Professional Documents

Culture Documents

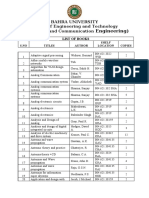

WCECS2015 pp38-42

Uploaded by

zinabuhaile26Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WCECS2015 pp38-42

Uploaded by

zinabuhaile26Copyright:

Available Formats

Proceedings of the World Congress on Engineering and Computer Science 2015 Vol I

WCECS 2015, October 21-23, 2015, San Francisco, USA

Design and Construction of a Microcontroller-

Based Automatic Irrigation System

Aderemi A. Atayero and Adeyemi S. Alatishe, Members, IAENG

important parameter for control of crop growth is the range

AbstractAgricultural produce and (consequently) the of soil moisture the crops maintain throughout their

quality of harvest is adversely affected by prevailing draught in lifecycle. The prosperity of crops depends on their receiving

specific regions of the world in general and Africa in adequate nutrition during seedtime as well as a good balance

particular. The African Union has developed a set of

Aspirations towards meeting its Agenda 2063 tagged The

of exposure to the elements. For crops to thrive, they require

Africa We Desire. The very first of these aspirations is water, sunlight and nutrients from the soil. It is water that

concerned with Africas prosperity, and there can be no helps to present the nutrients from the soil in a form that the

sustainable prosperity without food security. Presently, the roots of the crops can assimilate.

main themes in irrigation management are cost-effective

technology and efficient water and labor management. This The crop roots must receive adequate water to dissolve and

paper presents the design of a low-cost microcontroller-based absorb the nutrients in the soil so that they can develop

irrigation controller capable of managing irrigation for a small properly. However, with an over-supply of water, nutrients

area of land based on real-time values of soil moisture and can be lost through run-off on the soil surface. Hence we

temperature. The developed system allows for user setting of dont only need to supply water to the soil but we need to

the desired soil moisture range suitable for the crop. It will keep the water level at the appropriate level to prevent

display values of same parameters as well. There is also the

added feature of water filling of a water-storage medium for surface run-off. The natural source of water is rainfall, but

such schemes where it will be required. The design presented due to random distribution in the nation, some places receive

in this paper has (to some) extent attempted to meet the more water supply than required, while others receive less

present day requirements of irrigation management. By than the amount of water required. Irrigation is the only

extension, it will aid in the achievement of a vital Aspiration of means through which the latter can be compensated for

Agenda 2063. successful cultivation of crops. Electronics in its versatility

has found application in irrigation management and diverse

Index TermsAgenda 2063, aspiration, irrigation, soil

moisture, sensor designs have been implemented to achieve this. With the aid

of knowledge in electronic engineering, we can introduce

automation and control to irrigation and this will ultimately

I. INTRODUCTION lead to increased productivity in the agricultural sector.

C ROP production is a necessity for mans existence. We

get most of the resources we use in our daily living like

foods (e.g., cocoa, beans, rice etc.) and textiles (cotton, II. LITERATURE SURVEY

raffia, jute etc.) from crops, and therefore the practice of Irrigation is the artificial application of water to the land for

crop production attains great relevance. The practice of crop various purposes, which may include crop cultivation, re-

production from the soil is referred to as agriculture. vegetation of disturbed soils in dry areas and during periods

Agriculture plays an important role in the economy of most of inadequate rainfall, and maintenance of landscapes. With

nations. Agriculture forms the greater part of the source of the invention of sensors and transducers, a great opening

revenue of most nations. Agriculture is a major branch of has been achieved for the application of electronics to

the economy in Nigeria, providing employment for 70% of solving physical day-to- day problems. Through the

the population [1]. Prospects for development in agriculture invention of soil moisture sensors and transducers, the real

have recently emerged and the government has been giving time soil moisture status can be electronically monitored

more attention to developing the sector. If there can be any and same information can be used to determine the water

enhancement in the productivity of the sector, then it should requirement and through actuators, induce irrigation. An

actuator will induce a mechanical action from an electrical

be pursued. Irrigation has done this nationwide and

input. Different approaches have been undertaken to

worldwide in past years. Experiments have been carried out

manage irrigation using electronics. G. K. Banerjee and

over the years, which have shown that the single most

Rahul Singhal [2] proposed a method for the control of

temperature and relative humidity inside a poly house using

Manuscript received July 07, 2015; revised August 20, 2015. a microcontroller. In the proposed method the greenhouse

