Professional Documents

Culture Documents

Typical Reinforced Concrete Details and Construction Notes - 1

Uploaded by

Aly Arquillano JrOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Typical Reinforced Concrete Details and Construction Notes - 1

Uploaded by

Aly Arquillano JrCopyright:

Available Formats

TYPICAL REINFORCED CONCRETE DETAILS AND CONSTRUCTION NOTES - 1

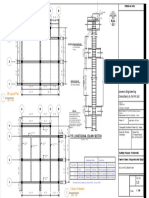

LAP SPLICE LENGTH: BARS SHALL BE

1. AT ANY LEVEL NO MORE THAN ADEQUATELY

ALTERNATE BARS SHOULD BE DEVELOPED AND

BENT WITHIN THE

SPLICED. WALL BOUNDERY

2. MIN. DISTANCE BETWEEN TWO SEE WALL ELEMENTS

H (CLEAR HIEGHT OF COL.)

ADJACENT BARS SPLICED SHALL SCHEDULE

550

BE 600mm.

WALLS LESS THAN

200 mm THK.

SEE SHEARWALL

WITHIN CENTER

SCHEDULE

L

HALF OF "H"

550

L/4 (TYP.)

TOP BARS @ THE SUPPORT (CONT.) MAIN REINFORCEMENTS TO BE AT INTERSECTION

DEPRESSION

CONTINUOUS (TOP & BOT. BARS) @ INTERSECTION

VERIFY

REQ'D. BOT. BARS @ SUPPORT 30 BAR DIA.

(MIN.)

LAT. TIES JT.

30 BAR DIA. MAIN REINFORCEMENTS 25 WALLS LESS THAN

REINF.

(MIN.) 200 mm THK.

D = FOR BEAM

(MIN.) (MIN.)

t = FOR SLAB

25 SEE WALL

SCHEDULE

t/2

t

CONF. REINF. TIES

t /2

550

EXTRA BOT. BARS @

(TYP.)

SEE SHEARWALL

550

0.165L MIDSPAN SCHEDULE

30 BAR DIA. BARS SHALL BE

SPLICE HOOPS

(MIN.) ADEQUATELY

BOT. BARS @ MIDSPAN (PLACED AT MID-DEPTH OF SLAB IF DEVELOPED AND

550 BENT WITHIN THE

D = FOR BEAM THE LOCATION OF THE CONST. JOINT SIDE IF BEAM CONSTRUCTION JOINT

2d WALL BOUNDERY

EXTRA TOP BARS @ 2t = FOR SLAB IS NOT WITHIN THE MIDDLE THIRD. IS NOT WITHIN THE MIDDLE THIRD (TYP.) ELEMENTS

SUPPORT OF THE SPAN.

AT CORNER @ CORNER

A

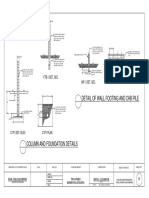

COLUMN LAP SPLICE AND EXT. B BEAM / SLAB CHANGE C SUSPENDED SLAB CONST. D BEAM CONST. JOINT DETAIL E WALL CONNECTION AT F DEV'T HOOK FOR SHEAR RESISTING HOR. BAR

S 1 GIRDER TO COLUMN CONN. DETAIL S 1 SOFFIT DETAIL S 1 JOINT DETAIL S 1 S 1 INTERSECTION S 1 INTO SHEARWALL'S CONFINEMENT ZONES

PROPOSED PIPE SLEEVE LOCATIONS

2D ( NO PIPE SLEEVE SHALL SCH. 40 G.I. PIPE SLEEVE

BE ALLOWED WITHIN THIS

2 - EXTRA STIRRUPS ON EACH

ZONE (TYP.) )

SIDE OF SLEEVE

2D 2D

2 EXTRA STIRRUPS W W

BARS BENT DOWN INTO LONG TOP BARS

FACE OF B

EACH SIDE OF SLEEVE EDGE BEAM. EXTEND BARS

TOP BARS

ANCHORAGE LENGTH

(T 500

SUPPORT MIN. OF 1200 (4' - 0")

.)

