Professional Documents

Culture Documents

Torsion Theory and Applications

Uploaded by

Victoria JungOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Torsion Theory and Applications

Uploaded by

Victoria JungCopyright:

Available Formats

6

TORSION

OBJECTIVES:

This chapter starts with torsion theory in the circular cross section

followed by the behaviour of torsion member. The calculation of

the stress stress and the angle of twist will be also showed here.

Lastly, the topics that include the members having noncircular

cross sections will be discussed. The examples and exercises will

be included to better understanding.

5.1 Introduction

Torsion refers to the twisting of a structural member that is loaded by

couples or torque. It will produce rotation about the members longitudinal

axis. Couples that produce twisting of a bar are called torques, twisting

couples or twisting moments and may be represented in several ways.

The example of shafts;

a) Rotating Machinery; Propeller shaft, Drive shaft

b) Structural Systems; Landing gear strut, Flap drive mechanism

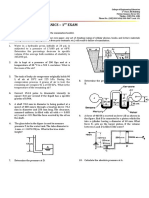

Figure 6.1: Example of driving shaft

Mechanics of Materials 177

5.2 Torsion theory of circular cross section

Figure 6.2 : The circular cross section

Shaft connecting gears and pulleys are a common application involving

torsion members. To examine the stress and deformation of a torsion

member, a prismatic bar with a circular cross section that is twisted by

torques, T acting at the ends will be considered as shown in Figure 6.2.

(a) Before deformation

(b) After deformation

Figure 6.3: Deformation of bar

To better understand the behaviour of a torsion member, superimpose a

grid on the surface of shaft and observe the deformation of the shaft as a

result of the applied torque, T. Hold the left end of the bar fixed in

position. When a bar or shaft of circular section is twisted by moment, its

Mechanics of Materials 178

called pure tension and the deformed element shown in Figure 6.3 are said

to be in a state of pure shear.

Referring to Figure 6.3 and 6.4, several

characteristics of torsional loading on the

circular prismatic bar is observed;

1. The longitudinal axis of the shaft

remains straight.

2. The shaft does not increase or

decrease in length.

3. Radial lines remain straight and

Figure 6.4 radial as the cross section rotates.

4. Cross sections rotate about the

axis of the member.

The warping does not occur in circular section. The theory of torsion with

the circular section is relatively simple.

5.2.1 Shear stress in circular section, (tau)

Tr

J

Where;

: Shear stress in the shaft if max=maximum shear stress occurs at the

outer surface @ tegasan ricih. (N/m2)

J : Polar moment of inertia of the cross sectional area @ moment

sifatekun kutub (m4)

T : Applied torque acting at the cross section (Nm)

r : Radius of the shaft (m)

Mechanics of Materials 179

5.2.2 Types of circular section

5.2.3 Angles of twist, ( phi ) @ sudut piuhan

TL

JG

Where;

= angle of twist (radians)

T = applied torque

L = length of member

G = shear modulus of material/ modulus of rigidity@modulus

ketegaran (N/m2)

J = polar moment of inertia

5.2.4 Power transmission

Circular bars or shafts are commonly used for transmission of power.

From design stand point, it is necessary for the shaft to be strong enough to

transmit power safely without exceeding the shaft material's elastic limit.

Power is defined as the work performed per unit of time. The work

transmitted by a rotating shaft equals to the torque applied times the angle

of rotation.

Work = Torque x Angular Displacement

Mechanics of Materials 180

Power = d/dt (Work)

If torque is not a function of time, then the equation for power simply

becomes:

P=T

Where;

is the angular velocity of the shaft (rad/s)

T : Applied torque acting at the cross section (Nm)

P : Power (W)(1W = 1 Nm/s)

For machinery, the frequency of a shafts rotation, f is often reported. This

is a measure of the revolutions number@cycles of the shaft.

P = 2 f T

Where;

f : frequency (Hz @ hertz) (1 Hz = 1 cycle/s)

: 2 f

It is important that we use consistent units for P, T, and . Power is

commonly specified in horsepower, HP. Angular velocity is usually given

in revolutions per minute or RPM. It should then be converted to rad/sec.

To do this multiply the value in RPM by 2 and divide by 60.

EXAMPLE 6.1

Determine the maximum torque of a hollow circular shaft with inside diameter of

60mm and an outside diameter of 100mm without exceeding the maximum

shearing stress of 70MPa.

Solution;

Given;

di = 60mm, do = 100mm

max = 70MPa

J (100 4 604 ) 8.55x106 mm4

32

Mechanics of Materials 181

Tmax r

max

J

max J

Tmax

r

(70 x10 6 )(8.55 x10 6 )

11.97kNm

0.05

Remember: max=maximum shear stress occurs at the outer surface/radius.

