Professional Documents

Culture Documents

Geo Tech Term Symbols

Uploaded by

jasminetsoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Geo Tech Term Symbols

Uploaded by

jasminetsoCopyright:

Available Formats

Guideline

Geotechnical Terms and Symbols

October 2014

Copyright

http://creativecommons.org/licenses/by/3.0/au/

State of Queensland (Department of Transport and Main Roads) 2014

Feedback: Please send your feedback regarding this document to: mr.techdocs@tmr.qld.gov.au

Guideline, Transport and Main Roads, October 2014

Geotechnical Terms and Symbols

The following information is intended to assist in the interpretation of terms and symbols used in geotechnical

borehole logs, test pit logs and reports issued by or for the Queensland Department of Transport and Main

Roads (TMR). More detailed information relating to specific test methods is available in the TMR Materials

Testing Manual (MTM) and the relevant Australian Standards.

Soil Descriptions

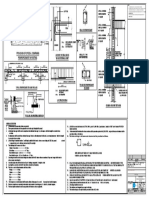

Description and Classification of Soils for Geotechnical Purposes: Refer to AS1726-1993 (Appendix A).

The following chart (adapted from AS1726-1993, Appendix A, Table A1) is based on the Unified Soil Classification System (USCS).

USCS

Particle

Major Divisions Group Typical Names Laboratory Classification

size mm

Symbol

% < 0.075 mm Plasticity of D

Cu = 6 0 C c =

(D30 ) 2

D10

NOTES

BOULDERS (2) fine fraction ( D10 )( D60 )

__________ ____200

(more than half of material less than 63 mm is larger than 0.075 mm)

COBBLES

__________ _____63 Well graded gravels and

Between

GW gravel-sand mixtures, little or 0-5 __ >4 (1) Identify fines by

1 and 3

no fines the method given

Poorly graded gravels and Use the gradation curve of material passing 63 mm for classification of fractions according to the criteria given in 'Major Divisions' for fine-grained

Fails to comply with soils.

GRAVELS coarse GP gravel-sand mixtures, little or 0-5 __

COARSE GRAINED SOILS

above

no fines, uniform gravels

(more than _____20

half of Silty gravels, gravel-sand-silt 12-50 Below 'A'

GM __ __

coarse medium mixtures (1) line or PI<4

fraction is

______6 Above 'A'

larger than Clayey gravels, gravel-sand-

fine GC 12-50 line and __ __

2.36 mm) clay mixtures (1)

PI>7 (2) Borderline

___2.36 classifications

Well graded sands and occur when the

__________ Between

SW gravelly sands, little or no 0-5 __ >6 percentage of

SANDS 1 and 3

fines fines (fraction

(more than coarse

Poorly graded sands and smaller than

half of ____0.6 Fails to comply with 0.075 mm size)

SP gravelly sands, little or no 0-5 __

coarse above is greater than

fines

fraction is 5% and less

medium

smaller than Silty sands, sand silt 12-50 Below 'A' __ __ than 12%.

____0.2 SM

2.36 mm) mixtures (1) line or PI<4 Borderline

fine classifications

Above 'A' require the use

0.075 Clayey sands, sand-clay

SC 12-50 line and __ __ of SP-SM, GW-

mixtures (1)

PI>7 GC.

(more than half of material less than 63 mm is smaller than 0.075 mm

Inorganic silts, very fine

sands, rock flour, silty or

ML

clayey fine sands or clayey

silts with slight plasticity

SILTS & CLAYS Inorganic clays of low to

(Liquid Limit 50%) CL medium plasticity, gravelly

CI clays, sandy clays, silty

clays, lean clays

FINE GRAINED SOILS

Organic silts and clays of

OL

low plasticity

Inorganic silts, mic- aceous

MH or diato-maceous fine sands

or silts, elastic silts

SILTS & CLAYS

Inorganic clays of high

(Liquid Limit >50%) CH

plasticity, fat clays

Organic silts and clays of

OH

high plasticity

HIGHLY ORGANIC Peat and other highly

PT

SOILS organic soils

Guideline, Transport and Main Roads, October 2014 1

Geotechnical Terms and Symbols

Soil Colour: Is described in the moist condition using black, white, grey, red, brown, orange, yellow, green or blue. Borderline cases can be

described as a combination of two colours, with the weaker followed by the stronger. Modifiers such as pale, dark or mottled, can be used

as necessary. Where colour consists of a primary colour with secondary mottling, it should be described as follows:

(Primary) mottled (Secondary). Refer to AS 1726-1993, A2.4 and A3.3.

