Professional Documents

Culture Documents

42m BowString

Uploaded by

sorowareCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

42m BowString

Uploaded by

sorowareCopyright:

Available Formats

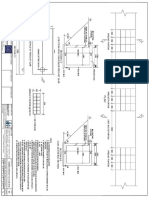

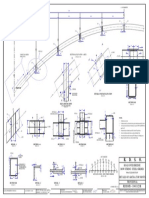

OF SYMMETRY

U4

U3 U3

U2 U2

ARCH LINE OF SYMMETRY

B U1 U1

A

OF BEARING

OF BEARING

L0 L1 L2 L3 L4 L3 L2 L1 L0

KEY ELEVATION - BOW STRING GIRDER

HAND RAIL (SCALE 1:300)

HANGER

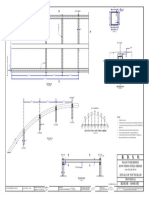

S.NO. DRG. NO. DESCRIPTION

1. RDSO/B - 10408 GENERAL ARRANGEMENT

2. RDSO/B - 10408/1 DETAILS OF STEEL FRAME

3. RDSO/B - 10408/2 DETAILS OF ARCH & TOP JOINTS

BEARING 4. RDSO/B - 10408/3 DETAILS OF TOP TIE BEAM

CONCRETE PEDESTAL

5. RDSO/B - 10408/4 DETAILS OF HANGER & JOINT L0

6. RDSO/B - 10408/5 DETAILS OF BOTTOM LONG. BEAM

A B

7. RDSO/B - 10408/6 DETAILS OF BOTTOM CROSS BEAM

8. RDSO/B - 10408/7 DETAILS OF CONCRETE DECK SLAB

9. RDSO/B - 10408/8 SPLICING LOCATIONS

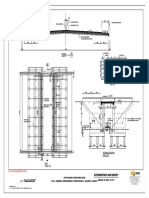

NOTE:

1. All dimensions are in mm.

2. No dimensions shall be scaled from this drawing, only written dimension shall be

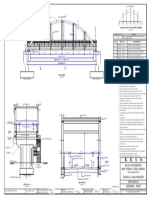

ELEVATION

followed.

SUITABLE FOUNDATION (SCALE 1:100) SUITABLE FOUNDATION

3. This bridge span is designed for 70R and A-class loading as per IRC:6-2010.

4. This bridge span is designed for earthquake zone V.

5. Analysis and design of steel frame is as per IRC:24-2001.

WEIGHT OF STEEL REMARKS 6. Analysis and design of composite concrete deck is as per IRC:22-1986.

THIS VALUE IS APPROXIMATE SO SHOULD NOT BE USED 7. This bridge shall not be converted into three lane after removal of RCC crash barrier

176 ton

FOR PAYMENT PURPOSE

because it is designed for two lane loading only ( as per IRC:6-2010).

6. All steel plates used in fabrication of this bridge are of grade Fe 490B.

Only ISMB 600 is of grade Fe 410C.

7. Grade of concrete for deck, crash barrier and concrete panels shall be M40.

OF CARRIAGE WAY

8. All material shall pass test/analysis prescribed by relevant IS specifications.

9. All steel work fabrication shall be done in accordance with Indian Codes.

ARCH 10. Workshop welding:

a. All workshop fabrication shall be done using SAW (Submerged Arc Welding)

process only.

TOP TIE BEAM

11. On site welding:

ARCH

a. All welding, other than workshop welding, shall be done through Gas Shielded

FCAW (Flux Core Arc Welding) process only. SMAW (Shielded Metal Arc

Welding) also known as Manual Metal Arc Welding shall NOT be permitted

M. S. HAND RAIL RCC CRASH BARRIER anywhere in the structure.

WITH WELD MESH

b. The gas Shield to be used in the FCAW process may be CO Argon or CO -Argon

POT/PTFE mixture.

BEARING

c. In FCAW process, wind screen and/or enclosures shall be provided around the

BOTTOM CROSS BEAM

welding location to prevent shielding gas from blown out.

RCC BEARING

PEDESTAL STAIR CASE IS SITE SPECIFIC d. Welding shall be performed on prepared metal surfaces free from rust, dust,

moisture etc. and before every new pass, slag must be carefully chipped off

from weld surface.

12. Radiography test shall be conducted to ensure weld quality.

RCC PIER CAP 13. Method of launching shall be approved by RDSO.

