Professional Documents

Culture Documents

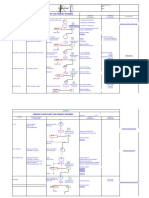

Audit Observation-BEFORE AFTER

Uploaded by

Priyanka Chaudhary0 ratings0% found this document useful (0 votes)

68 views4 pagesbefore after

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentbefore after

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

68 views4 pagesAudit Observation-BEFORE AFTER

Uploaded by

Priyanka Chaudharybefore after

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 4

Dataking Audit observation and correctiv

S.No. Obsevation Area

IQC inspection results found not recorded

1 properly, observed value mentioned as IQC

copy of specification.

Measuring Equipments(Vernier

2 Calliper,Micrometer) found not IQC

calibrated.

PVC(Tensile

Strength,Elongation,Hardness) measured

3 IQC

value mentioned as OK in place of

observed result.

4 FIFO not in system at W/H. W/H

No Identification of ACCEPT/REJECT

5 IQC

material

No separate area for IQC lot reject

6 IQC/WH

material

Reliability Test Report of each lot is not

7 IQC

available

Salt Spray Tester,Bending Tester,Thermal

8 Shock equipment not available; High IQC/OQC

Temp High humidity test not conducted.

Relaibility Test at Product level/Part

9 Reliability

Level(Connectors) is not conducted.

Validation of Function Tester used at line

10 is not found/Golden samples not Prod.

available

11 IMF samples verification not in practice. Prod.

No any specified area for NG semi FG

12 Prod.

material at line.

Function Tester, Voltage Drop Tester not

13 OQC

available at OQC inspection.

Dedidicated manpower not available for

14 OQC

OQC Insepction.

Strenghteninng of OS&D feedback is

15 Prod.

lagging.

4M/ECN management need to implement

16 R&D

effectively

Quality Audit(Weekly/Monthly) not in

17 OQC

practice.

Equipment Parameters changed by

18 Operators without any information to Prod.

PQC/Equipment.

ation and corrective report & status

Detail Action Plan Target Date Evidence

IQC Checksheet formats are

changed and data is recorded 11/26/2016

as per standard requirement

All equipment is send

calibration by NABL 12/1/2016

approoved agengy

all observed numeric value is

11/28/2016

recorded in checksheets

FIFO system is implemented

and displayed in W/H and 11/29/2016

also applied in FG area

each and every raw

material ,WIP is identified by 11/26/2016

QC OK and NG stickers

Seprate area for IQC rejection

11/26/2016

area is identified

Reliabilty test report is

conducted for every incoming

11/29/2016

material and attached with

IQC report

salt spray tester,bending

tester ,pin insertion tester is

purchased and installed in

12/1/2016

factory rest thermal shock

tester will available in factory

on 1-12-2016

part level relaibility is started

12/1/2016

at part level

golden sample jig verification

is started and molding prod 11/29/2016

line

IMF sample verification is in

practice(process validation

11/29/2016

check sheet) and data is

recorded hourly basis in a day

all material trolly is divided in

two part for ok and ng

material and opertaors has 11/29/2016

statred to kept material as

per statndard

seprate function tester is

installed in oqc and voltaged

12/1/2016

drop tester is orderd and will

installed on 1 st december

dedicated engineer

mr.anubhav is appointed on 11/28/2016

oqc

rework report ,rework SOP

and os&d feedback by

11/28/2016

operator performance chart is

displayed on prod line

4M/ECN record is corrected

11/29/2016

and verified

Internal quality audit plan is

prepared and is conducted on 12/1/2016

1-12-2016

all operators and workers are

strictly prohibitted for change

of parameter ,prod supervisor

is authorised for change of 11/30/2016

machine parameter and will

generate a report on daily

basis

You might also like

- Procedure For Set Up Approval, in Process & Final InspectionDocument7 pagesProcedure For Set Up Approval, in Process & Final InspectionRavi javaliNo ratings yet

- 5S Audit PlanDocument1 page5S Audit PlanPRABHAT RANJANNo ratings yet

- Poka Yoke Training ModuleDocument31 pagesPoka Yoke Training ModulePRABHAT RANJANNo ratings yet

- Work Instruction For Inspection of Raw MaterialDocument28 pagesWork Instruction For Inspection of Raw Materialm.manikandan maniNo ratings yet

- Work Instruction For MFIDocument4 pagesWork Instruction For MFILijin LeonNo ratings yet

- 00the 7 MFG WasteDocument15 pages00the 7 MFG WasteRohit PrakashNo ratings yet

- Why analysis root cause manufacturing defectsDocument4 pagesWhy analysis root cause manufacturing defectsmaulikgadaraNo ratings yet

- MACHINE STARTUP STEPSDocument28 pagesMACHINE STARTUP STEPSshanmugam86100% (2)

