Professional Documents

Culture Documents

Paper4 Water-Tank PDF

Uploaded by

Eddie TangOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Paper4 Water-Tank PDF

Uploaded by

Eddie TangCopyright:

Available Formats

International Journal of u- and e- Service, Science and Technology

Vol.8, No. 6 (2015), pp.267-276

http://dx.doi.org/10.14257/ijunesst.2015.8.6.26

Designing of Fuzzy Logic Controller for Liquid Level Controlling

Ashish Singh Thakur, Himmat Singh and Sulochana Wadhwani

Department of Electrical Engineering

Madhav Institute of Technology & Science, Gwalior, India

e-mail: ashish05singh1990@gmail.com, himmatmind100@yahoo.com,

sulochana_wadhwani1@rediffmail.com

Abstract

In control system there are a number of general systems and methods which are

encountered in all areas of industry and technology. There are many ways to control any

system, in which fuzzy is often the very best way. The only reason is faster and cheaper.

One of successful application that is used for the controlling of liquid level is fuzzy logic

controller. In order to find the best design to stabilize the liquid level in this method, some

factors will be considered. For this paper, the liquid level was controlled by using three

rules of membership function which then extended to five rules, seven rules and nine rules

for verification purpose and further improvement of the system. This paper was focused to

the software part only. By doing some modification in this paper, the design will be very

useful for the system relates to liquid level control that widely use in industry nowadays.

For a long time, the selection and definition of the parameters of PID controller are very

difficult. There must be a bad effect if you do not choose nicely parameters. To strictly

limit the overshoot, the use of Fuzzy controller can achieve a great control cause. In this

paper, we take the liquid level water tank, and use MATLAB to design a Fuzzy Controller.

Then we analyze the control effect and compare it with the effect of PID controller. As a

result of comparing, Fuzzy Logic Controller is superior to PID controller. Comparison of

the control results from these two systems indicated that the Fuzzy logic controller

significantly reduced overshoot and steady state error.

Keywords: PID Controller, Fuzzy Logic Controller, Rule Viewer, FIS, Graphical User

Interface, Liquid Level System, MATLAB Simulation

1. Introduction

Traditionally, accurate mathematical model-based strategy has been applied to deal with

control problems. However, liquid level control system is very complex system.

Conventional control approaches are convenient to solve these difficulties. Level control is

one of the most important aspects widely used in industrial process control. It got a wide

range of applications like in nuclear power plants, chemical industries, etc. As the

parameters of the plant changes frequently, maintaining the water level at its set point

value is difficult. Hence, it is required to design a controller which controls the level of the

liquid at its set point value and also it must accept the variable disturbances on the plant.

PID controller is the earliest used controller in the industries [1]. But it is difficult to get

the efficient control because the PID gains setting is a challenging task. It is hard to control

nonlinear processes with linear classic controllers. If the nonlinear process working point

changes all the conventional controller parameters must be modified in order to keep the

control performance. An interesting approach fuzzy logic controller is used to control

nonlinear processes [2].

Applying fuzzy logic in the designing of the fuzzy logic controllers the control

knowledge of the operators can be used to obtain the necessary fuzzy rule bases in the

ISSN: 2005-4246 IJUNESST

Copyright 2015 SERSC

International Journal of u- and e- Service, Science and Technology

Vol.8, No. 6 (2015)

control strategies. The fuzzy rule bases consist of linguistic rules that give full details of

the Fuzzy Logic Controllers actions to achieve good performances for the controlled

nonlinear processes. To implement a fuzzy logic controller a fuzzy inference reasoning

method must be used to activate the fuzzy rule base. The sensory data from process go to

the Fuzzy Logic Controller input through an analog digital interface and then through a

fuzzification block that converts the crisp numerical data into fuzzy data. These fuzzy

data fire some rules from Fuzzy Logic Controller rule base and from each fired rule a

value of a fuzzy control output is obtained. The final fuzzy control output is computed

applying a fuzzy inference reasoning method over all simultaneously fuzzy control output

obtained from the fired rules. Then the final fuzzy control outputs go through a

defuzzification block to be converted from fuzzy to crisp numerical signals and through a

digital - analog interface to be converted into an analogue control signal [3]. The Fuzzy

Logic Controller must contain a number of set of parameters that can be altered to modify

the controller performance. These parameters are: - the scaling factors for each variable; -

the fuzzy set representing the meaning of linguistic values; the fuzzy rules. For a

successfully work the number of parameters to be tuned should be as small as possible

[4]. This paper presents a practical method to achieve Fuzzy Logic Controllers with

decision tables that can be used to solve the control problems in the real time industrial

applications.