14. Pier and foundation used here are to represent arrangement of bow string girder.

DRAIN PIPE CARRIAGE WAY Actual dimensions of pier and foundation is site specific.

HANGER

200 THK. WEARING COAT 15. Staircase is optional and may be modified as per site requirement.

65 MM THK. WEARING COAT RCC CRASH

EXISTING ROAD/OGL

BARRIER

R. D. S. O.

2.5% SLOPE 2.5% SLOPE M.S HANDRAIL

RCC PIER ROAD OVER BRIDGE

RCC PILE CAP

BOTTOM LONG.

BOW STRING STEEL GIRDER

BEAM

42m CLEAR SPAN

DRAIN PIPE BOTTOM CROSS BEAM

SUITABLE FOUNDATION

PCC LEVELING COURSE

RCC SHUTTERING

GENERAL ARRANGEMENT

SECTION B-B PROVISIONAL

(SCALE 1:60)

SECTION A-A

(SCALE 1:100) (PAPER SIZE A1) RDSO/B - 10408

DRAWN BY: M/S Abhinav Associates DESIGNED BY: SCRUTINIZED & CHECKED BY: APPROVED BY:

"THIS DRAWING IS THE PROPERTY OF RESEARCH DESIGN AND STANDARD ORGANIZATION ( MINISTRY

CALCULATION REGISTER NO. DD/2014/9 AutoCAD FILE NO.: B-10408 OF RAILWAY ), LUCKNOW-226011, INDIA, AND SHALL NOT BE USED, COPIED OR REPRODUCED IN PART

CHECKED BY: V.K.PANDEY (SSE) VIVEK KUMAR (ADEN/NCR/B&S/RDSO) SRIJAN TRIPATHI (DBS /SB-I) A. K. DADARYA (EDBS) OR WHOLE, WITHOUT PRIOR CONSENT IN WRITING."

You might also like

- 42 M Bow String Girder-10408-R PDFDocument1 page42 M Bow String Girder-10408-R PDFPhanindra MajetiNo ratings yet

- Technical Due Diligence ReportDocument30 pagesTechnical Due Diligence Reportarpondev100% (2)

- Modified LVUP DrawingsDocument1 pageModified LVUP DrawingsAldrinNo ratings yet

- 60 M.bow String Girder-10411-RDocument1 page60 M.bow String Girder-10411-Rkesharinaresh80% (5)

- Precast u-section drain with concealed slab detailsDocument2 pagesPrecast u-section drain with concealed slab detailsGOMASH RCP100% (5)

- Box CUlvert Drawings 5 X 3Document2 pagesBox CUlvert Drawings 5 X 3Soni Jitubhai100% (3)

- Key elevation of bow string girderDocument1 pageKey elevation of bow string girdergoutammand100% (1)

- 42 M Bow String Girder-10408-7-R PDFDocument1 page42 M Bow String Girder-10408-7-R PDFPhanindra MajetiNo ratings yet

- Arabia:The Untold Story, Book 1: Search For PharaohDocument122 pagesArabia:The Untold Story, Book 1: Search For PharaohWazir Khan90% (10)

- Arch Bridge SymmetryDocument1 pageArch Bridge SymmetrygoutammandNo ratings yet

- 60 M.bow String Girder 10411 1 RDocument1 page60 M.bow String Girder 10411 1 RkesharinareshNo ratings yet

- Joint Details of Bridge StructureDocument1 pageJoint Details of Bridge StructurePhanindra MajetiNo ratings yet

- 36m BowString PDFDocument1 page36m BowString PDFgoutammand100% (2)

- Drawings For Culvert at 293+538 PDFDocument3 pagesDrawings For Culvert at 293+538 PDFSurya GowthamNo ratings yet

- 42 M Bow String Girder-10408-3-R PDFDocument1 page42 M Bow String Girder-10408-3-R PDFPhanindra MajetiNo ratings yet

- Bridge Elements GuideDocument86 pagesBridge Elements GuideAbhishekNo ratings yet

- 42 M Bow String Girder-10408-8-R1 PDFDocument1 page42 M Bow String Girder-10408-8-R1 PDFPhanindra MajetiNo ratings yet

- C/S of Staircase (SCALE-1:25) : Pradeep YadavDocument1 pageC/S of Staircase (SCALE-1:25) : Pradeep YadavRVNLPKG6B VBL-GTLM100% (1)

- 60 M.bow String Girder 10411 3 RDocument1 page60 M.bow String Girder 10411 3 RkesharinareshNo ratings yet

