discussion herein of various processes or compositions is not to

hr hr be interpreted as representation that they are free from

domination of patents owned by others or as a license under

Motor Oil 125 100 95 90 85

any Loctite Corporation patents that may cover such processes

C

or compositions. We recommend that each prospective user

Leaded Petrol 22C 95 95 95 95

Brake Fluid 95 95 95 90

test his proposed application before repetitive use, using this

22C

Water/Glycol 80 80 80 80 data as a guide. This product may be covered by one or more

87C

(50%/50%) United States or foreign patents or patent applications.

Ethanol 22C 95 95 90 90

Acetone 22C 100 90 90 90

GENERAL INFORMATION

This product is not recommended for use in pure oxygen

and/or oxygen rich systems and should not be selected as a

sealant for chlorine or other strong oxidising materials.

Loctite is a Registered Trademark of Loctite Corporation, Hartford, CT 06106

You might also like

- Technical Data Sheet Product 243: Worldwide Version, October 1995Document2 pagesTechnical Data Sheet Product 243: Worldwide Version, October 1995Yacine MARICHENo ratings yet

- Technical Data Sheet Product 290: Worldwide Version, October 1995Document2 pagesTechnical Data Sheet Product 290: Worldwide Version, October 1995quang trinhNo ratings yet

- Loctite 243: Technical Data SheetDocument6 pagesLoctite 243: Technical Data SheetMarcoNo ratings yet

- Loctite 243 Updated-EnDocument4 pagesLoctite 243 Updated-Enதமிழன் இராமசாமிNo ratings yet

- Loctite 641 enDocument3 pagesLoctite 641 engeorgeNo ratings yet

- Literature File 181Document3 pagesLiterature File 181FERSNo ratings yet

- LOCTITE 243 RAIL en - GLDocument4 pagesLOCTITE 243 RAIL en - GLGheorghe Adrian SavuNo ratings yet

- Aa 326-EnDocument3 pagesAa 326-EnmorashidNo ratings yet

- Loctite 574™: Product DescriptionDocument3 pagesLoctite 574™: Product DescriptionmykedindealNo ratings yet

- 648 TDS PDFDocument3 pages648 TDS PDFSenthil Kumar GanesanNo ratings yet

- Loctite 5400™: Product Description Cure Speed vs. Bond GapDocument3 pagesLoctite 5400™: Product Description Cure Speed vs. Bond GapMototest HarleybmwNo ratings yet

- Loctite 263 ThreadlockerDocument3 pagesLoctite 263 Threadlockerqistinaramli2024No ratings yet

- Loctite 603: Technical Data SheetDocument3 pagesLoctite 603: Technical Data SheetibrahimNo ratings yet

- 262 enDocument4 pages262 enshashibagewadiNo ratings yet

- 620 enDocument3 pages620 enJoseph wheelerNo ratings yet

- Loctite 620: Product Description Technology Cure Speed vs. Bond GapDocument3 pagesLoctite 620: Product Description Technology Cure Speed vs. Bond GapKamrange100% (1)

- Loctite 601: Technical Data SheetDocument3 pagesLoctite 601: Technical Data SheetMahendra NanayakkaraNo ratings yet

- Loctite 277Document3 pagesLoctite 277Sreenivas TalariNo ratings yet

- LOCTITE 603 en - GLDocument4 pagesLOCTITE 603 en - GLAdrian SetyadharmaNo ratings yet

- Loctite 510™: Technical Data SheetDocument4 pagesLoctite 510™: Technical Data SheetYasser RezkNo ratings yet

- Loctite 573 - Tech - Info - Sheet - ENDocument3 pagesLoctite 573 - Tech - Info - Sheet - ENChristopherNo ratings yet

- Locktite 2701Document3 pagesLocktite 2701keerthivasan_mrvNo ratings yet

- Loctite 222MS™: Product DescriptionDocument3 pagesLoctite 222MS™: Product DescriptionVaibhav ChaudharyNo ratings yet

- Loctite 515™: Technical Data SheetDocument3 pagesLoctite 515™: Technical Data SheetVincent EsperanzaNo ratings yet