2. Liquid-tank System

Liquid is flowing into a tank at some rate water in (Q in) and out of the tank at some

rate water out (Q out). The liquid in the tank at some height or level H it is known as output

flow rate varies as the square root of the height Q out= a, so the higher the level, faster

the water flow out. If the output flow rate is not accurately equal to input flow rate, the

level will drop, (Q out > Qin) or rise, if (Q out < Qin) [5]. This process has a property called

self-regulation. This means that at some input water flow rate, the water height will rise

until it reaches a height for which the output flow rate matches the input flow rate.

Figure 1. Schematic Diagram for Liquid-Tank System

A self-regulating system does not provide regulation of a variable to any particular

reference value. In this example, the liquid level will accept some value for which input

and output flow rate are the same, and there it will stay. But if the input flow rate

changed, then the level would modify also. So it is not synchronized to a reference value.

Suppose we want to keep the level at some particular value H in Figure 1 regardless of

the input flow rate then something more than self-regulation is needed. Water enters a

tank from the top and leaves through an orifice in its base. The rate that water enters is

directly proportional to the voltage, V, applied to the pump. The rate at which water

leaves is directly proportional to the square root of the height of water in the tank.

268 Copyright 2015 SERSC

International Journal of u- and e- Service, Science and Technology

Vol.8, No. 6 (2015)

A. Model Equation

The equation for the height of liquid in the tank H is given by

= = (1)

Water-Tank System Block is given as

= = (2)

Where V: volume of liquid in the tank, A: cross-sectional area of the tank, b:

constant related to the flow rate into the tank and a: constant related to the flow rate out

of the tank. The values of the parameters are specified as a=2 cm2.5/s, A=20 cm2, b=5

cm3. The equation describes the water height, H, as a function of time, due to the

difference between flows rates into and out of the tank. It is nonlinear due to its

dependence on the square-root of H. Linearizing the model, using Simulation Control

Design, simplifies the analysis of this model [6].

The level is sensed by a suitable sensor and converted to a signal acceptable to the

controller. The controller compares the level indicator to the preferred set-point

temperature and actuates the control element. The control element alters the manipulated

variable to change position of the valve so that the quantity of liquid being added can be

controlled in the process. The purpose of the controller is to regulate the level as close to

the set point as possible.

B. Working of Liquid Level

A continuous square wave is applied at current to pressure converter to the controller

for creating continuous disturbance. Another current to pressure converter of the

controller comes from feedback. The controller acts according to the error generated. This

error and its derivative is useful for the controller which then takes the necessary action

and decides the location of the valve which gives the desired flow of the water into the

tank. The position of the valve is decided by PID Controller or by the rules written in the

Fuzzy Logic Controller Rule Editor. If the water level in the tank is low then the valve

open completely and if the water level is high in the tank then the valve closes or opens

up to a point. When the level is full then the valve is fully closed. The PID controller can

be changed by varying the values of Proportional Gain, Integral Gain & Derivative Gain

and effect of the changed values can be seen effectively using rule viewer.

3. Designing of Fuzzy Logic Controller

A. FIS Editor

We have defined two Inputs for the Fuzzy Controller. One is level of the water in the

tank denoted as Level and the other one is rate of change of water in the tank denoted as

Rate. Both these Inputs are applied to the Rule Editor [7]. According to the Rules

written in the Rule Editor the controller takes the action and gives the opening of the

Valve which is the output of the controller and is denoted by Valve.

