Professional Documents

Culture Documents

Overlap and prepare PILC and XLPE cables

Uploaded by

Sugali Danvers JuniorOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Overlap and prepare PILC and XLPE cables

Uploaded by

Sugali Danvers JuniorCopyright:

Available Formats

1. OVERLAP PILC AND XLPE CABLES 300mm. 3. PILC - REMOVE LEAD SHEATH TO DIMENSION A. DO NOT DAMAGE 5.

SHEATH TO DIMENSION A. DO NOT DAMAGE 5. PILC - SLIDE THE CLEAR INSULATING TUBINGS OVER THE CORES

PILC CABLE - REMOVE OUTER SHEATH, AND BRASS TAPES TO THE THE UNDERLYING SCREEN PAPERS ON THE CORES. UNWIND THE PUSHING THEM AS FAR INTO THE CRUTCH AS POSSIBLE. SHRINK

DIMENSIONS SHOWN. XLPE CABLES - REMOVE OUTER PVC, NYLON COPPER WOVEN FABRIC (CWF) TAPE, REMOVE FILLERS FROM BETWEEN DOWN EVENLY STARTING AT THE CRUTCH AND WORKING TOWARDS THE

AND INNER HDPE SHEATHS TO THE DIMENSIONS SHOWN. MARK CORES. REWIND THE CWF TAPE AROUND THE CORES AT THE CRUTCH CORE ENDS. ENSURE THERE ARE NO POCKETS OF TRAPPED AIR OR

CENTRE OF OVERLAP AS A REFERENCE LINE AND COVER CABLES TO THE DIMENSION SHOWN AND TIE OFF. TIE A TWINE BINDER GREASE.

WITH PLASTIC WRAP. AROUND THE SCREEN PAPERS TO DIMENSION S. REMOVE SCREEN BEFORE BENDING OR SETTING THE CORES PROTECT THE CRUTCH

PAPERS BY UNWINDING AND TEARING CAREFULLY AGAINST THE WITH COTTON TAPE (WHICH IS REMOVED AFTER STEP 14).

Reference BINDER. BIND THE INSULATING PAPERS AT THE ENDS OF THE CORES

Reference

Line WITH A FEW TURNS OF TWINE.

CAREFULLY MARK THE Line

XLPE PILC

550 550 Reference REFERENCE LINE ON

Line THE CORES.

A 350 PILC 3 core

200 150 150 TEMPORARILY PROTECT THE

160

PILC 3 core PREPARED CORES FROM

S 160

40 DIRT WITH PLASTIC WRAP.

Lead sheath

20

Clear

insulating

Outer sheath tubing

Brass tapes

Screen wires CWF tape 6. XLPE CABLES - CLEAN, DEGREASE AND ABRADE THE INNER SHEATH.

Lead sheath

Inner sheath HDPE Screen paper

REMOVE THE RELEASE PAPER FROM THE RED SEALANT MASTIC STRIP

Nylon Paper insulation

FOR NYLON: 55 120 Twine binding AND WRAP ONE LAYER AROUND THE SHEATH (100mm). APPLY MASTIC

Outer sheath

WITH SLIGHT TENSION AND A SMALL OVERLAP.

Reference Line

Lead 4. PILC - CUT A 50mm PIECE FROM THE STRESS CONTROL MASTIC,

HDPE Nylon Outer 100 550

REFER DETAIL. PLACE THE POINT OF THE MASTIC AT THE EDGE OF

PVC

THE SCREEN PAPER ON ONE OF THE CORES. TENSION THE MASTIC

2. PILC CABLE - CLEAN LEAD SHEATH AND BRASS TAPES. POSITION

TO HALF ITS ORIGINAL WIDTH WHILE APPLYING 4-5 TURNS,

3 EARTH BRAIDS AS SHOWN AND BIND TO LEAD SHEATH AND BRASS

OVERLAPPING THE SCREEN AND INSULATION PAPERS BY 10mm.

TAPES WITH COPPER WIRE. SOLDER TO LEAD SHEATH AND BRASS

REPEAT ON REMAINING CORES.

