Professional Documents

Culture Documents

Polyurethane Finish: Iso Cyanate Cured

Uploaded by

Engr Saeed AnwarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Polyurethane Finish: Iso Cyanate Cured

Uploaded by

Engr Saeed AnwarCopyright:

Available Formats

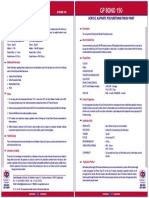

INDUSTRIAL PAINTS

POLYURETHANE FINISH

Iso Cyanate Cured PU 01

HIGH GLOSS FINISH-EXCELLENT GLOSS RETENTION ON EXTERIOR & INTERIOR EXPOSURES

OUTSTANDING MAR RESISTANCE-RECOMMENDED AS ABRASION RESISTANT FINISH

RESISTANT TO CHEMICALS, YELLOWING AND YELLOWING IN DARK.

EASY APPLICATION: CAN BE APPLIED BY BRUSH, ROLLER OR SPRAY

USES: Polyurethane Finish has high chemical resistance and is particularly suited to surfaces where high

durability is required. It is a versatile coating with excellent gloss retention and is easily applicable by

brush, roller or spray.

RESISTANCE GUIDE:

HEAT RESISTANCE: Upto 120oC (Dry) ALKALIES: Good resistance to splash and spillage of

most common alkalies.

WEATHERABILITY: Excellent SALTS: Unaffected by splash and spillage of most

salt solutions.

SOLVENTS: Unaffected by splash and spillage WATER: Excellent resistance to fresh and salt but not

of common alcohols, aliphatic and recommended for immersion.

aromatic hydrocarbons, esters and

ketones.

ABRASION: Excellent.

ACIDS: Suitable for mild exposure to TOXICITY: Paint is cured with cynate hardener. Though

Inorganic acids. dry film is not harmful but should not be used

in or near food items.

TYPICAL PROPERTIES AND APPLICATION DATA:

CLASSIFICATION: Polyurethane coating. DRY FILM PER COAT (30-40) Micrometers

FINISH: Gloss

COLOUR Limited color range NUMBER OF COATS: Two Three

REFERENCE:

DRYING TIME AT 25C

COMPONENTS: Two AND 50% HUMIDITY MIN MAX

TOUCH 2 hours

HANDLE 16 hours

RECOAT 8 hours

FULL CURE 7 days

VOLUME SOLIDS: 472% (Vary with color)

S. GRAVITY: 1.300.05% (Vary with color)

FLASH POINT: 23o C (mixed)

THINNER Thinner For PU SUITABLE Suitably primed timber, steel primers

SHELF LIFE: 12 months min SUBSTRATES:

PRIMERS: Zinc Rich Epoxy Primer, Ethyl Zinc Silicate

Primer, Epoxy Zinc Phosphate Primer

POT LIFE: 4Hours @ 25oC for 4 litres.

MIXING RATIO: Parts A 4 ( By volume.)

Parts B 1

LINE/SHADE: PART A: 424- APPLICATION Brush, roller air or airless spray.

PART B: 275- METHODS:

THEORETICAL SPREADING RATE AT RECOMMENDED A spreading rate of (14-12) m2/litre corresponds to (30-40) micrometers

DRY FILM THICKNESS dry film thickness assuming no losses on a non-porous and non-absorbent

surface. Practical spreading rates will vary depending on such factors as

methods, conditions of application and surface roughness.

PDS-PUFI

INDUSTRIAL PAINTS

POLYURETHANE FINISH

TYPICAL APPLICATION SPECIFICATION

SURFACE PREPARATION: Polyurethane Finish is a specialized chemical resistant finish and requires sound preparation and a suitable

priming system to perform to its optimum. It is recommended that potential specifiers follow guidelines for

surface preparation from the Data Sheet for the primer system selected.

APPLICATION: Stir each component thoroughly before mixing. Add Comp. B to Comp. A in the ratio supplied and mix until

uniform in colour and consistency. Allow to digest for 20 minutes before application.

ROLLER/ BRUSH: As this material tends to set up quickly, application should be made with minimum of crossing or laying off.

