Professional Documents

Culture Documents

Ib 46

Uploaded by

Chester SmithOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ib 46

Uploaded by

Chester SmithCopyright:

Available Formats

INFORMATION BULLETIN: IB 46

Vibration of Concrete

Introduction There are three inter-related properties that may

influence the behaviour of a concrete mix during

vibration. These are known as compactibility,

The correct placing and compaction of fresh

mobility and stability. Each is affected by changes

concrete are probably the most important parts of

in the physical make-up of the mix, and can control

the whole sequence of concreting operations.

the degree to which efficient consolidation of the

Success relies on careful planning, the right

particles is possible.

manpower and internal equipment. This

information bulletin discusses various aspects of

Compactability refers to the ease with which a

the compaction process. It is pertinent to

concrete can be compacted properly with efficient

remember that the mixing process for concrete

removal of entrapped air and the repositioning of

entraps air within the mix. For each 1% of voids left

constituent particles into a denser state.

within the concrete the strength is reduced by

approximately 5-6%. Air entrapped in the concrete

Mobility of mix related to aspects of flow. Internal

leaving the mixer typically may vary from 5-20%.

cohesion due to frictional effects, surface forces

and the like is an important factor here.

Compaction is vital to achieve:

Stability of a mix refers to its resistance to

1. Maximum strength of the placed concrete.

segregation effects during transporting, handling,

placing and compacting.

2. Maximum durability.

Segregation. A significant separation of the course

3. Adequate bond and protection for

and fine fractions is highly detrimental to concrete

reinforcement in the concrete.

quality.

4. Avoidance or reduction of visual blemishes,

The object in vibrating concrete is to mobilise it

such as honeycombing and blowholes on the

sufficiently, so that it becomes plastic enough to

surface of form cast concrete.

enable air voids to be removed and the aggregate

particles to gravitate together to form a

The ease with which optimum compaction can be

homogeneous mass. The stiffer the mix and the

achieved by vibration techniques is related to:

larger the aggregate particle sizes, the greater will

be the force required to energise the mix.

1. Physical properties of the fresh concrete which

in turn depend on the type of aggregate,

Lower water cement ratio concrete has a lower

constituent particle shapes, and relative mix

workability, but becomes a much stronger

proportions. Harsh mixes are more difficult to

compacted concrete. A high degree of compaction

consolidate. Mixes high in fines or cement are

with harsh mixes requires very efficient vibration

"sticky" and may also present problems of

both in terms of effectiveness of the applied poker

compaction;

vibrator and the number of insertions made.

2. Types of vibrators, associated characteristics

and vibration patterns through the concrete;

Vibration Mechanisms

3. Techniques in handling vibrators, in particular

spacing and duration of vibration. The equipment that is used in compacting concrete

IB 46: Vibration of Concrete Page 1

..

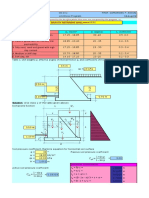

develops its vibrations by a form of eccentric cycle is given by x = a sin (2ft) where the

rotation. Because of this, the vibrations are maximum acceleration is given by a = 42f2s metres

generated in a steady flow of cycles, and are per second2 (figure 1).

transmitted into and through the medium in

contact with the vibrator.

The cycle of vibrations travel through the concrete,

transferring their energy to the particles in the mix.

Eventually, at some distance from their source, the

vibrations lose their effectiveness.

As the vibrations pass a certain point, the mix at

that location moves back and forward about its

original point of rest. As this occurs, the entrapped

air is released and moves the surface while

individual particles oscillate about and settle down

into the mix.

The components of the vibration cycle are

amplitude, frequency and acceleration, and these

terms are used to describe the performance

characteristics of vibration equipment. See Table 1. Figure 1: Sinusoidal vibratory motion.

Table 1: Recommended accelerations and The maximum acceleration during a vibratory

frequencies of concrete vibration motion is often expressed as a multiple of the

acceleration due to gravity, g; for example 5 g (50

Recommended m/sec2) for table vibration.

Vibration Acceleration Recommended

Method (without concrete Frequency

load) From research conducted by Dr L. Forssblad of the

g Hz vib/min

Dynapac organization in Sweden, the interactions

of concrete of properties, frequency and amplitude

Internal 100-200 150-250 9,000-15,000 of internal vibration are shown in graphs of radius

Form 5-10 50-200 3,000-12,000 of action versus frequency, for various amplitudes

Surface 5-10 50-100 3,000-6,000

and times of operation with a constant mix design.

The studies indicated that there was an optimum

Table 5-10 50-100 3,000-6,000 combination of vibratory conditions for the

response of the concrete mix (figure 2, page 3).