Soil Moisture Condition: Is based on the appearance and feel of soil. Refer to AS 1726-1993, A2.5.

Term Description

Cohesive soils; hard and friable or powdery, well dry of plastic limit.

Dry

Granular soils; cohesionless and free-running.

Soil feels cool, darkened in colour.

Moist Cohesive soils can be moulded.

Granular soils tend to cohere.

Soil feels cool, darkened in colour.

Wet Cohesive soils usually weakened and free water forms on hands when handling.

Granular soils tend to cohere and free water forms on hands when handling.

Consistency of Cohesive Soils: May be estimated using simple field tests, or described in terms of a strength scale. In the field, the

undrained shear strength (su) can be assessed using a simple field tool appropriate for cohesive soils, in conjunction with the relevant

calibration. Refer to AS 1726-1993, Table A4.

Consistency - Essentially Cohesive Soils Soil Particle Sizes

SPT Undrained Unconfined

N Shear Compressive

Term Field Guide Symbol Strength Term Size Range

Value Strength

su (kPa) qu (kPa)

Oozes between fingers BOULDERS >200 mm

Very soft VS 0-2 <12 <25

when squeezed in hand. COBBLES 63-200 mm

Easily moulded with Coarse GRAVEL 20-63 mm

Soft S 2-4 12-25 25-50

fingers. Medium GRAVEL 6-20 mm

Can be moulded by Fine GRAVEL 2.36-6 mm

Firm strong pressure of F 4-8 25-50 50-100 Coarse SAND 0.6-2.36 mm

fingers.

Medium SAND 0.2-0.6 mm

Stiff St 8-15 50-100 100-200 Fine SAND 0.075-0.2 mm

Not possible to mould

Very stiff VSt 15-30 100-200 200-400 SILT 0.002-0.075 mm

with fingers.

CLAY <0.002 mm

Can be indented with

Hard H >30 >200 >400

difficulty by thumb nail.

Note: SPT - N to qu correlation from Terzaghi and Peck, 1967. (General guide only).

Consistency of Non-Cohesive Soils: Is described in terms of the density index, as defined in AS 1289.0-2000. This can be assessed using a field

tool appropriate for non-cohesive soils, in conjunction with the relevant calibration. Refer to AS 1726-1993, Table A5; BS5930-1999, p117.

Consistency - Essentially Non-Cohesive Soils

Term Symbol SPT N Value Field Guide Density Index (%)

Very loose VL 0-4 Foot imprints readily 0-15

Loose L 4-10 Shovels Easily 15-35

Medium dense MD 10-30 Shovelling difficult 35-65

Dense D 30-50 Pick required 65-85

Very dense VD >50 Picking difficult 85-100

Standard Penetration Test (SPT): Refer to. AS 1289.6.3.1-2004. Example report formats for SPT results are shown below:

Test Report Penetration Resistance (N) Explanation / Comment

4, 7, 11 N=18 Full penetration; N is reported on engineering borehole log

18, 27, 32 N=59 Full penetration; N is reported on engineering borehole log

4, 18, 30/15 mm N is not reported 30 blows causes less than 100 mm penetration (3rd interval) test discontinued

30/80 mm N is not reported 30 blows causes less than 100 mm penetration (1st interval) test discontinued

rw N<1 Rod weight only causes full penetration

hw N<1 Hammer and rod weight only causes full penetration

hb N is not reported Hammer bouncing for 5 consecutive blows with no measurable penetration test

discontinued

Guideline, Transport and Main Roads, October 2014 2

Geotechnical Terms and Symbols

Rock Descriptions

Refer to AS 1726-1993 (Appendix A3.3) for the description and classification of rock material composition, including:

(a) Rock type (Table A6, (a) and (b))

(b) Grain size

(c) Texture and fabric

(d) Colour (describe as per soil).

The condition of a rock material refers to its weathering characteristics, strength characteristics and rock mass properties. Refer to AS 1726-

1993 (Appendix A3 Tables A8, A9 and A10).

Weathering Condition (Degree of Weathering):

The degree of weathering is a continuum from fresh rock to soil. Boundaries between weathering grades may be abrupt or gradational.