CONVENTIONAL SPRAY: Thin up to 10-20% per litre with Thinner for PU mixing thoroughly before application.

TYPICAL SET-UP

De Vilbiss JGA 502 Gun: 704 Air Cap. FF Fluid Tip, FF Needle

Iwata W70 Gun: 021 Air Cap; 021 Fluid Needle; 021 Fluid Nozzle

Pressure at Pot: 10-15 p.s.i.

Pressure at Gun: 55-60 p.s.i.

AIRLESS SPRAY: Standard airless spray equipment such as Graco, Hermex, Binks and others using a 28:1 pump ratio, with a fluid

tip of 475 micrometers (019") and an air supply of 80-100p.s.i. Thin if necessary with upto 100 ml per liter.

OTHERS: Freshly mixed material must not be added to material which has been in use for sometime. Ensure you read and

understand safety precautions on data sheet. Never add thinner other than recommended. Do not apply

polyurethane filler at temperature below 10oC or relative humidity above 85%. Maximum recoat intervals 48

hours at 25oC should this time interval be exceeded the surface must be lightly abraded.

CLEAN UP: Clean up all equipment with Urethane Thinner immediately after use.

RECOATING AGED COATING Abrade surface, clean from dust and foreign matter. Apply further coat of Polyurethane filler to specified

thickness.

RECOMMENDED HEALTH & HYGIENE GUIDELINES FOR HANDLING PAINT PRODUCTS CONTAINING ISOCYANATES MUST BE READ BEFORE

USE

THESE PRECAUTIONS These guidelines relate to those two pack paint systems, one part of which is a base colour: Free of isocyanates

and other an isocyanate hardener.

TOXICITY SUMMARY: In general, the base colours used in such paints are no more toxic or irritant than other commonly used paints

containing organic solvents. However, both the hardener and the mixture of hardener and base will contain free

organic isocyanates and must be handled using the protective clothing, equipment and handling procedure set

out in these guidelines. Organic isocyanates themselves are mild skin irritants although rarely skin sensitisers.

They are severe eye irritant and cause chemical conjunctivitis. They are also known to be respiratory irritants

which, if inhaled at sufficiently high concentrations, can produce symptoms of dry throat and cough. In more

severe cases, asthmatic breathing and chest tightening may occur, but there is usually a rapid recovery when

exposure ceases. There may be a delay period of several hours after contract before symptoms appear.

Susceptible works may become sensitized by exposure to isocyanates and subsequently exhibit symptoms of

distress when exposed to atmospheric concentrations well below the normal industrial hygiene standard.

Repeated attacks may lead to permanent respiratory disability.

PERSONNEL Persons with a history of asthma or other respiratory problems or known to be sensitive to isocyanates should

not be engaged in any work involving the handling of isocyanates. Spray painters who handle such products

should be made aware of this fact.

OPERATOR PROTECTIVE

CLOTHING &EQUIPMENT: All mixing and handling of hardener, and mixed paint, is to be carried out under working conditions that prevent

skin contact or inhalation of vapors. For example, wear impervious gloves in ventilated booth which is fitted with

an effective, filtered exhaust system. Wear a positive-pressure, air supplied, full-face respirator, and wear gloves

while spraying, during all subsequent use. Dust respirator must not be relied on any time to give protection from

isocyanate paint Spray mist.

POLYURETHANE FINISH

HANDLING: Containers must be kept tightly closed when not in use and not be allowed to come into contact with water at

any time. Isocyanates react with water, which destroys their effectiveness. Gas is evolved when isocyanate

reacts with water. If a closed container shows signs of internal pressure, cover it completely with a cloth and

remove the lid slowly to prevent splashing or expulsion of the lid. If using only a portion of the hardener in a can,

re-seal and use the balance of contents within 36 hours, as it will deteriorate on exposure to air. Store away

from heat and moisture. Accidental spillage should be absorbed into dry sand or earth, remove from the work

area cover with water for 24 hours. Do not allow materials of this kind to enter drains. Dispose of treated waste

as directed by the relevant waste disposal authorities. Fill empty hardener containers with water for 24 hours.

