Professional Documents

Culture Documents

Qa Imco Hse Ms QT 001 Hse Management System

Uploaded by

Francis Enriquez TanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Qa Imco Hse Ms QT 001 Hse Management System

Uploaded by

Francis Enriquez TanCopyright:

Available Formats

ISSUE DATE:

IMCO Engineering & Construction Company WLL Rev : 2

04-08-2016

Procedure No: Procedure Title: Page: 2 of 21

AN IMS CERTIFIED Health, Safety and Environmental Management System

COMPANY QA/IMCO/HSE/MS/QT-001

TABLE OF CONTENTS

1. INTRODUCTION ................................................................................................................................. 3

2. HSE POLICY ......................................................................................................................................... 4

3. OUR MISSION .................................................................................................................................... 5

4. OUR VISION ........................................................................................................................................ 6

5. HSE MANAGEMENT SYSTEM .......................................................................................................... 7

5.1. COMMITMENT AND LEADERSHIP ............................................................................................. 9

5.2. POLICIES AND OBJECTIVES ....................................................................................................... 10

5.3. ORGANIZATION, RESOURCES AND DOCUMENTATION ..................................................... 11

5.3.1. ORGANIZATIONAL STRUCTURES ........................................................................................ 12

5.3.2. RESPONSIBILITIES AND ACCOUNTABILITIES .................................................................... 13

5.3.2.1. COUNTRY MANAGER ............................................................................................................ 13

5.3.2.2. HSE MANAGER ....................................................................................................................... 14

5.3.2.3. PROJECT MANAGER .............................................................................................................. 14

5.3.2.4. PROJECT HSE ENGINEER/OFFICER ...................................................................................... 15

5.3.2.5. PROJECT ENGINEER/SUPERVISOR ...................................................................................... 16

5.3.2.6. EMPLOYEE ................................................................................................................................ 17

5.3.2.7. SUBCONTRACTOR .................................................................................................................. 18

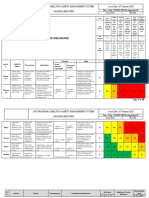

5.4. RISK EVALUATION AND MANAGEMENT ............................................................................... 18

5.5. PLANNING .................................................................................................................................... 19

5.6. IMPLEMENTATION, RECORDING AND MONITORING......................................................... 19

5.7. AUDIT AND REVIEW ( ASSESSMENT AND CONTINUOUS IMPROVEMENT) ................... 20

Blue Copy = Controlled by Quality Assurance Executive

White Copy = Controlled by Division Managers

White Uncontrolled Copy to be marked "Uncontrolled"

ISSUE DATE:

IMCO Engineering & Construction Company WLL Rev : 2

04-08-2016

Procedure No: Procedure Title: Page: 3 of 21

AN IMS CERTIFIED Health, Safety and Environmental Management System

COMPANY QA/IMCO/HSE/MS/QT-001

1. INTRODUCTION

Health, Safety and Environmental (HSE) Management is an integral and essential part

of the way we do our business and is considered an equal part of the wider system for

the management of our business.

Through effective management, IMCO aims to be the preferred contractor and the

favored employer. The requirements set out in this document constitute the expectation

for compliance with IMCO policy.

The purpose of this document is to describe;

The structure for the management of Health, Safety and Environmental (HSE)

within the IMCO projects

The expectations for each element of the HSE Management System

It is the responsibility of each project to determine how these expectations and

requirements are to be achieved.

Blue Copy = Controlled by Quality Assurance Executive

White Copy = Controlled by Division Managers

White Uncontrolled Copy to be marked "Uncontrolled"

ISSUE DATE:

IMCO Engineering & Construction Company WLL Rev : 2

04-08-2016

Procedure No: Procedure Title: Page: 4 of 21

AN IMS CERTIFIED Health, Safety and Environmental Management System

COMPANY QA/IMCO/HSE/MS/QT-001

2. HSE POLICY

Blue Copy = Controlled by Quality Assurance Executive

White Copy = Controlled by Division Managers

White Uncontrolled Copy to be marked "Uncontrolled"

ISSUE DATE:

IMCO Engineering & Construction Company WLL Rev : 2

04-08-2016

Procedure No: Procedure Title: Page: 5 of 21

AN IMS CERTIFIED Health, Safety and Environmental Management System

COMPANY QA/IMCO/HSE/MS/QT-001

3. OUR MISSION

We provide good services to strive for global excellence in Oil and Gas Industry and

Construction worldwide.

To distinguish ourselves through listening, learning and understanding industry

challenges and to capitalize on strategic and opportunistic possibilities.

To provide services those are attractive and fair to our Client and earn their loyalty while

also providing value to our shareholders.

To create a work place that protects worker health and safety with due respect for the

environment, and promote an atmosphere to grow employee learning and opportunity in

a way that is fulfilling, recognized and fairly rewarded.

Blue Copy = Controlled by Quality Assurance Executive

White Copy = Controlled by Division Managers

White Uncontrolled Copy to be marked "Uncontrolled"

ISSUE DATE:

IMCO Engineering & Construction Company WLL Rev : 2

04-08-2016

Procedure No: Procedure Title: Page: 6 of 21

AN IMS CERTIFIED Health, Safety and Environmental Management System

COMPANY QA/IMCO/HSE/MS/QT-001

4. OUR VISION & VALUES

IMCO expects its personnel to achieve year-over-year improvement in safety

performance while Go to Zero injuries.

IMCO is aiming for a destination called zero zero safety incidents, zero injuries and

zero days off work due to injury; in other words, a perfect HSE record. Go to Zero

means accepting that every incident is preventable.