TAPES. PLUMB BRAIDS TO LEAD SHEATH. DO NOT OVERHEAT THE Outer Nylon Red sealant mastic Screen wires

10

sheath over inner sheath

LEAD SHEATH. FOLD BRAIDS BACK ALONG CABLE AND TEMPORARILY Reference

TAPE IN POSITION. Line 10

Extend one braid 7. XLPE - UNWIND THE SCREEN WIRES AND LAY THEM BACK BACK OVER THE

75 over brass tapes

PILC SHEATH. SPREAD THEM EVENLY AROUND THE CABLE, BEDDING THEM

3 copper PILC 3 core

braids INTO THE RED SEALANT MASTIC. TEMPORARILY BIND THE WIRES WITH

PVC TAPE. PROTECT FROM DIRT WITH PLASTIC WRAP.

Reference Line

Screen wires

Outer sheath

Lead sheath

50

Copper wire binding

max lead Stress

- 4 turns

wipe control 50

PVC Embed wires into Semi-con

mastic mastic

Detail - tape

PAWA Cables: 11kV 300sq.mm Al PILC S2-1-1-2 Stress Control Mastic

11kV 240sq.mm Al XLPE S2-1-1-6 Raychem kit EFSJ-11-D-T4

DES JEH/ICV 10/96 POWER STANDARD DRAWING

DRN R.INNES CABLE JOINTING & TERMINATIONS

CKD - RAYCHEM JOINTING INSTRUCTIONS

APPD F.ROBSON

11kV 3C 300sq.mm SCREENED PILC

NO SCALE

SCALE TO 11kV 3x1C 240sq.mm XLPE

1 SUPERSEDED A.T. DEC12 B.C. B.C. ISSUED MAY98

DRAWING

NORTHERN TERRITORY A3 NUMBER S02-2-2-27

NO DESCRIPTION DRN DATE CKD APPD ALL DIM. IN mm 1

AMENDMENTS DRAFTING STANDARD TO A.S.1100 CAD PRODUCT - DO NOT AMEND MANUALLY AMDT

You might also like

- Lighting FixtureDocument1 pageLighting Fixtureahmed.abdelmegeed78No ratings yet

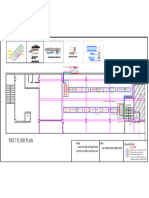

- ELLIPTICAL SPIRAL DUCTABLE LAYOUT FOR THE ROCKS-23-ModelDocument1 pageELLIPTICAL SPIRAL DUCTABLE LAYOUT FOR THE ROCKS-23-ModelAbdullah.N FAAliNo ratings yet

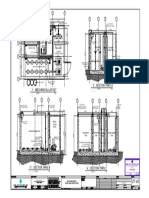

- Oil Tank Metering: GIS - Insulation Is Sf6 Gas Oil Tank Hermetically SealedDocument1 pageOil Tank Metering: GIS - Insulation Is Sf6 Gas Oil Tank Hermetically SealedMahyar MashayekhiNo ratings yet

- Tarayao Elec 01Document1 pageTarayao Elec 01Gerald telanNo ratings yet

- Standard Drawing For Storm Water Drain & Grating Cover - 2Document1 pageStandard Drawing For Storm Water Drain & Grating Cover - 2zohaibimranNo ratings yet

- Juno Lighting Recessed Architectural HID Downlight Catalog 1987Document8 pagesJuno Lighting Recessed Architectural HID Downlight Catalog 1987Alan MastersNo ratings yet

- As Built Billpboard LastDocument1 pageAs Built Billpboard LastSancho AcbangNo ratings yet

- General Intructions: Drawing Number Amdt 297 X 420 A3Document5 pagesGeneral Intructions: Drawing Number Amdt 297 X 420 A3iamlpNo ratings yet

- Attachment Chain: Over 300 Years of Chain ExperienceDocument2 pagesAttachment Chain: Over 300 Years of Chain ExperienceGustavo Urueña OrozcoNo ratings yet

- Archt 10Document1 pageArcht 10Gerard Paul CusiNo ratings yet

- 2020 04 01 - BladeDocument84 pages2020 04 01 - BladeThiago ZorzettoNo ratings yet