- Anand Kumar ResumeDocument3 pagesAnand Kumar ResumeArun ShishodiaNo ratings yet

- Supplier Name Auditors: Vendor Attendees:: JudgmentDocument4 pagesSupplier Name Auditors: Vendor Attendees:: Judgment3A System SolutionNo ratings yet

- 5.6 MRM Minutes 2020Document7 pages5.6 MRM Minutes 2020Musyoka Urbanus100% (1)

- Defect Control Report FITMENT PROBLEMDocument1 pageDefect Control Report FITMENT PROBLEMamritanshuNo ratings yet

- APQP (27) ElementsDocument31 pagesAPQP (27) Elementssam1hi5No ratings yet

- SOP Warranty RepairsDocument2 pagesSOP Warranty RepairsKristantyo PrasetyaNo ratings yet

- Incoming Quality Control Procedure (IQCDocument4 pagesIncoming Quality Control Procedure (IQCteresaNo ratings yet

- Red Bin AnalysisDocument5 pagesRed Bin AnalysisDINESHCHOUDHARY88No ratings yet

- 4m Change Before After FormatDocument3 pages4m Change Before After FormatpsathishthevanNo ratings yet

- KiazenDocument12 pagesKiazenAmogh KulkarniNo ratings yet

- CARA NC Management Tool Instructions For Client: IATF OversightDocument8 pagesCARA NC Management Tool Instructions For Client: IATF OversightAvinash CCMSNo ratings yet

- Initial Product Quality Control ProcessDocument3 pagesInitial Product Quality Control ProcessSameer SaxenaNo ratings yet

- LP LA N: Control PlanDocument26 pagesLP LA N: Control PlanSyed ShabbirNo ratings yet

- MTTR & MTBF RecordsDocument6 pagesMTTR & MTBF Recordspraagthish100% (1)

- CARA NC Management Tool Instructions For Client: IATF OversightDocument8 pagesCARA NC Management Tool Instructions For Client: IATF OversightOBSC PerfectionNo ratings yet

- 5S SYSTEMATIC HOUSEKEEPINGDocument38 pages5S SYSTEMATIC HOUSEKEEPINGpbalawin43900% (1)

- ZED PresentationDocument13 pagesZED PresentationSatbir SinghNo ratings yet

- IATF16949,2016Document28 pagesIATF16949,2016Vinni WadeNo ratings yet

- Difference Between Rework Repair PDFDocument19 pagesDifference Between Rework Repair PDFRavichandranNo ratings yet

- Formato 8DDocument2 pagesFormato 8DALEJANDRONo ratings yet

- 8D & 7QC ToolsDocument117 pages8D & 7QC ToolsAshok Kumar100% (1)

- DK Qap QHS 12-FR 03-R6 - CarDocument1 pageDK Qap QHS 12-FR 03-R6 - CarErlan Gus HermawanNo ratings yet

- Operator Check Sheet SEODocument2 pagesOperator Check Sheet SEORavi YadavNo ratings yet

- pure cotton pvt ltd final inspection reportDocument4 pagespure cotton pvt ltd final inspection reportTarun PariharNo ratings yet

- Nonconformity Management Using Cara Tool: Iatf 16949 AuditsDocument19 pagesNonconformity Management Using Cara Tool: Iatf 16949 AuditssharanNo ratings yet

- Capa - 2Document1 pageCapa - 2Quality DWINo ratings yet

- In House PPM MonitoringDocument2 pagesIn House PPM MonitoringSrinath NavadaNo ratings yet

- Capacity Planning and Analysis PDFDocument22 pagesCapacity Planning and Analysis PDFShimanta EasinNo ratings yet

- Manufacturing Process Audit: RatingDocument3 pagesManufacturing Process Audit: Ratingrajesh.bNo ratings yet

- Samples Inspection ReportDocument5 pagesSamples Inspection ReportArun GuptaNo ratings yet

- Cost of Quality: Understanding Prevention & Failure CostsDocument4 pagesCost of Quality: Understanding Prevention & Failure CostsnowsheenbdNo ratings yet

- Quality Circle - EM58M - AUQCCDocument75 pagesQuality Circle - EM58M - AUQCCpverma02No ratings yet

- Chintamani Metal 4M Change SheetDocument6 pagesChintamani Metal 4M Change Sheetcmu qmsNo ratings yet

- FRM-WS-11 DWM Check Sheet (Weld SHP)Document2 pagesFRM-WS-11 DWM Check Sheet (Weld SHP)Ashok PanchalNo ratings yet

- Kaizen - Esp02 221B4 DamperDocument4 pagesKaizen - Esp02 221B4 DamperRakesh Kumar Singh (Phase 1B)No ratings yet