A. A. Atayero and A. S. Alatishe are with the Department of Electrical controller senses the change in temperature and relative

and Information Engineering (EIE), Covenant University, Ota, Nigeria

humidity with the help of input sensors and process the

A. A. Atayero and A. S. Alatishe are with the Department of Electrical

and Information Engineering (EIE), Covenant University, Ota, Nigeria output to take appropriate control action. The proposed

(phone: +234-807-886-6304; e-mail: atayero@covenantuniversity.edu.ng). system is a low cost and user friendly system with high

A. S. Alatishe is currently with the Electrical Engineering Department, stability and reliability.

Salford University, UK, on leave from Covenant University, Nigeria. (e-

Purna Prakash Dondapati and K. Govinda Rajulu [3]

mail: a.s.e.alatishe@edu.salford.ac.uk).

ISBN: 978-988-19253-6-7 WCECS 2015

ISSN: 2078-0958 (Print); ISSN: 2078-0966 (Online)

Proceedings of the World Congress on Engineering and Computer Science 2015 Vol I

WCECS 2015, October 21-23, 2015, San Francisco, USA

proposed a method in which the microclimatic parameters the lower limit) until the temperature falls below this set

are monitored round the clock for cultivation of specific value - in the evening. Irrigation action will be resumed at

plant species which could maximize their production over this point, until afternoon temperature is reached the next

the whole crop growth season and to eliminate the afternoon. In this mode of operation, the soil will only

difficulties involved in the system by reducing human experience stress due to absence of water, if ever, in the

intervention to the best possible extent. When any of the short period of the afternoon hence the optimal conditioning

climatic parameters crossed a safety threshold which had to of the soil is scarcely compromised. This is an adaptive and

be maintained to protect the crops, the sensors sensed the optional function and is included for users who work with

change and the microcontroller after having read this change the principle of not irrigating under the high temperatures

then performed the specified actions through the use of commonly obtained in the afternoons. It is made optional.

relays until the strayed-out parameter has been brought It can be activated (if required by the user) or deactivated

back to its optimum level. The use of a microcontroller (if not required by the user).

made the set-up low-cost and effective nevertheless.

B. The Water-Storage Controller

III. SYSTEM ARCHITECTURE The system also includes the option of filling up a water

storage medium (i.e. tank) used in the irrigation scheme and

The system is a simple circuit developed to control an

monitoring its water quantity to ensure that it does not go

irrigation scheme on a farmland. It is designed to manage

below a certain set water level (lower limit) by

irrigation based on response to the real-time status of the

commencing filling action of the storage medium as soon as

soil moisture. The system will cause the soil moisture to

it falls below this level. It then refills the medium until the

always be in a certain range suitable for proper crop

water level reaches another set water level (upper limit) at

development. The architecture of the system can be divided

its full capacity. At this point, the water filling action is

into two subsections based on function carried out. These

terminated. It will again resume the water filling as soon as

are:

the water level falls below the lower limit and the cycle

1. The irrigation controller and

would continue. This feature is made optional as well and

2. The water-storage controller.

can be activated - if desired by the user - or deactivated if

the user does not require it. An operational block diagram

A. The Irrigation Controller for the device is presented in Fig. 1.

This section of the device performs the action of irrigation

management. It does so by monitoring the moisture content

of the soil continuously and comparing the values with two

set reference values-the upper-limit and lower-limit moisture

content values- and then inducing corresponding actions

required. Provision is made through control knobs for the

user to set these values as so desired. When the soil moisture

content goes below the lower-limit value set by the user, the

system observes this and begins irrigation action. The land

section will be irrigated until the soil moisture level reaches

the upper limit value set by the user. At this point irrigation

action will cease until the soil moisture level is observed to

fall below the lower limit value again. In this way, the soil

moisture is kept within the desired range suitable for optimal

growth of the crops and water is only supplied, as the crop

requires. Fig. 1. Block diagram for the device operation

There is also the option of including temperature sensing

and control if the user so desires. When the temperature IV. CIRCUIT DESCRIPTION

function is activated, the temperature is continuously The developed circuit consists of several components

monitored and whenever the temperature is observed by the like a power supply section through which regulated d.c.