APPLICATION: If applying by brush or roller all mixing and application must be carried out under well ventilated conditions that

prevent inhalation of vapors. Its spray application should be carried out in a spray booth fitted with an effective

filtered exhaust system. The operator must wear the protective equipment prescribed in these guidelines.

FLAMMABILITY: Polyurethane Finishes are highly flammable. All sources of ignition must be eliminated, in or near the working

area. DO NOT SMOKE. Fight fire with foam, CO2 and dry chemical powder. On burning will emit toxic fumes.

WELDING: Avoid inhalation of fumes if welding surfaces coated with this paint. Grind off coating

before welding.

EMERGENCY TREATMENT: EYES: Irrigate with copious quantities of water for fifteen minutes. Seek medical assistance if

effect persists.

SKIN: Remove paint using proprietary industrial skin cleanser. Wash skin thoroughly with

soap and water. Remove contaminated clothing and wash before re-use. If irritation

occurs seek medical advice.

INHALATION: Remove victim from exposure - avoid becoming a casualty. Remove contaminated

clothing and loosen remaining clothing. Allow patient to assume the most comfortable

position and keep warm. Keep at rest until fully recovered. Seek medical advice if

effects persist.

INGESTION: Seek immediate medical assistance. Do not induce vomiting.

PACKING: Available in 4 litres packs (Comp. A in 3.2 Ltrs and Comp. B in 0.8 Ltrs)

All information contained in this Data Sheet is as accurate and up-to-date as possible. Products can be expected to perform as indicated in this

Sheet, so long as applications and application procedures are as recommended. However there are no expressed or implied warranties other than

those implied mandatorily by State.

You might also like

- KAN-SUPRA Polyurethane FinishDocument2 pagesKAN-SUPRA Polyurethane Finishazam RazzaqNo ratings yet

- Thor ZcepDocument2 pagesThor Zcepazam RazzaqNo ratings yet

- Characteristics: Thinning ApplicationDocument2 pagesCharacteristics: Thinning Applicationazam RazzaqNo ratings yet

- GP Primeguard 235Document1 pageGP Primeguard 235Krunal RudaniNo ratings yet

- Relipoxy P 301: Epoxy Based PrimerDocument3 pagesRelipoxy P 301: Epoxy Based PrimerPRERAKNo ratings yet

- KAN-TAURUS High Build Epoxy Finish: CharacteristicsDocument2 pagesKAN-TAURUS High Build Epoxy Finish: Characteristicsazam RazzaqNo ratings yet

- Nippon ArocoatDocument3 pagesNippon ArocoatHANIF IZANI ISHAKNo ratings yet

- Hi-Acryl 1901 Acrylic Top Coat Is A One-Pack, Fast-Drying AcrylicDocument4 pagesHi-Acryl 1901 Acrylic Top Coat Is A One-Pack, Fast-Drying AcrylicEvonne LeeNo ratings yet

- Thor EfccDocument2 pagesThor Efccazam RazzaqNo ratings yet

- Revchem HRC 870Document3 pagesRevchem HRC 870marciobispoalmeidaNo ratings yet

- DS - 752-Rev01 - Epilux 485 HB IntermediateDocument2 pagesDS - 752-Rev01 - Epilux 485 HB IntermediatePammy JainNo ratings yet

- Zinc Anode 304 NPC Coating Zinc Anode 304 NPC Coating: Berger Industrial Manual Berger Industrial ManualDocument1 pageZinc Anode 304 NPC Coating Zinc Anode 304 NPC Coating: Berger Industrial Manual Berger Industrial Manualআফজাল -উল ইসলাম নূর0% (1)

- TDS-EN-Conflex PS - Rev 016-Aug21Document2 pagesTDS-EN-Conflex PS - Rev 016-Aug21LONG LASTNo ratings yet

- NP ArocoatDocument4 pagesNP ArocoatJohn HaNo ratings yet

- DS BR ACRYLIC PU CoatingDocument3 pagesDS BR ACRYLIC PU CoatingSomak DuariNo ratings yet

- Nippon HB Epoxy LinerDocument3 pagesNippon HB Epoxy LinerRai Hasnain Ahmad DahaNo ratings yet