- All RDSO Bow String Girder of Span 60-72 MDocument9 pagesAll RDSO Bow String Girder of Span 60-72 MAjay Sinha60% (5)

- Toll Plaza at Ch.81+150 - 07.09.21 - 1-8Document8 pagesToll Plaza at Ch.81+150 - 07.09.21 - 1-8Maninder ChaudharyNo ratings yet

- M Bow String Girder-10408-9-R PDFDocument1 pageM Bow String Girder-10408-9-R PDFPhanindra MajetiNo ratings yet

- Machine Foundations in Oil and Gas IndustryDocument64 pagesMachine Foundations in Oil and Gas IndustryPower PowerNo ratings yet

- Benjamin Britten BiographyDocument1 pageBenjamin Britten BiographyAndrew Major100% (1)

- 42 M Bow String Girder-10408-1-RDocument1 page42 M Bow String Girder-10408-1-RPhanindra MajetiNo ratings yet

- The Self from Philosophical PerspectivesDocument23 pagesThe Self from Philosophical PerspectivesCludeth Marjorie Fiedalan100% (1)

- R. D. S. O.: Rdso/b - 10408/6Document1 pageR. D. S. O.: Rdso/b - 10408/6MUTHU PANDINo ratings yet

- RCC Retaining Wall-01Document1 pageRCC Retaining Wall-01HegdeVenugopalNo ratings yet

- Itr Fob PDFDocument1 pageItr Fob PDFAlok Kumar100% (1)

- Spayed Wing Wall BBS 155+586 RHSDocument1 pageSpayed Wing Wall BBS 155+586 RHSHegdeVenugopal100% (1)

- Stodder y Palkovich. 2012. The Bioarchaeology of IndividualsDocument305 pagesStodder y Palkovich. 2012. The Bioarchaeology of IndividualsLucia Curbelo100% (2)

- DESIGN OF PIER CAPDocument13 pagesDESIGN OF PIER CAPRohit VermaNo ratings yet

- Bridge DrawingDocument1 pageBridge DrawingsorowareNo ratings yet

- 60 M.bow String Girder-10411-7-RDocument1 page60 M.bow String Girder-10411-7-RkesharinareshNo ratings yet

- 36m BowString PDFDocument1 page36m BowString PDFD SRINIVASNo ratings yet

- Fob Drawing Chikhli PKG-4Document2 pagesFob Drawing Chikhli PKG-4Maninder Chaudhary100% (1)

- 42 M Bow String Girder-10408-2-R PDFDocument1 page42 M Bow String Girder-10408-2-R PDFPhanindra MajetiNo ratings yet

- 60 M.bow String Girder-10411-4-RDocument1 page60 M.bow String Girder-10411-4-RkesharinareshNo ratings yet

- Adult Hospital Gown PDF PatternDocument10 pagesAdult Hospital Gown PDF PatternRebecca Jacobs AlfordNo ratings yet

- 60 M.bow String Girder 10411 2 RDocument1 page60 M.bow String Girder 10411 2 Rkesharinaresh100% (1)

- HI-SI Toll Plaza Marking R2-23-01-2020 Final PDFDocument4 pagesHI-SI Toll Plaza Marking R2-23-01-2020 Final PDFRamBhuvan SonkarNo ratings yet

- Bridge BookDocument76 pagesBridge BookSunkara Hemanth KumarNo ratings yet

- RDSO B 11754 4R1 (Mod)Document1 pageRDSO B 11754 4R1 (Mod)shibnath lahiriNo ratings yet

- Cost Estimate - Package 1Document78 pagesCost Estimate - Package 1dheeraj sehgalNo ratings yet

- The Early Irish Church and Iar ConnachtDocument48 pagesThe Early Irish Church and Iar Connachtstefan vlad barac100% (2)

- BOX CULVERT LSM 1 X 5 X 3 PDFDocument67 pagesBOX CULVERT LSM 1 X 5 X 3 PDFamitkukna100% (2)

- Pipe - Culvert Design PDFDocument1 pagePipe - Culvert Design PDFDarshan M TNo ratings yet

- 30 M Bow String Girder-10409-7rDocument1 page30 M Bow String Girder-10409-7rprejithNo ratings yet

- 60 M.bow String Girder-10411-5-RDocument1 page60 M.bow String Girder-10411-5-RkesharinareshNo ratings yet

- 40 M COMPOSITE GIRDER New-ModelDocument1 page40 M COMPOSITE GIRDER New-Modelabhijeet sahuNo ratings yet