Rock Material Weathering Classification

Weathering Grade Symbol Definition

Soil-like material developed on extremely weathered rock; the mass structure and substance fabric

Residual Soil RS are no longer evident; there is a large change in volume but the material has not been significantly

transported.

Extremely Weathered Rock is weathered to such an extent that it has 'soil' properties, i.e. it either disintegrates or can be

XW

Rock remoulded in water, but substance fabric and rock structure still recognisable.

Strong discolouration is evident throughout the rock mass, often with significant change in the

Highly Weathered Rock HW

constituent minerals. The intact rock strength is generally much weaker than that of the fresh rock.

Moderately Weathered Modest discolouration is evident throughout the rock fabric, often with some change in the constituent

MW

Rock minerals. The intact rock strength is usually noticeably weaker than that of the fresh rock.

Slightly Weathered Rock SW Rock is slightly discoloured but shows little or no change of strength from fresh rock.

Fresh Rock FR Rock shows no sign of decomposition or staining.

Notes:

1. Minor variations within broader weathering grade zones will be noted on the engineering borehole logs.

2. Extremely weathered rock is described in terms of soil engineering properties.

3. Weathering may be pervasive throughout the rock mass, or may penetrate inwards from discontinuities to some extent.

4. The Distinctly Weathered (DW) class as defined in AS 1726-1993 is divided to incorporate HW and MW in the above table. The symbol DW

should not be used.

Strength Condition (Intact Rock Strength):

Strength of Rock Material

(Based on Point Load Strength Index, corrected to 50 mm diameter Is(50). Field guide used if no tests available. Refer to AS 4133.4.1-2007.

Point Load

Term Symbol Index (MPa) Field Guide to Strength

Is(50)

Extremely Low EL 0.03 Easily remoulded by hand to a material with soil properties.

Material crumbles under firm blows with sharp end of pick; can be peeled with knife;

Very Low VL >0.03 0.1 too hard to cut a triaxial sample by hand. Pieces up to 3 cm thick can be broken by

finger pressure.

Easily scored with a knife; indentations 1 mm to 3 mm show in the specimen with firm

blows of the pick point; has dull sound under hammer. A piece of core 150 mm long

Low L >0.1 0.3

by 50 mm diameter may be broken by hand. Sharp edges of core may be friable and

break during handling.

Readily scored with a knife; a piece of core 150 mm long by 50 mm diameter can be

Medium M >0.3 1.0

broken by hand with difficulty.

A piece of core 150 mm long by 50 mm diameter cannot be broken by hand but can

High H >1 3

be broken by a pick with a single firm blow; rock rings under hammer.

Very High VH >3 10 Hand specimen breaks with pick after more than one blow; rock rings under hammer.

Specimen requires many blows with geological pick to break through intact material;

Extremely High EH >10

rock rings under hammer.

Notes:

1. These terms refer to the strength of the rock material and not to the strength of the rock mass which may be considerably weaker due to the

effect of rock defects.

2. Anisotropy of rock material samples may affect the field assessment of strength.

Guideline, Transport and Main Roads, October 2014 3

Geotechnical Terms and Symbols

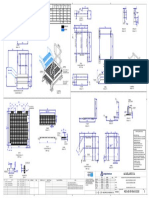

Discontinuity Description: Refer to AS 1726-1993, Table A10.

Anisotropic Fabric Roughness (e.g. Planar, Smooth is abbreviated Pl / Sm) Class Other

BED Bedding Rough or irregular (Ro) I Cly Clay

FOL Foliation Stepped (Stp) Smooth (Sm) II Fe Iron

LIN Mineral lineation Slickensided (Sl) III Co Coal

Defect Type Rough (Ro) IV Carb Carbonaceous

LP Lamination Parting Undulating (Un) Smooth (Sm) V Sinf Soil Infill Zone

BP Bedding Parting Slickensided (Sl) VI Qz Quartz

FP Cleavage / Foliation Parting Rough (Ro) VII CA Calcite

J, Js Joint, Joints Planar (Pl) Smooth (Sm) VIII Chl Chlorite

SZ Sheared Zone Slickensided (Sl) IX Py Pyrite

CZ Crushed Zone Aperture Infilling Int Intersecting

BZ Broken Zone Closed CD No visible coating or infill Clean Cn Inc Incipient

HFZ Highly Fractured Zone Open OP Surfaces discoloured by mineral/s Stain St DI Drilling Induced

AZ Alteration Zone Filled FL Visible mineral or soil infill <1mm Veneer Vr H Horizontal

VN Vein Tight TI Visible mineral or soil infill >1mm Coating Ct V Vertical

Note: Describe Zones and Coatings in terms of composition and thickness (mm).

