Professional Documents

Culture Documents

7 Corena S4 R 46

Uploaded by

Mudabbir Shan AhmedOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7 Corena S4 R 46

Uploaded by

Mudabbir Shan AhmedCopyright:

Available Formats

Technical Data Sheet

Previous Name: Shell Corena AS

Extra Long Life

Shell Corena S4 R 46 Improved Efficiency

Severe Applications

Advanced Synthetic Rotary Air Compressor Oil

Shell Corena S4 R is primarily an advanced synthetic air compressor oil incorporating a unique high performance

additive system. It is designed to deliver the highest performance lubrication of rotary sliding vane and screw air

compressors. It uses an advanced additive system to provide excellent protection and performance for compressors

running at pressures over 25 bar and in excess of 1000C discharge temperatures with oil maintenance intervals of up

to 12,000 hours. Shell Corena S4 R is also perfectly suitable to cover applications where a synthetic bearing &

circulating oil or R&O oil (ISO VG 32-68) is needed.

Performance, Features & Benefits Shell Corena S4 R has low volatility and oil carryover to

Long oil life Maintenance saving provide reduced oil top-up requirements in combination with

increased air quality.

hell Corena S4 R is capable of providing oil maintenance

intervals of up to 12,000 hours (where allowed by In addition, Shell Corena S4 R has excellent water separation

manufacturers) even when operating at maximum discharge properties to help ensure continuous efficient operation of the

temperatures in excess of 100 C.0

compressor even in the presence of water.

The advanced formulation of Shell Corena S4 R helps deliver Main Applications

exceptional oil life through:

Exceptional resistance to thermal and chemical breakdown.

Resist formation of deposits on rotating components in screw

compressors and in sliding vane slots for continuous efficient

operation.

Rotary sliding vane and screw air compressors

Shell Corena S4 R is suitable for oil-flooded/oil injected, single

Exceptionally low levels of deposit formation to help maintain or two-stage compressors, operating at pressures of in excess of

25 bar and with air discharge temperatures of over 1000C

excellent internal surface cleanliness particularly in oil/air

separator and coalescer systems. (including intermittent operation under these conditions).

Outstanding wear protection Severe service conditions

Shell Corena S4 R is designed to provide rapid air release May also be used where exceptionally high ambient

without excessive foaming to give trouble-free operation even temperatures are found, when the oil temperature cannot be

under cycling conditions helping to ensure reliable start-up reduced to normal levels.

and continuous compressed air availability. . ABB Turbochargers

Shell Corena S4 R has low volatility and oil carryover to The product is recommended for use in ABB turbochargers fitted

provide reduced oil top-up requirements in combination with to low and medium speed diesel engines used in marine and

increased air quality. power generation applications.

Maintaining system efficiency Bearing & Circulating oil

Shell Corena S4 R is designed to provide rapid air release Perfectly suitable to cover applications where a synthetic

without excessive foaming to give trouble-free operation even bearing & circulating oil or R&O oil (ISO VG 32-68) is required

under cycling conditions helping to ensure reliable start-up and will provide benefits due to increased resistance to deposit

and continuous compressed air availability. formation, improved low temperature fluidity, and lowering

equipment operating temperatures.

Page 1 of 3 Shell Corena S4 R 46, v 2.1 22.08.2014.11.33

When a higher viscosity grade synthetic oil is required we Compatibility & Miscibility

recommend to use Shell Morlina S4 B grades for such

applications.

Miscibility

Shell Corena S4 R oils are fully miscible with mineral oils,

although dilution with mineral lubricants will markedly reduce

Specifications, Approvals & Recommendations

its performance. Care must be taken to avoid mixing Shell

ISO 6743-3A-DAJ. Corena S4 R with certain other types of synthetic fluids. Contact

For a full listing of equipment approvals and

your Shell representative for further information.

recommendations, please consult your local Shell Technical

Helpdesk. Seal Compatibility

Shell Corena S4 R oils are compatible with seal materials

specified for use with mineral oils.