EXAMPLE 6.2

A hollow steel shaft has an outside diameter of 150mm and an inside diameter

100mm. The shaft is subjected to a torque of 35kNm. The modulus of rigidity for

the steel is 80GPa. Determine;

a) the shearing stress at the outside surface of the shaft.

b) the shearing stress at the inside surface of the shaft.

c) the magnitude of the angle of twist in a 2.5m length.

Solution;

J (150 4 100 4 ) 39.89 x106 mm4

32

a) the shearing stress at the outside surface of the shaft.

Tr

out

J

35 x103 (0.075)

65.81MPa

39.89 x10 6

b) the shearing stress at the inside surface of the shaft

Tr

in

J

35 x103 (0.05)

43.9 MPa

39.89 x10 6

c) the magnitude of the angle of twist in a 2.5m length.

TL

JG

35x103 (2.5)

0.027rad

80 x109 (39.89 x10 6 )

Mechanics of Materials 182

EXAMPLE 6.3

A 3m long hollow steel shaft has an outside diameter of 100mm and an inside

diameter of 60mm. The shear modulus of steel is 80GPa. The maximum shearing

stress in the shaft is 80MPa and the angular velocity is 200rpm. Determine;

a) the power being transmitted by the shaft.

b) the magnitude of the angle of twist in the shaft.

Solution;

J (1004 604 ) 8.55x106 mm4

32

Tmax r

max

J

max J

Tmax

r

(80 x106 )(8.55 x10 6 )

13.68kNm

0.05

a) the power being transmitted by the shaft.

From the previous notes stated that angular velocity is usually given in revolutions

per minute or RPM. It should then be converted to rad/sec. To do this multiply the

value in RPM by 2 and divide by 60.

2T 2 (200)(13.68 x103 )

P Hp(horse power ) 286.55kW

60 60

b) the magnitude of the angle of twist in the shaft.

TL

JG

13.68 x103 (3)

0.06rad

80 x109 (8.55x10 6 )

Mechanics of Materials 183

EXAMPLE 6.4

A solid circular steel shaft 1.5m long transmits 200kW at a speed of 400rpm. If

the allowable shearing stress is 70MPa and the allowable angle of twist is 0.045

rad. The shear modulus of steel is 80GPa.

a) the minimum permissible diameter for the shaft.

b) the speed at the same power that can be delivered if the stress is not exceed

50MPa in a diameter of 75mm.

Solution;

Given L =1.5m

P = 200kW

= 400 rpm

allow = 70MPa

allow = 2.6 or 0.045 rad

G = 80GPa

a)

P T

2T

60

2 (400)T

200 x103

60

T 4.77kNm

Tr TL

i) allow ii) allow

J JG

d 4.77 x103 (1.5)

4.77 x103 0.045

2 d 4

allow (80 x109 )

d 4 32

32 9.109 x10 7

=

2385d d4

70 x106

0.0982d 4 d 0.067mm @ 67.1mm

70 x106 d 3 24287.2

d 0.07m @ 70.27mm

Pick d = 70.27mm

b) Given d = 75mm

d 4 (75) 4

J 3.11x106 mm 4

32 32

Tr

J

Mechanics of Materials 184

T (0.0375)

50 x106

3.11x10 6

T = 4.15kNm

P T

2T

60

2 (4.15x103 )

200 x103

60

= 461rpm

EXERCISE 6.1

A hollow circular shaft has an outside diameter D 2 of 100mm and an inside

diameter D1 of 60mm. Given the maximum allowable shearing stress is 55

N/mm2.

a) Show that its polar moment of inertia , J is 8.55x10 6 mm4.

b) Calculate the maximum torque, T that can applied to the shaft

c) Determine the shear stress at the inner surface of the hollow shaft

EXERCISE 6.2

A tubular shaft having an inner diameter of 30mm and outer diameter of 42mm is

to be used to transmit 90kW of power. Determine the frequency of rotation of the

shaft so that the shear stress will not exceed 50MPa.

[Ans: f = 26.62Hz]

Mechanics of Materials 185

5.3 Composite Bars

A B C

Shaft 1 Shaft 2

To solve the problem of combined/composite shaft;

a) T = Tshaft 1 + Tshaft 2 + ..Tshaft n

n = number of shaft

b) 1 2

TL

c)

JG

EXAMPLE 6.5

The composite bars with the different material is subjected to the torque is shown

in figure. Determine the maximum shear stress and the position. Determine the

angle of twist at C.