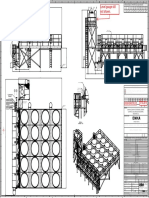

Discontinuity Spacing: On the geotechnical borehole log, a graphical representation of defect spacing vs depth is shown. This representation

takes into account all the natural rock defects occurring within a given depth interval, excluding breaks induced by the drilling / handling of core.

Refer to AS 1726-1993, BS5930-1999.

Bedding Thickness

Defect Spacing Defect Spacing in 3D

(Sedimentary Rock Stratification)

Spacing/Width Spacing/Width

Descriptor Symbol Descriptor Term Description

(mm) (mm)

Thinly Laminated <6 Blocky Equidimensional

Extremely Thickness much less than

<20 EC Thickly Laminated 6 20 Tabular

Close length or width

Height much greater than

20 60 Very Close VC Very Thinly Bedded 20 60 Columnar

cross section

60 200 Close C Thinly Bedded 60 200

200 600 Medium M Medium Bedded 200 600 Defect Persistence

600 2000 Wide W Thickly Bedded 600 2000 (areal extent)

2000 6000 Very Wide VW Very Thickly Bedded > 2000

Trace length of defect given in metres

>6000 Extremely Wide EW

Symbols

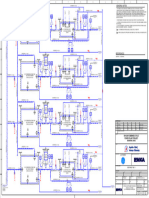

The list below provides an explanation of terms and symbols used on the geotechnical borehole, test pit and penetrometer logs.

Test Results Test Symbols

PI Plasticity Index c Effective Cohesion DCP Dynamic Cone Penetrometer

LL Liquid Limit cu Undrained Cohesion SPT Standard Penetration Test

LI Liquidity Index cR Residual Cohesion CPTu Cone Penetrometer (Piezocone) Test

DD Dry Density Effective Angle of Internal Friction PANDA Variable Energy DCP

WD Wet Density u Undrained Angle of Internal Friction PP Pocket Penetrometer Test

Undisturbed Sample 50 mm (nominal

LS Linear Shrinkage R Residual Angle of Internal Friction U50

diameter)

Undisturbed Sample 100mm

MC Moisture Content cv Coefficient of Consolidation U100

(nominal diameter)

OC Organic Content mv Coefficient of Volume Compressibility UCS Uniaxial Compressive Strength

Coefficient of Secondary

WPI Weighted Plasticity Index c Pm Pressuremeter

Compression

Guideline, Transport and Main Roads, October 2014 4

Geotechnical Terms and Symbols

Test Results Test Symbols

Weighted Linear

WLS e Voids Ratio FSV Field Shear Vane

Shrinkage

DoS Degree of Saturation cv Constant Volume Friction Angle DST Direct Shear Test

Piezocone Tip Resistance

APD Apparent Particle Density qt / qc PR Penetration Rate

(corrected / uncorrected)

su Undrained Shear Strength qd PANDA Cone Resistance A Point Load Test (axial)

Unconfined Compressive

qu Is(50) Point Load Strength Index D Point Load Test (diametral)

Strength

R Total Core Recovery RQD Rock Quality Designation L Point Load Test (irregular lump)

Groundwater level on the date shown Water Inflow Water Outflow

28/11/13

Guideline, Transport and Main Roads, October 2014 5

You might also like

- The Techniques of Sedimentary MineralogyDocument231 pagesThe Techniques of Sedimentary MineralogyarkoesteaNo ratings yet

- Kurdistan GeologyDocument174 pagesKurdistan Geologygeorgesoden100% (1)

- Manitou Telehandler MTL 634-1030 Repair Manual - 647412Document438 pagesManitou Telehandler MTL 634-1030 Repair Manual - 647412Dariusz D86% (7)

- Middle Primary Division Competition Paper: ThursdayDocument10 pagesMiddle Primary Division Competition Paper: ThursdayOlga Rudenko BradfordNo ratings yet

- GCSE Rivers River Landforms FormationDocument48 pagesGCSE Rivers River Landforms FormationWill TeeceNo ratings yet

