Professional Documents

Culture Documents

Contractor Work Method Statement For Fire Hydrant Pipe Reprair

Uploaded by

nsadnanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Contractor Work Method Statement For Fire Hydrant Pipe Reprair

Uploaded by

nsadnanCopyright:

Available Formats

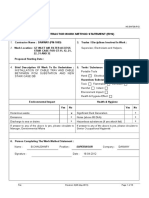

HS.SAF.09.

F12

CONTRACTOR WORK METHOD STATEMENT (EHS)

1. Contractor Name : DANWAY E & M ENGG 4. Trades / Disciplines Involved In Work :

Engineer, Supervisor, Electricians and

Helpers.

2. Work Location : Cast House III

3. Proposed Starting Date :

5. Brief Description Of Work To Be Undertaken : 6. Tools / Substance

Fire hydrant pipeline repair

Portable Tools

Hand Electrical Pneumatic

Hazardous Substances

Toxic Flammable Corrosive

Harmful Irritant

Environment Impact

Health & Hygiene Effect

Environmental Impact Health & Hygiene

Yes No Yes No

Hazardous waste Significant Dust Generation

Emissions Noise (above 85 DbA)

Discharge to sea or drains Hazardous substances (if yes attach list)

If answer to any of the above is yes, please circulate to If answer to any of the above is yes, please circulate to

Manager, Environmental Affairs Senior Occupational Hygienist

7. Person Completing The Work Method Statement :

Name : B.CHUDHARY Position : SUPERVISOR Company : DANWAY

Signature : Date : 21/03/2012

Revision: 0(26-May-2011) Page 1 of 8

HS.SAF.09.F12

8. Approvals

Contractor Site Rep. Name PRAVEN Signature : Date : 21/03/12

EMAL Contract Admin. Name Signature : Date :

Area Owner Name Signature : Date :

Name Signature: Date:

EMAL EHS Department

The completed Work Method Statement must be submitted at least seven full working days prior to the

commencement of activities.

Where the Work Method Statement indicates the use of Hazardous Substances, a Material Hazard Data

Sheet must be attached.

After the Area Owners approval the Work Method Statement shall be forwarded to EHS department for

approval

The approved Work Method Statement must be attached to the permit(s) to work and all persons involved

in the job instructed in its requirements.

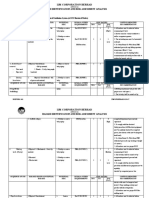

2. RISK ESTIMATOR CHART

The Risk Estimator chart should be used as an assistant for filling out the work

method statement.

Severity

Probability Low x1 Medium x 2 High x3

Low x1 Low Probability x Low LP x MS LP x HS

Severity 1 x 1 = 1 1x2 = 2 1x3 =3

Medium x2 MP x LS MP X MS MP x HS

2x1 =2 2x2 =4

2x3 =6

High x3 HP x LS HP X HS HP x HS

3 x 1 =3 3x2 = 6 3x3=9

Significant Risk = High Risk (6-9) or Medium Risk (3-4) in terms of probability and severity

Tolerable Risk = Risk reduced to an acceptable level = Low Risk (1-2)

Residual Risk = Risk remaining after implementing recommended control actions (usually very minor).

Revision: 0(26-May-2011) Page 2 of 8

HS.SAF.09.F12

9. Safety Analysis

Identified Hazard(s) Persons Precautions and Plan of actions To Be Taken To Severity x Probability =

Individual Activities To Associated With Activity Exposed To Remove / Control Hazards Risk

Complete Work. List In Hazard

Sequence of Activity Residual Risk

(Use Risk Estimator Chart)

1.APPROVAL(Permit to Client coordination Emal , Engr., Verify isolations.

work from EMAL) fails, job stopped, work Supv. Elec,

helpers After getting valid permit from EMAL only

unapproved.

starts work.

Operatives should be

Engineer / supervisor ensure that the work

aware of emergency

procedure of EMAL permit is valid for the date and tine

All work force are inducted by EMAL

All personnel involve in the activities must

wear the required PPEs at all

times(eg.hard hat, appropriate safety 2 X 2=4

glass, safety shoe, hand gloves, dust

mask, disposable coverall)

Advance planning by contractor

considering the time consumption to recive

the permit from EMAL

Emergency procedure must be displayed

at prominent location and cascade to

operatives on regular interval and

recorded.