10kNm

A B C

4kNm

BAR r (mm) G(Pa)

2m 0.3m AB 50 3x1010

BC 25 8x1010

Solution;

d 4 (1002 )

J AB 9.82 x106 mm4

32 32

d 4 (502 )

J BC 0.62 x106 mm4

32 32

10kNm

A B C T = outward ()

4kNm

T = inward ()

2m 0.3m Or applied Right Hand

Rule

Mechanics of Materials 186

10kNm

A B C

6kNm 4kNm

TA

2m 0.3m

6kNm

TAB = 6kNm (T)

6kNm TBC = 4kNm(C)

10kNm

Maximum shear stress;

T r 6 x106 (50)

AB AB AB 30.55N / mm2

J AB 9.82 x106

TBC rBC 4 x106 (25)

BC 6

161.3N / mm2

J BC 0.62 x10

The maximum shear stress occurs in the bar of BC.

Angle of twist at the end of C;

TL TL TL

JG JG AB JG BC

(6 x106 )(2000) ( 4 x106 )(300)

0.0158rad

9.82 x106 (3x10 4 ) 0.62 x106 (8 x104 )

Mechanics of Materials 187

EXERCISE 6.3

The horizontal shaft AD is attached to a fixed support at D and is subjected to

point torques as shown in figure. A 40mm diameter hole has been drilled into the

portion CD of the shaft. By assuming that the entire shaft is made of steel and G

=70GN/m2, determine the angle of twist at end A.

5.4 Torsion of non-cylindrical member

Generally, we deal with axisymmetric bodies and the shear strain is linear

through the entire body. However, non-circular cross-sections are not

axisymmetric causing complex behaviors, which may cause bulging or

warping when the shaft is twisted.

Figure 6.5: Condition of bulging of non-circular shaft

Mechanics of Materials 188

The mathematics is beyond the scope of the course, however there are

empirical formulas for various shapes.

Table 6.1: Formula for various shapes

EXAMPLE 6.6

The aluminum shaft shown in figure has a cross sectional area in the shape of an

equilateral triangle. Determine the largest torque, T that can be applied to the end

of the shaft if the allowable shear stress,

allow is = 56MPa and the angle of twist at

its end is restricted to allow = 0.02 rad. Given Gal = 26GPa.

Mechanics of Materials 189

Solution;

By inspection, the type of shaft is equilateral triangle. Refer to Table 6.1,

20T

i) allow 3

a

20 T

56 N / mm2 3

40

T 179.2kNmm

46TL

ii) allow

a 4Gal

46T (1200mm) 46T (1.2m)

0.02rad or 0.02rad

N N

(40 4 mm)( 26 x103 ) (0.04 4 m)( 26 x109 )

mm 2 m2

T 24.12kNmm T 24.12 Nm

By comparison, the torque is limited due to the angle of twist.

T 24.12kNmm

5.5 Thin-walled Having Closed Cross Sections

Thin walled of noncircular shape are often used to construct lightweight

frameworks which is used in aircraft. In this section, we will analyze the

effects of applying a torque to a thin walled having a closed cross section.

The section does not have any breaks or slits along its length.

5.5.1 Shear flow, q.

Due the applied torque, T, shear stress is developed on the front face of the

element. Shear flow in a solid body is the gradient of a shear stress through

the body. Shear flow is the product of the tubes thickness and the average

shear stress. This value is constant at all points along the tubes cross

section. As a result, the largest average shear stress on the cross section

occurs where the tubes thickness is small.

q avg t

Mechanics of Materials 190

5.5.2 Average shear stress, ave

In non-circular thin walled shafts for closed segments. We assume that the

stress is uniformly distributed across the thickness and that we can assume

an average shear stress. The average shear stress in the body is;

T

ave

2tAm

where,

ave - average shear stress

t - the thickness of the shaft at the point of interest

Am - mean area enclosed within the boundary of the centerline

of the shaft thickness.

T - the applied torque

Am is shown in shaded area.

The relationship between shear stress, and torque, T;

ds

dF

ave

t h

ave

T dT h(dF )

Mechanics of Materials 191

h ( avet ds )

avet h ds

2 avet d Am

2 avet Am

T

ave

2tAm

Since q avg t , we can determine the shear flow throughout the cross

section using the equation;

T

q

2 Am

5.5.3 Angle of twist,

This angle can be determined by using the energy method. The angle given

in radians, can be expressed as;

TL ds

2

4 Am G t

Here the integration must be performed around the entire boundary of the

tubes cross sectional area.

where,

t - thickness of the interior segment

L - length of the section

G - modulus of rigidity of the section/shear modulus

Mechanics of Materials 192

EXAMPLE 6.7

The tube is made of bronze and has a rectangular section as shown in figure. If it

is subjected to the two torques;

a) determine the average shear stress in the tube at points A and B.

b) determine the angle of twist at end C. Given G = 38GPa.