- Coaltar Epoxy - C 200Document2 pagesCoaltar Epoxy - C 200azam RazzaqNo ratings yet

- Ultra Cote 401 HsDocument3 pagesUltra Cote 401 HsGilbert Dela Serna IINo ratings yet

- Aluminium Paint HR NipponDocument2 pagesAluminium Paint HR Nipponyarth88No ratings yet

- Hi Pon 50 01 Polyurethane Top Coat Ver 12.0Document4 pagesHi Pon 50 01 Polyurethane Top Coat Ver 12.0kominthitsar7474No ratings yet

- Jen. 2 Pack Pu Enamel Jen. 2 Pack Pu Enamel: Berger Industrial Manual Berger Industrial ManualDocument1 pageJen. 2 Pack Pu Enamel Jen. 2 Pack Pu Enamel: Berger Industrial Manual Berger Industrial Manualআফজাল -উল ইসলাম নূরNo ratings yet

- Hipon 20 DechloDocument3 pagesHipon 20 DechloLopez GardoNo ratings yet

- Nippon Arocoat: Product DescriptionDocument3 pagesNippon Arocoat: Product DescriptionHamza GhaniNo ratings yet

- ROYALPOXY UW 410-tdsDocument3 pagesROYALPOXY UW 410-tdsSyed FaridNo ratings yet

- Epoxy Primer216Document2 pagesEpoxy Primer216kishortilekarNo ratings yet

- Hi Pon 20 07 Epoxy Zinc Phosphate 70 Ver 13.0 PDFDocument4 pagesHi Pon 20 07 Epoxy Zinc Phosphate 70 Ver 13.0 PDFPushpendraNo ratings yet

- 2.chemoxy 102HB EPOXY ZINC PHOSPHATE PRIMERDocument3 pages2.chemoxy 102HB EPOXY ZINC PHOSPHATE PRIMERisan.structural TjsvgalavanNo ratings yet

- Luxepoxy UHB: Ultra High Build EpoxyDocument2 pagesLuxepoxy UHB: Ultra High Build EpoxylivefreakNo ratings yet

- Grand Polycoat PolyurethaneDocument1 pageGrand Polycoat PolyurethaneAniket GaikwadNo ratings yet

- Nitocote EP405: Constructive SolutionsDocument4 pagesNitocote EP405: Constructive SolutionsrayNo ratings yet

- Interm & Top Coat (Polyurethane)Document2 pagesInterm & Top Coat (Polyurethane)Fadi HamandiNo ratings yet

- 1.DiaAcryl 2K Polyurethane Finish (3.8+0.8)Document4 pages1.DiaAcryl 2K Polyurethane Finish (3.8+0.8)bublooo123No ratings yet

- FINISH COAT-Bergerthane PU CoatingDocument2 pagesFINISH COAT-Bergerthane PU CoatingMANIMARAN QCNo ratings yet

- TDS Epoxy Zinc Phosphate Primer HB 50 GreyDocument3 pagesTDS Epoxy Zinc Phosphate Primer HB 50 GreySAlman Khan50% (2)

- Hi Pon 90 08 Epoxy Ultra HB Ver 2.0 PDFDocument5 pagesHi Pon 90 08 Epoxy Ultra HB Ver 2.0 PDFPushpendraNo ratings yet

- HB Epoxy Zinc Rich Primer - TDSDocument2 pagesHB Epoxy Zinc Rich Primer - TDSazam RazzaqNo ratings yet

- Hi Pon 50 10 Polyester PU Primer Ver 2.0 PDFDocument4 pagesHi Pon 50 10 Polyester PU Primer Ver 2.0 PDFPushpendraNo ratings yet

- SteelkobeDocument3 pagesSteelkobealexamaigutNo ratings yet

- DS 428 LuxathaneFDFinishDocument2 pagesDS 428 LuxathaneFDFinishRatish NairNo ratings yet

- Epoxy Floor Coating: Description FeaturesDocument2 pagesEpoxy Floor Coating: Description FeaturesRayon 9No ratings yet