Figure 2. Mamdani Type Fuzzy Controller

Copyright 2015 SERSC 269

International Journal of u- and e- Service, Science and Technology

Vol.8, No. 6 (2015)

B. Membership Function Editor

The Membership Function Editor shares some features with the FIS Editor. In fact, all

of the five basic graphical user interface tools have similar menu options. The MF Editor

is the tool that let you display and edits all of the membership functions associated with

all of the input and output variables for the entire fuzzy inference system [8-9]. When you

open the Membership Function Editor to work on a fuzzy inference system that does not

already exist in the workspace, there is not yet any membership functions associated with

the variables that you have just defined with the FIS Editor.

a) Fuzzy Set Characterizing Input

i. Level [Range (-10 to 10)]

Table I. Crisp Range Table for Level

Fuzzy Variable MF Used Crisp Input

Range

Negative Triangular MF (-18 -10 1)

Zero Triangular MF (-8 0 8)

Positive Triangular MF (0 10 18)

Figure 3. Membership Function Fuzzy Set Characterize Input

ii. Rate [Range (-0.5 to 0.5)]

Table II. Crisp Range Table for Rate

Fuzzy Variable MF Used Crisp Input

Range

Negative Triangular MF (-0.9 -0.5 0)

Zero Triangular MF (-0.4 0 0.4)

Positive Triangular MF (0 0.5 0.9)

Figure 4. Membership Function Fuzzy Set Characterize Output

b) Fuzzy Set Characterizing Output

Use triangular membership function types for the output. First, set the Range (and the

Display Range) to (-5 5), to cover the output range. Initially, the negative membership

270 Copyright 2015 SERSC

International Journal of u- and e- Service, Science and Technology

Vol.8, No. 6 (2015)

function will have the parameters (-9 -5 0), the zero membership function will be (-4 0 4),

for the positive membership function will be (0 5 9).

i. Valve [(Range (-5 to 5)]

Table III. Crisp Range Table for Valve

Fuzzy Variable MF Used Crisp Input Range

Negative Triangular MF (-9 -5 0)

Zero Triangular MF (-4 0 4)

Positive Triangular MF (0 5 9)

Figure 5. Triangular Membership Function Output

Rule Editor

Constructing rules using the graphical Rule Editor interface is fairly self-evident.

Based on the input and output variables defined with the FIS Editor, the Rule Editor

allows you to create the rule statements automatically [10].

1. If (Level is negative) and (Rate is negative) then (Valve is negative) (1).

2. If (Level is negative) and (Rate is zero) then (Valve is negative) (1).

3. If (Level is negative) and (Rate is positive) then (Valve is negative) (1).

4. If (Level is zero) and (Rate is negative) then (Valve is negative) (1).

5. If (Level is zero) and (Rate is zero) then (Valve is zero) (1).

6. If (Level is zero) and (Rate is positive) then (Valve is positive) (1).

7. If (Level is positive) and (Rate is negative) then (Valve is positive) (1).

8. If (Level is positive) and (Rate is zero) then (Valve is positive) (1).

9. If (Level is positive) and (Rate is positive) then (Valve is positive) (1).

4. Simulation Block Diagram

A. Valve

The liquid flow level can be controlled by using limited integrator in the simulated

valve subsystem is given as

Figure 6. Block Diagram of Valve Subsystem

Copyright 2015 SERSC 271

International Journal of u- and e- Service, Science and Technology

Vol.8, No. 6 (2015)

B. Water Tank

The simulation block diagram for the water tank is given

Figure 7. Block Diagram of Water Tank

C. Controller Block

The circuitry for the controller of liquid tank is given as

Figure 8. Block Diagram of Pid Controller

The output of the controller governs the opening or closing of the valve [11-13]. The

liquid level is sensed by the liquid level sensors and the rate of change is calculated by the

derivative of the level signal after that the limits of which are decided by a saturation non-

linearity.

D. Simulation Model of PID Controller

Simulation model of Conventional PID Controller for liquid level control as shown in

Figure 9. In this we control the water level of the system with the help of PID controller in

the MATLAB simulation. Two inputs are given in the valve these are control and source

flow with an limited integrator the control valve is connected to the PID controller for

controlling the outflow and a constant is connected to the valve source flow for

controlling the level the output of valve is given to the water tank at which we observe the

liquid flow out, water level and over flow.