Typical physical characteristics

Properties Method S4 R 46

ISO Viscosity Grade ISO 3448 46

Kinematic Viscosity @400C mm2/s ASTM D445 46

Kinematic Viscosity @100 C 0

mm /s2 ASTM D445 7.7

Viscosity Index (VI) DIN ISO 2909 135

Density 0

@15 C kg/m 3 ASTM D1298 843

Flash Point (COC) 0

C ASTM D92 230

Pour Point 0

C ASTM D97 -45

Air Release mins 2

Rust Prevention - Synthetic Sea Water ASTM D665B Pass

Water Separability mins ASTM D1401 10

Rotating Pressure Vessel Oxidation mins ASTM D2272 2200

FZG Load Carrying Test failure load stage CEC-L-07-A-95 >12

These characteristics are typical of current production. Whilst future production will conform to Shell's specification, variations in

these characteristics may occur.

Health, Safety & Environment

Health and Safety

Shell Corena S4 R Oil is unlikely to present any significant health or safety hazard when properly used in the recommended

application and good standards of personal hygiene are maintained.

Avoid contact with skin. Use impervious gloves with used oil. After skin contact, wash immediately with soap and water.

Guidance on Health and Safety is available on the appropriate Material Safety Data Sheet, which can be obtained from

http://www.epc.shell.com/

Protect the Environment

Take used oil to an authorised collection point. Do not discharge into drains, soil or water.

Additional Information

Advice

Advice on applications not covered here may be obtained from your shell representative.

Page 2 of 3 Shell Corena S4 R 46, v 2.1 22.08.2014.11.33

Page 3 of 3 Shell Corena S4 R 46, v 2.1 22.08.2014.11.33

You might also like

- Ja Delmas Brochure Large Mining PFBJ0030 enDocument68 pagesJa Delmas Brochure Large Mining PFBJ0030 enmohamed nizmyNo ratings yet

- Hy Gard DKE7358 Sep02Document2 pagesHy Gard DKE7358 Sep02Jocelyn Milla MoralesNo ratings yet

- Ultraspin Oily WaterDocument3 pagesUltraspin Oily WaterAnonymous QSfDsVxjZNo ratings yet

- Aeon 9000spDocument2 pagesAeon 9000spSergiSerranoNo ratings yet

- d11t Manual de MantenimientoDocument4 pagesd11t Manual de MantenimientoAnonymous SpT4OHYMyNo ratings yet

- Komatsu D475A-5E0 Crawler DozerDocument6 pagesKomatsu D475A-5E0 Crawler Dozereplim6050% (2)

- Tyresense Is A Registered Trademark of Rimex Supply LTDDocument16 pagesTyresense Is A Registered Trademark of Rimex Supply LTDWisan Nursamsi SidikNo ratings yet

- YresatDocument79 pagesYresatGallegos MONo ratings yet

- Technical Specs for KAMAZ 4326 TruckDocument4 pagesTechnical Specs for KAMAZ 4326 TruckJavier GodoyNo ratings yet

- Crankcase OilsDocument2 pagesCrankcase OilsPhillip CronjeNo ratings yet

- Test Manual 2657668154 - 007Document63 pagesTest Manual 2657668154 - 007SMMAR Soluciones MecanicasNo ratings yet

- 6 - Waste Tyre Processing Technology Comparison May 2006 PDFDocument6 pages6 - Waste Tyre Processing Technology Comparison May 2006 PDFalvaroNo ratings yet

- Every Ton.: For Mining ApplicationsDocument4 pagesEvery Ton.: For Mining ApplicationsRafaelNo ratings yet

- Motiva Group II Base OilDocument1 pageMotiva Group II Base Oiliescobar0702No ratings yet

- DPUMP Installation, Operation and Maintenance ManualDocument48 pagesDPUMP Installation, Operation and Maintenance Manualjavier ChemooNo ratings yet

- Trucks and Buses PDFDocument116 pagesTrucks and Buses PDFRizki Maulana100% (1)

- Rotorcomp: The Screw Compressor CompanyDocument26 pagesRotorcomp: The Screw Compressor CompanyMoncef RedNo ratings yet

- PEHJ015602 Cat Bulk Fuel Filtration Aug 2011Document4 pagesPEHJ015602 Cat Bulk Fuel Filtration Aug 2011thailanNo ratings yet

- Mine Air Systems No Idle System BrochureDocument2 pagesMine Air Systems No Idle System Brochureelia nugraha adiNo ratings yet