Solution;

a)

25Nm

60Nm

C D E

60Nm TCD = 60Nm (T)

60Nm

25Nm 35Nm TDE = 35Nm (T)

60Nm

OR

The tube is subjected to the two torques at C and D. The

free body diagram is shown in figure. The internal torque

is 35 Nm.

T= T

60 = 25 ----> to balance (60-25)=35Nm

Mechanics of Materials 193

The area, Am; Am (0.035)(0.057) 0.002m 2

57mm

The shaded area = Am

35mm

The average shear stress at point A with t A = 5mm;

T

ave

2tAm

35

A 1.75MPa

2(0.005)(0.002)

The average shear stress at point B with t B = 3mm;

35

B 2.92 MPa

2(0.003)(0.002)

b)

The internal torques in regions DE and CD are 35Nm and 60Nm, respectively.

TL ds TL ds

2 2

4 Am G t CD 4 Am G t DE

60(0.5) 57mm 35mm

9

2 2

4(0.002 )(38 x10 ) 5mm 3mm

2

Mechanics of Materials 194

35(1.5) 57mm 35mm

9

2 2

4(0.002 )(38 x10 ) 5mm 3mm

2

30

22.8 23.33 52.5 22.8 23.33

608000 608000

3 3

2.28 x10 3.98 x10

6.26 x10 3 rad

EXAMPLE 6.8

A square aluminum tube has the dimensions as shown in figure.

a) determine the average shear stress in the tube at point A if it is

subjected to a torque of 85Nm.

b) compute the angle of twist due to this loading. Given G al = 26GPa.

1.5m

Solution;

a)

The area, Am; Am (50)(50) 2500mm2

50mm

The shaded area = Am

T 50mm

85x103

avg 1.7 N / mm2

2tAm 2(10)(2500)

Mechanics of Materials 195

Since t is a constant because of the square tube, the average shear stress is the

same at all points on the cross section.

b)

Angle of twist;

TL ds

2

4 Am G t

(85x103 )(1500) 50mm

4

4(2500) 2 (26 x103 ) 10mm

1.962 x10 4 (20)

3.92 x10 3 rad

Here, the integral represents the length around the centerline boundary of the tube.

EXERCISE 6.4

If a =25mm and b = 15mm, determine the maximum shear stress in the circular

and elliptical shafts when applied torque is T=80Nm. By what percentage is the

shaft of circular section more efficient at withstanding the torque than the shaft of

elliptical cross section?

[Ans: b) (max)c = 3.26MPa, (max)e = 9.05MPa, 178%]

Mechanics of Materials 196

EXERCISE 6.5

The square shaft is used at the end of a drive cable in order to registrar the rotation

of the cable on a gauge. If it has the dimensions shown and is subjected to a torque

of 8Nm, determine the shear stress in the shaft at point A.

Mechanics of Materials 197

TUTORIAL 5

1.

a) If the shearing stress is not exceed 70 N/mm2, determine the maximum

torque that may be transmitted by a solid circular shaft of diameter

98.5mm and length of 1.62m. Take shear modulus of steel is 80kN/mm2.

b) The square thin walled tube is subjected to a torque of 150Nm. Determine

the average shear stress in the tube if the mean dimension a = 200mm.

Each side has a thickness of t = 3mm.

[Ans: a) ave = 1.25MPa]

2.

a) A hollow circular shaft has an outside diameter D 2 of 100mm and an

inside diameter D1 of 75mm. Show that its polar moment of inertia , J is

6.71x106 mm4. Given the maximum allowable shearing stress is 65

N/mm2. Calculate;

i) the maximum torque, T that can applied to the shaft.

ii) the shear stress at the inner surface of the hollow shaft.

b) A continuous circular shaft is made of two segments AB and BC with

diameters 205mm and 105mm respectively. The shaft is fixed at the end A

and subjected to anticlockwise torques of 60kNm at B and 30kNm at C as

shown in figure. Take G = 80kN/mm2. Find the total angle of twist at the

end C.

Mechanics of Materials 198

3.

a) The figure shows the crosssectional of a hollow shaft. Prove the torsion

equation for concentrically hollow circular shafts is given by expression;

T max

J R2

where;

T = applied torque

R2 = outer radius of the shaft

R1 = inner radius of the shaft

max= shear stress at outer radius R2

J = polar moment of inertia

dr = an elementary ring of a thickness

at r, radius.

b) A hollow steel shaft is subjected to receive a torque of 30kNm. The shaft

has an outside diameter of 150mm and inside diameter of 100mm. The

Modulus of Rigidity for the steel is 80GPa. Determine;

i) the shear stress on the outside surface of the shaft.

ii) the shear stress on the inside surface of the shaft.

iii) the maximum shear stress of the shaft.

iv) the twist angle for a 3.5m length of the shaft.