TOP BARS

YP

SEE TABLES OF

(TYPICAL)

40

EF. (DIAGONALS)

SEE BEAM

SCHED.

825

D

DIAGONALS AT DIAGONALS AT

75

PIPE SLEEVE

D/5

MID-DEPTH OF WALL MID-DEPTH OF WALL

40

BOT. BARS A7a WELDED TO SLEEVE AT EACH CORNER AT EACH CORNER

(TYPICAL)

FACE OF

WINDOW

60

STIR. AS SCHED. BOTTOM BARS

0

4d (MIN.)

G SECTION

H

SUPPORT BOTTOM BARS

L/4 L/2 L/4

OPENING SPACED @ 150MM O.C.

LIMIT LOCATION OF PIPE SLEEVE

S 1 DOOR

H

NOTES: OPENING BOTTOM BARS

L SPACED @ 150MM O.C.

1.SEEK STRUCT'L ENGINEER'S

600

APPROVAL FOR PIPE SLEEVES W/

LEGEND: PIPE SLEEVE MAXIMUM DIAMETER DIAMETERS BIGGER THAN THE OPENING (TYP.)

1. D = DEPTH OF BEAM OR GIRDER IS: (LEAST GOVERNS) MINIMUM STIPULATED. 1050 600

2. d = PIPE SLEEVE DIAMETER A. 1/5 OF BEAM DEPTH 2.PIPE SLEEVES SHALL BE LOCATED

B. 100MM WITHIN TENSION ZONES OF BEAM.

FOR SUSPENDED SLAB FOR FLAT SLABS

3.NO PIPE SLEEVE SHALL BE

ALLOWED AT TWICE THE BEAM

DEPTH (2D) FROM THE SUPPORT.

G PIPE SLEEVE THRU BEAM DETAIL H DOOR OPENING DETAIL I WINDOW OPENING DETAIL J CORNER SLAB DETAIL K CORNER SLAB DETAIL

S 1 S 1 S 1 S 1 S 1

MID-DEPTH OF SLAB AT EACH CORNER.

400

BOT. BARS

RET. WALL/CHB WALL

38mm. CLEAR 75 mm

MAXIMUM

SAW-CUT GROOVE 8MM SEALANT W/ BACKER

SAW-CUT GROOVE 8MM S

POLYURETHANE SEALANT WIDE TO BE FILLED WITH WIDE 6.5 DEEP TO BE FILLED ROD ON BOTH SIDE

IN TWO WAY POLYURETHANE SEALANT S 1

400

WITH POLYURETHANE SEALANT

SLAB EXTEND SLAB REINF. FLR. LVL.

BARS UP TO SLAB REINF. SLAB REINF. TYP. FLR LVL

BEAM SUPPORT FLR. LVL. FLR. LVL.

20MM MIN. 20MM MIN.

SLAB

SLAB

"t"

"t"

CONC. COVER CONC. COVER

SEALANT W/ BACKER

VERIFY

VERIFY

ADDITIONAL TRIMMER BARS (SHOWN AS CONSTRUCTION JOINT COLUMN

NOTES: ROD ON BOTH SIDE

DOTTED LINES), AT SIDES OF OPENING P WINDOW

OMIT TRIMMER BARS WHERE EQUAL TO THE NUMBER OF BARS OPENING

OPENING IS FRAMED BY BEAMS. TERMINATED BY THE OPENING.