- Detailed Survey Data: Public Works Region, Pune Public Works Circle, SolapurDocument23 pagesDetailed Survey Data: Public Works Region, Pune Public Works Circle, SolapurPravin MasalgeNo ratings yet

- Hume Pipe Culvert Drawing PDFDocument1 pageHume Pipe Culvert Drawing PDFDrainage Division CHIRALA0% (2)

- GAD of Structure - A-13 - 2 PDFDocument30 pagesGAD of Structure - A-13 - 2 PDFmayank007aggarwal0% (1)

- North Western Railway: Sr. Den (Co) /JP CBE....... JPDocument1 pageNorth Western Railway: Sr. Den (Co) /JP CBE....... JPEr Navneet JassiNo ratings yet

- PCC Breast Wall 11-05-2021-ModelDocument1 pagePCC Breast Wall 11-05-2021-ModelEr navneet jassiNo ratings yet

- 3.0 Effective Width of Tyres and Load Distribution For IRC Class Special Vehicle 385 T (SV Class)Document2 pages3.0 Effective Width of Tyres and Load Distribution For IRC Class Special Vehicle 385 T (SV Class)vivekNo ratings yet

- Link Road DRGSDocument8 pagesLink Road DRGSBasava Sowmya100% (2)

- 36 MTR SpanDocument13 pages36 MTR SpanAnonymous sfkedkymNo ratings yet

- Proof Checking of BridgesDocument18 pagesProof Checking of BridgesShuzeeNo ratings yet

- Arrangement of pot PTFE bearings diagramDocument1 pageArrangement of pot PTFE bearings diagramkesharinaresh100% (1)

- OHT DesignDocument55 pagesOHT Designdheeraj tiwariNo ratings yet

- Package V bridge drawingsDocument67 pagesPackage V bridge drawingsMandeep Singh100% (1)

- Rdso B-11753 5R1Document1 pageRdso B-11753 5R1shibnath lahiriNo ratings yet

- LC 08Document1 pageLC 08Ramadan GhanmNo ratings yet

- Power LayoutDocument1 pagePower LayoutEng-Al Raie SaadNo ratings yet

- 75 Yacht 2013 With HardtopDocument1 page75 Yacht 2013 With HardtopRoland GrardNo ratings yet

- Sistema Eléctrico C7 CaterpillarDocument2 pagesSistema Eléctrico C7 CaterpillarDana CarvajalNo ratings yet

- LC 07Document1 pageLC 07Ramadan GhanmNo ratings yet

- Electrical Schematic 750L and 850L CRAWLER: V M P TDocument1 pageElectrical Schematic 750L and 850L CRAWLER: V M P TfeliizzNo ratings yet

- Neoprene Bearing Pad 749Document6 pagesNeoprene Bearing Pad 749sorowareNo ratings yet

- L E L E E T P W: SPENCER MethodDocument14 pagesL E L E E T P W: SPENCER MethodsorowareNo ratings yet

- Pile LayoutDocument1 pagePile LayoutsorowareNo ratings yet

- Abutment HeadDocument1 pageAbutment HeadsorowareNo ratings yet

- Analysis of A Slip On A Long Natural SlopeDocument4 pagesAnalysis of A Slip On A Long Natural SlopesorowareNo ratings yet

- Analysis of A Slip On A Long Natural SlopeDocument4 pagesAnalysis of A Slip On A Long Natural SlopesorowareNo ratings yet

- Etabs DimentioningDocument1 pageEtabs DimentioningsorowareNo ratings yet

- Pile Layout RightDocument1 pagePile Layout RightsorowareNo ratings yet

- Semi Through BridgeDocument1 pageSemi Through BridgesorowareNo ratings yet

- Abutment Elevation Section C 10m SpanDocument1 pageAbutment Elevation Section C 10m SpansorowareNo ratings yet

- Abutment Connecting BeamDocument1 pageAbutment Connecting BeamsorowareNo ratings yet

- Abutment Plan 10m SpanDocument1 pageAbutment Plan 10m SpansorowareNo ratings yet

- Abutment Elevation 10m SpanDocument1 pageAbutment Elevation 10m SpansorowareNo ratings yet

- Bearing PedestalDocument1 pageBearing PedestalsorowareNo ratings yet

- Abutment Sectional Plan 10m SpanDocument1 pageAbutment Sectional Plan 10m SpansorowareNo ratings yet