4.

a) Discuss THREE (3) assumptions to be made in the derivation of torsion

equation for a circular shaft.

b) A steel circular bar in torsion consists of two parts, as shown in Figure

Q4(a). Part AB has diameter 60 mm and length 1 m, and part BC has

diameter 30 mm and length 1.2 m. What is the allowable torque T if the

angle of twist between the ends of the bar is not to exceed 0.035 radians

and the shear stress is not to exceed 30 MPa? Assume Modulus of

Rigidity, Gsteel = 80 GPa.

c) A torque of 5 kNm is applied to the rectangular section shown in Figure

Q4(b). Determine the wall thickness t so as not to exceed a shear stress of

80 MPa.

Mechanics of Materials 199

60 mm 30 mm

T A B C T

1m 1.2 m

Figure Q4(a)

50 mm

100 mm

Figure Q6(c)

(FINAL EXAM SEM II 2007/2008 UTHM)

5.

A hollow section as shown in Figure Q5 is subjected to a torque of 100Nm at

point A.

a) Sketch a thin wall tube to show elements subjected to torsion.

b) Derive the equation of average shear stress, ave in terms of internal torque,

T, the thickness of hollow section, t and the mean area enclosed within the

boundary of the centre line of the thickness of the hollow section.

c) Determine the average shear stress in the hollow section at point A.

Mechanics of Materials 200

d) Calculate the angle of twist assuming G = 200GPa.

A

20

L = 3m

200

20 All units in mm

150

Figure Q5

(FINAL EXAM SEM I 2007/2008 UTHM)

6.

a) Determine the torque T that can be applied to the rectangular tube if the

average shear stress is no exceed 85MPa. The mean dimensions of the tube are

shown and the tube has thickness of 3mm.

50mm

100mm

[Ans: a) T = 2.55kNm]

b) The solid compound rod made of three different materials carried

the two torques as shown in Figure Q3. Given Galuminum = 28GPa, Gbronze =

35GPa dan Gsteel = 83GPa. (Answer in unit N/mm2 ).

i) Calculate the maximum shear stress in each material.

ii) Find the angle of rotation of the free end of the rod.

Mechanics of Materials 201

5 kN.m

Aluminum 2 kN.m

Steel Bronze

100 mm 75 mm

3m 2m 1.5 m

Mechanics of Materials 202

You might also like

- Module 3 TorsionDocument13 pagesModule 3 TorsionJay LopezNo ratings yet

- Esfuerzos en Vigas - PDFDocument6 pagesEsfuerzos en Vigas - PDFgerardo jose de la espriella alvarezNo ratings yet

- Reinforced Concrete - Shear StrengthDocument7 pagesReinforced Concrete - Shear StrengthDenice CastroNo ratings yet

- Thermal Stresses: Mechanics of Deformable BodiesDocument15 pagesThermal Stresses: Mechanics of Deformable BodiesJake CanlasNo ratings yet

- Dynamics of Rigid Bodies Problem SetDocument7 pagesDynamics of Rigid Bodies Problem SetRichelle Valerie BastroNo ratings yet

- CelerityDocument23 pagesCelerityswabrightNo ratings yet

- Exercises: Ans. F = 1404.917 N; θ = 7.05ºDocument3 pagesExercises: Ans. F = 1404.917 N; θ = 7.05ºRhey LuceroNo ratings yet

- PPSDocument94 pagesPPSaamirNo ratings yet

- Ce 343L - Fluid Mechanics - 1 ExamDocument2 pagesCe 343L - Fluid Mechanics - 1 ExamMichelle Daarol100% (1)

- Gis Located Above B)Document10 pagesGis Located Above B)Apple AterradoNo ratings yet

- BrasdaDocument3 pagesBrasdaJayson Brylle MojaresNo ratings yet

- DynamicsDocument3 pagesDynamicsjj012586No ratings yet

- Lesson 6 - TORSION PDFDocument30 pagesLesson 6 - TORSION PDFBaux/比叡0% (1)

- F.A.L. Conducive Engineering Review Center: 2 Floor, Cartimar Building, C.M. Recto Avenue, Quiapo, ManilaDocument2 pagesF.A.L. Conducive Engineering Review Center: 2 Floor, Cartimar Building, C.M. Recto Avenue, Quiapo, ManilaBluezed14No ratings yet

- DIFFERENTIAL CALCULUS AND APPLICATIONSDocument2 pagesDIFFERENTIAL CALCULUS AND APPLICATIONSEricson CapuaNo ratings yet

- April 2024 - PSAD 2Document2 pagesApril 2024 - PSAD 2rando12345No ratings yet

- Topic 8 Fundamentals of Fluid FlowDocument39 pagesTopic 8 Fundamentals of Fluid FlowMerwin Andrew UyNo ratings yet