SEE REIN. SCHEDULE S 1

SUBGRADE COMPACTED SEALANT W/

COMPACTED GRAVEL TO 95% OF MAXIMUM DRY TYP. FLR LVL BACKER ROD

BEDDING (TYP.) @OPTIMUM MOISTURE CONTENT SUBGRADE COMPACTED SUBGRADE COMPACTED

NOTES: COMPACTED GRAVEL COMPACTED GRAVEL ON BOTH SIDE

(MAX. DEPTH OF COMPRESSED TO 95% OF MAXIMUM DRY TO 95% OF MAXIMUM DRY EXTERIOR R.C WALL WITH

1. PROVIDE THESE ADDITIONAL FOR ALL OPENINGS BEDDING (TYP.) BEDDING (TYP.)

VAPOR BARRIER FILL = (200mm PER LAYER). @OPTIMUM MOISTURE CONTENT @OPTIMUM MOISTURE CONTENT DOWEL BAR TO MATCH SIZE AND

PLUS BARS (SHOWN AS DOTTED LINES) PARALLEL TO SIDE OF OPENING 12 MM

WHEN REQUIRED (MAX. DEPTH OF COMPRESSED (MAX. DEPTH OF COMPRESSED SPACING OF VERTICAL BARS WRAPPED

EQUAL TO THE NUMBER OF INTERRUPTED BARS OF THE OPENING.

VAPOR BARRIER FILL = (200mm PER LAYER). VAPOR BARRIER FILL = (200mm PER LAYER). IN FELT PAPER OR PVC PIPE

WHEN REQUIRED WHEN REQUIRED

2. SEE ARCHITECTURAL & MECHANICAL PLANS FOR SLAB OPENING LOCATION.

BENTONITE

STRIP

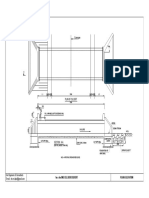

L SLAB OPENING DETAIL MSLAB-ON-GRADE EXPANSION N SLAB-ON-GRADE CONSTRUCTION O SLAB-ON-GRADE CONTRACTION P SECTION (SHOWING EXT. R.C. QTYP. EXTERIOR R.C. WALL ELEV.

S 1 S 1 JOINT DETAIL S 1 JOINT DETAIL S 1 JOINT DETAIL S 1 WALL) SUPPORT @ COLUMN S 1 AT WINDOW OPENING

COLUMN TIES AS PER

SCHEDULE, MAX.

STIRRUPS SPACING=

NOTES ON NON-STRUCTURAL PRE-CAST WALLS:

1. IF THE CONTRACTOR OPTED TO USE PRE-CAST WALLS

STRUCTURAL R.C. FOR NON-STRUCTURAL WALL (EXTERIOR & INTERIOR),

R.C. WALL COLUMN ALL EMBEDS & OTHER REQUIRED ACCESSORIES FOR

SEALANT W/ BACKER TYPICAL PROPER CONNECTION AND SEALANT IN BETWEEN

DOWEL BAR

ROD ON BOTH SIDE T CONFINING REINF. ZONE FOUNDATION TOP ADDITIONAL SHEAR BARS GAPS (BOTH SIDES) MUST BE FOR THE CONTRACTOR'S

S 1 MAXIMUM OF BARS AS SCHEDULED ACCOUNT.

1. CLEAR HEIGHT - 6 (EACH DIAGONAL PAIR PER SET) 2. THE CONTRACTORS MUST SUBMIT SHOP DRAWING/S

SEALANT W/ BACKER

TYP. FLR LVL TYP. FLR LVL 2. MAX. COL. DIMENSION (INCLUDING CALCULATIONS) SHOWING ALL

THICKNESS (H)

TYP. FLR LVL ROD ON BOTH SIDE

H/3 H/3 H/3

25MM

BENTONITE STRIP 3. 450mm. CONNECTION DETAILS & WALL REINFORCEMENTS FOR

SEE REINF. STRUCTURAL ENGINEER'S APPROVAL. ALL

BEAM SCHEDULE BEAM 300 min. JOINT TOP OF PILE CAP CONNECTIONS MADE BY THE STRUCTURAL ENGINEER

DOWEL BARS TO MATCH SIZE

REINF. ZONE MUST NOT CONSTITUTE A CHANGE ORDER.