system to surpass a certain preset temperature value, the supply is provided for energizing the circuit, a

irrigation action is terminated if it is in operation or else it microcontroller, soil moisture sensor, locally-made water

will be prevented from commencing if it is required to do so sensor, relays, actuators, solenoid valves, two-way switches,

(i.e. if the soil moisture level falls below the lower limit variable resistors, connectors for power supply etc. To

of soil moisture). In other words, the temperature sensing properly understand the circuit, the circuit can be

action bypasses the soil moisture-based irrigation operation. subdivided into several units. These units are as follows:

The temperature value above, which this operation 1) The power supply unit

occurs, is set in the firmware program code to represent the 2) The sensor/transducer unit

average afternoon temperature (36C), which is considered 3) The signal conditioning unit and peripherals

unsuitable for irrigation by some users. What this means is 4) The control unit

that once the afternoon temperature is reached, irrigation 5) The display unit

action is suspended (even if the soil moisture level is below 6) The actuators

ISBN: 978-988-19253-6-7 WCECS 2015

ISSN: 2078-0958 (Print); ISSN: 2078-0966 (Online)

Proceedings of the World Congress on Engineering and Computer Science 2015 Vol I

WCECS 2015, October 21-23, 2015, San Francisco, USA

A. The Power Supply Unit group of conductors separated by a little spacing to give

The power supply unit (Fig. 2) supplies 12V D.C. and room for water running through it to bridge it. If a voltage is

5V D.C. for the microcontroller from mains of 220VA.C. applied to the switch, it is found to be short- circuited when

water flows through it. We can therefore say it takes either

of two states relative to voltage across its terminals - on or

off - hence the name switch. It is with this property that

we are able to control the water filling of the tank.

Fig. 2. Power supply circuit

B. The Sensor/Transducer Unit

This unit is the unit responsible for the detection of the

presence of the physical parameters and converting same to

electrical form for processing. The physical parameters of

interest are the soil moisture, the ambient temperature and

the presence of water in the tank.

The Soil Moisture Transducer

Fig. 4. Analog/Digital Converter Module

The soil moisture transducer used in this circuit was

purchased from Amazon (Fig 3).

C. The Signal Conditioning Circuit and peripherals

This circuit consists of the all components, which are used to

present the transducers outputs in a form that the control

unit or processing unit can process. The component included

in this unit is the Analog/Digital Converter module of the

microcontroller.

Fig. 3. Soil moisture transducer Analog/Digital Converter (ADC)

The analog/digital converter used in this work is a module

Its voltage output is proportional to the quantity of water in embedded in the microcontroller. It produces discrete values

the soil. There is no datasheet available for it and all from a continuous values fed into it which the

information about it is given on Amazons site. Its specified microcontroller can process. The analog input charges a

supply voltage is from 3.3V to 5V and with this supply, it sample and hold capacitor. The output of the sample and

gives an output voltage of between 0V to 2.3V for the full hold capacitor is the input into the converter.

range of complete dryness to submersion in water. Its rating

for maximum operating current is 15mA. The transducer is D. The Control Unit

buried in the soil near the root zone of the crops for This unit is basically the section that provides the control

accurate monitoring. Its output is fed into the ADC input of of the whole system. It consists of a microcontroller IC

the microcontroller. chip plus peripheral components and the control logic

(firmware), which the chip functions with. The

The Temperature Transducer microcontroller chip is the central hardware component

The temperature transducer used in this circuit is the while the program/code written in Mikro-C language is the

LM35 temperature transducer. It is a precision firmware component. The microcontroller used in this

temperature transducer with a linear voltage output over work is the PIC18F452. The PIC18F452 is a 40-pin, 8-bit

the range of -55 oC to 150 oC. Its favorable property is its microcontroller. The features of the PIC18F452

linearity and step-wise sensitivity. It has a sensitivity of microcontroller make it a suitable choice for use in this

0.01V/oC starting from 0oC hence its temperature can automatic irrigation controller system. These features

easily be calculated. The output of the transducer is include: The microcontroller has 5 sets of input/output

applied to the ADC segment of the microcontroller for pins categorized into ports namely PORTS A, B, C, D, and

processing.