Our Go to Zero vision is a decision to change change behavior and the way things

are done to ensure safety is always at the forefront for every employee. As a global oil

and gas contracting company, we expect our workers to make safety on-the-job and off-

the-job an everyday priority by emphasizing five safety principles:

Participation

Accountability

Consistency

Communication

Training

At IMCO, we expect people to come to the job site and for just one shift, not have any

injures. Then we achieve it on the next shift, and the next. Day after day. We know it

can be done because many of our work sites achieve it every day, year after year.

The Go to Zero vision does not mean that another injury will never occur. Rather, it

means a commitment to working as many hours as possible without an injury. And it

requires an attitude an attitude that says any injury or incident, even a small one,

shouldnt be taken lightly. Any incident is unacceptable. Thats the attitude that is key to

Go to Zero.

Its an attitude that we expect from each employee at IMCO.

Blue Copy = Controlled by Quality Assurance Executive

White Copy = Controlled by Division Managers

White Uncontrolled Copy to be marked "Uncontrolled"

ISSUE DATE:

IMCO Engineering & Construction Company WLL Rev : 2

04-08-2016

Procedure No: Procedure Title: Page: 7 of 21

AN IMS CERTIFIED Health, Safety and Environmental Management System

COMPANY QA/IMCO/HSE/MS/QT-001

5. HSE MANAGEMENT SYSTEM

IMCO Engineering & Construction Company HSE Management System defines the

elements by which we will conduct our operations worldwide in order to protect our

people, the public, our property and the environment in which they work and live.

The HSE Management System model is comprised of seven interrelated elements with

underlying expectations:

1. Commitment and Leadership

2. Policies and Objectives

3. Organization, Resources and Documentation

4. Risk Evaluation and Management

5. Planning

6. Implementation, Recording and Monitoring

7. Audit and Review

Each division must communicate these expectations to all employees, customers and

third parties associated with our business. Each division must provide positive evidence

of conformance to this Management System and continuous improvement.

Blue Copy = Controlled by Quality Assurance Executive

White Copy = Controlled by Division Managers

White Uncontrolled Copy to be marked "Uncontrolled"

ISSUE DATE:

IMCO Engineering & Construction Company WLL Rev : 2

04-08-2016

Procedure No: Procedure Title: Page: 8 of 21

AN IMS CERTIFIED Health, Safety and Environmental Management System

COMPANY QA/IMCO/HSE/MS/QT-001

ELEMENT IN THE BUSINESS

Blue Copy = Controlled by Quality Assurance Executive

White Copy = Controlled by Division Managers

White Uncontrolled Copy to be marked "Uncontrolled"

ISSUE DATE:

IMCO Engineering & Construction Company WLL Rev : 2

04-08-2016

Procedure No: Procedure Title: Page: 9 of 21

AN IMS CERTIFIED Health, Safety and Environmental Management System

COMPANY QA/IMCO/HSE/MS/QT-001

5.1. Commitment and Leadership

Management shall provide strong visible commitment, leadership and personal

involvement in health, safety and the environment. Management shall make

available the resources necessary to achieve our HSE objectives.

Expectations

Set a personal example day to day by following HSE rules.

Make decisions that consider HSE matters equal to cost, quality, morale and

production.

Delegate the necessary authority to the appropriate personnel and allocate

resources to carry out HSE functions.

Visit operations on a regular basis to demonstrate commitment and recognize

performance in HSE matters.

Hold those in positions of authority accountable at all levels of the company for

compliance with company policies and global standards.

Develop HSE objectives at your level of responsibility.

Communicate with employees, clients, subcontractors and industry personnel so

that they know and understand the intent of HSE policies.

Celebrate and promote your HSE success.

Blue Copy = Controlled by Quality Assurance Executive

White Copy = Controlled by Division Managers

White Uncontrolled Copy to be marked "Uncontrolled"

ISSUE DATE:

IMCO Engineering & Construction Company WLL Rev : 2

04-08-2016

Procedure No: Procedure Title: Page: 10 of 21

AN IMS CERTIFIED Health, Safety and Environmental Management System

COMPANY QA/IMCO/HSE/MS/QT-001

5.2. Policies and Objectives

Say what you are going to do. Develop and communicate policies demonstrating a

commitment to HSE that is consistent with, and at least equal to, other business

aims. Supporting objectives shall be defined, deployed and maintained at all

organizational levels.

Expectations

Develop local HSE policies that support and are consistent with corporate

standards.

Set objectives for continuous improvement.

Involve all levels of management and personnel in the development of objectives

for the division.

Develop specific objectives for the reduction of risk.

Communicate the policies and objectives to all employees in a clear, readily

understood, medium.

Develop performance measures to guide and gauge progress towards achieving

objectives.

Meet and strive to exceed regulatory requirements in all jurisdictions.

Review policies and objectives at all levels on a regular basis, to determine

continued validity.

Blue Copy = Controlled by Quality Assurance Executive

White Copy = Controlled by Division Managers

White Uncontrolled Copy to be marked "Uncontrolled"

ISSUE DATE:

IMCO Engineering & Construction Company WLL Rev : 2

04-08-2016

Procedure No: Procedure Title: Page: 11 of 21

AN IMS CERTIFIED Health, Safety and Environmental Management System

COMPANY QA/IMCO/HSE/MS/QT-001

5.3. Organization, Resources and Documentation

Define, document and communicate the roles, responsibilities and accountabilities to

enable every individual to fulfill their role in improving HSE performance.

Expectations

Define the interrelationships between individuals, operating groups, support

functions, employees, clients and partners in joint activities, trade associations

and regulatory bodies.

Appoint and support a management team representative to act as the focal point

for HSE matters.

Ensure that each group and individual receives sufficient information and

training to fulfill their role with respect to HSE.

Allocate sufficient resources to support policies and work towards achieving

objectives set for HSE issues.

Ensure a system that provides and maintains effective procedures, resource

material and records on HSE subjects.