OPENING

AND SPACING OF VERTICAL

WINDOW

P DOWEL BARS TO MATCHSIZE DOWEL BARS TO MATCH SIZE BARS @ MAT FTG. JOINT - REINF.

S 1 AND SPACING OF VERTICAL BARS AND SPACING OF VERTICAL CROSS-TIES

SEE REINF. CROSS TIES

SEALANT W/ SEE REINF. BARS PILE CAP 225 mm WIDE x 6mm THK. NOTES:

TYP. FLR LVL TYP. FLR LVL SCHEDULE SPACED @ 300

TYP. FLR LVL BACKER ROD SCHEDULE SEE DETAILS FOUNDATION BOTTOM WATERSTOP W/ FLAT TYPE 1. IF THE DETAILS SHOWN ON THIS STANDARD SHEETS ARE

ON BOTH SIDE R.C. EXTERIOR WALL O.C. W/IN & REINF. UNDERSIDE W/ FINS ON THE

FOLLOWED, NO APPROVAL FROM THE STRUCTURAL

BENTONITE STRIP MAT FOOTING BARS AS SCHEDULED FOUNDATION SIDE

BENTONITE STRIP PROVIDE REBAR ENGINEER'S IS REQUIRED. FOLLOW AS PER DETAIL NOTE:

BUNDING CONCRETE

BEAM BEAM CHAIRS AS REQUIRED.

(THICKNESS AS DETAILED)

SEALANT W/ BACKER

BORED PILE BOT. OF PILE CAP

DEEMED 2. IF DRAWINGS FROM THESE DETAILS ARE REQUIRED, SUBMIT NOT DRAWN TO SCALE.

ROD ON BOTH SIDE NECESSARY BY SHOP DRAWINGS SHOWING PROPOSED DETAILS FOR

BENTONITE THE CONTRACTOR. APPROVAL OF THE STRUCTURAL ENGINEER'S. DEVIATION

STRIP DOES NOT NECESSARIRL MEAN DISAPPROVED.

R TYP. EXTERIOR R.C. S

SECTION (SHOWING EXT. R.C. WALL) T SECTION (SHOWING EXT. R.C. WALL) U COLUMN/SHEARWALL VERT. BARS V

FOOTING CONSTRUCTION

S 1 WALL ELEVATION S 1 SUPPORT @ TOP & BOT. OF BEAM S 1 SUPPORT @ TOP & BOT. OF BEAM S 1 EMBEDMENT TO FOOTING DETAIL S 1 JOINT DETAIL

JV LANDMARK INC. ELLY L. ESCOBRO, PICE, ASEP, ACEEP

CONSULTANTS BUILDER

MR. JOSEPH TAN S-1

TEL. NO. (63)(33)3366052 TELEFAX: (63)(33)3373624

OWNER

You might also like

- PlanDocument8 pagesPlanMark Christian EsguerraNo ratings yet

- Billboard DesignDocument1 pageBillboard DesignMark Kenneth P. OntejoNo ratings yet

- Slab and Beam Schedule with General Notes for Proposed School ProjectDocument1 pageSlab and Beam Schedule with General Notes for Proposed School ProjectAtul ShrivastavaNo ratings yet

- Construction of Covered Court-SDocument1 pageConstruction of Covered Court-SAlbert Christian BesmanosNo ratings yet

- 2 Storey Commercial Building Structural Plan-03-06-23Document4 pages2 Storey Commercial Building Structural Plan-03-06-23Francis John F. LopezNo ratings yet

- Building Official Office ContentsDocument1 pageBuilding Official Office ContentsRomel Remolacio AngngasingNo ratings yet

- Structural Report of Proposed Fencing and ExtensionDocument21 pagesStructural Report of Proposed Fencing and ExtensionLester LazoNo ratings yet

- Structural Design Analysis of Proposed Residential BuildingDocument14 pagesStructural Design Analysis of Proposed Residential BuildingSayra SapornaNo ratings yet