- Rehabilitation of Billboard Elevation and PlanDocument1 pageRehabilitation of Billboard Elevation and PlanSancho AcbangNo ratings yet

- PanelDoor Rev07 PDFDocument32 pagesPanelDoor Rev07 PDFSun ChaNo ratings yet

- Corning Fan Out Kit - Standard Recommended Procedure 000-084Document6 pagesCorning Fan Out Kit - Standard Recommended Procedure 000-084markNo ratings yet

- 757 Schematics Layout 1Document25 pages757 Schematics Layout 1hariharanjack100% (7)

- 160 2499 983Document1 page160 2499 983Anonymous 3NDrQadzRNo ratings yet

- Hdpe 81aDocument1 pageHdpe 81aAli RaheemNo ratings yet

- 2022_versionA_AFPCatalog_May2022_Web-95(1)Document1 page2022_versionA_AFPCatalog_May2022_Web-95(1)Tunnel PeruNo ratings yet

- Jdajpr Steel 4Mm 10 Nos - Horizontal 5 Nos - Vertical: Authority Jaipur DevelopmentDocument1 pageJdajpr Steel 4Mm 10 Nos - Horizontal 5 Nos - Vertical: Authority Jaipur DevelopmentAnkur BarsainyaNo ratings yet

- Industrial Cables LPDocument26 pagesIndustrial Cables LPprashant menonNo ratings yet

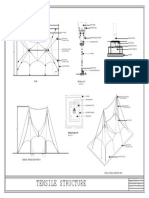

- Tensile StructureDocument1 pageTensile StructureChndrashekhar DombNo ratings yet

- Pavement Design Parameters: SLOPE 1.5 % SLOPE 1.5 %Document1 pagePavement Design Parameters: SLOPE 1.5 % SLOPE 1.5 %cristian gonzalesNo ratings yet

- Test Beam Details For SLT-1 Static Load Test Pile of P-93 PDFDocument1 pageTest Beam Details For SLT-1 Static Load Test Pile of P-93 PDFAna MargaritaNo ratings yet

- BC Pile Foundation 1Document1 pageBC Pile Foundation 1syk7045No ratings yet

- QP10 Q 1580 TypicalPipelineDitchForSingleAndTwinLineDocument1 pageQP10 Q 1580 TypicalPipelineDitchForSingleAndTwinLineMohammad HegazyNo ratings yet

- Untitled Extract PagesDocument1 pageUntitled Extract Pagesnauman faiziNo ratings yet

- Two (2) Storey Residential Unit: PB-PB - Existing PB-1 PB - PB - PBDocument1 pageTwo (2) Storey Residential Unit: PB-PB - Existing PB-1 PB - PB - PBSarah MartinNo ratings yet

- 02.facade Pekan Baru-17.facade DetailDocument1 page02.facade Pekan Baru-17.facade Detailmuflih hudaNo ratings yet

- Perimeter Fence Rev 02-6Document1 pagePerimeter Fence Rev 02-6Victorino SantosNo ratings yet

- Wastewater Treatment Plant LayoutDocument1 pageWastewater Treatment Plant LayoutPeter John RoblesNo ratings yet

- 12.5-310-100 High Mast Lighting SystemDocument1 page12.5-310-100 High Mast Lighting SystemrituNo ratings yet

- Pye Model 552 Olympic Stereogram As Well As 5010 Soundmaster and 5011 Tunemaster Tuner Amps - Service DocDocument2 pagesPye Model 552 Olympic Stereogram As Well As 5010 Soundmaster and 5011 Tunemaster Tuner Amps - Service DocStefan KirkwoodNo ratings yet

- Epson WF C5790 WF C5790A WF C5710 ET 8700 WF C5210 WF C5290 WF C5290A Service Manuals 351 400Document50 pagesEpson WF C5790 WF C5790A WF C5710 ET 8700 WF C5210 WF C5290 WF C5290A Service Manuals 351 400조장현No ratings yet

- Compact design for septic tank containment facilityDocument2 pagesCompact design for septic tank containment facilityLouieNo ratings yet