- Characteristics: Uses ApplicationDocument2 pagesCharacteristics: Uses Applicationazam RazzaqNo ratings yet

- Hi Pon 20 01 Epoxy Primer Ver 8.0Document4 pagesHi Pon 20 01 Epoxy Primer Ver 8.0PushpendraNo ratings yet

- H. V. NC: Satin WhiteDocument1 pageH. V. NC: Satin Whiteمحمد عزتNo ratings yet

- Hi Pon50 01PolyurethaneTopCoat - TDSDocument4 pagesHi Pon50 01PolyurethaneTopCoat - TDSDenny AgusNo ratings yet

- Bergerthane PU Glossy Finish: Product Data Resistance GuideDocument2 pagesBergerthane PU Glossy Finish: Product Data Resistance Guidesangram keshari pattanaikNo ratings yet

- DS 165 Rev01 Bergerthane PU Glossy Finish (Berger)Document2 pagesDS 165 Rev01 Bergerthane PU Glossy Finish (Berger)Ranjan Kumar SahuNo ratings yet

- Arocoat - Repair Paint Data SheetDocument3 pagesArocoat - Repair Paint Data SheetIsboNo ratings yet

- Food Grade Epoxy Coating Centre Govt Lab Approved and Nabl Lab Tested As Per Fda GuidilinesDocument5 pagesFood Grade Epoxy Coating Centre Govt Lab Approved and Nabl Lab Tested As Per Fda GuidilinesdineshNo ratings yet

- H. V. NC Sanding Sealer: ClearDocument1 pageH. V. NC Sanding Sealer: Clearمحمد عزتNo ratings yet

- Microsoft Word - L3 - Epilux82Document2 pagesMicrosoft Word - L3 - Epilux82vitharvanNo ratings yet

- Epilux 155Document2 pagesEpilux 155Allana100% (1)

- 805 Steelkote Ep ZN Hs Datasheet enDocument3 pages805 Steelkote Ep ZN Hs Datasheet enprasanth cp100% (1)

- EA9 Red Oxide PrimerDocument3 pagesEA9 Red Oxide PrimernkhhhNo ratings yet

- Nerothane 1000Document1 pageNerothane 1000nimish.aquamarine0% (1)

- H. V. NC: High Gloss - WhiteDocument1 pageH. V. NC: High Gloss - Whiteمحمد عزتNo ratings yet

- Nippon EA9 Finish HBDocument3 pagesNippon EA9 Finish HBHamza GhaniNo ratings yet

- Ultracote Ultracote Ultracote Ultracote: Ultrazinc 2120Document3 pagesUltracote Ultracote Ultracote Ultracote: Ultrazinc 2120Cherbee FerrerNo ratings yet

- Nippon 8048Document3 pagesNippon 8048Armanda SiryogiawanNo ratings yet

- 2401-00 Simacover EP UnicoatDocument3 pages2401-00 Simacover EP UnicoatSAEFUDDIN SAEFUDDINNo ratings yet

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- WPS For Different Materail by BhelDocument176 pagesWPS For Different Materail by Bhelsaisssms911691% (46)

- EN 388 StandardDocument11 pagesEN 388 StandardEngr Saeed Anwar100% (1)

- Faisal New 15 March PDF UdatedDocument54 pagesFaisal New 15 March PDF UdatedEngr Saeed AnwarNo ratings yet

- Heliyon: Lam Thi Bich Le, Toan Thai Tran, Ngoc Hai TranDocument7 pagesHeliyon: Lam Thi Bich Le, Toan Thai Tran, Ngoc Hai TranMUHAMMAD ARIF DZIKRI ASMADINo ratings yet

- Arc Welding Filler Metal Selection ChartDocument7 pagesArc Welding Filler Metal Selection Chartepriyono0% (1)

- An Analysis of STEM in Early Childhood Education 8 MarchDocument60 pagesAn Analysis of STEM in Early Childhood Education 8 MarchEngr Saeed AnwarNo ratings yet

- Effective Interviewing TechniquesDocument17 pagesEffective Interviewing TechniquesEngr Saeed AnwarNo ratings yet