- 1720069M 6013Document1 page1720069M 6013GHULAM NABINo ratings yet

- International Standard: Risk Management - GuidelinesDocument24 pagesInternational Standard: Risk Management - Guidelinesjasminetso100% (14)

- Example 1 - Geotechnical Data ReportDocument63 pagesExample 1 - Geotechnical Data ReportValar MorghulisNo ratings yet

- Correction TD 1 Identification Des Sols, CHEBAP 2009 2010Document15 pagesCorrection TD 1 Identification Des Sols, CHEBAP 2009 2010AcadAcad100% (9)

- JAM003MQN400 pulley specificationsDocument1 pageJAM003MQN400 pulley specificationsSebastian Davila hernandezNo ratings yet

- MB Schematics Xt2053 Moto E6sDocument21 pagesMB Schematics Xt2053 Moto E6sAxel Vazquez100% (1)

- The Next Normal in ConstructionDocument90 pagesThe Next Normal in ConstructionRodrigo Giorgi100% (1)

- Construction Equipment Product Range and SpecsDocument2 pagesConstruction Equipment Product Range and Specsjose luis juarezNo ratings yet

- Shalow Lady Gaga Guit 1Document5 pagesShalow Lady Gaga Guit 1ITALO MOLINARINo ratings yet

- BIM International Edition 2020Document36 pagesBIM International Edition 2020Edward C100% (1)

- NEC Collaboration CLLB Ti: Practice NotesDocument122 pagesNEC Collaboration CLLB Ti: Practice NotesCT0011No ratings yet

- Example Research ProposalDocument8 pagesExample Research ProposalMarco BarretoNo ratings yet

- Weld MapDocument3 pagesWeld Mapeffiezool mohdNo ratings yet

- USCSDocument1 pageUSCSAnggi RahimNo ratings yet

- Power Tools - Montly HSE Inspection ChecklistDocument2 pagesPower Tools - Montly HSE Inspection ChecklistAbdus SamadNo ratings yet

- Jam003mqn400 407Document1 pageJam003mqn400 407Sebastian Davila hernandezNo ratings yet

- Manual DT50-P2113Document2 pagesManual DT50-P2113Alexandre FerreiraNo ratings yet

- Design Codes & Standarts & Specifications: Plan ViewDocument1 pageDesign Codes & Standarts & Specifications: Plan ViewIonut FloricaNo ratings yet

- Provision of Special Confining Reinforcement in FootingDocument1 pageProvision of Special Confining Reinforcement in FootingSS INFRAZONENo ratings yet

- Usb Type BDocument6 pagesUsb Type Bbg632707No ratings yet

- Micro Mist Separator - 70APAMDDocument7 pagesMicro Mist Separator - 70APAMDAdrianus AjaNo ratings yet

- 0120 CSS Subsea Diver Installed ConnectorsDocument2 pages0120 CSS Subsea Diver Installed ConnectorsThamer KhatibNo ratings yet

- Module 1 AssessmentDocument4 pagesModule 1 AssessmentSheela AliNo ratings yet

- Terminal Block LegrandDocument1 pageTerminal Block LegrandRava OshopNo ratings yet

- Assessment Packages Electrician Level IIDocument22 pagesAssessment Packages Electrician Level IISheela AliNo ratings yet

- SPC 1.05Document1 pageSPC 1.05MahendraNo ratings yet

- A: Bracket: Supported Types (0.2uf) M3-S-3kV P3-S-3kV M3-S-4.16kV P3-S-4.16kV M3-S-6kV P3-S-6kV M3-S-7.2kV P3-S-7.2kVDocument1 pageA: Bracket: Supported Types (0.2uf) M3-S-3kV P3-S-3kV M3-S-4.16kV P3-S-4.16kV M3-S-6kV P3-S-6kV M3-S-7.2kV P3-S-7.2kVnisarbashaNo ratings yet

- Cube Register LogDocument1 pageCube Register LogNickNo ratings yet

- D11493530aa PDFDocument1 pageD11493530aa PDFGaurav VashishtNo ratings yet

- Varifuel2 300-190 30.45.300-190D: Technical Reference Material Created by DateDocument1 pageVarifuel2 300-190 30.45.300-190D: Technical Reference Material Created by DateRIGOBERTO LOZANO MOLINANo ratings yet

- Primary Side View: Rim Confidential B Printed Wiring Board Javelin W/ GND StitchingDocument2 pagesPrimary Side View: Rim Confidential B Printed Wiring Board Javelin W/ GND StitchingRoger ValderramaNo ratings yet