- CE 010 Module 1.2-1.3Document29 pagesCE 010 Module 1.2-1.3NIÑO LEANDRO LEYESNo ratings yet

- Strength 4 May 2021Document3 pagesStrength 4 May 2021Jon SnowNo ratings yet

- Hydraulics 3 DiscussionDocument19 pagesHydraulics 3 DiscussionRaymund PertudoNo ratings yet

- Chapter 3Document30 pagesChapter 3Victoria JungNo ratings yet

- Module 3 and 5 PDFDocument55 pagesModule 3 and 5 PDFSaptadip SahaNo ratings yet

- Exer1322 PDFDocument21 pagesExer1322 PDFNelva CSNo ratings yet

- Specific Gravity Determination Using U-Tube ManometerDocument9 pagesSpecific Gravity Determination Using U-Tube ManometerEly ReyesNo ratings yet

- Prismoidal Formula 2Document11 pagesPrismoidal Formula 2anggaxkusumaNo ratings yet

- Strength of MaterialsDocument1 pageStrength of MaterialsAnonymous P1iMibNo ratings yet

- Surveying FundamentalsDocument14 pagesSurveying FundamentalsJared RoseNo ratings yet

- VERTICAL STRESS BELOW CIRCULAR AREADocument20 pagesVERTICAL STRESS BELOW CIRCULAR AREAJess PalmaNo ratings yet

- METHOD OF JOINTS AND SECTIONS FOR TRUSS ANALYSISDocument67 pagesMETHOD OF JOINTS AND SECTIONS FOR TRUSS ANALYSISDianne VillanuevaNo ratings yet

- Practice Problems - Strema Part 1Document4 pagesPractice Problems - Strema Part 1Meverlyn RoqueroNo ratings yet

- Engineering Mechanics DynamicsDocument2 pagesEngineering Mechanics DynamicsMallene EhurangoNo ratings yet

- Ejercicios TimothyDocument32 pagesEjercicios TimothyvanessaNo ratings yet

- Civil Engineering November 2020 Review Innovations Hydraulics ProblemsDocument1 pageCivil Engineering November 2020 Review Innovations Hydraulics ProblemsJustine Ejay MoscosaNo ratings yet

- CE Board Nov 2020 Strength of Materials Set 1Document2 pagesCE Board Nov 2020 Strength of Materials Set 1Eugenio Genesis AbadNo ratings yet

- TENSION MEMBERS STRENGTHDocument10 pagesTENSION MEMBERS STRENGTHRi MarkuNo ratings yet

- Quiz No 1Document2 pagesQuiz No 1Tris ZackNo ratings yet

- Homework 1 3Document6 pagesHomework 1 3inisdeprawn100% (2)

- Chapter 5 - Setting Out (In Progress)Document42 pagesChapter 5 - Setting Out (In Progress)aminNo ratings yet

- Head Losses LectureDocument1 pageHead Losses Lecturebang sieNo ratings yet

- MASTERY TEST SOLUTIONSDocument6 pagesMASTERY TEST SOLUTIONSU-line Anne Roque VillafloresNo ratings yet

- Approximate Analysis of Statically Indeterminate StructuresDocument36 pagesApproximate Analysis of Statically Indeterminate StructuresRommel BaesaNo ratings yet

- RCD-Lecture 6-Shear DesignDocument94 pagesRCD-Lecture 6-Shear DesignHassan AhmedNo ratings yet

- Shear ReinforcementDocument7 pagesShear ReinforcementJohn Saniel J. EstacionNo ratings yet

- REVIEW INNOVATIONS CE BOARD EXAMDocument3 pagesREVIEW INNOVATIONS CE BOARD EXAMKian Inductivo100% (1)

- PROBLEM 2.124: SolutionDocument14 pagesPROBLEM 2.124: SolutionCharbel Abou KhalilNo ratings yet

- November 2023 - PSAD 1Document2 pagesNovember 2023 - PSAD 1Viele Antonette NaranjoNo ratings yet

- Refresher (Probability Discussion)Document33 pagesRefresher (Probability Discussion)sadonNo ratings yet

- CS Apr22Document8 pagesCS Apr22John Taylor BernasNo ratings yet

- CIVIL ENGINEERING BOARD EXAMDocument7 pagesCIVIL ENGINEERING BOARD EXAMConan EdogawaNo ratings yet

- 1thermal Stresses - 16 Maret 2021Document10 pages1thermal Stresses - 16 Maret 2021Ginanjar Hadi SukmaNo ratings yet

