Professional Documents

Culture Documents

Seat Leakage Classifications

Uploaded by

Martin AndradeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Seat Leakage Classifications

Uploaded by

Martin AndradeCopyright:

Available Formats

TECNOLOGA EN AUTOMATIZACIN Y

CONTROL ELCTRICO, S.A. DE C.V.

DISTRIBUIDOR EXCLUSIVO MXICO

Mxico, D.F. a 5 de Junio de 2013

Seat Leakage Classifications

There are actually six different seat leakage classifications as defined by ANSI/FCI 70-2 2006 (European equivalent

standard IEC 60534-4).

The most common used are

CLASS IV

CLASS Vl

CLASS IV is also known as metal to metal. It is the kind of leakage rate you can expect from a valve with a metal plug and metal seat.

CLASS Vl is known as a soft seat classification. Soft Seat Valves are those where either the plug or seat or both are made from some

kind of composition material such as Teflon or similar.

Valve Leakage Classifications

Class I - Valve Leakage Classifications

Identical to Class II, III, and IV in construction and design intent, but no actual shop test is made. Cass I is also known as dust tight and

can refer to metal or resilient seated valves.

Class II - Valve Leakage Classifications

Intended for double port or balanced singe port valves with a metal piston ring seal and metal to metal seats.

0.5% leakage of full open valve capacity.

Service dP or 50 psid (3.4 bar differential), whichever is lower at 50 to 125 oF.

Test medium air at 45 to 60 psig is the test fluid.

Typical constructions:

Balanced, single port, single graphite piston ring, metal seat, low seat load

Balanced, double port, metal seats, high seat load

Class III - Valve Leakage Classifications

Intended for the same types of valves as in Class II.

0.1% leakage of full open valve capacity.

Service dP or 50 psid (3.4 bar differential), whichever is lower at 50 to 125 oF.

Test medium air at 45 to 60 psig is the test fluid.

Typical constructions:

Balanced, double port, soft seats, low seat load

Balanced, single port, single graphite piston ring, lapped metal seats, medium seat load

Calle 9 No. 103 Col. Progreso Nacional, 07600 Mxico D.F.

Tel.: 5016 5708 Fax: 5039 2582

TECNOLOGA EN AUTOMATIZACIN Y

CONTROL ELCTRICO, S.A. DE C.V.

DISTRIBUIDOR EXCLUSIVO MXICO

Class IV - Valve Leakage Classifications

Intended for single port and balanced single port valves with extra tight piston seals and metal to-metal seats.

0.01% leakage of full open valve capacity.

Service dP or 50 psid (3.4 bar differential), whichever is lower at 50 to 125 oF.

Test medium air at 45 to 60 psig is the test fluid.

Typical constructions:

Balanced, single port, Teflon piston ring, lapped metal seats, medium seat load

Balanced, single port, multiple graphite piston rings, lapped metal seats

Unbalanced, single port, lapped metal seats, medium seat load

Class IV is also known as metal to metal

Class V - Valve Leakage Classifications

Intended for the same types of valves as Class IV.

The test fluid is water at 100 psig or operating pressure.

Leakage allowed is limited to 5 x 10 ml per minute per inch of orifice diameter per psi differential.

Service dP at 50 to 125 oF.

Typical constructions:

Unbalanced, single port, lapped metal seats, high seat load

Balanced, single port, Teflon piston rings, soft seats, low seat load

Unbalanced, single port, soft metal seats, high seat load

Class Vl - Valve Leakage Classifications

Class Vl is known as a soft seat classification. Soft Seat Valves are those where the seat or shut-off disc or both

are made from some kind of resilient material such as Teflon. Intended for resilient seating valves.

The test fluid is air or nitrogen.

Pressure is the lesser of 50 psig or operating pressure.

The leakage limit depends on valve size and ranges from 0.15 to 6.75 ml per minute for valve sizes 1 through 8 inches.

Calle 9 No. 103 Col. Progreso Nacional, 07600 Mxico D.F.

Tel.: 5016 5708 Fax: 5039 2582

TECNOLOGA EN AUTOMATIZACIN Y

CONTROL ELCTRICO, S.A. DE C.V.