- Rejection Record.Document10 pagesRejection Record.karan shahNo ratings yet

- Integrated System Change Management ProceduresDocument3 pagesIntegrated System Change Management ProceduresMASU BRAKE PADS QANo ratings yet

- Switchyard Jishu Hozen Fugai SheetDocument8 pagesSwitchyard Jishu Hozen Fugai SheetAnonymous vcadX45TD7No ratings yet

- Format Issue RecordDocument4 pagesFormat Issue RecordBharatNo ratings yet

- Internal Audit Check List MRDocument3 pagesInternal Audit Check List MRGanesh Iyer100% (1)

- Process flow chart for primary structural steel fabricationDocument3 pagesProcess flow chart for primary structural steel fabricationmadhu krishnaNo ratings yet

- APQP Guide Pre-U1aDocument241 pagesAPQP Guide Pre-U1aФедя ПлукчиNo ratings yet

- Turtle Diagrams ExplainedDocument3 pagesTurtle Diagrams ExplainedTatiana Rilo0% (1)

- Improvement KaizenDocument11 pagesImprovement KaizenAnkur DhirNo ratings yet

- 6W2H For Side Wrinkles MY17 - RearDocument4 pages6W2H For Side Wrinkles MY17 - RearVishvendra Pratap SinghNo ratings yet

- Cii Erode: 1S PresentationDocument19 pagesCii Erode: 1S PresentationsathyabalaramanNo ratings yet

- PPAP Readiness AuditDocument4 pagesPPAP Readiness AuditPurushothama Nanje GowdaNo ratings yet

- Customer Complaint RegisterDocument3 pagesCustomer Complaint RegistermuthuselvanNo ratings yet

- SOP Quality ProceduresDocument28 pagesSOP Quality ProceduresUttam KumarNo ratings yet

- Test Paper: Fifo & TraceabiltyDocument2 pagesTest Paper: Fifo & TraceabiltyAtul SharmaNo ratings yet

- Sec BDocument4 pagesSec BPriyanka ChaudharyNo ratings yet

- Guangdong Shunde BESTUSIN International Trade Co Tools and Machines Company ProfileDocument19 pagesGuangdong Shunde BESTUSIN International Trade Co Tools and Machines Company ProfilePriyanka ChaudharyNo ratings yet

- ResumeDocument7 pagesResumePriyanka ChaudharyNo ratings yet

- Simulation of Job Shop Using Arena - Mini Project ReportDocument32 pagesSimulation of Job Shop Using Arena - Mini Project ReportKailas Sree Chandran100% (7)

- Dataking Electronics Pvt. LTDDocument16 pagesDataking Electronics Pvt. LTDPriyanka ChaudharyNo ratings yet

- MCQsDocument11 pagesMCQsPriyanka Chaudhary0% (2)

- Simulation of Job Shop Using Arena - Mini Project ReportDocument32 pagesSimulation of Job Shop Using Arena - Mini Project ReportKailas Sree Chandran100% (7)

- Simulation of Job Shop Using Arena - Mini Project ReportDocument32 pagesSimulation of Job Shop Using Arena - Mini Project ReportKailas Sree Chandran100% (7)

- Assignment SubmitDocument2 pagesAssignment SubmitPriyanka ChaudharyNo ratings yet

- Guangdong Shunde BESTUSIN International Trade Co Tools and Machines Company ProfileDocument19 pagesGuangdong Shunde BESTUSIN International Trade Co Tools and Machines Company ProfilePriyanka ChaudharyNo ratings yet

- Catalog International MarketDocument4 pagesCatalog International MarketPriyanka ChaudharyNo ratings yet

- Final PPT FirewallDocument12 pagesFinal PPT FirewallPriyanka ChaudharyNo ratings yet

- Kei PDFDocument48 pagesKei PDFvasanthi8025No ratings yet

- Kei PDFDocument48 pagesKei PDFvasanthi8025No ratings yet

- Product Manual USBDocument12 pagesProduct Manual USBPriyanka ChaudharyNo ratings yet

- Data KingDocument16 pagesData KingPriyanka ChaudharyNo ratings yet

- MOSFET Operation: 97.398, Physical Electronics, Lecture 21Document17 pagesMOSFET Operation: 97.398, Physical Electronics, Lecture 21santoshkumar1234567No ratings yet

- Tamali ChatterjeeDocument3 pagesTamali ChatterjeePriyanka ChaudharyNo ratings yet

- CryptographyorgDocument15 pagesCryptographyorgPriyanka ChaudharyNo ratings yet

- Invoice OD121910980854018000Document1 pageInvoice OD121910980854018000Lord XNo ratings yet

- Strategi Perencanaan Pembiayaan SekolahDocument10 pagesStrategi Perencanaan Pembiayaan SekolahSD NEGERI 2 KLATENNo ratings yet