E. PORT E is not utilized in this circuit.

The Water Switch

The software

The water switch is a locally made sensor. It is constructed

The software used for writing the control logic for the

using a Vero board. It is simply an open circuit formed by a

microcontroller processor is the Mikro-C software and the

ISBN: 978-988-19253-6-7 WCECS 2015

ISSN: 2078-0958 (Print); ISSN: 2078-0966 (Online)

Proceedings of the World Congress on Engineering and Computer Science 2015 Vol I

WCECS 2015, October 21-23, 2015, San Francisco, USA

Mikro-C compiler is used as a platform for storing and current temperature, the state of the system (whether

running the program. A programmer is used for the purpose irrigating, or filling the tank) etc. The LCD screen is

of interfacing the code with the hardware chip. The program powered by a 5V supply voltage, and has backlight to enable

is first written as a flowchart before it is converted to a code the user to see the character that may be displayed on the

in the Mikro-C language. screen where external light may be insufficient. The contrast

of the display can also be controlled using a simple

E. The Display Unit potentiometer or variable resistor with the sweep terminal

connected to the V EE pin of the LCD screen. When the

device is used in the 4-bit mode, the pins D0, D1, D2 and D3

are left unconnected, while D4, D5, D6 and D7 are

connected to corresponding output pins of the

microcontroller.

F. The Actuators

The actuators used in this work consist of the solenoid

valves, the low-power D.C. motor and all the relay switches

used to energize and de-energize them.

Fig. 5. The 16x4 LCD

V. METHODOLOGY

The display unit is simply an output unit used for the The circuit was designed and simulated using the circuit

purpose giving the user required information. The display diagram of Fig. 6, on the Proteus design suite. However,

unit is a simple 16x4 LCD module. This means it has sixteen the outputs Q1, Q2, and Q3 were replaced with the red,

columns and four rows. Each column can represent only a green and blue LEDs for demonstration purposes only.

single character. The device can display the ASCII

The programming code was written and built for

alphanumeric characters, some Japanese characters, and

simulation - with the Proteus Design software using

some symbols. The information to be displayed are the

Mikro-C compiler software.

current soil moisture - on a percent base of which

submersion in water is a 100% and in dry air is 0%, the

lower limit soil moisture, the upper limit soil moisture, the

Fig. 6. System Circuit

ISBN: 978-988-19253-6-7 WCECS 2015

ISSN: 2078-0958 (Print); ISSN: 2078-0966 (Online)

Proceedings of the World Congress on Engineering and Computer Science 2015 Vol I

WCECS 2015, October 21-23, 2015, San Francisco, USA

VI. TESTING sensing units can then be interfaced to a single control

Several tests were made to ensure the proper functioning of unit.

the system. The physical model was tested using the actual 3. This system can be programmed in assembly

components on a breadboard, as the components were language to make the response of the system much

interconnected just like in the software simulation. During faster.

the physical testing, measurements were taken and a number

of observations were made. The overall response and REFERENCES

performance of the system were checked. [1] Agriculture in Nigeria, Online, available at: http://en.wikipedia.org/

wiki/Agriculture_in_Nigeria, accessed 20.08.2015.

[2] G. K. Banerjee, Rahul Singhal, Microcontroller Based Polyhouse

A. Transducer Testing Automation Controller, ISED '10 Proceedings of 2010 International

Symposium on Electronic System Design.

For the moisture sensor, in order to understand its voltage [3] Purna Prakash Dondapat , K. Govinda Rajulu . (2012, August). An

output characteristics, it was immersed in water and biased Automated Multi Sensored Green House Management. International

to give the output of 2.3V and less than 15mA current given Journal of Technological Exploration and Learning. Volume 1 (Issue

inits specifications and then submerged in a soil sample 1).

initially filled to its capacity. Readings were taken at

intervals, and the results shown in Table I.