DISTRIBUIDOR EXCLUSIVO MXICO

Port Diameter

Bubbles per minute ml per minute

inches Millimeters

1 25 1 0.15

1 1/2 38 2 0.30

2 51 3 0.45

2 1/2 64 4 0.60

3 76 6 0.90

4 102 11 1.70

6 152 27 4.00

8 203 45 6.75

10 254 63 9

12 305 81 11.5

Typical constructions:

Unbalanced, single port, soft seats, low load

Control Valve Leakage Classification - Overview

Leakage

Maximum Leakage Testing Procedures Required

Class Test Medium Test Pressure

Allowable for Establishing Rating

Designation

I x x x No test required

45 - 60 psig or

Air or water at 45 - 60 psig or maximum

maximum operating

II 0.5% of rated capacity 50 - 125o F operating differential whichever is

o differential whichever is

(10 - 52 C) lower

lower

III 0.1% of rated capacity As above As above As above

IV 0.01% of rated capacity As above As above As above

0.0005 ml per minute of Maximum service

Water at 50 Maximum service pressure drop

water per inch of port pressure drop across

V to125oF (10 to across valve plug not to exceed

diameter per psi valve plug not to exceed

52oC) ANSI body rating

differential ANSI body rating

50 psig or max rated Actuator should be adjusted to

Not to exceed amounts Air or nitrogen

differential pressure operating conditions specified

VI shown in the table at 50 to 125o F

across valve plug with full normal closing thrust

above (10 to 52oC)

whichever is lower applied to valve plug seat

Calle 9 No. 103 Col. Progreso Nacional, 07600 Mxico D.F.

Tel.: 5016 5708 Fax: 5039 2582

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- 3a3101en-E Manual Bomba NeumaticaDocument56 pages3a3101en-E Manual Bomba NeumaticaMartin AndradeNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Bomba Dosificadora Serie VDocument12 pagesBomba Dosificadora Serie VMartin AndradeNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- 14 330SoilClassification PDFDocument40 pages14 330SoilClassification PDFMartin Andrade100% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Astm A350 LF2 PDFDocument1 pageAstm A350 LF2 PDFTanah Tak BertuanNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Access Fitting Assembly ManualDocument12 pagesAccess Fitting Assembly Manualmaz234No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- ASTM A350 LF2 Standard Specification Carbon Steel ForgingsDocument1 pageASTM A350 LF2 Standard Specification Carbon Steel ForgingsMartin AndradeNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Bomba Neumatica Wilden PX1Document43 pagesBomba Neumatica Wilden PX1Martin AndradeNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- CFR 2011 Title49 Vol3 Part192Document115 pagesCFR 2011 Title49 Vol3 Part192Martin AndradeNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Bomba Neumatica Wilden PX1Document43 pagesBomba Neumatica Wilden PX1Martin AndradeNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Astm B843-93 PDFDocument2 pagesAstm B843-93 PDFMartin AndradeNo ratings yet

- Virgo Trunnion Ball ValveDocument16 pagesVirgo Trunnion Ball ValveKamalNo ratings yet

- Torque Specifications Chart for Acura, Alfa Romeo, and Allis Chalmers EnginesDocument124 pagesTorque Specifications Chart for Acura, Alfa Romeo, and Allis Chalmers EnginesZack Leon85% (13)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Qulting16115001jc JDN GruasDocument4 pagesQulting16115001jc JDN GruasMartin AndradeNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Seat Leakage ClassificationsDocument3 pagesSeat Leakage ClassificationsMartin AndradeNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Rsl-Operation and MaintenanceDocument32 pagesRsl-Operation and MaintenanceAustin AsuquoNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hydratight RSL Torque Wrench BrochureDocument4 pagesHydratight RSL Torque Wrench BrochuresubbusenthilNo ratings yet

- Bombas Truper PDFDocument12 pagesBombas Truper PDFMartin AndradeNo ratings yet

- Anti Jump ProsimecDocument2 pagesAnti Jump ProsimecMartin AndradeNo ratings yet

- Static and Kinetic Coefficients of Friction of Plastic Film and SheetingDocument6 pagesStatic and Kinetic Coefficients of Friction of Plastic Film and SheetingMartin AndradeNo ratings yet

- Válvula de Control Fisher GXDocument2 pagesVálvula de Control Fisher GXMartin AndradeNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- SHORTSTOPP 300D Split Tees With Guide BarsDocument3 pagesSHORTSTOPP 300D Split Tees With Guide BarsMartin AndradeNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- CAT Valvula Bola Richter BVA FDocument4 pagesCAT Valvula Bola Richter BVA FMartin AndradeNo ratings yet

- Sizes: 4-Inch and Larger: Typical SetupDocument4 pagesSizes: 4-Inch and Larger: Typical SetupMartin Andrade100% (2)

- Tie-In Spool - A Verification Study (MSC)Document213 pagesTie-In Spool - A Verification Study (MSC)Binh PhamNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- SHORTSTOPP 300D Split Tees With Guide BarsDocument3 pagesSHORTSTOPP 300D Split Tees With Guide BarsMartin AndradeNo ratings yet

- Válvula de Control Fisher GXDocument2 pagesVálvula de Control Fisher GXMartin AndradeNo ratings yet

- PSS UserGuideDocument15 pagesPSS UserGuideMichael Perez CisternasNo ratings yet

- Brooks MT 3018Document16 pagesBrooks MT 3018Martin AndradeNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Tie inDocument6 pagesTie inthmaraishriNo ratings yet