- IQ347-000-V1A-MEA0-00001 - Code 2Document1 pageIQ347-000-V1A-MEA0-00001 - Code 2arasNo ratings yet

- DB 000 13302 0301 001 01 Member List For Module Steel StructureDocument1 pageDB 000 13302 0301 001 01 Member List For Module Steel StructurekohilanrkNo ratings yet

- Clapton's Nobody Know When You're Down and OutDocument1 pageClapton's Nobody Know When You're Down and OutMarianoNajeraNo ratings yet

- MVH 1:50 16.10.2012 16.10.2012 11173.1 KG: ACCORDING TO SYSTEM 159/000-DET-Q1-013Document1 pageMVH 1:50 16.10.2012 16.10.2012 11173.1 KG: ACCORDING TO SYSTEM 159/000-DET-Q1-013Yahya AteeniNo ratings yet

- Laser sensor specifications and dimensionsDocument4 pagesLaser sensor specifications and dimensionsAlejandro PortilloNo ratings yet

- MNF. Name PlateDocument2 pagesMNF. Name PlateSuper 7No ratings yet

- Model Papers For 2nd Year AutoDocument40 pagesModel Papers For 2nd Year AutoOmar Rashdi83% (6)

- Dicoat Punches: Products DataDocument1 pageDicoat Punches: Products Dataluis ortaNo ratings yet

- Rev. Change Description Date Drawn: Notes 1. MUST MEET DELTA SPEC. 10000-0162 2. Eltek P/N: N/A 3. Eltek Doc No. N/ADocument4 pagesRev. Change Description Date Drawn: Notes 1. MUST MEET DELTA SPEC. 10000-0162 2. Eltek P/N: N/A 3. Eltek Doc No. N/AIsac ClaroNo ratings yet

- ITC One Colombo Sheet Notes and LegendDocument1 pageITC One Colombo Sheet Notes and LegendAfthal AhamedNo ratings yet

- LaneDocument3 pagesLaneVanessa Gotta VergaraNo ratings yet

- DICS6100 PDocument2 pagesDICS6100 PИван ПарлапановNo ratings yet

- Miniature steam engine designDocument1 pageMiniature steam engine designQTG channelNo ratings yet

- Planta - Ixachi 12 - ProyDocument1 pagePlanta - Ixachi 12 - ProyJuan Rodriguez GleNo ratings yet

- IBE (Luminaria)Document5 pagesIBE (Luminaria)Jose CachonNo ratings yet

- Neralized WaterDocument1 pageNeralized Watermohamed abourayaNo ratings yet

- Tank Datasheet - CS-8000KL - RADocument1 pageTank Datasheet - CS-8000KL - RASumantrra ChattopadhyayNo ratings yet

- Schematic Diagram of Relay & Tcms Panel T: REV Revised by Checked by Approved byDocument1 pageSchematic Diagram of Relay & Tcms Panel T: REV Revised by Checked by Approved byTaufiq HidayatNo ratings yet

- Crankshaft RodDocument1 pageCrankshaft Rodmavas88069No ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- WD Drawing 3.01 & 3.02 BA19ARC005Document2 pagesWD Drawing 3.01 & 3.02 BA19ARC005BA19ARC009 Deepali BhatiaNo ratings yet

- Web 2.0 Weekly First Quarter Deal Value Down, Volume Stable: David Shore, CFA, MBA 416.860.6784Document24 pagesWeb 2.0 Weekly First Quarter Deal Value Down, Volume Stable: David Shore, CFA, MBA 416.860.6784David ShoreNo ratings yet

- Tugas 1 Cs SoketDocument1 pageTugas 1 Cs Soketilham dwi putraNo ratings yet

- MQ13 600 DR 5840 SS3282Document1 pageMQ13 600 DR 5840 SS3282David Borja HuarachiNo ratings yet

- D3K, D4K and D5K Electrical System Track-Type Tractor: Operator Console Wiring Erops Console WiringDocument6 pagesD3K, D4K and D5K Electrical System Track-Type Tractor: Operator Console Wiring Erops Console Wiringjulio peña limaNo ratings yet

- Sectiune 1-1: SCARA 1:50Document1 pageSectiune 1-1: SCARA 1:50George EnacheNo ratings yet