TABLE I

OUTPUT VOLTAGE OF THE SOIL MOISTURE TRANSDUCER

Duration (Hrs) Voltage (V)

0 2.3

6 2.21

12 2.03

18 1.87

24 1.65

30 1.31

36 0.70

42 0.45

C. Continuity Test

Continuity testing was carried out to ensure that there

were no connections between isolated sections and

components and that all connected points were

connected.

D. Power-On Test

This test is performed to check whether the voltage at

different terminals is according to the requirement or not. It

is carried out before inserting the microcontroller.

VII. CONCLUSION

The system was developed successfully, meeting the aims

of functionality, low-cost design and simplicity of

operation. Hence irrigation can be automatically controlled

in the rural areas of the country for low-earning farmers

leading to greater productivity of crops and efficiency of

irrigation management. This work could be developed to

meet the requirements of irrigation in agriculture in the

following ways:

1. The system could be developed for larger farmlands

by integrating into the system a wireless transmission

system of range suitable for the size of the land so

that wires will not have to be run on the farmland for

long distances, which will make the system bulky and

difficult to implement in a large irrigation scheme.

2. The system can also be developed to meet farming

practices like crop rotation by making the system

have a separate sensing unit per section, so that each

section can have different set soil moisture ranges

suitable for the crops in those sections. The different

ISBN: 978-988-19253-6-7 WCECS 2015

ISSN: 2078-0958 (Print); ISSN: 2078-0966 (Online)

You might also like

- Grade 11 Lab ExamDocument3 pagesGrade 11 Lab Examzinabuhaile26100% (1)

- Grade 11 Lab ExamDocument3 pagesGrade 11 Lab Examzinabuhaile26100% (1)

- BEC Post-Test MCQs 2 PDFDocument6 pagesBEC Post-Test MCQs 2 PDFzinabuhaile26No ratings yet

- CSCI399 "Laboratory Manual": Lab SetupDocument78 pagesCSCI399 "Laboratory Manual": Lab Setupzinabuhaile26No ratings yet

- Microcontroller Based Automation of Drip Irrigation SystemDocument6 pagesMicrocontroller Based Automation of Drip Irrigation Systemzinabuhaile26No ratings yet

- BEC Post-Test Answer Key 2Document1 pageBEC Post-Test Answer Key 2zinabuhaile26No ratings yet

- Mysql Lab ManualDocument3 pagesMysql Lab Manualzinabuhaile260% (1)

- Micro Controller Based Automatic Plant Irrigation System PDFDocument5 pagesMicro Controller Based Automatic Plant Irrigation System PDFzinabuhaile26No ratings yet

- Lab ManualDocument17 pagesLab Manualzinabuhaile26No ratings yet

- Blackhole Attack Implementation in Aodv Routing ProtocolDocument5 pagesBlackhole Attack Implementation in Aodv Routing Protocolzinabuhaile26No ratings yet

- Mpin TDocument55 pagesMpin Tzinabuhaile26No ratings yet

- Astm C 150 2007Document8 pagesAstm C 150 2007Nikolay Drumev100% (1)

- MPI Godse TextBookDocument606 pagesMPI Godse TextBookRam50% (2)

- MP Int Chapter4Document85 pagesMP Int Chapter4zinabuhaile26No ratings yet

- Mpi Chapter1Document57 pagesMpi Chapter1zinabuhaile26No ratings yet

- Lecture 13 - Memory InterfacingDocument9 pagesLecture 13 - Memory Interfacingzinabuhaile26No ratings yet

- Electronics and Microprocessor PDFDocument523 pagesElectronics and Microprocessor PDFzinabuhaile26No ratings yet

- Microprocessor by A P Godse D A Godse PDFDocument135 pagesMicroprocessor by A P Godse D A Godse PDFzinabuhaile26No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Mark 3E1 Service PDFDocument53 pagesMark 3E1 Service PDFmapsengineeringNo ratings yet