- BearingChecker User Guide (English)Document43 pagesBearingChecker User Guide (English)abdurohmanNo ratings yet

- 002 Cat-6040AC CAMP-SIL-BCS4 UndercarriageDocument21 pages002 Cat-6040AC CAMP-SIL-BCS4 UndercarriageJorby CuadrosNo ratings yet

- PC-0088 9A Valve and Coil ChangeDocument3 pagesPC-0088 9A Valve and Coil ChangeMarcelo ArayaNo ratings yet

- S O S Services: Maintenance Products and ServicesDocument8 pagesS O S Services: Maintenance Products and Servicescaptain_commanderNo ratings yet

- EmitDocument20 pagesEmitecavalinNo ratings yet

- Camiones para Mineria Cat 785c 2011englishDocument12 pagesCamiones para Mineria Cat 785c 2011englishJuan Manuel Visitacion LavadoNo ratings yet

- Basic Principles of Kidney Loop Filtering of HydraulicDocument8 pagesBasic Principles of Kidney Loop Filtering of HydraulicmostafaNo ratings yet

- Fluid Analysis For Bearing Reliability 1684619066Document30 pagesFluid Analysis For Bearing Reliability 1684619066Alvaro Javier Reyes ParraNo ratings yet

- Roulement Timken PDFDocument828 pagesRoulement Timken PDFWissem El'MissaouiNo ratings yet

- Goulds Pump Curves 3175Document3 pagesGoulds Pump Curves 3175RichNo ratings yet

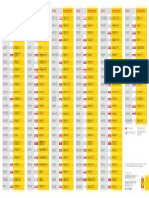

- SOS Wear Table - June 2015Document3,089 pagesSOS Wear Table - June 2015ricardo manriquez100% (2)

- Test Method Units of Measure Sample Reqd Rush Availability NotesDocument5 pagesTest Method Units of Measure Sample Reqd Rush Availability Notesjuanmanuel_4615958No ratings yet

- 005 Cat-6040ac Camp-Sil-Bcs4 Tank, Pumps and PmsDocument22 pages005 Cat-6040ac Camp-Sil-Bcs4 Tank, Pumps and PmsFrancisco MartinezNo ratings yet

- 830e Ac PDFDocument4 pages830e Ac PDFManuel Ruiz CayunNo ratings yet

- 004 - Cat-6060 - Engine and Pump Drive - CumminsDocument34 pages004 - Cat-6060 - Engine and Pump Drive - Cumminssubramani Srinivasan100% (1)

- 834k Wheel Dozer L4y00001-Up (Machine) Powered by c18 Engine (m0087637 - 18) - DocumentationDocument12 pages834k Wheel Dozer L4y00001-Up (Machine) Powered by c18 Engine (m0087637 - 18) - DocumentationenricoNo ratings yet

- Grafloscon A-G 1 Ultra: Priming LubricantDocument1 pageGrafloscon A-G 1 Ultra: Priming Lubricantalanwar general contracting&suppliesNo ratings yet

- Camion de Obra 777G - TNMDocument1 pageCamion de Obra 777G - TNMMónica Rada UrbinaNo ratings yet

- Goulds PUMPSDocument10 pagesGoulds PUMPSMoustafa ElsadanyNo ratings yet

- Playbook Launchpackage Cassida Chain Oil XteDocument11 pagesPlaybook Launchpackage Cassida Chain Oil XteKiệt NgôNo ratings yet

- Jenbacher: Determining The Initial PH Value (Iph) of Used Lubrication Oil As Defined in Ti 1000-0099BDocument2 pagesJenbacher: Determining The Initial PH Value (Iph) of Used Lubrication Oil As Defined in Ti 1000-0099BArîfNo ratings yet

- 631D Trans Shift PointsDocument20 pages631D Trans Shift PointsDaveNo ratings yet

- Spur GearDocument18 pagesSpur GearSam LowNo ratings yet

- Engine LubricationDocument4 pagesEngine LubricationmkNo ratings yet

- Shell lubricants portfolio guideDocument1 pageShell lubricants portfolio guideCara GutierrezNo ratings yet

- Hypro Housing Fa-Mf3Document4 pagesHypro Housing Fa-Mf3Roberto Torres ArancibiaNo ratings yet