Ensure the operatives must be go through

EMAL and DANWAY safety induction

Revision: 0(26-May-2011) Page 3 of 8

HS.SAF.09.F12

2. PREPARATION OF Workers are not aware Emal , Engr., Crew meeting to held prior to start the

WORK(cutting and for the moving vehicles Supv. Elec, task.

grinding of FRP & equipment on site. helpers

pipe). Experience and competent for the task

Using bad condition of

Dont use excessive force to the hand

hand power tools.

power tools(grinder)

Not using proper PPEs

Use cutting machine with dead man switch

while cutting & grinding

of FRP pipe only.

Flooding of water from Never remove cutters guard.

FRP pipe. Dont use cutting wheel for grinding

3 X 2=6

Ensure disc wheel RPM is matching with

machine RPM.

Stack the pipe / materials properly to the

designated area and barricade the area,

pipe must be chocked to stop roll over,

warning sign must be displayed to warn

the nearby operatives existing activity

must in take in account.

All personnel involve in the activities must

wear the required PPEs at all times(eg.

hard hat, appropriate safety glass, safety

shoe, hand gloves, dust mask, disposable

coverall)

Use appropriate dust mask and full face

shield during the cutting & grinding the

FRP pipe

Revision: 0(26-May-2011) Page 4 of 8

HS.SAF.09.F12

3.0 JOINING OF FRP Incompetent workers Supv. Elec, Competent workers to be deployed,

PIPES helpers supervisor to ensure work safe system 2 X 1=2

3.1 TRIMMING & Hand injury, Supv. Elec, Trained personals are carrying the work

CLEANING electrocution, cutting, helpers with a competent supervisor.

burning.

The machine using for edge cleaning

purpose must be in good condition.

(grinding machine)

Competent electrician check all electrical

equipments periodically. 3 X 2=6

All portable electrical equipments using

are 110V ELCB to reduce the

electrocution.

Ensure to provide proper earthing.

Drip try to provide for power generator.

Ensure to wear all PPEs.(site standard

PPE, disposable cover all, dust mask and

full face shields.)

3.2 SOLVENT Skin & eye irritations, Emal , Engr., Solvent using for joining purpose are

APPLICATIONS environmental issues. Supv. Elec, approved by client and according to

helpers MSDS.

3 X 2=6

Storage and disposal of solvents as

instructed by MSDS

Minimum quantities of chemicals only

Revision: 0(26-May-2011) Page 5 of 8

HS.SAF.09.F12

allowed to store in site.

MSDS COSHH assessment to be

submitted to EMAL EHS.

All chemical must be kept inside drip tray

to avoid spillage.

Toll box talk / crew meeting to conduct

before starting the work.

Strictly follow the instructions of MSDS

Not using PPEs Emal , Engr., All personnel involve in the activities must

Supv. Elec, wear the required PPEs at all times(eg. 3 X 1=3

helpers hard hat, appropriate safety glass, safety

shoe, hand gloves, dust mask, disposable

coverall)

Revision: 0(26-May-2011) Page 6 of 8

HS.SAF.09.F12

Only competent and authorized person

Other workers to do the inspection, ensure notified the

4. INSPECTION. 1x3=3

Unauthorized workers nearby client with all necessary documents.

Slip / Trip / Fall - same Maintain good housekeeping around

level Engr., Supv. the area.

1x2=2

Elec. All temporary cable should be

properly organized.

Wear P.P.E.'s at all times (hard hat,

Emal , Engr., appropriate safety glass, safety shoes, 2x2=4

Not using P.P.E.'s Supv. Elec. hand gloves, dust mask, fire retardant long

sleeve shirt / pants.

This sheet must be properly completed detailing all of the steps required to complete the job along with the sequence of events and each of the hazards

arising. Failure to properly complete the form will result in non-approval.

(Additional sheets to be used as required)

9. Chemical Analysis (This form to be used as required)

Revision: 0(26-May-2011) Page 7 of 8

HS.SAF.09.F12

Product Name

MSDS supplied Yes / No

Dangerous Goods Class

Hazardous Material Yes / No

Nature of Hazard Irritation / Carcinogen / Corrosive / Toxic / Other

Form Solid /Liquid / Gas / Dust / Vapour / Mist

Exposure Route Inhalation / Skin / Eye / Ingestion

Number of People Exposed

Duration of Exposure

Frequency of Exposure

Controls to be implemented

Estimate of Exposure Negligible / Marginal / High

This sheet must be properly completed detailing all the necessary information. Failure to properly complete the form will result in non-approval.