- b70 3570en PDFDocument84 pagesb70 3570en PDFAshish TripathiNo ratings yet

- CurriculumforB Tech3-8 PDFDocument119 pagesCurriculumforB Tech3-8 PDFRavi ShankarNo ratings yet

- Bob Pease AnalogDocument57 pagesBob Pease AnalogRoberto AraizaNo ratings yet

- En Acq80-04 FW ADocument270 pagesEn Acq80-04 FW AZhen Xing HengNo ratings yet

- Max Signal Properly TipsTrick Acq Analog Signals DS00004225Document21 pagesMax Signal Properly TipsTrick Acq Analog Signals DS00004225jay lowkeyNo ratings yet

- Numerical generator protection REG 316*4Document40 pagesNumerical generator protection REG 316*4varofNo ratings yet

- Mixed Signal Circuit Design ELL 731Document11 pagesMixed Signal Circuit Design ELL 731Anmol SinhaNo ratings yet

- Control Panel Active Faults MenuDocument2 pagesControl Panel Active Faults Menuxargle100% (2)

- VLSI Lab Question BankDocument4 pagesVLSI Lab Question BankSav ThaNo ratings yet

- Fromato de Archivos ComtradeDocument4 pagesFromato de Archivos ComtrademarcospowerNo ratings yet

- BMS CSE Lab ManualDocument84 pagesBMS CSE Lab ManualRuthwik S GowdaNo ratings yet

- Print List of Books List of Books Necessary For Reading EngineeringDocument22 pagesPrint List of Books List of Books Necessary For Reading EngineeringRatish DhimanNo ratings yet

- Henzler - 2010 - Time-To-Digital Converters PDFDocument132 pagesHenzler - 2010 - Time-To-Digital Converters PDFmimitech mimitechNo ratings yet

- Ads 8556 EVMDocument16 pagesAds 8556 EVMchethannitkNo ratings yet

- Tracking Solar Panel: Data AnalysisDocument3 pagesTracking Solar Panel: Data AnalysisPravat Satpathy100% (1)

- Activity Sheet Introduction To Radar Systems: Transmitters and Receivers, Parts 1 and 2Document4 pagesActivity Sheet Introduction To Radar Systems: Transmitters and Receivers, Parts 1 and 2Ciprian IonelNo ratings yet

- IrrigationDocument10 pagesIrrigationIgor ŠuntićNo ratings yet

- Design and Implementation of CCTV Network ThesisDocument93 pagesDesign and Implementation of CCTV Network Thesisoaldwaib94% (18)

- Ap 30Document6 pagesAp 30Hoàng NguyễnNo ratings yet

- Panel Meter Series C124.1 / D124.1 / E124.1 Measuring Frequency, Ratio, DifferenceDocument24 pagesPanel Meter Series C124.1 / D124.1 / E124.1 Measuring Frequency, Ratio, DifferenceKvss GuptaNo ratings yet

- TM2AMM3HTDocument7 pagesTM2AMM3HTBadrulUmamNo ratings yet

- Iec 60688 - 2002Document37 pagesIec 60688 - 2002bilgiislem773267% (3)

- PCB Technical Interview QuestionsDocument55 pagesPCB Technical Interview Questionssandee kumarNo ratings yet

- App-4Sdd Data Acquisition Software Operation Manual: Technoap Co., LTDDocument37 pagesApp-4Sdd Data Acquisition Software Operation Manual: Technoap Co., LTDOmar SuarezNo ratings yet

- 1.number SystemDocument25 pages1.number Systemajith p pNo ratings yet

- Sensor Supply - Test: TroubleshootingDocument18 pagesSensor Supply - Test: TroubleshootingCarel100% (1)

- 3 Embedded Systems - Raj KamalDocument37 pages3 Embedded Systems - Raj KamalAshokkumar ManickamNo ratings yet

- Introduction To Discrete Time Signals & SystemDocument119 pagesIntroduction To Discrete Time Signals & SystemMahesh Abnave100% (1)

- Troubleshooting of Electronic CircuitsDocument2 pagesTroubleshooting of Electronic Circuitsmoh_68100% (1)