Amplitude is the maximum departure for a point of During the vibration process the concrete

rest during a displacement cycle under vibration. undergoes three different stages. The first is the

Most concrete vibrators operate with an amplitude initial rapid collapse of the uncompacted mix. This

of 0.5 mm to 2.0 mm. requires a large energy usage. If the vibration effort

is too low, the internal resistance of the mix

Frequency (f) is usually described by the number of dampens the motion and the concrete absorbs the

vibrations per unit time. 1 Hertz (hz) = 1 vibration energy without any plastic deformation occurring.

per second, or 60 vibrations per minute. Therefore As the force is increased, the mechanical

200 Hz refers to 12,000 vibrations per minute. properties of the mix and its resistance to the

compaction effort falls until the material is

The displacement at any time during a simple sine transformed into a liquid. The mass then begins to

wave oscillation is given by the formula x = s sin flow.

(2ft) where s denotes the amplitude.

As the concrete then liquefies, de-aeration begins

Similarly, the acceleration (which is the rate at and most of the entrapped air is released. Finally,

which the velocity is changing) at any time in the as the number of air bubbles being liberated

IB 46: Vibration of Concrete Page 2

Figure 2: Graphs showing the correlation between radius of action, frequency, and amplitude for a 60 mm

internal vibrator.

ceases, little energy is required to overcome the selection of power sources and types of vibrating

internal friction and damping effect of the concrete mechanisms. The power source is either electric,

as the mix is behaving nearly as an ideal fluid, and pneumatic, petrol or diesel based. The vibrating

its surface begins to acquire a glistening smooth mechanism in the poker head can be driven by a

appearance. flexible shaft, motor-in-head or pneumatically.

Pneumatic poker vibrators that operate a rotating

mechanism within the head, are used in areas

Types of Vibrators where it is convenient to have compressed air

available and when it would be dangerous to use

The four most commonly used systems for

other types of machines.

compacting concrete are internal vibration, table

vibration and surface vibration. With each of these

Whatever the form of vibrator, the rotating member

the mechanism of vibration and the effect of the

in the head produces an eccentric motion that

formwork on the concrete mix is different.

generates the vibrations. Circular compression

waves are produced in rapid succession. These

travel away from their source and through the

Internal Vibrators concrete. The further they travel through the

concrete, the amplitude of vibration imparted to

Internal or poker vibrators are available with a the particles that are met reduces, due not only to

IB 46: Vibration of Concrete Page 3

the damping effect at the vibrator itself and in the head. The diameter of the rotor is smaller than the

concrete, but also to the increased length around inside diameter of this rolling ring, and since the

the circular wave (figure 3). inside of the tube is scrupulously clean, the rotor

grips and skids inside the ring four times for every

revolution of the flexible shaft. This system

effectively gears up the 3,000 rpm to produce

12,000 vibrations per minute at the nose cap end.

Since the maximum amplitude is at the nose cap,

the pendulum vibrator when withdrawn from the

concrete compacts the upper surface without

leaving holes or voids.

Developments to the principle have been made

over the years to produce longer lasting and cooler

running vibrators with improved efficiency of

vibration. These features, coupled with the

availability of waterproof joint extension shafts to

make the flexible shaft up to 11 m long and rubber

covered nose caps to protect formwork, have made

the pendulum vibrator a popular choice for

concrete compaction.

Figure 3: Principle of internal vibration.

Pneumatic Poker Vibrators

Flexible Shaft Poker Vibrators

These vibrators generally have an integral oil bottle

These vibrators employ two sections for generating and throttle control and a compressed air hose

their vibratory output. They are known as parallel inside a large diameter exhaust hose to allow used

or pendulum vibrators. The parallel design air to escape by the oil bottle. The poker heads

embodies an eccentric shaft rotating between comprise four basic types. The oldest style uses an

bearings at both ends, whilst the pendulum design airmotor inside the tube driving an eccentric shaft

involves the use of a suspended rotor with a self between two bearings. Another type uses an

aligning bearing at the drive end, with the lower airblown ball bearing in a race to produce the

end being allowed to freely orbit when rotated vibrations. The most common two types in use are

within the housing. the rotary vane vibrator and the helical rotor

vibrator.

The vibratory characteristics of the two types are

different, in as much as the vibratory output from The helical rotor vibrator was a development from

the parallel machine gives a force of equal power the rotary vane to primarily reduce the weight of the

over the length of the tube, while with the vibrator which was required in the vane operation.

pendulum design the power is at its maximum at The spinning rotor is forced outwards by a series of

the nose cap end of the vibrator. discretely located airflow paths to produce the

vibration.

The parallel vibrator historically was the preferred

system, but it was found with harsh mixes that This process is repeated over 20,000 times a

although it effectively compacted the mix, it left a minute which reduces to 12,000 times when placed

hole when the poker head was withdrawn. in the concrete, producing the characteristic rise

and fall droning noise of an air vibrator.

The pendulum system developed in Sweden in

1936 overcame this problem. In this design the

flexible shaft is driven at 3,000 rpm and is screwed External Vibrator

(via an end shank) to the top end of the solid steel

rotor. The self aligning bearing at this end allows The selection and application of external vibrators

the other bottom end to float inside a hard steel requires careful consideration. The units are

ring which is permanently fixed inside the tube available in varying output powers, that are defined

IB 46: Vibration of Concrete Page 4

either by the centrifugal force developed or the frequencies used range between 3,000 and 12,000

wattage of the motor. The transfer of vibratory vibrations per minute. The high frequency use

power though the formwork must be considered as tends to give a better surface appearance. Large

the nature of the mix and density of any contracts benefit by the use of external vibration

reinforcement within the section (figure 4). with regard to a lower manpower and reduction of

human error. Far stiffer mixes can also be used.