- 993k Wheel Loader Before Operation ManualDocument6 pages993k Wheel Loader Before Operation ManualGustavo VargasNo ratings yet

- A64 ExC Transporter S PDFDocument8 pagesA64 ExC Transporter S PDFCruzado Vilca AmesquitaNo ratings yet

- Square Flanges JIS B2291-JIS F7806Document14 pagesSquare Flanges JIS B2291-JIS F7806QUYEN TRANNo ratings yet

- J620V22 enDocument4 pagesJ620V22 enMartin KratkyNo ratings yet

- Cat NGEC 50 - 50Document2 pagesCat NGEC 50 - 50shamsalihu2729No ratings yet

- Pehj0327-02 Cat Open Gear LubricantDocument2 pagesPehj0327-02 Cat Open Gear LubricantdpomahNo ratings yet

- Lubricación Forzada Compresor ArielDocument26 pagesLubricación Forzada Compresor ArielAnonymous FH8OunZrXNo ratings yet

- Sistema MegaDocument26 pagesSistema Megapatricio ramirezNo ratings yet

- TRIBOLOGY LUBRICATION TECHNOLOGY Sep 2016 PDFDocument92 pagesTRIBOLOGY LUBRICATION TECHNOLOGY Sep 2016 PDFoperationmanagerNo ratings yet

- Hand ToolsDocument98 pagesHand ToolsAndry Perdana PutraNo ratings yet

- 1.3 Lubrication Routines (LUB)Document55 pages1.3 Lubrication Routines (LUB)Busuioc AlexNo ratings yet

- Wilfley BrochureDocument8 pagesWilfley BrochureCarlos de la TorreNo ratings yet

- Shell Corena S4 R 68: Performance, Features & BenefitsDocument3 pagesShell Corena S4 R 68: Performance, Features & BenefitsGera BdNo ratings yet

- Shell Corena S4 R 68: Performance, Features & BenefitsDocument3 pagesShell Corena S4 R 68: Performance, Features & BenefitsAMITNo ratings yet

- Sinamics V90 Servo Motor DatasheetDocument3 pagesSinamics V90 Servo Motor DatasheetSavalia HardikNo ratings yet

- A5e43215508a Sicherheitshinweise Simotics GP SD DP FL En-UsDocument10 pagesA5e43215508a Sicherheitshinweise Simotics GP SD DP FL En-UsMudabbir Shan AhmedNo ratings yet

- Anviz A350C Catalogue en 10.22.2019Document2 pagesAnviz A350C Catalogue en 10.22.2019Mudabbir Shan AhmedNo ratings yet

- Shell Gadus: Designed To Do More. Just Like Our Greases - Shell GadusDocument2 pagesShell Gadus: Designed To Do More. Just Like Our Greases - Shell Gadusperi irawanNo ratings yet

- GL XX Mobil Vacuoline 1400Document3 pagesGL XX Mobil Vacuoline 1400Mudabbir Shan AhmedNo ratings yet

- Tds Renolin 500 Series enDocument3 pagesTds Renolin 500 Series enNadia SalemNo ratings yet

- Napier Aftermarket ServicesDocument5 pagesNapier Aftermarket ServicesMudabbir Shan AhmedNo ratings yet

- Heat Exchanger DesignDocument1 pageHeat Exchanger DesignMudabbir Shan AhmedNo ratings yet

- Mobil Pegasus™ 1100 Series Mobil Pegasus™ 1100 Series Mobil Pegasus™ 1100 Series Mobil Pegasus™ 1100 SeriesDocument3 pagesMobil Pegasus™ 1100 Series Mobil Pegasus™ 1100 Series Mobil Pegasus™ 1100 Series Mobil Pegasus™ 1100 SeriesMudabbir Shan AhmedNo ratings yet

- VHP 5904 Gsi GsidDocument2 pagesVHP 5904 Gsi GsidFabricio RubioNo ratings yet

- Specifications: SS-9048214-18406768-000 SS Page 1 of 6Document6 pagesSpecifications: SS-9048214-18406768-000 SS Page 1 of 6Ali KarahanNo ratings yet

- Jenbacher J624 Gas Engines To Support High Efficiency Combined Heat and Power in South KoreaDocument2 pagesJenbacher J624 Gas Engines To Support High Efficiency Combined Heat and Power in South KoreaMudabbir Shan AhmedNo ratings yet