- Hotel Building Load CalculationsDocument5 pagesHotel Building Load CalculationsJERALDNo ratings yet

- Water Supply Isometric: C-DesignsDocument1 pageWater Supply Isometric: C-DesignsJenselle CarzaNo ratings yet

- Loadings - NSCP 2015 - 2 Storey Residential Concrete Structure1Document52 pagesLoadings - NSCP 2015 - 2 Storey Residential Concrete Structure1Renvil PedernalNo ratings yet

- Construction Notes: 30 BAR. DIA. 30 BAR. DIA. 40Document1 pageConstruction Notes: 30 BAR. DIA. 30 BAR. DIA. 40MARKCHRISTMASNo ratings yet

- Perimeter Fence Rev 02-6Document1 pagePerimeter Fence Rev 02-6Victorino SantosNo ratings yet

- Covered Court (16m X 30m)Document6 pagesCovered Court (16m X 30m)Engr. D I Y100% (1)

- Structural ReportDocument49 pagesStructural Reportmanuelmelvin20No ratings yet

- Trench Plan and Foundation DetailsDocument1 pageTrench Plan and Foundation DetailsGsUpretiNo ratings yet

- RC Beam - Singly - NSCP 2015 by RgceDocument4 pagesRC Beam - Singly - NSCP 2015 by RgceJet ToledoNo ratings yet

- Structural design notes for G+1 buildingDocument1 pageStructural design notes for G+1 buildingRaghul ShangarthiyanNo ratings yet

- Vicinity Map: This SiteDocument4 pagesVicinity Map: This SiteDeborah EspirituNo ratings yet

- Department of Public Works and Highways: Region VDocument11 pagesDepartment of Public Works and Highways: Region VMarianne Jocel CostacioNo ratings yet

- Fascia Frame Details: Foundation PlanDocument1 pageFascia Frame Details: Foundation PlanRod NajarroNo ratings yet

- Roof 7Document1 pageRoof 7Bekaar AadameeNo ratings yet

- Structural Analysis of Three Storey Commercial BuildingDocument184 pagesStructural Analysis of Three Storey Commercial Buildingjossan doplaynaNo ratings yet

- Column Detailed 3Document1 pageColumn Detailed 3Azaina1No ratings yet

- Design rectangular beam reinforced for tensionDocument8 pagesDesign rectangular beam reinforced for tensionaltavanoarNo ratings yet

- General notes and dimension detailingDocument1 pageGeneral notes and dimension detailingMuhammad SulaimanNo ratings yet

- Structural Design Criteria 1.0 Codes and StandardsDocument4 pagesStructural Design Criteria 1.0 Codes and StandardsChrispin BarnigoNo ratings yet

- Canal II Layout1Document1 pageCanal II Layout1Xan KulitzNo ratings yet

- Load ComputationDocument11 pagesLoad ComputationMIHDI PALAPUZNo ratings yet

- 3 Storey BuildingDocument4 pages3 Storey BuildingManuelito ZapataNo ratings yet

- Proposed 5 Storey Building with Roof Deck Structural DesignDocument4 pagesProposed 5 Storey Building with Roof Deck Structural DesignAlvin SantosNo ratings yet

- Stair Foundation Detail at Beam: Rosario L. RostataDocument1 pageStair Foundation Detail at Beam: Rosario L. RostataJesusAntonioJugosNo ratings yet

- RESIDENTIAL BUILDING DESIGN USING STAAD & CONCRETE DESIGNERDocument46 pagesRESIDENTIAL BUILDING DESIGN USING STAAD & CONCRETE DESIGNERKenneth LauronNo ratings yet

- Building floor plans and elevationsDocument2 pagesBuilding floor plans and elevationsruel buntogNo ratings yet

- Footing Reinforcement DetailsDocument1 pageFooting Reinforcement DetailsMurthy GunaNo ratings yet

- Design Loads for Covered CourtDocument39 pagesDesign Loads for Covered CourtLouise CarleyNo ratings yet