- 01 Activity 1 Strategic MGTDocument1 page01 Activity 1 Strategic MGTAlvarez JafNo ratings yet

- GOCToolKit Installation and Quick Start GuideDocument25 pagesGOCToolKit Installation and Quick Start GuideabhayuietNo ratings yet

- Holley 1-Barrel Parts IndexDocument38 pagesHolley 1-Barrel Parts IndexBillyNo ratings yet

- AHRI Standard 1060 I-P 2018 PDFDocument17 pagesAHRI Standard 1060 I-P 2018 PDFGuy BlouinNo ratings yet

- Step by Step Process For Creating AdobeDocument23 pagesStep by Step Process For Creating AdobeGL1254No ratings yet

- Answers Simplest Form: Grade 8 NOTES: Unit 3 - FractionsDocument17 pagesAnswers Simplest Form: Grade 8 NOTES: Unit 3 - FractionsKumidi SampatNo ratings yet

- Dumitrașcu, Nicolae-Adrian Dincă, Alexandru Predincea, Nicolae. Virtual Commissioning of A Robotic Cell Using Tecnomatix Process SimulateDocument16 pagesDumitrașcu, Nicolae-Adrian Dincă, Alexandru Predincea, Nicolae. Virtual Commissioning of A Robotic Cell Using Tecnomatix Process SimulateStephanie RiccoNo ratings yet

- Empowerment Technology Week 5-6Document17 pagesEmpowerment Technology Week 5-6Sonia Agustin100% (2)

- SEKSYEN RADIATOR 4B11 Mitsubishi Motors Service ManualDocument5 pagesSEKSYEN RADIATOR 4B11 Mitsubishi Motors Service ManualAz Zahra AzmanNo ratings yet

- Frequency Drive - ZapMetaDocument4 pagesFrequency Drive - ZapMetaJemerald MagtanongNo ratings yet

- mPro-200-V2 CatalogDocument20 pagesmPro-200-V2 CatalogAmol BhaleraoNo ratings yet

- The Ignoring of "People" in The Journalistic Coverage of Economic Crises. The Housing Bubble and The Euro Crisis in SpainDocument4 pagesThe Ignoring of "People" in The Journalistic Coverage of Economic Crises. The Housing Bubble and The Euro Crisis in SpainFernández HernándezNo ratings yet

- DBX 386 Dual Tube Mic Preamp SCHDocument21 pagesDBX 386 Dual Tube Mic Preamp SCHPablo RodriguezNo ratings yet

- 1st Review Report - Smart Distribution SystemDocument54 pages1st Review Report - Smart Distribution SystemretechNo ratings yet

- V94.2 Beggenum Experience & Improve Concept For Syngas Application PDFDocument24 pagesV94.2 Beggenum Experience & Improve Concept For Syngas Application PDFEliyanto E BudiartoNo ratings yet

- Lab - Researching Network Attacks and Security Audit ToolsDocument4 pagesLab - Researching Network Attacks and Security Audit ToolsAlvaro Avila QuirosNo ratings yet

- SumaDocument84 pagesSumaOmar SalahNo ratings yet

- Lab - Convert Data Into A Universal Format PDFDocument9 pagesLab - Convert Data Into A Universal Format PDFNi Made ArtiniNo ratings yet

- Cadb He 21 Pro H - D 4930Document8 pagesCadb He 21 Pro H - D 4930IgorVutucNo ratings yet

- DIGITAL MARKETING ASSIGNMENTDocument6 pagesDIGITAL MARKETING ASSIGNMENTharshita khadayteNo ratings yet

- An Introduction To Statistics: Keone HonDocument14 pagesAn Introduction To Statistics: Keone HonArjhay GironellaNo ratings yet

- List of Companies Came To aUTO eXPODocument7 pagesList of Companies Came To aUTO eXPOSatish PradhanNo ratings yet

- ICT Era Living ModuleDocument24 pagesICT Era Living ModuleJohn Chelo Rodriguez100% (9)

- Granta EduPack Release NotesDocument8 pagesGranta EduPack Release Notes3220355No ratings yet

- A Single Stage Integrated Bidirectional AC/DC and DC/DC Converter For Plug-In Hybrid Electric VehiclesDocument6 pagesA Single Stage Integrated Bidirectional AC/DC and DC/DC Converter For Plug-In Hybrid Electric VehiclesAli HussienNo ratings yet

- Network Interface Audit LogDocument31 pagesNetwork Interface Audit LogVictor CuencaNo ratings yet

- Caterpillar To Perkins Engine Model Cross Reference InterchangeDocument1 pageCaterpillar To Perkins Engine Model Cross Reference InterchangeMaimun maimun100% (1)

- BMS Wiring DaigramDocument8 pagesBMS Wiring DaigramChukwuma OnukuNo ratings yet