Revision: 0(26-May-2011) Page 8 of 8

You might also like

- Gamma World Character SheetDocument1 pageGamma World Character SheetDr8chNo ratings yet

- Method of Duct Installation, Insulation, Leak TestingDocument4 pagesMethod of Duct Installation, Insulation, Leak Testinggangadharan00067% (6)

- RISK ASSESSMENT - TK-4742-Operation Training For Overhead CraneDocument6 pagesRISK ASSESSMENT - TK-4742-Operation Training For Overhead CranensadnanNo ratings yet

- DDC Systems2Document28 pagesDDC Systems2nsadnan100% (1)

- John PFTDocument231 pagesJohn PFTAlexander Santiago ParelNo ratings yet

- Risk Assessment - Installation of Ventilation FanDocument6 pagesRisk Assessment - Installation of Ventilation Fannsadnan100% (5)

- Mos (Sprinkler System)Document5 pagesMos (Sprinkler System)Syed Abbad QuadriNo ratings yet

- Method Statement For Sprinkler SystemDocument5 pagesMethod Statement For Sprinkler SystemJoyanta Deb100% (1)

- Newton Raphson Method MCQDocument15 pagesNewton Raphson Method MCQmd junaidNo ratings yet

- Method Statement For Installation of BMS M Tower PDFDocument16 pagesMethod Statement For Installation of BMS M Tower PDFAndrew HivNo ratings yet

- Structural - Analysis - Skid A4401 PDFDocument94 pagesStructural - Analysis - Skid A4401 PDFMohammed Saleem Syed Khader100% (1)

- 1 - Method Statement For Ventilation FanDocument9 pages1 - Method Statement For Ventilation FanASHWANI100% (1)

- CCTV Testing and Commissioning Pre-Check List (ID 1506)Document1 pageCCTV Testing and Commissioning Pre-Check List (ID 1506)nsadnan67% (3)

- Risk Assessment - Installation and Testing of Motorized Fire & Smoke DamperDocument10 pagesRisk Assessment - Installation and Testing of Motorized Fire & Smoke Dampernsadnan50% (2)

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocument3 pagesRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocument3 pagesRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- 07.01 Risk Assessment For Fire Alarm SystemDocument15 pages07.01 Risk Assessment For Fire Alarm SystemShah MuzzamilNo ratings yet

- Installation Method of Flow SwitchDocument1 pageInstallation Method of Flow SwitchBento BoxNo ratings yet

- RAMS For Installation of VRF System, FAHU & DX Package Unit & DX Split UnitDocument25 pagesRAMS For Installation of VRF System, FAHU & DX Package Unit & DX Split UnitAnandu Ashokan100% (1)

- Method Statement For Installation of HVAC Duct & AccessoriesDocument63 pagesMethod Statement For Installation of HVAC Duct & AccessoriesAnandu AshokanNo ratings yet

- Installation of Precision Air Conditioner (Autosaved)Document10 pagesInstallation of Precision Air Conditioner (Autosaved)Parikshit SharmaNo ratings yet

- Method of Statment of Fire HydrantDocument13 pagesMethod of Statment of Fire Hydrantzia100% (1)

- CMS For Cad WeldingDocument9 pagesCMS For Cad WeldingarockiyathassNo ratings yet

- Safe Work Method Statement: (Installation of Wet Sprinkler System)Document10 pagesSafe Work Method Statement: (Installation of Wet Sprinkler System)balaji100% (1)

- Method Statement HDPE PDFDocument1 pageMethod Statement HDPE PDFshameemNo ratings yet

- Risk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)Document3 pagesRisk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)nsadnan100% (1)

- SMChap 018Document32 pagesSMChap 018testbank100% (8)

- ADDC Electricity Wiring Regulations - Mar.2014Document276 pagesADDC Electricity Wiring Regulations - Mar.2014hajimak89% (18)

- Checklist For Pre Commissioning of Water Pump PDFDocument3 pagesChecklist For Pre Commissioning of Water Pump PDFRamadan Rashad0% (1)

- METHOD STATEMENT - Floor Drain & FCO InstallationDocument5 pagesMETHOD STATEMENT - Floor Drain & FCO InstallationGerlie Dimayuga100% (2)