Blue Copy = Controlled by Quality Assurance Executive

White Copy = Controlled by Division Managers

White Uncontrolled Copy to be marked "Uncontrolled"

ISSUE DATE:

IMCO Engineering & Construction Company WLL Rev : 2

04-08-2016

Procedure No: Procedure Title: Page: 12 of 21

AN IMS CERTIFIED Health, Safety and Environmental Management System

COMPANY QA/IMCO/HSE/MS/QT-001

5.3.1. Organizational Structures

Qatar Country

Manager

QA/QC HSE

Manager Manager

QA/QC HSE

Inspector Coordinator

HSE Officer

Administration Senior Head of Manager Manager

Manager Accountant Estimation Project Controls Projects

Govt. Assistant Estimation

Relation Accountant Engineer

Cost Planning Procurement Engineering Project

Control Dept. Dept. Dept. Manager

Admin

Asst.

Sr. Cost Planning Sr. Engineering Const.

Control Engineer Procurement Lead Manager

Personne

l Officer

Asst. Jr. Purchase Design Lead Discipline

Cost Planning Engineer Elect./Inst. Site Engr.

Logistic

Coordinator

Local Engineer Supervisor

Purchase

Drivers.

Draftsman Foreman

Skilled

Workers

Helpers

Blue Copy = Controlled by Quality Assurance Executive

White Copy = Controlled by Division Managers

White Uncontrolled Copy to be marked "Uncontrolled"

ISSUE DATE:

IMCO Engineering & Construction Company WLL Rev : 2

04-08-2016

Procedure No: Procedure Title: Page: 13 of 21

AN IMS CERTIFIED Health, Safety and Environmental Management System

COMPANY QA/IMCO/HSE/MS/QT-001

5.3.2. Responsibilities and Accountabilities

IMCO assigns the utmost importance to safety and accident prevention to

ensure that all employees are provided a safe and healthy work environment.

The success of the policy requires all levels of personnel management and

employees, to become totally supportive and to develop a thorough

understanding of safety as it pertains to their respective jobs. The following

responsibilities are assigned to accomplish this objective.

5.3.2.1. Country Manager

Country Managers shall be responsible and accountable for the

development, implementation and maintenance of all IMCO HSE

and rehabilitation policies and procedures.

The position carries the prime responsibility to demonstrate through

proactive measures the commitment of IMCO to all environmental

and safety issues. Pro-Active measures shall include management-

initiated actions to improve the safety and environmental systems

together with prompt response to meaningful suggestions and or

recommendations from all site personnel.

The Country Manager shall ensure that:

All on-site personnel are accountable for HSE performances

within their area of responsibility;

Appropriate safety standards are set through participation and

consultation with all site personnel including supervisors,

employees and client representatives.

All quality, safety and environmental reports and inspections

are reviewed and will initiate appropriate rectification responses

where necessary;

There will be an active participation in all accident/incident

investigations;

There will be active participation in safety/environment

meetings and programs;

Monitoring for compliance with environmental and safe work

methods shall occur.

Conduct Pre-start safety alignment meetings with Client As

required. Review first aid and accident/incident reports

Monthly Investigate serious incidents as required

Participate in workplace HSE hazard inspections

Monthly Review site safety performance Monthly

Participate in group safety meetings Monthly

Blue Copy = Controlled by Quality Assurance Executive

White Copy = Controlled by Division Managers

White Uncontrolled Copy to be marked "Uncontrolled"

ISSUE DATE:

IMCO Engineering & Construction Company WLL Rev : 2

04-08-2016

Procedure No: Procedure Title: Page: 14 of 21

AN IMS CERTIFIED Health, Safety and Environmental Management System

COMPANY QA/IMCO/HSE/MS/QT-001

Attend safety toolbox meetings Weekly

5.3.2.2. HSE Manager

The HSE Manager shall be responsible for the operation,

implementation and control of the HSE System. He shall ensure

that this procedure is well coordinated and explain to all HSE

personnel. He shall be the direct contact in the event that HSE

requirements deviation observed. He is accountable for the

incident/accident investigation and shall report to the Country

Manager Projects Group in a regular basis.

The HSE Manager has the full authority for the compliance of the

ISO 14001:2004 and OHSAS 18001:2007 requirements and the

requirements of legal, regulatory and statury requirements. He shall

be responsible for conducting HSE Management Review Meeting

and arranging internal audits to all corporate operations.

5.3.2.3. Project Manager

The Project Manager has the delegated responsibility for all

operations of the project team and as such assumes responsibility

for the teams conformance with all relevant IMCO, client and

statutory based HSE requirements.

Consistent with assigned responsibilities and authorities, the

management team shall provide and be accountable for

maintaining a safe place of work. Duties include:

Reporting to the general manager or delegate regularly and/or

immediately in the event of a significant incident;

Assisting in developing and controlling company procedures

and safety instructions in all workplaces;

In consultation, provide active support to GE personnel in all

HSE matters;

Liaising with the general manager or delegate to ensure

statutory compliance and conformance to HSE acts, regulations

standards and specifications;

Providing a safety example, encouraging safety, quality,

environment and productivity through visible presence at all

workplaces.

Blue Copy = Controlled by Quality Assurance Executive

White Copy = Controlled by Division Managers

White Uncontrolled Copy to be marked "Uncontrolled"

ISSUE DATE:

IMCO Engineering & Construction Company WLL Rev : 2

04-08-2016

Procedure No: Procedure Title: Page: 15 of 21

AN IMS CERTIFIED Health, Safety and Environmental Management System

COMPANY QA/IMCO/HSE/MS/QT-001

PROJECT MANAGER - ACTIVITIES FREQUENCY

Review HSE Plan Prior to job start

Conduct Pre-start safety alignment meetings with Client As required

Review first aid and accident/incident reports Monthly

Investigate serious incident As required

Participate in workplace HSE hazard inspection Monthly

Review site safety performance Monthly

Participate in group safety meetings Monthly

Attend safety toolbox meetings Weekly

5.3.2.4. Project HSE Engineer/Officer

The project HSE Engineer/Officer is responsible for all

administration of HSE program. He will report directly to the Project

Manager and serve in advisory capacity.