- Saeed Anwar Cover Letter 2022Document1 pageSaeed Anwar Cover Letter 2022Engr Saeed AnwarNo ratings yet

- ElectrodosDocument14 pagesElectrodosanon-635614100% (6)

- Asme Section IxDocument47 pagesAsme Section Ixمحمودالوصيف100% (8)

- Saeed Anwar Cover Letter 2022Document1 pageSaeed Anwar Cover Letter 2022Engr Saeed AnwarNo ratings yet

- Mild & Low Alloy Steel Bare WireDocument6 pagesMild & Low Alloy Steel Bare WireEngr Saeed AnwarNo ratings yet

- Faisal Anwar CV UpdatedDocument2 pagesFaisal Anwar CV UpdatedEngr Saeed AnwarNo ratings yet

- Asme Introduction & Inspection of Pressure Vessel: (ASME Section VIII Div. 1, Ed. 2015)Document47 pagesAsme Introduction & Inspection of Pressure Vessel: (ASME Section VIII Div. 1, Ed. 2015)TayfunwNo ratings yet

- E205 PDFDocument24 pagesE205 PDFFikri RahimNo ratings yet

- 8607 PDFDocument31 pages8607 PDFEngr Saeed AnwarNo ratings yet

- Challan FormDocument1 pageChallan FormFurqan ButtNo ratings yet

- SopDocument60 pagesSopanon-6927682% (11)

- Standard Operating Procedure Control of Quality Records: SOP-05 Document No.: Sop/Instruction/01Document3 pagesStandard Operating Procedure Control of Quality Records: SOP-05 Document No.: Sop/Instruction/01Engr Saeed AnwarNo ratings yet

- QAQCDocument14 pagesQAQCEngr Saeed AnwarNo ratings yet

- Pyramid Steel Structures (PVT.) Limited: Welding Consumable Control ProcedureDocument8 pagesPyramid Steel Structures (PVT.) Limited: Welding Consumable Control ProcedureEngr Saeed AnwarNo ratings yet

- ABC 5edDocument93 pagesABC 5edJuan Diego Garcia EsquenNo ratings yet

- Rashid KhanDocument2 pagesRashid KhanEngr Saeed AnwarNo ratings yet

- Selection of An NDT Method and The Extent of TestingDocument8 pagesSelection of An NDT Method and The Extent of TestingEngr Saeed AnwarNo ratings yet

- Flow Process Chart For Stage InspectionDocument1 pageFlow Process Chart For Stage InspectionEngr Saeed AnwarNo ratings yet

- Quality Inspection Status For Main Shed Pyramid Steel Structure (PVT.) LTDDocument92 pagesQuality Inspection Status For Main Shed Pyramid Steel Structure (PVT.) LTDEngr Saeed AnwarNo ratings yet

- Quality Inspection Status For Main Shed Pyramid Steel Structure (PVT.) LTDDocument92 pagesQuality Inspection Status For Main Shed Pyramid Steel Structure (PVT.) LTDEngr Saeed AnwarNo ratings yet

- Request For Inspection: SR No Activity. Description. Drawing No. Quality Performance Poor Avrg. GoodDocument4 pagesRequest For Inspection: SR No Activity. Description. Drawing No. Quality Performance Poor Avrg. GoodEngr Saeed AnwarNo ratings yet

- QAQC Daily Inspection Report Sir JabarDocument4 pagesQAQC Daily Inspection Report Sir JabarEngr Saeed AnwarNo ratings yet

- Project:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportDocument4 pagesProject:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportEngr Saeed AnwarNo ratings yet

- Pointy Hat - Rules For Psionic TransformationDocument5 pagesPointy Hat - Rules For Psionic Transformationlu babaluNo ratings yet

- Experiment 2 Determination of Specific Gravity and Absorption of Coarse AggregatesDocument6 pagesExperiment 2 Determination of Specific Gravity and Absorption of Coarse AggregatesRenNo ratings yet

- Astm D2196-10Document5 pagesAstm D2196-10Bryan de BarrosNo ratings yet

- Daylight Factor - Wikipedia, The Free EncyclopediaDocument2 pagesDaylight Factor - Wikipedia, The Free EncyclopediadasaNo ratings yet