Vibrating Screeds

Surface vibration is usually accomplished by

comparatively light single or double vibrating

screeds which can compact up to 200 mm thick

layers of flowing to plastic concrete mixtures. For

such screeds, a frequency range of 3,000 to 6,000

vibrations per minute and accelerations to 5-10 g

are customary. The amplitude distribution along

the screed should be reasonably uniform (figure 6).

Figure 4: Principle of form vibration.

Generally, the external vibrator consists of an

electric motor with an unbalanced member to

create the vibration (figure 5).

Figure 6: Principle of surface vibration.

Roller and Laser Screeds

The use of these two methods represents the most

recent advances in the placement and compaction

of concrete. It is important to note that additional

vibration will still be necessary when using these

methods to screed and finish concrete as the

amount of vibration imparted into the concrete by

Figure 5: An external vibrator clamped to a form. these two methods may not be enough to achieve

total compaction.

The best frequency of vibration depends mainly on Roller Screeds

the design of the formwork with high vertical forms

usually requiring the high frequency option. Roller screeds are sometimes used as a

However, very stiff mixes respond better to high placement and compaction tool in its own

amplitude and lower frequency. Generally, the right, but this is usually only in relatively thin

IB 46: Vibration of Concrete Page 5

slabs, and with the use of immersion vibrators Table vibrators can give less consistent results

around the perimeter forms, where additional even with careful operation. The compaction effect

compaction is usually required. is determined by the acceleration of the table.

Accelerations of about 5-10 g before the forms are

Manufacturers of these screeds claim that the placed on the table, and 2-4 g during vibration, are

placement of concrete using roller screeds required.

leaves more large aggregate at or near the

surface, which enhances the performance of For table vibration the optimum frequency range is

the slab under harsh operation conditions fairly low, 3,000-6,000 vibrations per minute.

(such as is found in warehouses for instance). Comparatively large amplitudes are generally

needed for efficient and rapid consolidation.

Laser Screeds

The location of the vibrators and direction of

Laser screeds are used primarily in large floor rotation is important since it effects the primary

pours where slab flatness is of prime concern. direction of the vibration which may be a rotational

While thinner slabs will only require motion or uni-directional.

supplemental vibration around the slab

perimeter, thicker slabs are generally placed

using a combination of immersion vibration Compaction Methods

and the vibrating laser screed. (This approach

is the recommended method to follow). The characteristics of concrete, effects of vibration

and equipment available, have been discussed in

Both methods will produce a slab with surface the previous sections. This section deals

levelness and flatness tolerances that are much specifically in turn with the practical consideration

better than free screeding techniques. in the workplace of using vibrators. Often the

cause of many problems of faults in concrete is

directly traceable to the failure to ensure adequate

Table Vibration vibration.

Vibrating table techniques are usually restricted to The main feature of construction work tends to be a

precasting operations. On a vibrating table, the lack of sufficient vibration to the concrete in terms

forms as well as the concrete can move during of providing manpower and equipment to match

vibration and resonance may occur. Also reflection the placing rate of the concrete. When placement

of the pressure waves against the concrete surface is by concrete pump considerable resources are

will influence the amplitude distribution (figure 7). needed if full compaction is to be achieved.

Internal Vibrators

Most concrete is compacted by means of

immersion or poker vibrators. This method is

considered the most satisfactory because the

poker works directly on the concrete and can be

moved from one position to another easily and

quickly. For most reinforced concrete work, pokers

of diameters from 25 mm up to 75 mm are used.

Diameters up to 100 and 150 mm are available, but

their use is mainly restricted to mass concrete in

heavy civil engineering works like dam

construction. Due to their weight, these large

pokers usually need two people to handle and

operate them. For efficient compaction, the largest

diameter that the complexity of formwork and

reinforcement will allow should be used. Table 2

Figure 7: Principle of table vibration. gives an indication of poker sizes and applications.

IB 46: Vibration of Concrete Page 6

Although the table indicates the radius of action for from a number of sites have shown that they are

various poker diameters, the actual effectiveness of often running wastefully, or at a reduced efficiency,

a particular poker in a specific situation depends for about 70% of their operating time:

on the workability of the concrete and the

characteristics of the poker itself. Generally, the 15% out of the concrete and running,

larger the diameter and the higher the frequency, 35% wrongly positioned in the concrete,

the greater will be the radius of action, but in 20% vibrating already compacted concrete.

practice it is best to judge by eye the actual radius

for a particular situation. This means that the poker is doing useful work for

only 30% of the time, which is why it is necessary

This radius will determine the spacing and pattern to plan the compaction, placing method and

of insertions of the poker. For example, if the technique in advance, so that both operations are

radius of action is about 200 mm, insertions will carried out as economically and quickly as

need to be about 300 mm apart and to a possible.

predetermined pattern if all the concrete is to be

fully compacted. The following guidelines are helpful to ensure a

well compacted mix (see also figures 8, 9 and 10):

As a guide, a spacing of about 450 mm (250 mm

radius of action) may be assumed for a 60 mm 1. Make sure the operator can see the concrete

diameter poker with concrete of medium surface.

workability.