In carrying out his responsibility, the project HSE/Officer Engineer:

Serves as technical advisor to the Project Manager / Site

Engineers in HSE planning.

Implements established policy, procedures and work practices

to promote the company project safety and health program

and administer assigned functions to aid in these overall

responsibilities.

Monitors compliance with mandatory HSE laws, standards or

codes.

Conducts inspection of job sites, documents and reports any

unsafe acts & unsafe conditions to the responsible Engineer /

Supervisor for immediate corrective action.

Tests the work environment and documents the results in

order to eliminate or control hazard which could contribute to

or result in an occupational illness.

Arranges and conducts regular HSE meeting for field

Supervisors. Ensures that a foreman or representative from

each unit is present at these meetings.

Attends all weekly progress and/or schedules meeting to

provide input regarding safety for current and future project

activities.

Ensures that unit supervisor conducts weekly tool box

meetings with all personnel in attendance provides appropriate

topic or discussion and initiates follow-up response to HSE

concerns addressed during these meetings.

Blue Copy = Controlled by Quality Assurance Executive

White Copy = Controlled by Division Managers

White Uncontrolled Copy to be marked "Uncontrolled"

ISSUE DATE:

IMCO Engineering & Construction Company WLL Rev : 2

04-08-2016

Procedure No: Procedure Title: Page: 16 of 21

AN IMS CERTIFIED Health, Safety and Environmental Management System

COMPANY QA/IMCO/HSE/MS/QT-001

Investigates all incidents and accidents that could involve

potential liability, maintains adequate records of relevant data

and complies the required reports on experience.

If assigned, monitors compliance with established pollution

control and environmental protection standards and

regulations.

Arranges for securing safety permits based on site conditions.

Performs air monitoring for harmful or explosive substance in

the work environment.

Ensure that all required notices, posters and other related

literature is properly displayed for employees information.

Organizes necessary HSE propaganda program for promoting

safety and health program for HSE awareness.

Recommends, selects and ensures that Safety, First aid, fire

protection equipment are of relevant standards and also

ensures that such material is always at hand.

Assists Project Supervisor in the inspection of tools,

equipment and facilities.

Provides training to site personnel with regards to specific safe

work practices / procedures, use and care of personnel

protective equipment, and handling hazardous material /

equipments.

Identifies the safe areas near by the work place, locations of

emergency facilities such as fire service, water, first aid clinic,

etc.

Ensures that all work forces are aware of such in 6.5.16.

The Safety Engineer / Officer has the full authority to stop any

work activity for any safety reasons.

5.3.2.5. Project Engineer/Supervisor

It is recognized by senior management that project supervisors play

an important role in the effective implementation of the safety

program. Every effort shall be made by senior management to

encourage feedback from the shop floor as a vital part of the

Safety Management System.

Project Supervisors shall play an active roll on the safety

committee. Duties include:

Blue Copy = Controlled by Quality Assurance Executive

White Copy = Controlled by Division Managers

White Uncontrolled Copy to be marked "Uncontrolled"

ISSUE DATE:

IMCO Engineering & Construction Company WLL Rev : 2

04-08-2016

Procedure No: Procedure Title: Page: 17 of 21

AN IMS CERTIFIED Health, Safety and Environmental Management System

COMPANY QA/IMCO/HSE/MS/QT-001

Reporting to the senior Project Manager;

A working knowledge of IMCO HSE policies;

Ensuring planned safe working methods are implemented;

Identifying and eliminating safety and environmental hazards in

the workplace;

Incorporating safety and environment instructions when

allocating tasks;

Convening tool box meetings;

Conducting incident investigations and reporting findings to the

HSE coordinator via the Project Manager;

Ensuring safety, quality inductions of all personnel including

subcontractors;

Undertake safety and environment inspections of workshops

and/or sites;

Liaise with the Project Manager at all times;

Provide a visible safety example, encouraging and promoting

safety and environmental policies and procedures in all

workplaces.

Attending safety and environment meetings;

ENGINEER/SUPERVISOR - ACTIVITIES FREQUENCY

Review and identify hazards in work scopes Tender

Attend safety toolbox meetings Weekly

Attend pre-start meetings Daily

Participate in informal hazard inspection Daily

Participate in formal hazard inspection Weekly

Review and authorize JSAs prior to task commencement As required

Participate in accident and incident investigations As required

5.3.2.6. Employee

IMCO believes that safety is everyones responsibility.

Employees shall:

Take reasonable care for their own safety and health;

Use all personal protective equipment that is issued to meet

safety requirements;

Report all identified hazards, defects in plant or equipment no

matter how minor;

Make all endeavors to warn other employees of known

hazards;

Comply with statutory, safety and environmental requirements

for the workplace;

Assist in achieving goals set by management

Actively support the project safety and environmental policies

Blue Copy = Controlled by Quality Assurance Executive

White Copy = Controlled by Division Managers

White Uncontrolled Copy to be marked "Uncontrolled"

ISSUE DATE:

IMCO Engineering & Construction Company WLL Rev : 2

04-08-2016

Procedure No: Procedure Title: Page: 18 of 21

AN IMS CERTIFIED Health, Safety and Environmental Management System

COMPANY QA/IMCO/HSE/MS/QT-001

Maintain a sound knowledge of safe work practices;

Comply with guidelines formulated and distributed through

inductions, toolbox meetings and site instructions.

5.3.2.7. Subcontractor

Sub-contractors are accountable for:

Safety performance in their respective areas of control;

Compliance with the Project HSE Management Plan where

they have not already had a system in place or current

systems are below the standards set out by the Alliance

partners.