- Report of PDA Test Pile T29Document20 pagesReport of PDA Test Pile T29bertaNo ratings yet

- Ucsp Collage MakingDocument2 pagesUcsp Collage MakingDiona MacasaquitNo ratings yet

- Operating Manual - Innova 2300, 2350Document46 pagesOperating Manual - Innova 2300, 2350scottstreetNo ratings yet

- Sponge ColoringDocument3 pagesSponge ColoringMavel Madih KumchuNo ratings yet

- Ecology Paper With AnswersDocument27 pagesEcology Paper With AnswersJoel EastNo ratings yet

- College For Research and Technology of Cabanatuan: Del Pilar ST., Cabanatuan CityDocument2 pagesCollege For Research and Technology of Cabanatuan: Del Pilar ST., Cabanatuan CityLove JcwNo ratings yet

- Assignment 1CDocument3 pagesAssignment 1CWinnifer KongNo ratings yet

- Defrino SummaryDocument1 pageDefrino SummaryAlma JavierNo ratings yet

- Community Stakeholder Engagement Within A NonDocument6 pagesCommunity Stakeholder Engagement Within A NonAmar narayanNo ratings yet

- Endterm QAM II 2019 BCFDocument3 pagesEndterm QAM II 2019 BCFABHISHEK KUMAR SINGHNo ratings yet

- Prof Ed QuestionsDocument35 pagesProf Ed QuestionsKatrina BautistaNo ratings yet

- Shadows of Esteren Universe PDFDocument293 pagesShadows of Esteren Universe PDFThibault Mlt EricsonNo ratings yet

- Thesis Technology ManagementDocument7 pagesThesis Technology Managementzidhelvcf100% (2)

- Declaration of Interdependence Steele 1976 2pgs GOV POLDocument2 pagesDeclaration of Interdependence Steele 1976 2pgs GOV POLsonof libertyNo ratings yet

- Chase Evan Oliphant BiographyDocument1 pageChase Evan Oliphant Biographyapi-248803155No ratings yet

- SUMMATIVE TEST IN SCIENCE 6 (Fourth Quarter)Document3 pagesSUMMATIVE TEST IN SCIENCE 6 (Fourth Quarter)Cindy Mae Macamay100% (2)

- Membership Application Form - FELLOW-MEMBER-ASSOCIATE MEMBER April2020Document5 pagesMembership Application Form - FELLOW-MEMBER-ASSOCIATE MEMBER April2020punit sarswatNo ratings yet

- Best Practice To Measure Physical Progress of An EPC ProjectDocument5 pagesBest Practice To Measure Physical Progress of An EPC ProjectShimelash Kassahun100% (1)

- SC WD 1 WashHandsFlyerFormatted JacobHahn Report 1Document3 pagesSC WD 1 WashHandsFlyerFormatted JacobHahn Report 1jackson leeNo ratings yet

- Fiori & Pratolongo-2021 - The Bahía Blanca EstuaryDocument579 pagesFiori & Pratolongo-2021 - The Bahía Blanca EstuarykevinNo ratings yet

- Luningetal2005 - SiluriansourcerocksandpetroleumplayJordanDocument32 pagesLuningetal2005 - SiluriansourcerocksandpetroleumplayJordanMary DNo ratings yet

- Term-2 Cycle Test Schedule 2023-24Document2 pagesTerm-2 Cycle Test Schedule 2023-24sarassinging22No ratings yet

- Worksheet in Bio 102: Microbiology and Parasitology - Week No. 3Document4 pagesWorksheet in Bio 102: Microbiology and Parasitology - Week No. 3DELOS SANTOS JESSIECAHNo ratings yet

- Literary, Photo Story, OpinionDocument9 pagesLiterary, Photo Story, OpinionMaya BabaoNo ratings yet

- Empathy in The WorkplaceDocument16 pagesEmpathy in The Workplacesritha_87100% (1)

- TI-EN-UVACURID C81 FarbserieDocument12 pagesTI-EN-UVACURID C81 FarbseriePatxi hernandez suellesNo ratings yet