- Complex Numbers GuideDocument17 pagesComplex Numbers GuideGus EdiNo ratings yet

- HVAC Split Unit Installation Procedure - Method Statement HQDocument7 pagesHVAC Split Unit Installation Procedure - Method Statement HQEngineer ZiaNo ratings yet

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Document4 pagesRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanNo ratings yet

- Method Statement 14728983812691479973057231Document6 pagesMethod Statement 14728983812691479973057231Abhinav SinhaNo ratings yet

- Method of Statement For Fire AlarmDocument9 pagesMethod of Statement For Fire AlarmUmair BaBerNo ratings yet

- FHC Installation Method StatementDocument9 pagesFHC Installation Method StatementMeriam DacunesNo ratings yet

- Method Statement For Installation of HVAC DampersDocument11 pagesMethod Statement For Installation of HVAC DampersITE MEPNo ratings yet

- 1.MST 48 - DX Split System, AC Unit and Refrigerant Pipe Rev.00Document12 pages1.MST 48 - DX Split System, AC Unit and Refrigerant Pipe Rev.00jaffrinNo ratings yet

- BL3B User Manual PDFDocument142 pagesBL3B User Manual PDFRandy VanegasNo ratings yet

- Gravity Test Report Water SupplyDocument1 pageGravity Test Report Water SupplygaineyskNo ratings yet

- Rev - 03 - Ms - Installation of Cable Tray or Trunking SystemDocument7 pagesRev - 03 - Ms - Installation of Cable Tray or Trunking Systemanon_534254691No ratings yet

- Method Statement For Hot Tapping Rev 0 PDFDocument9 pagesMethod Statement For Hot Tapping Rev 0 PDFsharif339No ratings yet

- 109 Installation CCTV Systems PDFDocument60 pages109 Installation CCTV Systems PDFRodelDavidNo ratings yet

- Method Statement For Installation of Ahu FahuDocument12 pagesMethod Statement For Installation of Ahu FahuRoger Akl75% (4)

- Installation, Testing - Flushing of Firefighting SystemDocument7 pagesInstallation, Testing - Flushing of Firefighting SystemWahid Husain100% (1)

- HVAC Installation Step-by-StepDocument12 pagesHVAC Installation Step-by-StepIzaaz Ahamed100% (1)

- Method Statement For Instalation of CCTV Camera and Junction Boc FoundationDocument18 pagesMethod Statement For Instalation of CCTV Camera and Junction Boc Foundationashishakare50% (2)

- Method Statement For Installation of Electrical DBDocument6 pagesMethod Statement For Installation of Electrical DBsamsungloverNo ratings yet

- MS For MEP IsolationDocument19 pagesMS For MEP IsolationAnandu Ashokan67% (3)

- Deepak Patil: Fire Fighting Description and WmsDocument5 pagesDeepak Patil: Fire Fighting Description and WmsDeepak PatilNo ratings yet

- Wms Acmv Duct WorksDocument8 pagesWms Acmv Duct Worksfahmi_majid_2No ratings yet

- PM-1009 Installation of Cable Tray and Cable Betwwen PCM Substation and New Stair Case DBDocument16 pagesPM-1009 Installation of Cable Tray and Cable Betwwen PCM Substation and New Stair Case DBnsadnanNo ratings yet

- Ventilation Fan Installation Method StatementDocument4 pagesVentilation Fan Installation Method Statementsamsul maarifNo ratings yet

- Checklist For Commissioning of CCTV SystemDocument2 pagesChecklist For Commissioning of CCTV Systemnsadnan70% (10)

- Method Statement for Testing Commissioning Foam SystemDocument3 pagesMethod Statement for Testing Commissioning Foam SystemDong Vanra100% (1)

- Checklist For Access Control System InstallationDocument6 pagesChecklist For Access Control System Installationnsadnan71% (7)

- Testing and Commissioning Pre-Check List (ID 1506)Document1 pageTesting and Commissioning Pre-Check List (ID 1506)nsadnan0% (2)

- Work Method Statement FOR HVAC DuctingCopper PipesDocument9 pagesWork Method Statement FOR HVAC DuctingCopper PipesSameer JogasNo ratings yet

- Method Statement For Attending Fire Fighting Snag WorksDocument8 pagesMethod Statement For Attending Fire Fighting Snag Worksfawzar100% (1)