- CE Board Nov 2020 Engineering Mechanics Set 1Document3 pagesCE Board Nov 2020 Engineering Mechanics Set 1Eugenio Genesis AbadNo ratings yet

- STR ModuleDocument10 pagesSTR ModuleViamae Avellana CabutajeNo ratings yet

- QUIZ ASSIGNMENT NO. 1 Dynamic of Rigid Bodies Answer KeyDocument15 pagesQUIZ ASSIGNMENT NO. 1 Dynamic of Rigid Bodies Answer KeyAicelleNo ratings yet

- Strain and Stress-Strain DiagramDocument12 pagesStrain and Stress-Strain DiagramChristine Mae TinapayNo ratings yet

- Chapter Three. 3.0 Shaft DesignDocument3 pagesChapter Three. 3.0 Shaft Designpkopus cosmas kotongNo ratings yet

- EMM213 Strength of Materials Torsion: Dr. Norwahida YusoffDocument25 pagesEMM213 Strength of Materials Torsion: Dr. Norwahida YusoffNorwahida YusoffNo ratings yet

- Lecture 6 - Torsion - 2015Document38 pagesLecture 6 - Torsion - 2015imranjamiNo ratings yet

- Shape Memory Alloy Actuators: Design, Fabrication, and Experimental EvaluationFrom EverandShape Memory Alloy Actuators: Design, Fabrication, and Experimental EvaluationNo ratings yet

- CHAPTER 5 (Part3 RSA) PDFDocument88 pagesCHAPTER 5 (Part3 RSA) PDFVictoria JungNo ratings yet

- Traffic Studies Techniques for Measuring Speeds and DelaysDocument28 pagesTraffic Studies Techniques for Measuring Speeds and Delaysumarabaziz17No ratings yet

- Lesson 34 Input DevicesDocument33 pagesLesson 34 Input DevicesVictoria JungNo ratings yet

- Sand ReplacementDocument14 pagesSand ReplacementMuniey Aziz75% (8)

- Celebrity Worship SyndromeDocument21 pagesCelebrity Worship SyndromeVictoria JungNo ratings yet

- Sieve analysis soil sample Sonoma ranchDocument8 pagesSieve analysis soil sample Sonoma ranchr6Yamaha100% (5)

- CD 6 L91 - L110Document61 pagesCD 6 L91 - L110Victoria JungNo ratings yet

- Chapter 1 New.a1 PDFDocument33 pagesChapter 1 New.a1 PDFvinoNo ratings yet

- Hydraulics Topic 6 Hydraulic Machinery PDFDocument48 pagesHydraulics Topic 6 Hydraulic Machinery PDFVictoria JungNo ratings yet

- CD 5 L67 - L90Document48 pagesCD 5 L67 - L90Victoria JungNo ratings yet

- To Information and Communication TechnologyDocument39 pagesTo Information and Communication TechnologyJanus Cesar Ruizan QuilenderinoNo ratings yet

- CD 2 L16 - L33Document43 pagesCD 2 L16 - L33Victoria JungNo ratings yet

- Deformation of Statically Determinate StructuresDocument25 pagesDeformation of Statically Determinate StructuresVictoria JungNo ratings yet

- Test Title Core CutterDocument8 pagesTest Title Core Cutteraniem_beeNo ratings yet

- Sieve AnalysisDocument14 pagesSieve Analysisneutron_8797% (38)

- Case Study of The Changi East Land Reclamation Project SingaporeDocument13 pagesCase Study of The Changi East Land Reclamation Project SingaporeVictoria JungNo ratings yet

- Sieve analysis soil sample Sonoma ranchDocument8 pagesSieve analysis soil sample Sonoma ranchr6Yamaha100% (5)

- Design of Steel BeamsDocument25 pagesDesign of Steel Beamsronaldnyirenda2230No ratings yet

- Chapter 7Document29 pagesChapter 7Victoria Jung100% (3)

- 2.0 IntroductionDocument11 pages2.0 IntroductionVictoria JungNo ratings yet

- Thesis Writing Guide PDFDocument68 pagesThesis Writing Guide PDFVictoria JungNo ratings yet

- Soil Shear Strength FundamentalsDocument71 pagesSoil Shear Strength FundamentalsVictoria Jung100% (1)

- Laboratory 4 Rock Slope Stability PDFDocument14 pagesLaboratory 4 Rock Slope Stability PDFVictoria JungNo ratings yet

- BFC21103 Project SemII 20152016Document9 pagesBFC21103 Project SemII 20152016Victoria JungNo ratings yet

- Jurnal Teknologi: Kajian Terhadap Penggunaan IBS Dalam Projek Swasta Di Kawasan Lembah KlangDocument7 pagesJurnal Teknologi: Kajian Terhadap Penggunaan IBS Dalam Projek Swasta Di Kawasan Lembah KlangVictoria JungNo ratings yet