- Front Page Row House PlanDocument1 pageFront Page Row House PlanDJNo ratings yet

- General Construction Notes: Bureau of DesignDocument15 pagesGeneral Construction Notes: Bureau of DesignRicoyan YanNo ratings yet

- Drawings and specifications for proposed 40-storey condominium buildingDocument1 pageDrawings and specifications for proposed 40-storey condominium buildingGarduque AngreysNo ratings yet

- Roof deck plumbing layoutsDocument1 pageRoof deck plumbing layoutsLalisa MNo ratings yet

- Structural Analysis-Pat G. CanlasDocument11 pagesStructural Analysis-Pat G. CanlasKali BearNo ratings yet

- Typical footing detail and column elevationDocument10 pagesTypical footing detail and column elevationPatricia PachecoNo ratings yet

- Wind Load AnalysisDocument5 pagesWind Load AnalysisJohn Lloyd JuanoNo ratings yet

- CAISSON Discussion PaperDocument5 pagesCAISSON Discussion PaperKeith GarridoNo ratings yet

- Cistern TankDocument10 pagesCistern TankRoselleNo ratings yet

- 2-Storey Glenn FernandezDocument66 pages2-Storey Glenn Fernandezclarkgagui100% (1)

- Detail of Wall Footing and CHB Pile: Ftb-1 Det. Sec. Wf-1 Det. Sec. Wf-1 CHB PileDocument1 pageDetail of Wall Footing and CHB Pile: Ftb-1 Det. Sec. Wf-1 Det. Sec. Wf-1 CHB PilejoanNo ratings yet

- WAREHOUSE PlanDocument2 pagesWAREHOUSE PlanKarlo CabanginNo ratings yet

- Loading Combination NSCP 2010 Vs 2001Document1 pageLoading Combination NSCP 2010 Vs 2001lauropaniergoNo ratings yet

- Various DPWH Proposed Projects (Detailed Engineering Design And/Or Special Studies)Document16 pagesVarious DPWH Proposed Projects (Detailed Engineering Design And/Or Special Studies)Anna Rose PueblaNo ratings yet

- Kaong PS, Silang Construction Drawings 11june2021-1-11Document11 pagesKaong PS, Silang Construction Drawings 11june2021-1-11Fred PascuaNo ratings yet

- FewfweefwDocument1 pageFewfweefwanthony christian yangNo ratings yet

- Sample Structural PlanDocument1 pageSample Structural PlanAl Drin100% (1)

- 2 Storey 8clDocument18 pages2 Storey 8clMichael Angel Bautista PascualNo ratings yet

- SCHEDULE of Roof BeamDocument1 pageSCHEDULE of Roof BeamJoseph Cloyd LamberteNo ratings yet

- Part1 Outline SpecificationsDocument16 pagesPart1 Outline SpecificationsAdrienne Margaux DejorasNo ratings yet

- 1x1m SINGLE CELL BOX CULVERT - UnlockedDocument6 pages1x1m SINGLE CELL BOX CULVERT - Unlockedsinghconst100% (1)

- Computation of LoadsDocument30 pagesComputation of Loadspablo naragNo ratings yet

- Foundation - 3-Storey With Roof Deck-Model PDFDocument1 pageFoundation - 3-Storey With Roof Deck-Model PDFAnjo BalucasNo ratings yet

- 31293F PDFDocument1 page31293F PDFHany NassimNo ratings yet

- Winload Calculation NSCPDocument4 pagesWinload Calculation NSCPAly Arquillano JrNo ratings yet

- Membership Application Form 2013Document11 pagesMembership Application Form 2013bong2rmNo ratings yet

- Evolution of Bridge Design SpecsDocument71 pagesEvolution of Bridge Design SpecsRC Dela RocaNo ratings yet

- Steel Ratio Check: Column Size 500x800mm, 28 Bars 32mm DiaDocument1 pageSteel Ratio Check: Column Size 500x800mm, 28 Bars 32mm DiaAly Arquillano JrNo ratings yet