2. When inserting the poker, allow it to penetrate

to the bottom of the layer as quickly as

Length of Head possible under its own weight. If done slowly,

the top part of the layer will be compacted

first, making it more difficult for the entrapped

Because it is only the head itself which is vibrating,

air in the lower part to escape the surface.

the concrete layer should not be deeper than the

head length, otherwise there is a danger that the

3. Leave the poker in the concrete for about 10

top part will not be fully compacted. For most

seconds and withdraw it slowly ensuring that

pokers within the range of diameters given in table

the hole made by the poker is closed up. If a

2, the poker head is likely to be between 350 and

hole is left (and it is often difficult to prevent if

600 mm long.

the concrete is very stiff), replace the poker

near enough to the hole for the next spell of

vibration to close it up. For the final insertion,

Using a Poker Vibrator withdraw the poker even more slowly and

wiggle it about to ensure that the hole closes

Pokers are often used inefficiently. Observations up properly.

Table 2: Poker sizes and applications

Diameter Radius of Appropriate rate of

of head action compaction, assuming Application

(mm) (mm) rapid placing (m3/h)

20-30 80-150 0.8-2 50 mm slump and above in very thin sections and

(Needle) confined places. May be needed in conjunction with

larger vibrators where reinforcement, ducts and other

obstructions cause congestion.

35-40 130-250 2-4 50 mm slump and above in thin columns and walls and

confined places.

50-75 180-350 3-8 25 mm slump and above in general construction free from

restrictions and congestion.

IB 46: Vibration of Concrete Page 7

4. Replace the poker in the concrete to correct there is a risk of the bearings overheating.

spacing.

6. Avoid sharp bends in flexible drives and do

5. Avoid touching the formwork face with the not move the vibrator by pulling on the flexible

poker as this will leave a poker burn on the drive.

formwork and a resulting mark will be left on

the finished concrete surface. To be on the 7. Remember that where finish is important, a

safe side, keep the vibrator about 75-100 mm little extra vibration can reduce the number of

away from the formwork. blowholes.

Avoid touching the reinforcement with the 8. Make sure the driver motor will not vibrate

poker, although, provided that all the concrete itself off the stagings, and when finished clean

is still fresh, vibrating the reinforcement all the equipment thoroughly.

should not do any harm and could improve

the bond. The danger lies in the vibrations in

the reinforcement being transmitted into parts

of the section where the concrete may have

stiffened, in which case the bond may be

affected.

Avoid using the poker to make the concrete

flow and never use it to flatten a heap.

Instead, insert the poker carefully around the

perimeter which will avoid segregation,

remembering that compaction starts only after

the heap has been flattened.

7. Make sure that the poker extends about 150

mm into any previous layer of concrete and

put the whole length of the poker head into

the concrete. This is essential to keep the

bearings cool. Avoid leaving the poker run- Figure 8: Diagram showing incorrect and correct

ning when it is not in the concrete, otherwise placing of poker in concrete.

Figure 9: Use of poker vibrator.

IB 46: Vibration of Concrete Page 8

1.

Length of Time Required for Full

Compaction

The length of time a poker has to be in the concrete

at any one position in order to fully compact the

surrounding concrete cannot be precisely stated

since it depends both on the workability of the mix

and on the size of the poker itself. The duration

will vary between 5 and 15 seconds for concrete

with a slump of 25-75 mm, so practically, a time of

around 10 seconds in the concrete should be

satisfactory.

Being able to tell when concrete is fully compacted

is a matter of experience. With a poker, one soon

gets the feel of it and can judge the right amount of

vibration to give. The following will help:

1. Initial consolidation is rapid and the level of

the concrete drops quickly but the entrapped

air has still to be removed.

2. As the concrete is vibrated, air bubbles come

to the surface. When the bubbles stop, it can

be taken as a sign that not much more useful

work can be done on the concrete. The

distance of the bubbles from the poker is also

a useful guide to its radius of action.

3. Sometimes the sound can be a helpful guide.

When the poker is inserted there is usually a

dropping off in frequency, and when the pitch

(whine) becomes constant the concrete is free

from entrapped air.

4. The surface appearance also gives an

indication of whether or not compaction is

complete. A thin film of glistening mortar on

the surface is a sign that the concrete is

compacted, as is cement paste showing at the

junction of the concrete and formwork.

In any case, the dangers from under-compaction

are far greater than those from over-compaction, so

if there is any doubt dont be in a hurry to stop

vibrating. Too much is better than too little, since it

is virtually impossible to over-vibrate a properly

designed mix.

Figure 10: Sequence of the stages that occur

during vibration of a heap of concrete. The

photographs show the spacings of the vibrator

insertions and the glistening appearance that is

given to the surface.