- Tech Data: Sentron™ LD 8000 P N G E ODocument2 pagesTech Data: Sentron™ LD 8000 P N G E OMudabbir Shan AhmedNo ratings yet

- Exxonmobil and Innio Announce Introduction of Jenbacher N Oil 40 Lubricant For Jenbacher Gas EnginesDocument2 pagesExxonmobil and Innio Announce Introduction of Jenbacher N Oil 40 Lubricant For Jenbacher Gas EnginesMudabbir Shan AhmedNo ratings yet

- Mobil-DTE-Named-Series Turbine Oils PDSDocument4 pagesMobil-DTE-Named-Series Turbine Oils PDSLuka BornaNo ratings yet

- TDS Shell Tellus S2 M 46Document4 pagesTDS Shell Tellus S2 M 46stevierayoNo ratings yet

- GPCDOC Local TDS Hong Kong Shell Gadus S2 V220 2 (en-HK) TDS PDFDocument2 pagesGPCDOC Local TDS Hong Kong Shell Gadus S2 V220 2 (en-HK) TDS PDFQatar home RentNo ratings yet

- GPCDOC Local TDS Hong Kong Shell Gadus S2 V220 2 (en-HK) TDS PDFDocument2 pagesGPCDOC Local TDS Hong Kong Shell Gadus S2 V220 2 (en-HK) TDS PDFQatar home RentNo ratings yet

- High Temp Grease for Heavy IndustryDocument2 pagesHigh Temp Grease for Heavy IndustryMudabbir Shan Ahmed100% (1)

- GE Waukesha Lube Oil Recommendation October 2017Document15 pagesGE Waukesha Lube Oil Recommendation October 2017MuhammadShadab100% (6)

- Shell Omala S2 G 320: Performance, Features & BenefitsDocument3 pagesShell Omala S2 G 320: Performance, Features & BenefitsMudabbir Shan AhmedNo ratings yet

- 2014 609 - Mobil SHC 524 Synthetic Hydraulic Oil Success StoryDocument1 page2014 609 - Mobil SHC 524 Synthetic Hydraulic Oil Success StoryMudabbir Shan Ahmed100% (1)

- 004 Oo 3Document3 pages004 Oo 3GilarHerlianaPutraNo ratings yet

- An Energy Saving Guide For Plastic Injection Molding MachinesDocument16 pagesAn Energy Saving Guide For Plastic Injection Molding MachinesStefania LadinoNo ratings yet

- Customer Technical Guide: Customer: Palmiye Corap Teks - San.Tic - Ltd.StiDocument71 pagesCustomer Technical Guide: Customer: Palmiye Corap Teks - San.Tic - Ltd.StiMudabbir Shan Ahmed100% (1)

- Shell Tellus BrochureDocument2 pagesShell Tellus Brochurekarim3samirNo ratings yet

- Technical Data Sheet for Shell Heat Transfer Oil S2Document2 pagesTechnical Data Sheet for Shell Heat Transfer Oil S2Mudabbir Shan Ahmed100% (2)

- Shell Mysella S7 N Ultra 40: Performance, Features & BenefitsDocument2 pagesShell Mysella S7 N Ultra 40: Performance, Features & BenefitsMudabbir Shan AhmedNo ratings yet

- Shell Omala industrial gear oils product and specification guideDocument2 pagesShell Omala industrial gear oils product and specification guidehuseynseymenNo ratings yet

- Shell Gadus: Designed To Do More. Just Like Our Greases - Shell GadusDocument2 pagesShell Gadus: Designed To Do More. Just Like Our Greases - Shell Gadusperi irawanNo ratings yet

- Mcdonnell & Miller Service Parts CatalogDocument76 pagesMcdonnell & Miller Service Parts Catalogkamran shahNo ratings yet

- Repair of Tube-Tubesheet Weld Cracks in A Cracked Gas/Steam Heat ExchangerDocument8 pagesRepair of Tube-Tubesheet Weld Cracks in A Cracked Gas/Steam Heat Exchangermontie3No ratings yet

- Basic Pneumatic System ApplicationsDocument33 pagesBasic Pneumatic System Applicationsnarkuys syukranNo ratings yet