Provision and maintenance of safe systems of work.

The development and provision of Job Safety Analysis and

safe work procedures for their unique systems of work.

SUBCONTRACTOR - ACTIVITIES FREQUENCY

Develop JSAs for their scopes of work As required

Provide where requested representation to project safety meetings As required

Conduct workplace hazard inspection (formal and informal) Daily/weekly

Conduct toolbox meetings Weekly

Conduct pre-start meetings Daily

Report and investigate all accidents/incidents within their area of As required

control

5.4. Risk Evaluation and Management

Continually evaluate the HSE risks to the workforce, customers and the

environment. Continually evaluate processes and activities for specific hazards

assess potentials, record and control the subsequent risk to a tolerable level.

Expectations

Establish a methodology that identifies both acute and chronic hazards and their

associated impacts. Address routine and non-routine tasks, emergencies and

outside influences.

Conduct hazard assessments during the design, development, operating and

decommissioning stages of equipment, processes and facilities.

Control hazards and reduce risk to a tolerable level through mitigating and

recovery measures.

Blue Copy = Controlled by Quality Assurance Executive

White Copy = Controlled by Division Managers

White Uncontrolled Copy to be marked "Uncontrolled"

ISSUE DATE:

IMCO Engineering & Construction Company WLL Rev : 2

04-08-2016

Procedure No: Procedure Title: Page: 19 of 21

AN IMS CERTIFIED Health, Safety and Environmental Management System

COMPANY QA/IMCO/HSE/MS/QT-001

Apply risk management tools to all proposed activities including acquisitions, bids

and new business development.

5.5. Planning

HSE considerations shall be integral to all aspects of business planning or changes

in the design, development, purchasing and delivery of our products and services.

Expectations

Identify and evaluate the consequences to health, safety and the environment

when making changes to organizational structure, personnel, equipment,

processes or procedures.

Assign responsibility for the achievement of HSE objectives in plans at all levels

of the organization.

Determine the resources required to achieve the plan.

Identify the means by which the plan is to be achieved. Set a time scale and

develop milestones for implementation.

Develop contingency plans for emergencies and in cases when plans or

objectives cannot be completely achieved.

Regularly review and follow up on progress towards achieving the HSE plans and

objectives.

5.6. Implementation, Recording and Monitoring

Do what you said you would do. Determine and record whether those actions are

effective. Activities shall be conducted in accordance with defined standards, and

continuous improvement shall be promoted and monitored through active employee

participation.

Expectations

Assign necessary resources and authority to groups or individuals to implement

plans, processes, procedures and work instructions.

Hold personnel accountable for completing tasks according to plans and HSE

performance standards.

Blue Copy = Controlled by Quality Assurance Executive

White Copy = Controlled by Division Managers

White Uncontrolled Copy to be marked "Uncontrolled"

ISSUE DATE:

IMCO Engineering & Construction Company WLL Rev : 2

04-08-2016

Procedure No: Procedure Title: Page: 20 of 21

AN IMS CERTIFIED Health, Safety and Environmental Management System

COMPANY QA/IMCO/HSE/MS/QT-001

Develop and use systematic monitoring systems for both proactive and reactive

performance measures to measure and support HSE objectives.

Determine non-compliance and the opportunity for practicable improvement

against performance measures.

Determine what records are needed to meet HSE policies, objectives, company

standards, local laws or regulations and customer requirements.

Create records that are clear, easily understood and unambiguous in the

language applicable to Ensign. Store records for a time interval consistent with

good practice and local regulations.

Collect and record information on incidents which actually, or have the potential

to, affect health, safety and the environment.

Evaluate incident information to determine the need for corrective action to

prevent recurrence. Distribute lessons learned.

5.7. Audit and review ( Assessment and Continuous Improvement)

Prove you did what you said you would do. Is the Management System achieving

results and fulfilling policy intent? Audits and reviews shall be conducted to verify the

implementation and effectiveness of the HSE Management System and its

conformation to this specification.

Expectations

Set frequency and level for audits for each division or operation.

Document and distribute the audit report for corrective action and future

reference. Review with all affected employees.

Monitor progress towards achieving and completing corrective actions at

scheduled time intervals.

Schedule periodic management system reviews to include, but not be limited to:

Audit finding summaries

Analysis of incidents, regulatory citations and non-compliance to divisional

standards

Blue Copy = Controlled by Quality Assurance Executive

White Copy = Controlled by Division Managers

White Uncontrolled Copy to be marked "Uncontrolled"

ISSUE DATE:

IMCO Engineering & Construction Company WLL Rev : 2

04-08-2016

Procedure No: Procedure Title: Page: 21 of 21

AN IMS CERTIFIED Health, Safety and Environmental Management System

COMPANY QA/IMCO/HSE/MS/QT-001

Current and future requirements of customers and regulators - Feedback from

customers and regulators

Feedback from employees

Analysis of risk management processes

Appropriateness of current systems to meet business needs

Create review team with the authority to change the system and update the

system requirements.