- Case Study of The Changi East Land Reclamation Project SingaporeDocument13 pagesCase Study of The Changi East Land Reclamation Project SingaporeVictoria JungNo ratings yet

- Beams: Bending StressDocument0 pagesBeams: Bending StressArifsalimNo ratings yet

- Chapter 3Document30 pagesChapter 3Victoria JungNo ratings yet

- Case Study of The Changi East Land Reclamation Project SingaporeDocument13 pagesCase Study of The Changi East Land Reclamation Project SingaporeVictoria JungNo ratings yet

- Edoc - Pub - Canrig Top Drive Model 1275 Ac PDFDocument4 pagesEdoc - Pub - Canrig Top Drive Model 1275 Ac PDFlilianaNo ratings yet

- Coursework 1 - 2011Document3 pagesCoursework 1 - 2011James Cavan14% (7)

- EM Digital NotesDocument112 pagesEM Digital NotesSai SaiNo ratings yet

- ClutchDocument3 pagesClutchEjNo ratings yet

- Disturbance Compensation For Gun Control System of Tank Based On LADRC (289KB)Document4 pagesDisturbance Compensation For Gun Control System of Tank Based On LADRC (289KB)Suresh SNo ratings yet

- EJ Overhanging - Monorails 3rd - Q 1985 Tanner PDFDocument6 pagesEJ Overhanging - Monorails 3rd - Q 1985 Tanner PDFNavneet Rai100% (1)

- Section 27 - Ranarex GravitometerDocument48 pagesSection 27 - Ranarex GravitometeriqmpslabNo ratings yet

- RV N e PDFDocument60 pagesRV N e PDFdavev2005No ratings yet

- MAGNETISM PART I SUBJECTIVE QUESTIONS ON MAGNETS AND MAGNETIC FIELDSDocument15 pagesMAGNETISM PART I SUBJECTIVE QUESTIONS ON MAGNETS AND MAGNETIC FIELDSJatin SonwalNo ratings yet

- Hsslive-physics-Plus One Chapter7Document24 pagesHsslive-physics-Plus One Chapter7Aditi KrishnamurthyNo ratings yet

- Encorder SCM70Document20 pagesEncorder SCM70MakNo ratings yet

- Mechanics - Benjamin CrowellDocument515 pagesMechanics - Benjamin CrowellalpcruzNo ratings yet

- Design and Development of Box Shifting Mechanism Using Gearless Power Transmission SystemDocument4 pagesDesign and Development of Box Shifting Mechanism Using Gearless Power Transmission SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- MIT6 013S09 Chap06Document35 pagesMIT6 013S09 Chap06Jasmien HassanienNo ratings yet

- Isoflex GearGuardDocument32 pagesIsoflex GearGuardmehme48No ratings yet

- Parameters and Signals ReportDocument10 pagesParameters and Signals ReportLalit Prakash100% (1)

- 10079-CV-LA-001-00 Tank Level Gauges (Revision 00)Document96 pages10079-CV-LA-001-00 Tank Level Gauges (Revision 00)Kunal Jhingan100% (3)

- Using Special Functions on Scania VehiclesDocument24 pagesUsing Special Functions on Scania VehiclesRegistr Registr100% (6)

- Parallel Forces Course Learning Outcome:: MODULE OF INSTRUCTIONDocument6 pagesParallel Forces Course Learning Outcome:: MODULE OF INSTRUCTIONYoo JungNo ratings yet

- UNITI Motor Selection Automated Car JackDocument8 pagesUNITI Motor Selection Automated Car JackJamal Yusof0% (1)

- CH18Document91 pagesCH18FernandaNo ratings yet

- Physics XI: Rotational MotionDocument14 pagesPhysics XI: Rotational MotionSarvesh DubeyNo ratings yet

- Puc Ii PCMB Board Question Bank PDFDocument439 pagesPuc Ii PCMB Board Question Bank PDFkatti1084154100% (3)

- AN044 Robotic ArmDocument9 pagesAN044 Robotic Armhussien amare100% (1)

- Tekton ManualDocument4 pagesTekton ManualJosueNo ratings yet

- Diagnostico Parte 1 MalibuDocument161 pagesDiagnostico Parte 1 MalibuHugo Armando Escamilla LozanoNo ratings yet

- Phy022 PS1 PDFDocument7 pagesPhy022 PS1 PDFHaron BusranNo ratings yet

- Rotation Motion WorksheetDocument6 pagesRotation Motion WorksheetdaisyNo ratings yet

- CSS Physics Past Papers 2014-2023Document27 pagesCSS Physics Past Papers 2014-2023Ubaid khokharNo ratings yet