- Soil-Water Potential - Concepts and MeasurementDocument48 pagesSoil-Water Potential - Concepts and MeasurementAly Arquillano JrNo ratings yet

- Structural document layout analysisDocument1 pageStructural document layout analysisAly Arquillano JrNo ratings yet

- Soil Bearing Capacity ReportDocument1 pageSoil Bearing Capacity ReportAly Arquillano JrNo ratings yet

- Chapter2 00Document26 pagesChapter2 00r96221029No ratings yet

- Sample Floor PlansDocument1 pageSample Floor PlansAly Arquillano JrNo ratings yet

- Deflection CalcDocument8 pagesDeflection CalcRamadan100% (1)

- Phi SymbolDocument1 pagePhi SymbolAly Arquillano JrNo ratings yet

- Me16A: Chapter Three: Bending Moments and Shearing Forces in BeamsDocument68 pagesMe16A: Chapter Three: Bending Moments and Shearing Forces in BeamsAly Arquillano JrNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Factored Load: Type: Moment Unit: KN-M LoadsDocument1 pageFactored Load: Type: Moment Unit: KN-M LoadsAly Arquillano JrNo ratings yet

- Categorization Classification TableDocument2 pagesCategorization Classification TableChristopher Joshua MartinezNo ratings yet

- Sikadur - 30: Adhesive For Bonding ReinforcementDocument5 pagesSikadur - 30: Adhesive For Bonding ReinforcementAly Arquillano JrNo ratings yet

- 5 Plastic AnalysisDocument14 pages5 Plastic AnalysisParveen RidhalNo ratings yet

- How Peruvian Seismic Code Greatly Improved Building Response To Real EarthquakesDocument13 pagesHow Peruvian Seismic Code Greatly Improved Building Response To Real EarthquakesAly Arquillano JrNo ratings yet

- Bridge Slab Design PDFDocument89 pagesBridge Slab Design PDFNilesh Kumar100% (1)

- Mat Foundation PhilippinesDocument7 pagesMat Foundation PhilippinesAly Arquillano JrNo ratings yet

- Seminar on Analysis and Design of Tall BuildingsDocument2 pagesSeminar on Analysis and Design of Tall BuildingsAly Arquillano JrNo ratings yet

- Fixing Angle FoundationDocument1 pageFixing Angle FoundationAly Arquillano JrNo ratings yet

- Seismic Weight CheckDocument1 pageSeismic Weight CheckAly Arquillano JrNo ratings yet

- PBD of Tall BuilidingsDocument26 pagesPBD of Tall BuilidingsAly Arquillano Jr100% (1)

- Wide Flange SectionsDocument21 pagesWide Flange SectionsAly Arquillano Jr100% (1)

- Continuous Unbonded Post-Tensioned Members - Quantifying StrandDocument148 pagesContinuous Unbonded Post-Tensioned Members - Quantifying StrandAly Arquillano JrNo ratings yet

- BuildingmaintenanceDocument92 pagesBuildingmaintenanceAly Arquillano JrNo ratings yet

- No. of Bars ConverterDocument2 pagesNo. of Bars ConverterAly Arquillano JrNo ratings yet

- Deflection CalcDocument8 pagesDeflection CalcRamadan100% (1)

- 5 Tips For Young EngineersDocument1 page5 Tips For Young EngineersAly Arquillano JrNo ratings yet

- How Do Beams in RC Buildings Resist EarthquakesDocument2 pagesHow Do Beams in RC Buildings Resist Earthquakessamir_ssh7151No ratings yet

- 2ND Floor Beam Design SummaryDocument22 pages2ND Floor Beam Design SummaryErol VasquezNo ratings yet

- Composite Construction Method: Ii. Composite Action in BeamsDocument1 pageComposite Construction Method: Ii. Composite Action in Beamsjillian llanesNo ratings yet

- Space frame design group summaryDocument45 pagesSpace frame design group summaryAmol GoleNo ratings yet