IB 46: Vibration of Concrete Page 9

The result of over-vibrating badly designed mixes, cracks generally form about 1-2 hours after

such as those prone to segregation and lacking compaction and if they are noticed within this time,

cohesiveness or containing too much water, is at and provided the concrete is still workable,

the worst, only likely to cause an excess of laitance revibration of the top 75-100 mm can close them up

on the surface, and it is better to have to remove again.

this laitance than risk under-vibrating the mix.

With columns and wall tops, this removal is not

difficult and usually has to be done before the next

lift is placed. However with slabs, laitance removal

Care and Maintenance of Poker

is impossible, and it is therefore essential to make Vibrators

sure that the mix is designed to reduce bleeding to

a minimum, and that the surface is not overworked. Whatever the type of vibrator, it must be treated

with care and properly maintained if breakdowns

Concrete can be placed and compacted at any time are to be avoided. Obtain the manufacturers

after mixing provided that it is still workable by the instruction booklet and follow its recommendations

compacting method available, even if some loss of for both operation and maintenance. Some general

workability has taken place. For example, if a points of care and maintenance are given below:

poker will sink into the concrete under its own

weight and the hole closes up as the poker is 1. With electrically operated machines, check the

withdrawn, then that concrete can still be voltage and frequency before connection to

compacted. any power supply, ensure that the equipment

has a good earth connection and see that all

No fixed time limit can be applied to all concreting joints are adequately protected.

operations because the actual time will depend on

the stiffening of the mix which in turn depends on 2. With a petrol or diesel engine, periodically

the richness, on the temperature (both ambient check that it is running at the speed

and of the concrete itself), and on whether a recommended by the vibrator manufacturer. If

retarder has been used. On cool, damp days, most it isnt, the frequency developed in the poker

concrete is still workable 3-4 hours after mixing, head wont be correct either, and compaction

whereas on warm dry days, and especially with rich of the concrete wont be as quick and efficient

mixes, 30 minutes may be the limit. as it should be.

3. Always avoid sharp bends in drive shafts,

Revibration particularly when in use.

Provided that it is still workable, compacted 4. Regularly check all equipment for signs of

concrete will not be harmed if it is revibrated. In wear and get any faults seen to.

fact, tests have shown that the strength is

increased slightly if it is revibrated some time after 5. Never engage a poker drive to a motor that is

the initial compaction. running. Many accidents have happened

because the operator didnt bother to switch

On columns and walls where surface finish is of off the motor or, if it was fitted with a

importance, there is sometimes a tendency for centrifugal clutch, didnt throttle it back.

blowholes to occur in the top 600 mm of a lift;

because unlike the lower layers, this top layer does 6. Ensure there is enough grease in the bearings,

not have the advantage of the weight of additional for example, the vibrator tube may start to

concrete on top to increase the compaction. It can twist and jump about. If this happens, stop

often help to revibrate the top 600 mm or so some the vibrator, examine the bearings, and grease

thirty minutes to one hour after the initial them if necessary.

compaction.

7. Avoid leaving pokers in the same place for

In thick sections of slabs and beams, and long periods when vibrating concrete.

particularly with mixes that are prone to bleeding,

there is a danger of plastic settlement cracks 8. Dont leave pokers running while waiting for

appearing over the line of top reinforcement. These fresh supplies of concrete.

IB 46: Vibration of Concrete Page 10

9. If a pendulum-type poker fails to vibrate when and grout will find its way through the smallest

switched on, it can often be started by rattling of openings.

the head and giving the nose cap a smart rap

(but dont bang it hard). If this doesnt work, 2. Make sure that the vibrators are firmly

switch it off and check the motor coupling. clamped or bolted to the brackets, and keep a

Dont go on using the machine if it is still constant eye on them during use to see that

faulty. they dont loosen; otherwise the full vibrations

wont be transmitted to the formwork and the

With shaft driven machines, the drive shaft or concrete.

drive pin may have failed. With electric

machines, it could be a switch, fuse or a break 3. Feed the concrete into the section in small

in the wiring; it could even be a complete quantities so that it is placed uniformly in

motor burn-out. layers about 150 mm thick. This will prevent

air being trapped as the lift is built up.

10. When using a pneumatically driven vibrator,

clear the air line of moisture before coupling it 4. Keep a continuous watch on all fixing (which

up. Also check that there are no leaking lines should be screwed rather than nailed),

or connections otherwise the vibrator will not especially on nuts of through-bolts which can

be operating at full power. easily work loose under intense vibration.

Also watch out for grout loss, plugging leaks

whenever you can.