- Cable Tray Installation MethodDocument7 pagesCable Tray Installation MethodJamal Budeiri0% (1)

- Installation of Fire Alarm System Method StatementDocument9 pagesInstallation of Fire Alarm System Method StatementiamajumalNo ratings yet

- Gravity Drainage TestDocument1 pageGravity Drainage TestgaineyskNo ratings yet

- ASCP User GuideDocument1,566 pagesASCP User GuideThillai GaneshNo ratings yet

- Gas Chromatography - COLIN F. POOLE 2012 PDFDocument743 pagesGas Chromatography - COLIN F. POOLE 2012 PDFVo Manh Tien100% (1)

- Mathod Statement of Duct InsulationDocument14 pagesMathod Statement of Duct InsulationAhmed AlyNo ratings yet

- Checklist For Pre Commissioning of CCTV SystemDocument1 pageChecklist For Pre Commissioning of CCTV Systemnsadnan67% (6)

- Method Statement For PCW Piping (Tool Install)Document4 pagesMethod Statement For PCW Piping (Tool Install)amg007No ratings yet

- Sump Pump Method of StatementDocument10 pagesSump Pump Method of StatementKhaled NaguibNo ratings yet

- Installation Method for Gas DetectionDocument2 pagesInstallation Method for Gas DetectionvictorNo ratings yet

- Method Statement For Installation of Ahu FahuDocument12 pagesMethod Statement For Installation of Ahu FahuMohd Haroon100% (1)

- Risk Ass. - PM - 1009 - INSTALLATION OF CABLE TRAY AND CABLE BETWWEN PCM SUBSTATION AND NEW STAIR CASE DBDocument13 pagesRisk Ass. - PM - 1009 - INSTALLATION OF CABLE TRAY AND CABLE BETWWEN PCM SUBSTATION AND NEW STAIR CASE DBnsadnanNo ratings yet

- Method Statement For Installation of FansDocument5 pagesMethod Statement For Installation of FansBinod Davis50% (2)

- Block Work MS (Sample)Document18 pagesBlock Work MS (Sample)jones100% (1)

- VISCOSITY CLASSIFICATION GUIDE FOR INDUSTRIAL LUBRICANTSDocument8 pagesVISCOSITY CLASSIFICATION GUIDE FOR INDUSTRIAL LUBRICANTSFrancisco TipanNo ratings yet

- Method Statement For Hydrant As Per PVN CommentsDocument23 pagesMethod Statement For Hydrant As Per PVN CommentsAbcd efgh100% (1)

- Installation of GI Boxes Method StatementDocument12 pagesInstallation of GI Boxes Method StatementGufran TariqNo ratings yet

- Method Statement For Installation of Audio Visual and Iptv SystemDocument9 pagesMethod Statement For Installation of Audio Visual and Iptv SystemVibin0% (1)

- Air Conditioning and Mechanical Ventilation System (ACMV Electrical Works)Document5 pagesAir Conditioning and Mechanical Ventilation System (ACMV Electrical Works)haidil abd hamidNo ratings yet

- Fuel Gas Compressor Enclosures: Contractor Work Method Statement (Ehs)Document8 pagesFuel Gas Compressor Enclosures: Contractor Work Method Statement (Ehs)nsadnanNo ratings yet

- Method Statement For Chipping of False Floor OpeningDocument7 pagesMethod Statement For Chipping of False Floor Openingnsadnan0% (1)

- Methodology in Dismantling of DX and CHW Type Aircon UnitDocument2 pagesMethodology in Dismantling of DX and CHW Type Aircon UnitAJ Jarillas100% (1)

- Split Unit InstallationDocument33 pagesSplit Unit Installationsree100% (1)

- Air Terminal Device Installation MethodDocument13 pagesAir Terminal Device Installation MethodAnish Kumar100% (1)

- Risk Assessment - CHW PumpDocument4 pagesRisk Assessment - CHW PumpAdnan Attish100% (1)

- Doku - Pub Risk-AssessmentDocument10 pagesDoku - Pub Risk-AssessmentUlviyye ElesgerovaNo ratings yet

- ONVIF Profile Feature Overview v2-2Document6 pagesONVIF Profile Feature Overview v2-2nsadnanNo ratings yet

- ONVIF Profile - S Specification v1-2Document42 pagesONVIF Profile - S Specification v1-2nsadnan0% (1)