272 Copyright 2015 SERSC

International Journal of u- and e- Service, Science and Technology

Vol.8, No. 6 (2015)

Figure 9. Simulation Model by Using Pid Controller

E. Simulation Model of Fuzzy Logic Controller

A simulation model for Fuzzy Logic Controller for liquid level control

Figure 10. Simulation Model by Using Fuzzy Logic Controller

5. Simulation Results and Discussion

A. Simulation Result of PID Controller

1

0.9

0.8

Liquid Flowout

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

9940 9950 9960 9970 9980 9990 10000

Time (Sec)

Figure 11. Simulation Result Using Pid Controller

Copyright 2015 SERSC 273

International Journal of u- and e- Service, Science and Technology

Vol.8, No. 6 (2015)

From Figure 11 it is seen that PID controllers drives the system unstable due to

mismatch error generated by the inaccurate time delay parameter used in the plant model.

Transient & overshoot are present when PID controller is used to control the liquid level.

B. Simulation Result of Fuzzy Logic Controller

1.4

Input Signal

1.2

Fuzzy Logic Controller

Liquid Flowout

0.8

0.6

0.4

0.2

0

0 100 200 300 400 500 600 700 800 900 1000

Time (Sec)

Figure 12. Simulation Result Using Fuzzy Logic Controller

From Figure 12 Fuzzy Logic Controller provide good performance in terms of

oscillations and overshoot in the absence of a prediction mechanism. The FLC algorithm

adapts rapidly to longer time delays and provides a stable Response.

C. Discussion

From Figure 11 it is seen that PID controllers drives the system unstable due to

mismatch error generated by the inaccurate time delay parameter used in the plant model.

Transients & overshoots are present when PID controller is used to control the liquid

level. It is also clear that with the use of PID controller some steady state error is present

in the simulation result. The Fuzzy Logic Controller is applied to the plant described

above in Figure 10. Fuzzy Logic Controller simulation results are plotted against with that

of conventional controller PID controller for comparison purposes. The simulation results

are obtained using a 9 Fuzzy Logic Controller rules.

From the simulations, in the presence of unknown or possibly varying time delay, the

proposed Fuzzy Logic Controller shows a significant improvement in maintaining

performance and preserving stability over standard PID method. To strictly limit the

overshoot, using Fuzzy Controller can achieve a great control effect. Especially it can

give more attention to various parameters, such as the response time, the error of

steadying and overshoot. Comparison of these two systems indicated that the fuzzy logic

controller significantly reduced overshoot and steady state error. Comparison results of

PID and FLC are shown in Table IV. The overall performance may be summarized as

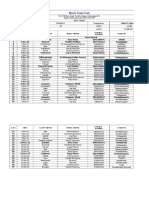

Table IV. Comparison Table of Pid & Flc

Parameters PID Controller Fuzzy Logic

Controller

Settling Time More Less

Transient Present Not Present

Rise Time Less More

274 Copyright 2015 SERSC

International Journal of u- and e- Service, Science and Technology

Vol.8, No. 6 (2015)

Steady State Present Not Present

Error

6. Conclusion

Unlike the conventional PID controller the Fuzzy Logic Controller has benefits on the

system response, a unique Fuzzy Logic Controller using a small number of rules and

straightforward implementation has been proposed to solve a class of level control

problems with unknown dynamics or variable time delays commonly found in industry

which cannot we reduced easily with the help of PID controller. Fuzzy Logic Controller is

easy to implement than PID controller. Additionally, the Fuzzy Logic Controller can be

easily programmed into many currently available industrial process controllers. The

Fuzzy Logic Controller on a level control problem with promising results can be applied

to an entirely different industrial level controlling apparatus.

7. Future Work

As a future work we can develop design a Fuzzy Logic Controller for a couple tanks

system as adaptive Fuzzy Logic Controller like PID algorithm, which gives high

performance for systems and high intelligence.

References

[1] The Control Handbook, CRC Press, (1999).

[2] H. J. Zimmermann, Fuzzy set theory and its applications, Springer Verlag, Berlin, (2001).

[3] A. Zilouchian and M. Jamshidi, Intelligent control systems using soft computing methodologies, CRC

Press, New York, (2001).

[4] L. Mastacan, New methods to improve fuzzy logic controllers performance, Bulletin of the

Polytechnic Institute of Iasi Electrotehnics, Powers, Electronics, LIV (LVIII), vol. 4, (2008), pp. 629

634.

[5] Q. Li, Y. Fang, J. Song and J. Wang, "The application of fuzzy control in liquid level system",

IEEE/ICMTMA, vol. 3, (2011) March, pp. 776-778.