- TCL ManualDocument40 pagesTCL Manualبوند بوندNo ratings yet

- Roofing sheet and ceiling board specificationsDocument1 pageRoofing sheet and ceiling board specificationsMalson GutierrezNo ratings yet

- Lightolier Lytecaster 7-11 Downlights Brochure 1980Document8 pagesLightolier Lytecaster 7-11 Downlights Brochure 1980Alan MastersNo ratings yet

- Radio 1934 10Document40 pagesRadio 1934 10Somriddha BasuNo ratings yet

- Pinjra Bridge 4 Span Bolan River Quetta 31.08.2023-1Document1 pagePinjra Bridge 4 Span Bolan River Quetta 31.08.2023-1aizaz ahmadNo ratings yet

- General Plumbing Notes and Specification GuideDocument1 pageGeneral Plumbing Notes and Specification GuideAntonio EstradaNo ratings yet

- Omega Lighting C3812TW INC PAR-38 45-Deg. Adj. Downlight Spec Sheet 1-86Document2 pagesOmega Lighting C3812TW INC PAR-38 45-Deg. Adj. Downlight Spec Sheet 1-86Alan MastersNo ratings yet

- Exhaust Fan Mounting Detail A Refrigerant Pipe Insulation Detail B Pipe Thru Wall Detail CDocument1 pageExhaust Fan Mounting Detail A Refrigerant Pipe Insulation Detail B Pipe Thru Wall Detail CMark Anthony ValbuenaNo ratings yet

- Khung Zamil-Tho Sua - 222Document17 pagesKhung Zamil-Tho Sua - 222Al-Razzaq Al-WahhabNo ratings yet

- 01.STD DrawingDocument82 pages01.STD Drawingjplaza3074No ratings yet

- Standards of Tubular Heat Exchanger DesignDocument883 pagesStandards of Tubular Heat Exchanger DesignFitra WahyudiNo ratings yet

- SNBC Piers Details PDFDocument1 pageSNBC Piers Details PDFZubair MuhammadNo ratings yet

- Ridce de Tail: ToorseDocument4 pagesRidce de Tail: ToorseTriveni TriveniNo ratings yet

- Man ElectrodesDocument2 pagesMan ElectrodesTirex Mata IkanNo ratings yet

- Detalji Krovova - OluciDocument31 pagesDetalji Krovova - OluciSamirNo ratings yet

- Khung Zamil-Tho Sua - 223Document16 pagesKhung Zamil-Tho Sua - 223Al-Razzaq Al-WahhabNo ratings yet

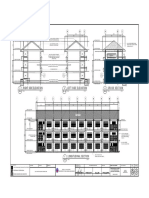

- Front Elevation 1:100 West Elevation 1:100: E E D D C C B B A ADocument1 pageFront Elevation 1:100 West Elevation 1:100: E E D D C C B B A AKamagara Roland AndrewNo ratings yet

- Price Labeller: Loosen The Two Screws N Both Sides of Labeler Close To Letterhead. HeadDocument2 pagesPrice Labeller: Loosen The Two Screws N Both Sides of Labeler Close To Letterhead. HeadЖеня ИльченкоNo ratings yet

- Rangka Atap Untuk Pustu IiDocument1 pageRangka Atap Untuk Pustu IiResya AstinNo ratings yet

- Adobe Scan 02-Jun-2021Document2 pagesAdobe Scan 02-Jun-2021Ashutosh SinghNo ratings yet

- Aspiration Accessories DataSheet CMDS002Document2 pagesAspiration Accessories DataSheet CMDS002sbmmkushanNo ratings yet

- 111Document1 page111Ngoc Pham Thi ThuNo ratings yet

- 6 MTR CONICALDocument1 page6 MTR CONICALSrDEE PowerNo ratings yet

- toboan2023-SECTION 6Document1 pagetoboan2023-SECTION 6Harold Kim SapianNo ratings yet

- Secondary Coating Line: Processing DataDocument2 pagesSecondary Coating Line: Processing DataAS TorrealbaNo ratings yet

- DME Chapter 2Document5 pagesDME Chapter 2dhananjayvermaNo ratings yet

- PET For CSD Bottles - Jade PET Resin ChinaDocument2 pagesPET For CSD Bottles - Jade PET Resin ChinaEudy CardozoNo ratings yet