- LOCTITE HY 4090 en - GLDocument4 pagesLOCTITE HY 4090 en - GLkhame006No ratings yet

- PT. Osmo Marina Mandiri Hunting 021 - 29070732: Accessories: Elbow / Grs-Guide Rail SystemsDocument2 pagesPT. Osmo Marina Mandiri Hunting 021 - 29070732: Accessories: Elbow / Grs-Guide Rail SystemsHamdi NaufelNo ratings yet

- Technical Data Sheet Product 577: Typical Value RangeDocument2 pagesTechnical Data Sheet Product 577: Typical Value RangeNabil DjaaboubNo ratings yet

- Loctite 2440™: Technical Data SheetDocument3 pagesLoctite 2440™: Technical Data SheetFabio ParceroNo ratings yet

- Loctite 638™: Technical Data SheetDocument4 pagesLoctite 638™: Technical Data SheetChinmoy BaruahNo ratings yet

- This Datasheet Is Presented by The Manufacturer Dieses Datenblatt Wird Vom Hersteller Bereitgestellt Cette Fiche Technique Est Présentée Par Le FabricantDocument5 pagesThis Datasheet Is Presented by The Manufacturer Dieses Datenblatt Wird Vom Hersteller Bereitgestellt Cette Fiche Technique Est Présentée Par Le FabricantAbdulSattarNo ratings yet

- Bombas Flygt-NP-3202-180-LDocument3 pagesBombas Flygt-NP-3202-180-LGerman RufanachtNo ratings yet

- Loctite 515™: Technical Data SheetDocument4 pagesLoctite 515™: Technical Data SheetNelson OsbornneNo ratings yet

- Loctite-577 Thread SealantDocument4 pagesLoctite-577 Thread SealantqcselvaNo ratings yet

- Employer:: 250mm Thick Filter MaterialDocument1 pageEmployer:: 250mm Thick Filter MaterialSudip ShresthaNo ratings yet

- Vishay Bccomponents: FeaturesDocument18 pagesVishay Bccomponents: FeaturesJose cuelloNo ratings yet

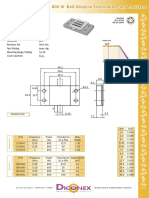

- 800 W Beo Stripline Terminations and ResistorsDocument1 page800 W Beo Stripline Terminations and ResistorsMarcos MillerNo ratings yet

- Loctite 243 New-EnDocument4 pagesLoctite 243 New-Enrazvan33No ratings yet

- LOCTITE 2422-tdsDocument4 pagesLOCTITE 2422-tdsIndo KalbarNo ratings yet

- Loctite 3090™: Product Description Cure Speed vs. SubstrateDocument4 pagesLoctite 3090™: Product Description Cure Speed vs. SubstrateNishant SenapatiNo ratings yet

- Desdeporfolio CorporativoDocument4 pagesDesdeporfolio CorporativoRaul FuentesNo ratings yet

- Loctite Fel-Pro C-102, 222 & 243Document9 pagesLoctite Fel-Pro C-102, 222 & 243Liu YangtzeNo ratings yet

- Philippine Electrical Code Table 9.1.1.9 AC Resistance Reactance TableDocument1 pagePhilippine Electrical Code Table 9.1.1.9 AC Resistance Reactance TableGlasee GoweeNo ratings yet

- Main Engine Room: Water Mist Fire Protection SystemsDocument1 pageMain Engine Room: Water Mist Fire Protection SystemsahmadtaiyabiNo ratings yet

- Features: Rechargeable Sealed Lead Acid Battery PS - General Purpose SeriesDocument2 pagesFeatures: Rechargeable Sealed Lead Acid Battery PS - General Purpose SeriesKevin ElizaldeNo ratings yet

- 4090 enDocument4 pages4090 enIvan MarijanovićNo ratings yet

- Dri Loc 218 Data SheetDocument2 pagesDri Loc 218 Data Sheetpalani.djpNo ratings yet