[6] Z. Zhi and H. Lisheng, Performance assessment for the water level control system in steam generator

of the nuclear power plant, IEEE/CCC, (2011) July, pp. 5842-5847.

[7] E. H. Mamdani, Advances in the linguistic synthesis of fuzzy controllers.

[8] E. H. Mamdani, Applications of fuzzy logic to approximate reasoning using linguistic synthesis, IEEE

Transactions on Computers, vol. 26, no. 12, (1977), pp. 1182-1191.

[9] P. J. King and E. H. Mamdani, The application of Fuzzy logic control systems to industrial processes,

Automated, vol. 11, (1997), pp. 235-212.

[10] A. A. Dharamniwas, V. Redhu and U. Gupta, Liquid Level Control by using Fuzzy Logic Controller,

International Journal of Advances in Engineering & Technology, vol. 4, Issue 1, (2012) July, pp. 537-

549.

[11] Fuzzy Reasoning & Application by Yager Wiley International.

[12] Fuzzy System Theory & Application T. Tarano, Asai & M. Sugeno - Academic Press.

[13] Mc. Neill, F. Martin and T. Allen, Fuzzy Logic (A Practical Approach), Academic Press. International

Journal of Man Machine Studies, vol. 8, (1976), pp. 669-678.

Copyright 2015 SERSC 275

International Journal of u- and e- Service, Science and Technology

Vol.8, No. 6 (2015)

276 Copyright 2015 SERSC

You might also like

- Lecture 9Document26 pagesLecture 9Eddie TangNo ratings yet

- Robot ARM SimulationDocument11 pagesRobot ARM SimulationBrijesh ReddyNo ratings yet

- Chapter 004Document59 pagesChapter 004Eddie TangNo ratings yet

- Machine VisionDocument41 pagesMachine VisionEddie TangNo ratings yet

- TutorialDocument4 pagesTutorialEddie TangNo ratings yet

- Memory InterfacingDocument181 pagesMemory InterfacingEddie TangNo ratings yet

- HardwareDocument92 pagesHardwareEddie TangNo ratings yet

- I O InterfacingDocument142 pagesI O InterfacingEddie TangNo ratings yet

- Chapter 002Document21 pagesChapter 002Eddie TangNo ratings yet

- Program Control GroupDocument101 pagesProgram Control GroupEddie TangNo ratings yet

- Microprocessor Based System CommunicationDocument39 pagesMicroprocessor Based System CommunicationEddie TangNo ratings yet

- Data Transfer GroupsDocument59 pagesData Transfer GroupsEddie TangNo ratings yet

- L06Document40 pagesL06Eddie TangNo ratings yet

- Addressing ModesDocument70 pagesAddressing ModesEddie TangNo ratings yet

- Fuzzy ch5Document59 pagesFuzzy ch5Eddie TangNo ratings yet

- MeasurementDocument5 pagesMeasurementEddie TangNo ratings yet

- RecommendationDocument1 pageRecommendationEddie TangNo ratings yet

- Assignment 1 AnaDocument2 pagesAssignment 1 AnaEddie TangNo ratings yet

- Fuzzy ch9Document46 pagesFuzzy ch9Eddie TangNo ratings yet

- BentleyDocument8 pagesBentleymanaj_mohapatra204180% (5)

- Chapter 4Document31 pagesChapter 4Eddie TangNo ratings yet

- InfoDocument1 pageInfoEddie TangNo ratings yet

- Sanwa Cd800aDocument2 pagesSanwa Cd800aEddie TangNo ratings yet

- TransducersDocument61 pagesTransducersEddie TangNo ratings yet

- Basic Ladder Logic Programming for Engine Assembly LinesDocument22 pagesBasic Ladder Logic Programming for Engine Assembly LinesJavier Ruiz ThorrensNo ratings yet

- Exp 3 CompleteDocument19 pagesExp 3 CompleteEddie TangNo ratings yet

- Fracture Class Notes - Important PDFDocument34 pagesFracture Class Notes - Important PDFbathinsreenivasNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- April SHETA Newsletter PDFDocument2 pagesApril SHETA Newsletter PDFtong_jNo ratings yet

- PCB Footprint Expert Output To XpeditionDocument11 pagesPCB Footprint Expert Output To XpeditionBenyamin Farzaneh AghajarieNo ratings yet