- High Torque Timing Belts GuideDocument6 pagesHigh Torque Timing Belts GuideCủa Tôi Thần TuợngNo ratings yet

- Proj Est Intercarta r0 04Document1 pageProj Est Intercarta r0 04joseNo ratings yet

- Detail-D RCC Cladding Wall CH-100+460-100+520: Produced by An Autodesk Student VersionDocument1 pageDetail-D RCC Cladding Wall CH-100+460-100+520: Produced by An Autodesk Student Versionrao shoaibNo ratings yet

- InputDocument3 pagesInputSugeng Hadi SusiloNo ratings yet

- DIN ISO 276811 tolerance chartDocument5 pagesDIN ISO 276811 tolerance chartSugeng Hadi SusiloNo ratings yet

- 01 GasolineDocument9 pages01 GasolineYarin HernandezNo ratings yet

- Note For Finance CommitteeDocument8 pagesNote For Finance CommitteejasminetsoNo ratings yet

- Bs en Iso 1 1:2012 4064Document32 pagesBs en Iso 1 1:2012 4064jasminetsoNo ratings yet

- Graduate STEM Education For The 21st CenturyDocument203 pagesGraduate STEM Education For The 21st CenturyJuan PobleteNo ratings yet

- Inspect The BuildingDocument5 pagesInspect The BuildingjasminetsoNo ratings yet

- WorldGBC ANZ Status Report 2021 - FINALDocument25 pagesWorldGBC ANZ Status Report 2021 - FINALjasminetsoNo ratings yet

- The Ultimate Guide To Benchmarking Construction WorkflowsDocument13 pagesThe Ultimate Guide To Benchmarking Construction WorkflowsjasminetsoNo ratings yet

- Revised RODP 500x500Document1 pageRevised RODP 500x500jasminetsoNo ratings yet

- NEC Certificate PrinciplesDocument1 pageNEC Certificate PrinciplesjasminetsoNo ratings yet

- Sample Format of Grand Summary of The Activity Schedule / Bill of Quantities in NEC ECC ContractsDocument1 pageSample Format of Grand Summary of The Activity Schedule / Bill of Quantities in NEC ECC ContractsjasminetsoNo ratings yet

- NEC3 Delegate Handbook v2 - Sept2018Document39 pagesNEC3 Delegate Handbook v2 - Sept2018jasminetsoNo ratings yet

- RICS Hong Kong Mediator RegisterDocument3 pagesRICS Hong Kong Mediator RegisterjasminetsoNo ratings yet

- PHP Error opening fileDocument2 pagesPHP Error opening fileSofia VelásquezNo ratings yet

- Appendix To The General Conditions of Tender Correction Rules For Tender Errors (General Conditions of Tender Clause GCT 11)Document15 pagesAppendix To The General Conditions of Tender Correction Rules For Tender Errors (General Conditions of Tender Clause GCT 11)Jasmine TsoNo ratings yet

- 11 Sample Template of WI Preambles To Specifications V1.0 201610Document5 pages11 Sample Template of WI Preambles To Specifications V1.0 201610Bruce WongNo ratings yet

- 01 Nec Ecc PN V1.0 201610 PDFDocument120 pages01 Nec Ecc PN V1.0 201610 PDFghjtyu0% (1)

- Emp 1201Document12 pagesEmp 1201jasminetsoNo ratings yet

- ICNIRPemfgdl 1Document38 pagesICNIRPemfgdl 1lukiNo ratings yet

- 13 Sample Template For BQ Preambles V1!1!201703Document7 pages13 Sample Template For BQ Preambles V1!1!201703Jasmine TsoNo ratings yet

- Contract Clause "Hired and Hire-Purchase Constructional Plant". The Project Offices ShouldDocument17 pagesContract Clause "Hired and Hire-Purchase Constructional Plant". The Project Offices ShouldjasminetsoNo ratings yet

- CWDCS Web Basic 20210129Document1,050 pagesCWDCS Web Basic 20210129jasminetsoNo ratings yet

- CWDCS Web Basic 20210129Document1,050 pagesCWDCS Web Basic 20210129jasminetsoNo ratings yet

- Experiments with ElectrostaticsDocument1 pageExperiments with ElectrostaticsjasminetsoNo ratings yet

- Bim 2019Document4 pagesBim 2019jasminetso100% (1)