External or Clamp-on Vibrators

5. If possible, compact the top 600 mm of

External vibration systems are available with concrete in a wall or column with a poker. If

different frequencies and centrifugal forces. this isnt feasible, compact the top 600 mm by

hand-rodding and spading down the face of

The external or clamp-on vibrator consists of an the formwork. External vibrators tend to create

electric motor with an unbalanced member. It is a gap between the formwork and the concrete.

fixed to the formwork so that the vibrations are In the lower lifts this gap is closed by the

transmitted through the formwork into the weight of the subsequent layers of concrete,

concrete. Although their use is mainly in precast but in the open layer it can remain to disfigure

concrete, they may sometimes be necessary for the surface.

insitu construction when it is not possible to insert

a poker, as in very narrow sections or where there

is congested reinforcement. They will only compact

concrete in sections up to 400 mm thick. Where it

Numbers and Spacing of External

is possible to fit vibrators on either side of Vibrators

formwork even greater thicknesses of concrete can

be compacted. Because of the variables involved, such as rigidity

of the formwork, the quality of the concrete and the

When external vibrators are used, the formwork has effective range of vibrators available, there are no

to be designed and constructed to stand up to the hard and fast rules about the number of vibrators

repeated reversals of stress, and to be capable of required and their most suitable arrangement. The

spreading the vibrations uniformly over a following points are suggested as guides.

considerable area. Specially designed brackets

must be fixed to the formwork to hold the vibrators. 1. The positions should generally be not more

Since vibrators are usually moved up or along as than 1.0 m apart in any direction when using

the forms are filled, the number of brackets may be small external vibrators with low centrifugal

greater than the number of vibrators available. force. In some instances, they may need to be

closer. More powerful vibrators can be spaced

The following points should be noted: up to 2.0 m apart.

1. Ensure that all joints, both within and between 2. At intersections and angles, the distance over

panels, are tight and sealed. The formwork which they are effective is reduced; they

moves more than it does with poker vibration should therefore be positioned about 0.5 m

IB 46: Vibration of Concrete Page 11

from corners and intersections.

3. For walls and columns no more than about

1.0 m high, a single row of vibrating

positions about mid-height will usually be

sufficient.

4. For heights greater than 1.0 m, the lowest row

should be fixed about 0.5 m above the

bottom, with subsequent rows at 1.0 m

spacings vertically. Once each 1.0 m lift of

concrete has been placed and compacted, the

lower row of vibrators can be switched off, the

next higher row being switched on until the

next layer has been compacted, and so on. If

there arent enough vibrators for the full Figure 11: The roll of concrete maintained in front

height, the vibrators will have to be raised as of leading beam of double vibrating beam.

concrete progresses.

4. Make sure however that the beam itself is

With modern equipment it is possible to have

riding on the side forms and not riding up on

quick release systems. This allows the

the concrete forced on to the side.

movement of vibrators either along or up a

shutter as the pour progresses. Many

5. Keep beams moving evenly when the vibrator

concrete works use only three or four units

is running.

over a much larger number of bracket mounts.

6. Turn vibrator off every time the beam stops.

5. Before concreting begins, the effectiveness of

the arrangement of vibrators can be roughly

checked by switching them on and moving a

hand over the formwork to feel the vibrations Table Vibration

and see whether there are distinct strong,

weak or dead areas. It may be necessary to This requires special design consideration since

adjust the positions of the vibrators to obtain every application is likely to be different.

uniform vibrations over the whole area.

Summary

Vibrating Screed

Optimum compaction of concrete must be achieved

These can be used for compacting slabs up to 200 if the concrete is going to achieve its strength and

mm in thickness. The following points should be durability requirements.

noted.

Modern day methods of mechanical vibration

1. The vibrating beams should be run over as provide the most economical means of compacting

long a length of slab as possible in one pass. concrete in most construction situations. They

One well controlled pass of a double beam cannot however make up for human deficiencies in

should be adequate. A second faster pass of the handling of the equipment which usually

the double beam may be necessary in some relates to having insufficient manpower and

cases to improve the finish on the concrete. equipment available to match the speed of

concrete placing that can be achieved.

2. Too many passes of the beam will bring

unwanted excess mortar to the surface.

Further Reading

3. A surcharge of concrete is required to be

maintained ahead of the beam (see figure 11). Cable, J.K., McDaniel, L., Schlorholtz, S., Redmond,

IB 46: Vibration of Concrete Page 12

D., & Rabe, K. (2000). Evaluation of vibrator concrete vibration Solna: Dynpac Research 1980

performance vs. concrete consolidation & air void (Research Bulletin No. 8023 Eng. February 1980).

system (Research and Development Information

2398). Skokie, Ill.: Portland Cement Association. Harding, M.A. (1995). Vibrating concrete in wall

forms: use proper internal vibrating techniques to

Chan, Y-W., Chen, Y-G., & Liu, Y-S. (2003). Effect of ensure adequate consolidation. Concrete

consolidation on bond of reinforcement in concrete Construction. [Online]. Retrieved April 1, 2005 from

of different workabilities. ACI Materials Journal, ftp://imgs.ebuild.com/woc/C950180.pdf.

100(4), 294-301.

Koski, J.A. (1994). Using Internal concrete vibrators.

Compaction of concrete using immersion and Concrete Producer. [Online]. Retrieved April 1, 2005

surface vibrators (Current Practice Note 33). (2002). from ftp://imgs.ebuild.com/woc/J941010.pdf.

North Sydney, N.S.W.: Concrete Institute of

Australia. New technologies for improving the consolidation

of concrete (Technical Report CPAR-SL 97-2). (1997).