- RIOLINE Shock TubeDocument2 pagesRIOLINE Shock TubeCyprien YENo ratings yet

- Diaphragm Mechanism, Fluid Isolation Pad-Mounting BodyDocument2 pagesDiaphragm Mechanism, Fluid Isolation Pad-Mounting BodyErick SantosNo ratings yet

- Accessories: Elbow / Grs-Guide Rail Systems: Submersible Wastewater Sump PumpsDocument2 pagesAccessories: Elbow / Grs-Guide Rail Systems: Submersible Wastewater Sump PumpsHamdi NaufelNo ratings yet

- MB-SK EnglishDocument2 pagesMB-SK EnglishMohamed Ahmed ElFekyNo ratings yet

- Aa 324-EnDocument3 pagesAa 324-EnManiNo ratings yet

- Tutorial Getting Started With Code Aster PDFDocument12 pagesTutorial Getting Started With Code Aster PDFEnriqueNo ratings yet

- AAF Product Leaflet MEGAcel II ePTFE ENDocument4 pagesAAF Product Leaflet MEGAcel II ePTFE ENVin KenNo ratings yet

- Toilet & Bath at Bedroom: Medicine Cabinet Counter Top Lavatory Installation Siphon Jet Water ClosetDocument1 pageToilet & Bath at Bedroom: Medicine Cabinet Counter Top Lavatory Installation Siphon Jet Water ClosetStephen Mark Garcellano DalisayNo ratings yet

- Deimos Bta: Cable Run Motor FasteningDocument2 pagesDeimos Bta: Cable Run Motor FasteningIliescu CristianNo ratings yet

- Zurcon o Rings GB enDocument2 pagesZurcon o Rings GB enSimen EllingsenNo ratings yet

- 248 enDocument4 pages248 enPaulo BertoNo ratings yet

- Frenzelit - Novatec PREMIUM II - e - BrochureDocument6 pagesFrenzelit - Novatec PREMIUM II - e - BrochureRuben PauwelsNo ratings yet

- Teclock SungshinDocument64 pagesTeclock Sungshinsomkiat kongprasiatNo ratings yet

- Mil DTL 5593dDocument13 pagesMil DTL 5593dSenthil KumarNo ratings yet

- Composition/Pro Perties S130DDocument1 pageComposition/Pro Perties S130DSenthil KumarNo ratings yet

- Mil H 25579Document22 pagesMil H 25579Senthil KumarNo ratings yet

- Oil Seal GuideDocument7 pagesOil Seal GuideSenthil KumarNo ratings yet

- Sp-799S Polyester/Glass Filament Tape: Technical Data Page 1 of 1Document1 pageSp-799S Polyester/Glass Filament Tape: Technical Data Page 1 of 1Senthil KumarNo ratings yet

- An818 Rev-20 2Document5 pagesAn818 Rev-20 2Senthil KumarNo ratings yet

- Tropicalised VarnishDocument4 pagesTropicalised VarnishSenthil KumarNo ratings yet

- Eccentric SleeveDocument20 pagesEccentric SleeveSenthil KumarNo ratings yet

- En 2491Document1 pageEn 2491Senthil KumarNo ratings yet

- Worm Drive & Screw Clamps: J J J J JDocument1 pageWorm Drive & Screw Clamps: J J J J JSenthil KumarNo ratings yet

- Durometer Conversion TableDocument1 pageDurometer Conversion TableSenthil KumarNo ratings yet

- Machine Design & Drawing - II - GEARSDocument12 pagesMachine Design & Drawing - II - GEARSSenthil KumarNo ratings yet

- Gerotor Modeling With NX3Document4 pagesGerotor Modeling With NX3Senthil KumarNo ratings yet

- BS 1449Document3 pagesBS 1449Senthil KumarNo ratings yet

- New Design and Analysis of A Geneva Device AbsDocument1 pageNew Design and Analysis of A Geneva Device AbsSenthil KumarNo ratings yet

- Wankel CompressorDocument6 pagesWankel CompressorSenthil KumarNo ratings yet

- Modern Bamboo SplitterDocument14 pagesModern Bamboo SplitterSenthil Kumar100% (1)