- Abutment DetailsDocument1 pageAbutment DetailssorowareNo ratings yet

- Abutment PlanDocument1 pageAbutment PlansorowareNo ratings yet

- 4/3/2012 3:43:26 PM, DWG To PDF - pc3: Produced by An Autodesk Educational ProductDocument1 page4/3/2012 3:43:26 PM, DWG To PDF - pc3: Produced by An Autodesk Educational ProductsorowareNo ratings yet

- Abutment SectionDocument1 pageAbutment SectionsorowareNo ratings yet

- Information Document: Not For ConstructionDocument1 pageInformation Document: Not For ConstructionsorowareNo ratings yet

- Sheet PilingDocument1 pageSheet PilingRoger SugatanNo ratings yet

- Construction plan for interchange bridge at feeder road 3Document1 pageConstruction plan for interchange bridge at feeder road 3sorowareNo ratings yet

- Guard RailDocument1 pageGuard RailsorowareNo ratings yet

- PC GirderDocument1 pagePC GirdersorowareNo ratings yet

- Information Document: Not For ConstructionDocument1 pageInformation Document: Not For ConstructionsorowareNo ratings yet

- Bridge LayoutDocument1 pageBridge LayoutsorowareNo ratings yet

- Sanskrit 101B Spring 2021 Class PracticeDocument2 pagesSanskrit 101B Spring 2021 Class PracticeGopal DasaNo ratings yet

- The Monster in The MachineDocument286 pagesThe Monster in The MachineStathis PapastathopoulosNo ratings yet

- DeskriptifDocument5 pagesDeskriptifJonny BaristuNo ratings yet

- How Did The Augustan Building Programme Help To Consolidate Imperial PowerDocument4 pagesHow Did The Augustan Building Programme Help To Consolidate Imperial PowerMrSilky232100% (1)

- Eucharist PDFDocument2 pagesEucharist PDFMarkNo ratings yet

- Answer To AppraisalDocument75 pagesAnswer To Appraisallwalper100% (2)

- What is Rhetoric: The Art of PersuasionDocument29 pagesWhat is Rhetoric: The Art of PersuasionpaulinaNo ratings yet

- Obituary Death Revhi PDFDocument6 pagesObituary Death Revhi PDFYildirimFrisk93No ratings yet

- Freds Baybayin ResearchDocument43 pagesFreds Baybayin ResearchFVPA100% (9)

- MonacoDocument7 pagesMonacoAnonymous 6WUNc97No ratings yet

- ) Caterina de Nicola Selected Works (Document19 pages) Caterina de Nicola Selected Works (Catecola DenirinaNo ratings yet

- Pengaruh Pijat Laktasi Terhadap Produksi ASI Pada Ibu Menyusui Di Kelurahan Sendang Sari Kabupaten Asahan Tahun 2019Document7 pagesPengaruh Pijat Laktasi Terhadap Produksi ASI Pada Ibu Menyusui Di Kelurahan Sendang Sari Kabupaten Asahan Tahun 2019MAS 16No ratings yet

- 54 Sayings of Sri RamakrishnaDocument3 pages54 Sayings of Sri RamakrishnamukadeNo ratings yet

- Working Out Difficulties in CFCDocument4 pagesWorking Out Difficulties in CFCRena ManzanaresNo ratings yet

- Parappa The Rapper 2Document65 pagesParappa The Rapper 2ChristopherPeter325No ratings yet

- Jejuri: Arun KolatkarDocument17 pagesJejuri: Arun KolatkarNirmalendu KumarNo ratings yet

- Wipo Intellectual Propertyand Traditional Culturalexpressions/folkloreDocument26 pagesWipo Intellectual Propertyand Traditional Culturalexpressions/folkloreFagbemijo Amosun FakayodeNo ratings yet

- Preparation TechniquesDocument3 pagesPreparation TechniquesMarian BulatinNo ratings yet

- PDF 1 A Maldicao Aurea - CompressDocument10 pagesPDF 1 A Maldicao Aurea - CompressJonathas RodriguesNo ratings yet

- Group 2 - PrepositionsDocument15 pagesGroup 2 - PrepositionsViaNo ratings yet

- Workman 2011 Children's CatalogDocument45 pagesWorkman 2011 Children's CatalogWorkman Extras0% (1)

- Home Lighting For Your Interior DecorationDocument1 pageHome Lighting For Your Interior DecorationNick GeneseNo ratings yet

- The True Story of PocahontasDocument22 pagesThe True Story of PocahontasKatherinFontechaNo ratings yet