Blue Copy = Controlled by Quality Assurance Executive

White Copy = Controlled by Division Managers

White Uncontrolled Copy to be marked "Uncontrolled"

You might also like

- QA-IMCO-HSE-P-QT-015 Hot Work Procedure PDFDocument16 pagesQA-IMCO-HSE-P-QT-015 Hot Work Procedure PDFFrancis Enriquez TanNo ratings yet

- How To Conduct Workplace Inspections: A Health and Safety Guideline For Your WorkplaceDocument6 pagesHow To Conduct Workplace Inspections: A Health and Safety Guideline For Your WorkplacemashanghNo ratings yet

- FirmDocument3 pagesFirmTatiana Garcia MendozaNo ratings yet

- Check Hard Hat Expiry Dates Before UseDocument1 pageCheck Hard Hat Expiry Dates Before UsetimbulNo ratings yet

- Pro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex IDocument3 pagesPro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex IMohammed Hamza100% (1)

- ABC Oilfield Services Emergency Drill RecordDocument1 pageABC Oilfield Services Emergency Drill RecordJaijeev PaliNo ratings yet

- Confined Vapor and Gas Fatalities in Upstream OperationsDocument16 pagesConfined Vapor and Gas Fatalities in Upstream Operationssmithyry2014No ratings yet

- Ineco Hse Manual-SignedDocument27 pagesIneco Hse Manual-SignedTantely RazafimahatratraNo ratings yet

- REGDOC2 1 2 Safety Culture Final EngDocument31 pagesREGDOC2 1 2 Safety Culture Final Engnagatopein6No ratings yet

- Workplace Risk AssessmentDocument27 pagesWorkplace Risk Assessmentannemor15100% (3)

- Safety Alert: Pipe Fall From Skids Resulting in 2 Fatalities - Investigation LessonsDocument4 pagesSafety Alert: Pipe Fall From Skids Resulting in 2 Fatalities - Investigation LessonskhaledNo ratings yet

- Pulse - BBS TrainingDocument41 pagesPulse - BBS TrainingRiccardo GastaldoNo ratings yet

- Monthly Site HSE Data - EmdadatDocument1 pageMonthly Site HSE Data - EmdadatVimal SinghNo ratings yet

- PDO Incident First Alert 2021 SummaryDocument16 pagesPDO Incident First Alert 2021 SummaryShambu S Vtk100% (1)

- Health, Safety, Security, Environment, and Quality PolicyDocument1 pageHealth, Safety, Security, Environment, and Quality PolicyVăn PhúcNo ratings yet

- OSH Risk Register - 01Document28 pagesOSH Risk Register - 01M.usmanNo ratings yet

- 2 32 2 1 13 01-CS-ProcedureDocument30 pages2 32 2 1 13 01-CS-ProcedureMahmoud SaiedNo ratings yet

- 7010 - Subcontractor Performance Assessment FormDocument4 pages7010 - Subcontractor Performance Assessment FormRifatRahmatullahNo ratings yet

- Incident Report FormDocument2 pagesIncident Report FormHamzaNoumanNo ratings yet

- PDO Hse AuditDocument21 pagesPDO Hse Auditnagul kmtcNo ratings yet

- PR001 HSE Auditing ProcedureDocument19 pagesPR001 HSE Auditing ProcedureThien NguyenNo ratings yet

- Oil India Limited: Onshore Emergency Response PlanDocument23 pagesOil India Limited: Onshore Emergency Response Planaji sathyanandanNo ratings yet

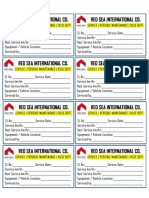

- Red Sea International periodic maintenance recordsDocument1 pageRed Sea International periodic maintenance recordsJunard Lu HapNo ratings yet

- Assignment Safety Report WALTON Factory Mahmudul HaqueDocument28 pagesAssignment Safety Report WALTON Factory Mahmudul Haquepunter07No ratings yet

- Hse MS SlidesDocument32 pagesHse MS SlidesEneyo Victor100% (1)

- Boyus Engineering Nigeria LimitedDocument26 pagesBoyus Engineering Nigeria LimitedBurak KucukkelesNo ratings yet

- COSHH Sodium MetabisulfiteDocument3 pagesCOSHH Sodium MetabisulfiteAhmad OmarNo ratings yet

- COME HSE Audit Plan 2015Document1 pageCOME HSE Audit Plan 2015Syafiq SudinNo ratings yet

- Health, Safety, Environment (HSE) Training Matrix - Houston: Today's DateDocument4 pagesHealth, Safety, Environment (HSE) Training Matrix - Houston: Today's Datemonica dwimandhaNo ratings yet

- Npe Project Ikpt Hsse Programs 2018: NO. Programmed & CoursesDocument1 pageNpe Project Ikpt Hsse Programs 2018: NO. Programmed & CoursesilhamNo ratings yet

- IGC3 - The Health and Safety Practical ApplicationDocument12 pagesIGC3 - The Health and Safety Practical Applicationshaiku shaikhNo ratings yet

- Name: SignDocument1 pageName: SignAdel AlKhedawyNo ratings yet

- David Provan Founder Safety 21 Safety Clutter Day 1Document17 pagesDavid Provan Founder Safety 21 Safety Clutter Day 1Baptiste ElliasNo ratings yet

- TBT and Training RecordDocument1 pageTBT and Training RecordHSE CERINo ratings yet

- QP Reg Rev 3Document75 pagesQP Reg Rev 3Murthy MullapudiNo ratings yet

- 51 Confined SpaceDocument1 page51 Confined SpaceAnonymous ANmMebffKRNo ratings yet

- Safty BookletDocument8 pagesSafty Bookletjinyuan74No ratings yet

- 4-Confined Space EntryDocument10 pages4-Confined Space EntryMohamed Mahmoud Rezk DimoNo ratings yet

- TW Nabors Chevron HES Bridging Document Annual Revision 2014Document35 pagesTW Nabors Chevron HES Bridging Document Annual Revision 2014bilouNo ratings yet

- Lab Design Guide ChecklistDocument9 pagesLab Design Guide ChecklistTanveer AzizNo ratings yet

- Induction Training ProcessDocument7 pagesInduction Training ProcessRanajit RoyNo ratings yet

- Bomdels: Information Technology Service ManagementDocument7 pagesBomdels: Information Technology Service ManagementJhonni GarzonNo ratings yet

- @waterfront: Health, Safety & Environment (Hse)Document6 pages@waterfront: Health, Safety & Environment (Hse)AmiibahNo ratings yet