Ford, J.H. (2003). Internal or external vibration. Vicksberg, Miss: United States Army Corps of

Concrete Construction. [Online]. Retrieved April 1, Engineers.

2005 from

ftp://imgs.ebuild.com/woc/C03A084.pdf Pneumatic external vibrators. (1997). Concrete

Producer [Online]. Retrieved April 1, 2005 from

Forssblad, Lars. Rheology and mechanism of ftp://imgs.ebuild.com/woc/J970690.pdf.

ISSN 0114-8826

Revised Edition March 2005. Cement & Concrete Association of New Zealand, Level 6, 142 Featherston Street, PO Box 448, Wellington, telephone

(04) 499-8820, fax (04) 499-7760, e-mail admin@cca.org.nz, www.cca.org.nz.

Since the information in the bulletin is for general guidance only and in no way replaces the services of professional consultants on particular projects,

no liability can be accepted by the Association by its use.

IB 46: Vibration of Concrete Page 13

You might also like

- Length Unit Conversion Imperial Thickness ConversionDocument2 pagesLength Unit Conversion Imperial Thickness ConversionChester SmithNo ratings yet

- ACI 318 08 Design of Retaining Wall With Counterfort Rev1Document4 pagesACI 318 08 Design of Retaining Wall With Counterfort Rev1KING ENG100% (2)

- VBA Engineers EB255AFDocument6 pagesVBA Engineers EB255AFSuhas NatuNo ratings yet

- OCPA DesignManualDocument145 pagesOCPA DesignManualVojin LepojevicNo ratings yet

- L AngleDocument1 pageL AngleChester SmithNo ratings yet

- Structural Strengthening With BASF FRP - Kalın Kumaş Doyurma Problemli Olabilir DikkatDocument28 pagesStructural Strengthening With BASF FRP - Kalın Kumaş Doyurma Problemli Olabilir DikkataygunbayramNo ratings yet

- G Series 15 7588 Laptop Service Manual en UsDocument113 pagesG Series 15 7588 Laptop Service Manual en UsChester SmithNo ratings yet

- Design of Gravity Retaining WallDocument36 pagesDesign of Gravity Retaining WallCarmel Buniel Sabado100% (10)

- ACI 318 08 Design of Retaining Wall With Counterfort Rev1Document4 pagesACI 318 08 Design of Retaining Wall With Counterfort Rev1KING ENG100% (2)

- Notes Reliability Theory 2004Document231 pagesNotes Reliability Theory 2004abduldanNo ratings yet

- Bentuk FungsiDocument6 pagesBentuk Fungsitrisna086No ratings yet

- Finite Element Equations For Heat TransferDocument8 pagesFinite Element Equations For Heat TransfertuckfoongNo ratings yet

- Precast Concrete Traffic Barriers: Purpose, Specifications & TypesDocument27 pagesPrecast Concrete Traffic Barriers: Purpose, Specifications & Typesjunaid112No ratings yet

- How2 Deflection Calculations v05.07Document8 pagesHow2 Deflection Calculations v05.07FlaviaNo ratings yet

- Unit3 HWDocument39 pagesUnit3 HWsubhyNo ratings yet

- Bms - Peraturan Perencanaan Teknik Jembatan PDFDocument390 pagesBms - Peraturan Perencanaan Teknik Jembatan PDFAnggit Pratama PutraNo ratings yet

- Fixed End MomentsDocument1 pageFixed End MomentsHarold DeanNo ratings yet

- NCHRP RPT 350-A PDFDocument74 pagesNCHRP RPT 350-A PDFuntung CahyadiNo ratings yet

- Civil 3D TutorialsDocument840 pagesCivil 3D TutorialsRebecca ZodinpuiiNo ratings yet

- AU214-2 - Photorealistic Rendering Techniques in AutoCAD 3DDocument15 pagesAU214-2 - Photorealistic Rendering Techniques in AutoCAD 3DAdi Tri WiyantoNo ratings yet

- ETABS - Concrete Frame Design ManualDocument161 pagesETABS - Concrete Frame Design ManualvardogerNo ratings yet

- Deflections PDFDocument9 pagesDeflections PDFChristopher SingletonNo ratings yet

- Distortional BucklingDocument16 pagesDistortional BucklingadnanmominNo ratings yet

- EtabsDocument75 pagesEtabsIndira Kei83% (6)

- Nikon ManualDocument46 pagesNikon ManualChester SmithNo ratings yet

- FRP-OFBG Smart Bars Monitor Reinforced Concrete BeamsDocument5 pagesFRP-OFBG Smart Bars Monitor Reinforced Concrete BeamsChester SmithNo ratings yet

- SW Design ManualDocument81 pagesSW Design ManualChester SmithNo ratings yet

- Measures of Distance Between Samples: Standardized Euclidean DistanceDocument11 pagesMeasures of Distance Between Samples: Standardized Euclidean DistanceCuong PolymeNo ratings yet