- Central Institute of Tool DesignDocument1 pageCentral Institute of Tool DesignManoj SahuNo ratings yet

- Vibration PDFDocument48 pagesVibration PDFtruva_kissNo ratings yet

- Manual Recambios 3.152.4 (CM51027) PDFDocument149 pagesManual Recambios 3.152.4 (CM51027) PDFValoys MirandaNo ratings yet

- Tecflex 400 Series Flexible DuctingDocument6 pagesTecflex 400 Series Flexible DuctingEN LeedNo ratings yet

- CFD Simulations of Acoustic and Thermoacoustic Phenomena in Internal Flows OPEN FOAMDocument21 pagesCFD Simulations of Acoustic and Thermoacoustic Phenomena in Internal Flows OPEN FOAMMohammadreza NaghaviNo ratings yet

- CHP 4 - 4.3 Determinate Structural AnalysisDocument57 pagesCHP 4 - 4.3 Determinate Structural Analysismhazarath murariNo ratings yet

- DIESEL CYCLE With ExplantionDocument5 pagesDIESEL CYCLE With ExplantionEES StudyNo ratings yet

- Parts List for Vacuum Systems with Location, Brand and Model DetailsDocument68 pagesParts List for Vacuum Systems with Location, Brand and Model DetailsJose Gregorio Lira SerranoNo ratings yet

- Measuring Distance of Heavenly BodyDocument28 pagesMeasuring Distance of Heavenly BodykhanNo ratings yet

- Date: Drawn Trac. Scale Checked Apprd.: Replacement: Replaced By: DWG: Rev.Document1 pageDate: Drawn Trac. Scale Checked Apprd.: Replacement: Replaced By: DWG: Rev.Deepak DasNo ratings yet

- Chapter 1 FrictionDocument20 pagesChapter 1 FrictionSherif Yehia Al Maraghy100% (1)

- Powerplant Quizlet 492Document63 pagesPowerplant Quizlet 492Jecah Angelu S. SaquianNo ratings yet

- UG-6th - Online Class TTDocument6 pagesUG-6th - Online Class TTFOODIE USNo ratings yet

- Hoop StressDocument3 pagesHoop Stresskarthikraja21No ratings yet

- Multi Stage Parabolic Leaf SpringDocument13 pagesMulti Stage Parabolic Leaf SpringahiremanojNo ratings yet

- MCL 703 Assignment - Heat Transfer AnalysisDocument4 pagesMCL 703 Assignment - Heat Transfer AnalysisabhijeetNo ratings yet

- Greenstar 25Si/30Si: User Instructions & Customer Care GuideDocument20 pagesGreenstar 25Si/30Si: User Instructions & Customer Care GuideJBNo ratings yet

- Allouzi 2018Document36 pagesAllouzi 2018arti sahuNo ratings yet

- Heat Transfer Study MaterialDocument100 pagesHeat Transfer Study MaterialMad GamersNo ratings yet

- Engine Controls Schematics (Delphi ECM - FX3)Document9 pagesEngine Controls Schematics (Delphi ECM - FX3)Data TécnicaNo ratings yet

- Syphon For Pressure Measuring Instruments Model 910.15: ApplicationsDocument4 pagesSyphon For Pressure Measuring Instruments Model 910.15: Applicationsluis carlos martin contrerasNo ratings yet

- Aisi 1010 Carbon Steel (Uns g10100)Document5 pagesAisi 1010 Carbon Steel (Uns g10100)spiderblackNo ratings yet

- Lecture 3 Pressure Measuring InstrumentsDocument47 pagesLecture 3 Pressure Measuring InstrumentsChristian Patrice100% (1)

- ONIXline BJ Series Dimensions GuideDocument5 pagesONIXline BJ Series Dimensions Guidemarcusa85No ratings yet

- DR650SEL2 Catalogo Partes PDFDocument75 pagesDR650SEL2 Catalogo Partes PDFEderNo ratings yet

- Adjustable Type EAZ SeriesDocument8 pagesAdjustable Type EAZ SeriesVimalendra SinghNo ratings yet

- Ship Dynamics in Waves - RostokDocument51 pagesShip Dynamics in Waves - Rostokvivekt510No ratings yet