- Activity 3.2.1 Training Needs Analysis (Document1 pageActivity 3.2.1 Training Needs Analysis (Mahnoor MasroorNo ratings yet

- ANTON - HSE Management Plan - 2022Document72 pagesANTON - HSE Management Plan - 2022Geyko RuslanNo ratings yet

- Incident ReportDocument5 pagesIncident Reportrizal azizanNo ratings yet

- 00 - Petrobel IMS Overview FinalDocument52 pages00 - Petrobel IMS Overview FinalAhmed El AmraniNo ratings yet

- Visitors HSES InductionDocument30 pagesVisitors HSES InductionPradeep KunduNo ratings yet

- Cossh Risk Assessment - Austren GarnetDocument3 pagesCossh Risk Assessment - Austren GarnetKishor KoshyNo ratings yet

- Job Safety Analysis for Caustic and Sulfuric Acid UnloadingDocument2 pagesJob Safety Analysis for Caustic and Sulfuric Acid UnloadingifoodNo ratings yet

- EIA Registration FormDocument2 pagesEIA Registration FormOluwaseun Babs LawalNo ratings yet

- CompletionDocument107 pagesCompletionAdel ALkhaligyNo ratings yet

- P Awjo Hse 003Document3 pagesP Awjo Hse 003fajarbamNo ratings yet

- Annex 07 - ODS-QHSE-SP-04 - Training & Competency ProcedureDocument6 pagesAnnex 07 - ODS-QHSE-SP-04 - Training & Competency ProcedureFahmi AbdullahNo ratings yet

- Pera JackhammerDocument7 pagesPera Jackhammerjumansyahamid1988No ratings yet

- 2014 04 Machine Guarding PresentationDocument24 pages2014 04 Machine Guarding PresentationRamasubramanian SankaranarayananNo ratings yet

- Scaffold inspection record formDocument2 pagesScaffold inspection record formLailNo ratings yet

- Safety Alert - Danger of Infection - January 2010Document1 pageSafety Alert - Danger of Infection - January 2010Meklo1No ratings yet

- Risk Assessment - 1059Document3 pagesRisk Assessment - 1059Francis Enriquez TanNo ratings yet

- Risk Assessment - 1106Document2 pagesRisk Assessment - 1106Francis Enriquez TanNo ratings yet

- Guidelines for LPG plan submissionsDocument7 pagesGuidelines for LPG plan submissionsPrathamesh ShevaleNo ratings yet

- 2021-10-02 - Ddab-Hse-Dor-Contraco - RBLDocument3 pages2021-10-02 - Ddab-Hse-Dor-Contraco - RBLFrancis Enriquez TanNo ratings yet

- Method Statement For Scaffolding WorksDocument17 pagesMethod Statement For Scaffolding WorksFrancis Enriquez TanNo ratings yet

- 2021-10-02 - Ddab-Hse-Dor-Contraco - RBLDocument3 pages2021-10-02 - Ddab-Hse-Dor-Contraco - RBLFrancis Enriquez TanNo ratings yet

- Risk Assessment For External Façade & Canopies CleaningDocument8 pagesRisk Assessment For External Façade & Canopies CleaningFrancis Enriquez Tan100% (1)

- Defensive DrivingDocument54 pagesDefensive DrivingFrancis Enriquez TanNo ratings yet

- Oct-Nov-WSO Newsletter-2022Document18 pagesOct-Nov-WSO Newsletter-2022Francis Enriquez TanNo ratings yet

- Cleaning Window Risk AssessmentDocument3 pagesCleaning Window Risk AssessmentFrancis Enriquez TanNo ratings yet

- Daily Observation Report: Health, Safety & EnvironmentDocument3 pagesDaily Observation Report: Health, Safety & EnvironmentFrancis Enriquez TanNo ratings yet

- 2021 - 10 - 04 - Ddab-Hse-Dor-Contraco - JJJDocument3 pages2021 - 10 - 04 - Ddab-Hse-Dor-Contraco - JJJFrancis Enriquez TanNo ratings yet

- Daily Observation Report: Health, Safety & EnvironmentDocument3 pagesDaily Observation Report: Health, Safety & EnvironmentFrancis Enriquez TanNo ratings yet

- Daily HSE report observationsDocument2 pagesDaily HSE report observationsFrancis Enriquez Tan100% (1)

- 2021.10.02 - Ddab-Hse-Dor-Contraco - VNDocument2 pages2021.10.02 - Ddab-Hse-Dor-Contraco - VNFrancis Enriquez TanNo ratings yet

- Daily Observation Report: Health, Safety & EnvironmentDocument3 pagesDaily Observation Report: Health, Safety & EnvironmentFrancis Enriquez TanNo ratings yet

- Daily HSE ReportsDocument3 pagesDaily HSE ReportsFrancis Enriquez TanNo ratings yet

- 2021.10.2 - Ddab-Hse-Dor-Contraco - JJJDocument3 pages2021.10.2 - Ddab-Hse-Dor-Contraco - JJJFrancis Enriquez TanNo ratings yet

- 2021.10.02 - Ddab-Hse-Dor-Contraco - RFMDocument2 pages2021.10.02 - Ddab-Hse-Dor-Contraco - RFMFrancis Enriquez TanNo ratings yet

- 2021.10.02 - Ddab-Hse-Dor-Contraco - MNLDocument3 pages2021.10.02 - Ddab-Hse-Dor-Contraco - MNLFrancis Enriquez TanNo ratings yet

- Additional Guidance Unit 1Document5 pagesAdditional Guidance Unit 1Francis Enriquez TanNo ratings yet

- Daily Observation Report: Health, Safety & EnvironmentDocument3 pagesDaily Observation Report: Health, Safety & EnvironmentFrancis Enriquez TanNo ratings yet