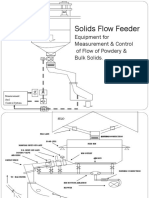

- Solids Flow Feeder Equipment for Precise Measurement & ControlDocument7 pagesSolids Flow Feeder Equipment for Precise Measurement & ControlAbhishek DuttaNo ratings yet

- Oops (Object Oriented Programming System)Document3 pagesOops (Object Oriented Programming System)shamagondalNo ratings yet

- Sat - RPMSDocument4 pagesSat - RPMSAeroz RednaxelaNo ratings yet

- PDF Ebook Pickle Things by Marc Brown Download BookDocument5 pagesPDF Ebook Pickle Things by Marc Brown Download BookCorissNo ratings yet

- Model Manajemen Rantai Pasok Industri Perikanan Tangkap Berkelanjutan Di Propinsi MalukuDocument12 pagesModel Manajemen Rantai Pasok Industri Perikanan Tangkap Berkelanjutan Di Propinsi MalukuEmanuellaNo ratings yet

- Gas LiftDocument35 pagesGas LiftHìnhxămNơigóckhuấtTimAnh100% (1)

- SKFDocument26 pagesSKFRahul ParikhNo ratings yet

- JVC TH-M606 - 603 - SMDocument101 pagesJVC TH-M606 - 603 - SMCaillouxNo ratings yet

- Auditing and Electronic Data Processing (EDP)Document6 pagesAuditing and Electronic Data Processing (EDP)Lizza Marie CasidsidNo ratings yet

- BDC Program To Create Routings Through BDCDocument10 pagesBDC Program To Create Routings Through BDCswapnil_265051509No ratings yet

- Managing Information for Better DecisionsDocument12 pagesManaging Information for Better DecisionsTosin WilliamsNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Installation - Operation - Maintenance - Instructions - 30 HXC PDFDocument36 pagesInstallation - Operation - Maintenance - Instructions - 30 HXC PDFNurmansyah Dwi Cahyono100% (3)

- Workman GTX: Utility VehicleDocument36 pagesWorkman GTX: Utility VehicleDaniel Carrillo BarriosNo ratings yet

- WFT Composite PlugsDocument11 pagesWFT Composite Plugsahmad haqkim muhamad malackNo ratings yet

- Stock PartDocument20 pagesStock PartGReyNo ratings yet

- Detail A: STEEL BEAM (300x150x6.5x9)Document1 pageDetail A: STEEL BEAM (300x150x6.5x9)Aaris AdeNo ratings yet

- Why I Play Bass March 14 2013Document293 pagesWhy I Play Bass March 14 2013Paul van Niekerk80% (5)

- How To Enable Nationality Field in IrecruitmentDocument2 pagesHow To Enable Nationality Field in IrecruitmentnhawiNo ratings yet

- Design of Miniature Maglev Using Hybrid MagnetsDocument4 pagesDesign of Miniature Maglev Using Hybrid MagnetsErmin FazlicNo ratings yet

- Unethical Business Pratices in Corporates: March 2016Document13 pagesUnethical Business Pratices in Corporates: March 2016Manju Nadh ChakravadhanulaNo ratings yet

- Soot Blower-MergedDocument20 pagesSoot Blower-MergedRahul S. ChandrawarNo ratings yet

- Communication in AfricaDocument5 pagesCommunication in AfricaJaque TornneNo ratings yet

- Samsung DRAM Module Handling Guide - 1128 - 10090119049407 PDFDocument9 pagesSamsung DRAM Module Handling Guide - 1128 - 10090119049407 PDFreza_azadNo ratings yet

- MAIN Electrical Parts List: Parts Code Design LOC DescriptionDocument22 pagesMAIN Electrical Parts List: Parts Code Design LOC DescriptionJerzy DziewiczkiewiczNo ratings yet

- 24C02BN Su18Document26 pages24C02BN Su18Dwp BhaskaranNo ratings yet

- SAP-Press - Abap Development For Sap HanaDocument30 pagesSAP-Press - Abap Development For Sap HananicocastanioNo ratings yet

- PBV20N2 Service Manual PDFDocument244 pagesPBV20N2 Service Manual PDFJack Norhy100% (1)

- Language As IdeologyDocument26 pagesLanguage As IdeologyAlcione Gonçalves Campos100% (2)

- How To Build A 43 Note CalliopeDocument14 pagesHow To Build A 43 Note CalliopeBrad SommersNo ratings yet

- Net HSMDocument4 pagesNet HSMJosé Tudela de la RosaNo ratings yet

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)

- Nir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryFrom EverandNir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryRating: 4 out of 5 stars4/5 (5)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsFrom EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo ratings yet

- The Cyanide Canary: A True Story of InjusticeFrom EverandThe Cyanide Canary: A True Story of InjusticeRating: 4 out of 5 stars4/5 (51)