- By Engosoft Training CenterDocument81 pagesBy Engosoft Training CenterEHABNo ratings yet

- Structural Analysis For Two Story Residential BuildingDocument4 pagesStructural Analysis For Two Story Residential BuildingMathan LuceroNo ratings yet

- Dead and Live Load Calculation for Perfect FactoryDocument98 pagesDead and Live Load Calculation for Perfect FactorypandianNo ratings yet

- Truss BridgesDocument21 pagesTruss BridgesAzaz Ahmed50% (2)

- Ds5 Ds5: / Detail External Horizontal Gutter / Detail - Frieze - Attika / Detail 09Document1 pageDs5 Ds5: / Detail External Horizontal Gutter / Detail - Frieze - Attika / Detail 09Andreja GjureskiNo ratings yet

- Project Name Project Duration Construction of A 2 Storey BuildingDocument4 pagesProject Name Project Duration Construction of A 2 Storey Buildingjoan67% (3)

- Mandalay SiteDocument27 pagesMandalay Sitehtethtet zaw77No ratings yet

- PROPOSED THREE STOREY TOWNHOUSE DESIGN REPORTDocument9 pagesPROPOSED THREE STOREY TOWNHOUSE DESIGN REPORTThomas ChuaNo ratings yet

- Tegral - Designer's Purlin & Rail GuideDocument44 pagesTegral - Designer's Purlin & Rail GuideRaymond KinnairdNo ratings yet

- Historic Roof StructuresDocument13 pagesHistoric Roof StructuresAucamanNo ratings yet

- Analysis of Flat Slab Building With and Without Shear Wall PDFDocument9 pagesAnalysis of Flat Slab Building With and Without Shear Wall PDFvishalgoreNo ratings yet

- WHE 154-Assam-Type House IndiaDocument22 pagesWHE 154-Assam-Type House IndiaLikhitaKaranamNo ratings yet

- Beam DesignDocument8 pagesBeam DesignFaraaz FaisalNo ratings yet

- LongspanstructuresDocument77 pagesLongspanstructuresKartik Saini100% (1)

- 4 Beam DesignDocument58 pages4 Beam DesignJoan Gonsalves Jean Jacques100% (2)

- Concrete volume report for October 16-30, 2019Document73 pagesConcrete volume report for October 16-30, 2019Simeon James Defeo VillacrusisNo ratings yet

- Staircase Design DrawingsDocument2 pagesStaircase Design DrawingsVivekanand SathyamoorthyNo ratings yet

- Roof TrussesDocument20 pagesRoof Trussesalexmihai00100% (1)

- Estimated Cost of Different Types of Bridge Structure Per Linear Meter (Pesos) 2019Document7 pagesEstimated Cost of Different Types of Bridge Structure Per Linear Meter (Pesos) 2019robeusef costacortaNo ratings yet

- All Tyep Beam BbsDocument4 pagesAll Tyep Beam BbsM.ARULSURYANo ratings yet

- CB Layout Plan 1: A B C D Official Use OnlyDocument1 pageCB Layout Plan 1: A B C D Official Use OnlyRooking Ewondo SfuutNo ratings yet

- Load ElevatorsDocument2 pagesLoad ElevatorsНемања КараклајићNo ratings yet

- Lesson Plan - Roofs Layout, Design, and Editing Lesson OverviewDocument34 pagesLesson Plan - Roofs Layout, Design, and Editing Lesson OverviewHabeebMohammedFarooqNo ratings yet

- Machinery Installations, Piping Plants, Tanks, Various Cranes and Steel StructuresDocument2 pagesMachinery Installations, Piping Plants, Tanks, Various Cranes and Steel StructuresThein Than AungNo ratings yet

- Timber Design Project ProposalDocument32 pagesTimber Design Project ProposalAlexander P. Igasan100% (1)

- Roof Truss GuideDocument12 pagesRoof Truss Guidedgib100% (1)