- TranslationsDocument19 pagesTranslationsAnonymous eSi1iZTNGNo ratings yet

- Mohit Soni ReportDocument104 pagesMohit Soni ReportMohitNo ratings yet

- Electronic Circuits - II Lab ManualDocument26 pagesElectronic Circuits - II Lab Manualbalabasker100% (1)

- CS506 - Web Design and Development (Handouts) PDFDocument471 pagesCS506 - Web Design and Development (Handouts) PDFSyed Shahzad100% (2)

- A5 MSMD 400WDocument1 pageA5 MSMD 400WInfo PLSNo ratings yet

- Scan 1111111111Document1 pageScan 1111111111angela1178No ratings yet

- GEMU - ZRSK - CheckDocument11 pagesGEMU - ZRSK - Checkmurugn08No ratings yet

- Database Testing: Prepared by Sujaritha MDocument21 pagesDatabase Testing: Prepared by Sujaritha Mavumaa22No ratings yet

- Series: 25 TON (222 KN)Document2 pagesSeries: 25 TON (222 KN)Marius IlcaNo ratings yet

- ALL SYSTEMS GO by Zenovia AndrewsDocument225 pagesALL SYSTEMS GO by Zenovia AndrewsTanya Gillie100% (3)

- Hi 8586pdiDocument9 pagesHi 8586pdiDunkMeNo ratings yet

- Creating Flight Plan and User Waypoint Files For The Flight1 GTNDocument6 pagesCreating Flight Plan and User Waypoint Files For The Flight1 GTNJosé A. Montiel QuirósNo ratings yet

- Density and Concentration Transmitter: Installation GuideDocument40 pagesDensity and Concentration Transmitter: Installation GuideOmid GhNo ratings yet

- Mdce InstallDocument67 pagesMdce Installrmehta26No ratings yet

- Shailendra - Yadav - R.F Design and Optimization Engineer - 5.10 - Yrs ExpDocument7 pagesShailendra - Yadav - R.F Design and Optimization Engineer - 5.10 - Yrs ExpGaurav TiwariNo ratings yet

- Value Creation Through Project Risk ManagementDocument19 pagesValue Creation Through Project Risk ManagementMatt SlowikowskiNo ratings yet

- Solenoid ValvesDocument23 pagesSolenoid ValvesmcsecNo ratings yet

- Project Goals/ ObjectivesDocument51 pagesProject Goals/ ObjectivesJoyce Abegail De PedroNo ratings yet

- IRGC (2021) - Spotlight - Risk Governance and The Rise of DeepfakesDocument4 pagesIRGC (2021) - Spotlight - Risk Governance and The Rise of DeepfakessaidNo ratings yet

- Sneha Foundation PlusDocument17 pagesSneha Foundation PlusBikash KumarNo ratings yet

- Model Variant Description Variant Code Extended Warranty Price Royal PlatinumDocument2 pagesModel Variant Description Variant Code Extended Warranty Price Royal PlatinumRiyasNo ratings yet

- PPG en-US P162.OutputDocument4 pagesPPG en-US P162.OutputChemical EngineerNo ratings yet

- Getting Started With DockerDocument8 pagesGetting Started With DockerdenisaNo ratings yet

- Anti Lock Brake Safety PrecautionsDocument1 pageAnti Lock Brake Safety Precautionssonny1234No ratings yet

- ReadMe PDFDocument31 pagesReadMe PDForaleculero117No ratings yet

- Shell Gadus S3 T100 PDFDocument1 pageShell Gadus S3 T100 PDFAgung BaskaraNo ratings yet

- Revista Stiinte Politice Issue 42Document264 pagesRevista Stiinte Politice Issue 42Costel111No ratings yet

- Feasibility Study Notes Revised PDFDocument10 pagesFeasibility Study Notes Revised PDFGilbert BettNo ratings yet

- Analysis and Design of Bridge Substructures PDFDocument195 pagesAnalysis and Design of Bridge Substructures PDFsuheilbugs100% (1)