- BSIA Cyber Secure It January 2019Document16 pagesBSIA Cyber Secure It January 2019nsadnanNo ratings yet

- ONVIF Profile T Specification v1-0Document77 pagesONVIF Profile T Specification v1-0nsadnanNo ratings yet

- Peer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GageDocument5 pagesPeer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GagensadnanNo ratings yet

- 1 45Document3 pages1 45nsadnan0% (1)

- Exc Fibre Installation GuideDocument38 pagesExc Fibre Installation GuidensadnanNo ratings yet

- HVAC ManualDocument107 pagesHVAC ManualWissam JarmakNo ratings yet

- Excel Intelligent PduDocument21 pagesExcel Intelligent PdunsadnanNo ratings yet

- Excel Intelligent Pdu User InstructionsDocument2 pagesExcel Intelligent Pdu User InstructionsnsadnanNo ratings yet

- Exc Installation GuideDocument1 pageExc Installation GuidensadnanNo ratings yet

- Sensor Line Cable InstallationDocument6 pagesSensor Line Cable InstallationnsadnanNo ratings yet

- Exc Fibre Installation GuideDocument16 pagesExc Fibre Installation GuideMohamad FaifNo ratings yet

- Risk Assessment - Tk-4741-Removal Works For Site Office FacilitiesDocument14 pagesRisk Assessment - Tk-4741-Removal Works For Site Office FacilitiesnsadnanNo ratings yet

- RISK ASSESSMENT - Load Current Measurement and Cleaning of Oil CoolerDocument5 pagesRISK ASSESSMENT - Load Current Measurement and Cleaning of Oil CoolernsadnanNo ratings yet

- Priming An Airplane EngineDocument6 pagesPriming An Airplane Enginejmoore4678No ratings yet

- Data Sheet FC SIDocument2 pagesData Sheet FC SIAndrea AtzeniNo ratings yet

- Diferencias Gas LP y Gas Natural: Adminigas, S.A. de C.VDocument2 pagesDiferencias Gas LP y Gas Natural: Adminigas, S.A. de C.VMarco Antonio Zelada HurtadoNo ratings yet

- IBM Systems Journal PerspectivesDocument24 pagesIBM Systems Journal PerspectivesSmitha MathewNo ratings yet

- Extraform RsDocument47 pagesExtraform RsCarlos David Duran AvilaNo ratings yet

- Mapeflex Pu50 SLDocument4 pagesMapeflex Pu50 SLBarbara Ayub FrancisNo ratings yet

- EasyLogic PM2000 Series - METSEPM2130Document4 pagesEasyLogic PM2000 Series - METSEPM2130ٍJordan SportNo ratings yet

- PSAII Final EXAMDocument15 pagesPSAII Final EXAMdaveadeNo ratings yet

- EE114-1 Homework 2: Building Electrical SystemsDocument2 pagesEE114-1 Homework 2: Building Electrical SystemsGuiaSanchezNo ratings yet

- AIIMS Mental Health Nursing Exam ReviewDocument28 pagesAIIMS Mental Health Nursing Exam ReviewImraan KhanNo ratings yet

- 4 DiscussionDocument2 pages4 DiscussiondreiNo ratings yet

- Fi 7160Document2 pagesFi 7160maxis2022No ratings yet

- Chapter 2 Literature ReviewDocument10 pagesChapter 2 Literature ReviewSharan BvpNo ratings yet

- The Top 10 Strategic Technology Trends For 2020: Tomas Huseby Executive PartnerDocument31 pagesThe Top 10 Strategic Technology Trends For 2020: Tomas Huseby Executive PartnerCarlos Stuars Echeandia CastilloNo ratings yet

- Rpo 1Document496 pagesRpo 1Sean PrescottNo ratings yet

- Benefits of Eating OkraDocument4 pagesBenefits of Eating Okraama931No ratings yet

- Efficient Power Supply for Inductive LoadsDocument7 pagesEfficient Power Supply for Inductive LoadsMary AndersonNo ratings yet

- BILL of Entry (O&A) PDFDocument3 pagesBILL of Entry (O&A) PDFHiJackNo ratings yet

- Wei Et Al 2016Document7 pagesWei Et Al 2016Aline HunoNo ratings yet

- Batool2019 Article ANanocompositePreparedFromMagn PDFDocument10 pagesBatool2019 Article ANanocompositePreparedFromMagn PDFmazharNo ratings yet