- catOI Upv PDFDocument2 pagescatOI Upv PDFPatria KusumaningrumNo ratings yet

- A New Dimension in Logistics in The Paper Industry: 24/7 Production and Logistics OperationDocument8 pagesA New Dimension in Logistics in The Paper Industry: 24/7 Production and Logistics OperationChester SmithNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- VRF Technical Data Book Highlights Key Specs (38k-61k BTU, 3-4.5 TonDocument55 pagesVRF Technical Data Book Highlights Key Specs (38k-61k BTU, 3-4.5 TonFred BensimonNo ratings yet

- Downtime BD TyreDocument127 pagesDowntime BD TyreRidhani IqbalNo ratings yet

- Product Release: CKMTA12 / 24Document9 pagesProduct Release: CKMTA12 / 24Zewdu TsegayeNo ratings yet

- BH35 2Document4 pagesBH35 2Bipin KumarNo ratings yet

- Turbulent Flow Exiting a Reservoir and Impacting a Solid ObjectDocument22 pagesTurbulent Flow Exiting a Reservoir and Impacting a Solid ObjectMariaEstherAlguacilRodriguezNo ratings yet

- Structural Design 1: Module inDocument4 pagesStructural Design 1: Module inkangkongNo ratings yet

- Escort Limited Champion F 11 Brand Name - FarmtracDocument12 pagesEscort Limited Champion F 11 Brand Name - Farmtrachugo fernandezNo ratings yet

- Eaton 420 PartsDocument16 pagesEaton 420 PartsF Labio Alex100% (1)

- SAE350 AND 450-SAE, - F3L-912 DEUTZ Engine Welders: Parts List TitlesDocument18 pagesSAE350 AND 450-SAE, - F3L-912 DEUTZ Engine Welders: Parts List TitlesCarlos IrabedraNo ratings yet

- Rav M05 0001Document40 pagesRav M05 0001DanielDeFrancescoNo ratings yet

- Split Case LRDocument8 pagesSplit Case LRmartin.rubenNo ratings yet

- Cadworx Cadworx Cadworx Cadworx Syllabus Syllabus Syllabus SyllabusDocument6 pagesCadworx Cadworx Cadworx Cadworx Syllabus Syllabus Syllabus SyllabusSelvaNo ratings yet

- Gear BoxDocument14 pagesGear Boxarackalfrancis0% (1)

- ChEg4124-Chap-3 (P-1)Document46 pagesChEg4124-Chap-3 (P-1)Yonas TarekegnNo ratings yet

- Characteristics Series CE, CP, C: 2 Way Slip-In Cartridge ValvesDocument17 pagesCharacteristics Series CE, CP, C: 2 Way Slip-In Cartridge Valvess_waqarNo ratings yet

- Kic API X70Document8 pagesKic API X70Ivan SilveiraNo ratings yet

- Single Aisle Maintenance Practice Training Manual CFM56 Engine Run Up Course (M70) ChecklistsDocument28 pagesSingle Aisle Maintenance Practice Training Manual CFM56 Engine Run Up Course (M70) ChecklistsLucas GabrielNo ratings yet

- 544-13 IndicatingDocument64 pages544-13 IndicatingHENIGUEDRINo ratings yet

- Design Criteria For Exposed Hydro Penstocks - Gordon1978 PDFDocument12 pagesDesign Criteria For Exposed Hydro Penstocks - Gordon1978 PDFDavid DelgadoNo ratings yet

- LHB Monograph PDFDocument60 pagesLHB Monograph PDFVijay Ranjan KumarNo ratings yet

- Hydraulic Puller Operating InstructionsDocument5 pagesHydraulic Puller Operating InstructionsMasterrNo ratings yet

- Sisweb Sisweb Techdoc Techdoc Print PageDocument4 pagesSisweb Sisweb Techdoc Techdoc Print PageGustavo PereiraNo ratings yet

- Solar Water Heaters Guidelines V1 Aug 2019Document49 pagesSolar Water Heaters Guidelines V1 Aug 2019Mile DjordjevicNo ratings yet

- Shuttlewagon Commander ManualDocument21 pagesShuttlewagon Commander ManualDecebalusII100% (2)

- ASTM C1609 - C1609M - 19a Standard Test Method For Flexural Performance of Fiber-Reinforced Concrete (Using Beam With Third-Point Loading)Document5 pagesASTM C1609 - C1609M - 19a Standard Test Method For Flexural Performance of Fiber-Reinforced Concrete (Using Beam With Third-Point Loading)ming_zhu10No ratings yet

- Kr451 Nepiro Ergo PR enDocument4 pagesKr451 Nepiro Ergo PR enForum PompieriiNo ratings yet

- Manual Volvo XC90 2005Document17 pagesManual Volvo XC90 2005Diego Alejandro QuinteroNo ratings yet

- Hyperbolic ShellsDocument42 pagesHyperbolic ShellshythamNo ratings yet

- Thermal Breakage and Impact Strength of Tempered GlassDocument7 pagesThermal Breakage and Impact Strength of Tempered GlassMartinBalanagNo ratings yet

- "DOL Starter": Submitted byDocument10 pages"DOL Starter": Submitted byKartik InamdarNo ratings yet