- Architecture Design Handbook - Fundamentals - Radio Frequency ShieldingDocument1 pageArchitecture Design Handbook - Fundamentals - Radio Frequency ShieldingjasminetsoNo ratings yet

- New Insight On The Stratigraphy of The Upper ThamamaDocument18 pagesNew Insight On The Stratigraphy of The Upper ThamamaAffan HasanNo ratings yet

- Assam StratigraphyDocument21 pagesAssam StratigraphyVijay Yadav100% (2)

- Soil Liquefaction ExplainedDocument21 pagesSoil Liquefaction ExplainedanpyaaNo ratings yet

- Geologic Evolution and Gas Resources of the Sabinas Basin in Northeastern MexicoDocument30 pagesGeologic Evolution and Gas Resources of the Sabinas Basin in Northeastern MexicoMoises HernandezNo ratings yet

- Chapter 4 StratigraphyDocument32 pagesChapter 4 StratigraphyahmadmuddassarNo ratings yet

- Dissertation Updated Nurul Izazi 21310Document79 pagesDissertation Updated Nurul Izazi 21310api-439638408No ratings yet

- Diagenesis ReferenceDocument7 pagesDiagenesis ReferenceNovia SetyaNo ratings yet

- sd103Document6 pagessd103Art Gil GranadaNo ratings yet

- LIMESTONE FACIES AND DIAGENESISDocument8 pagesLIMESTONE FACIES AND DIAGENESISarizalNo ratings yet

- Soil Science and Management 6th Edition Edward Plaster Test BankDocument7 pagesSoil Science and Management 6th Edition Edward Plaster Test BankDarla Lambe100% (35)

- Reineck y Sing Estructuras 01 PDFDocument130 pagesReineck y Sing Estructuras 01 PDFandmol5796No ratings yet

- DEPOSITS OF DEFLECTED.. TURBIDITES SORBAS BASIN - Haughton1994Document14 pagesDEPOSITS OF DEFLECTED.. TURBIDITES SORBAS BASIN - Haughton1994Miguel gonzálezNo ratings yet

- Genesa & Eksplorasi BB: Bagian 3 Penggambutan Sumber SAP ITBDocument15 pagesGenesa & Eksplorasi BB: Bagian 3 Penggambutan Sumber SAP ITBAndhiNo ratings yet

- Soils Investigation: Civil Engineering and ArchitectureDocument31 pagesSoils Investigation: Civil Engineering and ArchitectureRoman GonzalezNo ratings yet

- Influence of Aggradation and Degradation On River Channels: A ReviewDocument4 pagesInfluence of Aggradation and Degradation On River Channels: A ReviewerpublicationNo ratings yet

- 1 Kumar I Singh Khosla 2020Document19 pages1 Kumar I Singh Khosla 2020nomadNo ratings yet

- 3 & 4 Sedimentology NotesDocument14 pages3 & 4 Sedimentology NotesPerlievic TesoroNo ratings yet

- Soil Texture Soil ActivityDocument2 pagesSoil Texture Soil Activityapi-475616324No ratings yet

- Identify Sedimentary RocksDocument45 pagesIdentify Sedimentary RocksRomel PozoNo ratings yet

- Analisis Morfologi Dan Morfostruktur Serta Pengaruhnya Terhadap Banjir Luapan Sungai Bengawan Solo Hulu Tengah SDocument10 pagesAnalisis Morfologi Dan Morfostruktur Serta Pengaruhnya Terhadap Banjir Luapan Sungai Bengawan Solo Hulu Tengah SRafiq Eka PramdaniNo ratings yet

- The Indonesian Sedimentologists Forum (FOSI)Document46 pagesThe Indonesian Sedimentologists Forum (FOSI)Soeryawan Gilang100% (2)

- Breusers 1983Document111 pagesBreusers 1983tedy yidegNo ratings yet

- AprestRoadshow en PDFDocument138 pagesAprestRoadshow en PDFplyanaNo ratings yet

- Bodnar Torok Pollack Periodica 2014 1 17-18pDocument13 pagesBodnar Torok Pollack Periodica 2014 1 17-18pOthmane BoualamNo ratings yet

- Paleoseismicity of The Cascadia Subduction Zone: Evidence From Turbidites Off The Oregon-Washington MarginDocument15 pagesPaleoseismicity of The Cascadia Subduction Zone: Evidence From Turbidites Off The Oregon-Washington MarginMiguel GonzalezNo ratings yet