- Ev02 - Brief Program For New Work at Height CampaignDocument2 pagesEv02 - Brief Program For New Work at Height CampaignFrancis Enriquez TanNo ratings yet

- 2021.10.02 - Ddab-Hse-Dor-Contraco - AmpDocument2 pages2021.10.02 - Ddab-Hse-Dor-Contraco - AmpFrancis Enriquez TanNo ratings yet

- Ev05 - Safety Task Analysis Reduction - Star Card in Different LanguageDocument3 pagesEv05 - Safety Task Analysis Reduction - Star Card in Different LanguageFrancis Enriquez TanNo ratings yet

- Heat IndexDocument2 pagesHeat IndexFrancis Enriquez TanNo ratings yet

- Daily Observation Report: Health, Safety & EnvironmentDocument3 pagesDaily Observation Report: Health, Safety & EnvironmentFrancis Enriquez TanNo ratings yet

- Ev04 - Behavioral Based Safety Training SlidesDocument21 pagesEv04 - Behavioral Based Safety Training SlidesFrancis Enriquez TanNo ratings yet

- Ev01 - Hse Induction Attendance SheetDocument5 pagesEv01 - Hse Induction Attendance SheetFrancis Enriquez TanNo ratings yet

- Assignment Nos. 3 - Scaffolding Risk AssessmentDocument11 pagesAssignment Nos. 3 - Scaffolding Risk AssessmentFrancis Enriquez Tan100% (1)

- Masters of Death: The Assassin ClassDocument5 pagesMasters of Death: The Assassin Classjbt_1234No ratings yet

- 4 5895601813654079927 PDFDocument249 pages4 5895601813654079927 PDFqabsNo ratings yet

- The Beatles - Allan Kozinn Cap 8Document24 pagesThe Beatles - Allan Kozinn Cap 8Keka LopesNo ratings yet

- Noise Blinking LED: Circuit Microphone Noise Warning SystemDocument1 pageNoise Blinking LED: Circuit Microphone Noise Warning Systemian jheferNo ratings yet

- 150 Most Common Regular VerbsDocument4 pages150 Most Common Regular VerbsyairherreraNo ratings yet

- Standard Chartered BackgroundDocument6 pagesStandard Chartered BackgroundAwesum Allen MukiNo ratings yet

- Bluetooth Modules - Martyn Currey PDFDocument64 pagesBluetooth Modules - Martyn Currey PDFAng Tze Wern100% (1)

- Short EssayDocument3 pagesShort EssayBlue PuppyNo ratings yet

- PersonalDevelopment Q1 Module 2Document7 pagesPersonalDevelopment Q1 Module 2Stephanie DilloNo ratings yet

- Cultural Briefing: Doing Business in Oman and the UAEDocument2 pagesCultural Briefing: Doing Business in Oman and the UAEAYA707No ratings yet

- Bravo Jr. v. BorjaDocument2 pagesBravo Jr. v. BorjaMaria AnalynNo ratings yet

- Coal Bed Methane GasDocument10 pagesCoal Bed Methane GasErrol SmytheNo ratings yet

- Alberta AwdNomineeDocs Case Circle BestMagazine NewTrailSpring2016Document35 pagesAlberta AwdNomineeDocs Case Circle BestMagazine NewTrailSpring2016LucasNo ratings yet

- I Could Easily FallDocument3 pagesI Could Easily FallBenji100% (1)

- January: DiplomaDocument24 pagesJanuary: DiplomagwzglNo ratings yet

- Global GovernanceDocument20 pagesGlobal GovernanceSed LenNo ratings yet

- Var, CaR, CAR, Basel 1 and 2Document7 pagesVar, CaR, CAR, Basel 1 and 2ChartSniperNo ratings yet

- Diss - DLL QTR.1 - Week 3Document4 pagesDiss - DLL QTR.1 - Week 3michael r. cantorNo ratings yet

- CHP - 3 DatabaseDocument5 pagesCHP - 3 DatabaseNway Nway Wint AungNo ratings yet

- Impact of Agile On IT and BusinessDocument6 pagesImpact of Agile On IT and BusinessPurva RaneNo ratings yet

- ExpressionismDocument16 pagesExpressionismRubab ChaudharyNo ratings yet

- Unit-2 Fourier Series & Integral: 2130002 - Advanced Engineering MathematicsDocument143 pagesUnit-2 Fourier Series & Integral: 2130002 - Advanced Engineering MathematicsDarji DhrutiNo ratings yet

- Jamaica's Unemployment Aims, Causes and SolutionsDocument23 pagesJamaica's Unemployment Aims, Causes and Solutionsnetzii300067% (3)

- Challan Form OEC App Fee 500 PDFDocument1 pageChallan Form OEC App Fee 500 PDFsaleem_hazim100% (1)

- Junior Instructor (Computer Operator & Programming Assistant) - Kerala PSC Blog - PSC Exam Questions and AnswersDocument13 pagesJunior Instructor (Computer Operator & Programming Assistant) - Kerala PSC Blog - PSC Exam Questions and AnswersDrAjay Singh100% (1)

- U1 Presantation-MAK 032021Document15 pagesU1 Presantation-MAK 032021MD ANAYET ALI KHANNo ratings yet

- GRADE 8 English Lesson on Indian LiteratureDocument3 pagesGRADE 8 English Lesson on Indian LiteratureErold TarvinaNo ratings yet

- Thompson Industrial Products Inc Is A DiversifiedDocument4 pagesThompson Industrial Products Inc Is A DiversifiedKailash KumarNo ratings yet

- Toyota TPMDocument23 pagesToyota TPMchteo1976No ratings yet

- Essay Sustainable Development GoalsDocument6 pagesEssay Sustainable Development GoalsBima Dwi Nur Aziz100% (1)