- Ecf2 Module 2Document6 pagesEcf2 Module 2Blackwolf SocietyNo ratings yet

- Cronbach Reliability AnalysisDocument6 pagesCronbach Reliability AnalysisLesli Perez GarciaNo ratings yet

- M817 13 4-GO-LW A4 E ScreenDocument19 pagesM817 13 4-GO-LW A4 E ScreenRikyNo ratings yet

- 1025936797Document184 pages1025936797Wilson AgudeloNo ratings yet

- Handmaids Tale Affirmative - DDI 2015 CTDocument82 pagesHandmaids Tale Affirmative - DDI 2015 CTevansNo ratings yet

- Windows 10 Home Windows 10 HomeDocument9 pagesWindows 10 Home Windows 10 Homeगणेश पराजुलीNo ratings yet

- Micromouse: BY:-Shubham Kumar MishraDocument14 pagesMicromouse: BY:-Shubham Kumar Mishrashubham kumar mishraNo ratings yet

- Somove Lite V1.5: ReadmeDocument15 pagesSomove Lite V1.5: ReadmeNilton Manrique CossioNo ratings yet

- BRKNMS-2573 (2020)Document120 pagesBRKNMS-2573 (2020)Paul ZetoNo ratings yet

- Telit GL865-DUAL-QUAD Hardware User Guide r7Document76 pagesTelit GL865-DUAL-QUAD Hardware User Guide r7salasugo5751No ratings yet

- G 4 DocumentationDocument33 pagesG 4 DocumentationEsku LuluNo ratings yet

- Notes Polar Complex Numbers PDFDocument3 pagesNotes Polar Complex Numbers PDFXavier RodríguezNo ratings yet

- Assignment-1: Student Name: K. Sai CharanDocument12 pagesAssignment-1: Student Name: K. Sai CharanSai Charan KarangulaNo ratings yet

- An Introduction of Computer Programming - g10Document20 pagesAn Introduction of Computer Programming - g10zimran dave epelipciaNo ratings yet

- All mIRC CommandsDocument4 pagesAll mIRC CommandsAbhishek KunalNo ratings yet

- Process Performance Report Analyzes Netto CapabilityDocument1 pageProcess Performance Report Analyzes Netto CapabilityDita DesnasariNo ratings yet

- 8-Port Arbiter Specifications for Fixed Priority and Round Robin SchemesDocument4 pages8-Port Arbiter Specifications for Fixed Priority and Round Robin SchemesAnonymous ptSFzcfNo ratings yet

- A Simple and Effective Method For Filling Gaps in Landsat ETM+ SLC-off ImagesDocument12 pagesA Simple and Effective Method For Filling Gaps in Landsat ETM+ SLC-off ImagesJanos HidiNo ratings yet

- Sony Hvr-V1j U N e P C Ver1.3Document504 pagesSony Hvr-V1j U N e P C Ver1.3DanNo ratings yet

- Quiz1 - Conditional Control If StatementsDocument5 pagesQuiz1 - Conditional Control If StatementsAncuta CorcodelNo ratings yet

- Request For ProposalDocument216 pagesRequest For ProposalGilbert KamanziNo ratings yet

- Cucumber Gherkin LanguageDocument19 pagesCucumber Gherkin LanguageEddy PinzonNo ratings yet

- Sri Final Job SheetDocument4 pagesSri Final Job SheetMohan LalNo ratings yet

- HyperLynx Signal Integrity Analysis Student WorkbookDocument538 pagesHyperLynx Signal Integrity Analysis Student Workbookjagadees2189% (9)

- Cisco Collaboration Roadmap For Partners August 2023Document247 pagesCisco Collaboration Roadmap For Partners August 2023Cristian Campos AguadoNo ratings yet

- I. Electronic Commerce Act of 2000 (R.A. 8792)Document3 pagesI. Electronic Commerce Act of 2000 (R.A. 8792)Lorelie SantosNo ratings yet

- Oa-Kdp-Module 1Document4 pagesOa-Kdp-Module 1Ryan AmaroNo ratings yet

- Jura J9.3 Wiring DiagramDocument4 pagesJura J9.3 Wiring DiagramGrom NeposedaNo ratings yet