- 09a-Moteur-Ewj-3.1L TDDocument68 pages09a-Moteur-Ewj-3.1L TDfizou123No ratings yet

- Earthquake Base Shear Calculation for 3-Story Office BuildingDocument4 pagesEarthquake Base Shear Calculation for 3-Story Office Buildinggendadeyu552625100% (1)

- 12 Manual - On - RetrofittingDocument60 pages12 Manual - On - Retrofittingdarshiq dharshanNo ratings yet

- 8-1324-7 Pipe Class FC-7Document2 pages8-1324-7 Pipe Class FC-7Fredy Vázquez VelázquezNo ratings yet

- Fosroc Supercast PVC Waterstops: Technical Data SheetDocument4 pagesFosroc Supercast PVC Waterstops: Technical Data Sheetarvin jay santarinNo ratings yet

- Project Summary in ContractDocument3 pagesProject Summary in ContractJeboy ChackoNo ratings yet

- Woodland Classrooms, Belvue School, Northolt, West LondonDocument8 pagesWoodland Classrooms, Belvue School, Northolt, West LondonJayant NegiNo ratings yet

- Student Industrial Work Experience ReportDocument13 pagesStudent Industrial Work Experience ReportAWHEN FITZGERALD100% (1)

- Contract For ConstructionDocument9 pagesContract For ConstructionLouie LopezNo ratings yet

- Wind Load CalculationDocument3 pagesWind Load CalculationGajera HarshadNo ratings yet

- Degadur® 420 and Degadur® 526Document5 pagesDegadur® 420 and Degadur® 526申易No ratings yet

- Study Material ON: S.M. No. Rev. No. Effective DateDocument15 pagesStudy Material ON: S.M. No. Rev. No. Effective DateAbhishek AroraNo ratings yet

- Essel Ludhiana Talwandi Toll Roads PVT Limited-03!06!2014Document4 pagesEssel Ludhiana Talwandi Toll Roads PVT Limited-03!06!2014Jagadeesh YathirajulaNo ratings yet

- Internship presentation on Mutual Builder Pvt. LtdDocument14 pagesInternship presentation on Mutual Builder Pvt. LtdSoo CealNo ratings yet

- Tree Cutting MethodDocument14 pagesTree Cutting MethodBienSabadoNo ratings yet

- Leed GA Practice Questions - AnswersDocument26 pagesLeed GA Practice Questions - AnswersAl-Madinah Al-MunawarahNo ratings yet

- Soil Permeability LectureDocument34 pagesSoil Permeability LectureSheikh AnikNo ratings yet

- EXAMPLE OF MIX DESIGN .R.s.Document11 pagesEXAMPLE OF MIX DESIGN .R.s.Ramkiran TalariNo ratings yet

- FRP-Confined Column Cyclic LoadingDocument150 pagesFRP-Confined Column Cyclic Loadingf puglieseNo ratings yet

- My Dream House ProjectDocument12 pagesMy Dream House ProjectRobyn TinneyNo ratings yet

- Ce2252 - Strength of MaterialsDocument4 pagesCe2252 - Strength of Materialsmuru0105No ratings yet

- New COADocument15 pagesNew COAAhadNurParagNo ratings yet

- Design Management Manual - Vol 2 - Design StandardsDocument87 pagesDesign Management Manual - Vol 2 - Design StandardsWissam JarmakNo ratings yet

- CMO Aluminium Tank Vent Check Valve With Overflow PipeDocument2 pagesCMO Aluminium Tank Vent Check Valve With Overflow Piped13g0bcNo ratings yet

- General Overview On Site Drawings & TSSRDocument35 pagesGeneral Overview On Site Drawings & TSSRNazmul Hossain RakibNo ratings yet

- Turner's IOR Key to Risk ManagementDocument9 pagesTurner's IOR Key to Risk Managementremya_392830015No ratings yet

- LUSAS Hands OnDocument144 pagesLUSAS Hands OnmoodooNo ratings yet

- AVEs 2014Document529 pagesAVEs 2014ropmachadoNo ratings yet