Professional Documents

Culture Documents

Colornodic Chart PDF

Uploaded by

ValiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Colornodic Chart PDF

Uploaded by

ValiCopyright:

Available Formats

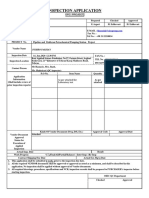

Arcadia Inc.

- Guide Specifications

ARCADIA INC TYPE FINISH ALUMINUM AAMA

DESIGNATION

DESCRIPTION ASSOCIATION SPECIFICATION

DESIGNATION DESIGNATION

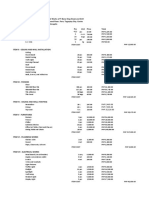

AC-3 COMMERCIAL CLEAR CLEAR AA-M12C22A21

AC-2 CLASS II CLEAR CLEAR AA-M12C22A31 AAMA 611

AC-1 CLASS I CLEAR CLEAR AA-M12C22A41 AAMA 611

AB-1 COMMERCIAL BRONZE LIGHT CHAMPAGNE AA-M12C22A24 AAMA 611

AB-1 CLASS II BRONZE LIGHT CHAMPAGNE AA-M12C22A34 AAMA 611

AB-1 CLASS I BRONZE LIGHT CHAMPAGNE AA-M12C22A44 AAMA 611

AB-2 COMMERCIAL BRONZE CHAMPAGNE AA-M12C22A24 AAMA 611

AB-2 CLASS II BRONZE CHAMPAGNE AA-M12C22A34 AAMA 611

AB-2 CLASS I BRONZE CHAMPAGNE AA-M12C22A44 AAMA 611

AB-3 COMMERCIAL BRONZE LIGHT BRONZE AA-M12C22A24 AAMA 611

AB-3 CLASS II BRONZE LIGHT BRONZE AA-M12C22A34 AAMA 611

AB-3 CLASS I BRONZE LIGHT BRONZE AA-M12C22A44 AAMA 611

AB-4 COMMERCIAL BRONZE LIGHT MEDIUM BRONZE AA-M12C22A24 AAMA 611

AB-4 CLASS II BRONZE LIGHT MEDIUM BRONZE AA-M12C22A34 AAMA 611

AB-4 CLASS I BRONZE LIGHT MEDIUM BRONZE AA-M12C22A44 AAMA 611

AB-5 COMMERCIAL BRONZE DARK MEDIUM BRONZE AA-M12C22A24 AAMA 611

AB-5 CLASS II BRONZE DARK MEDIUM BRONZE AA-M12C22A34 AAMA 611

AB-5 CLASS I BRONZE DARK MEDIUM BRONZE AA-M12C22A44 AAMA 611

AB-6 COMMERCIAL BRONZE DARK BRONZE AA-M12C22A24 AAMA 611

AB-6 CLASS II BRONZE DARK BRONZE AA-M12C22A34 AAMA 611

AB-6 CLASS I BRONZE DARK BRONZE AA-M12C22A44 AAMA 611

AB-7 COMMERCIAL BRONZE STANDARD DARK BRONZE AA-M12C22A24 AAMA 611

AB-7 CLASS II BRONZE STANDARD DARK BRONZE AA-M12C22A34 AAMA 611

AB-7 CLASS I BRONZE STANDARD DARK BRONZE AA-M12C22A44 AAMA 611

AB-8 CLASS II BLACK BLACK AA-M12C22A34 AAMA 611

AB-8 CLASS I BLACK BLACK AA-M12C22A44 AAMA 611

NOTE: Class II Anodic finishes have a minimum thickness of .4 mils, Class I Anodic finishes have a minimum thickness of .7 mils

QUALITY CONTROL FOR ARCADIA INC.'S ANODIZED FINISHES (Applies to doss II and I anodic finishes only)

The following parameters are tested in accordance with ASTM or ISO test methods:

A. Anodic Coating Thickness: ASTM B244 or ISO 2360

B. Anodic Coating Density (applies to exterior architectural applications only) : ASTM B137

C. Anodic Seal Integrity (ADT) : ASTM B680 or ISO 321 0

ARCADIA INC'S ANODIZED FINISH SPECIFICATIONS

Finish: All exposed surfaces of aluminum shall receive an architectural anodized finish (unless a commercial finish is specified) in conformance with Aluminum Association Standard #45.

Processing shall be sulfuric acid anodizing with electrolytic deposition of inorganic pigmentation in the coating. The resulting coating shall be continuous, fully sealed and free of

powdery surfaces, smut and blemishes.

Etching: Standard etch - medium matte, C22; unless otherwise specified.

Alloy: 6063-T6 is the standard alloy used for extruded architectural aluminum; 5005-H34 must be supplied for sheet and brake metal applications. Arcadia Inc. will not guarantee finish or

color range for any other alloys processed. For all other alloys a "best effort" applies.

ARCADIA INC.'S TERMS AND CONDITIONS

Extrusions: Prices are computed per lineal foot and are based on producing finish on exposed areas only. It is our option to process sections back to back unless otherwise specified by the customer

and priced accordingly. A minimum perimeter of 5.0 inches is used for price determination. Any perimeter less than 5.0 inches a minimum per foot charge applies, otherwise a solid or

hollow inch factor is used.

Lengths processed are 8 through 28 feet, special pricing is used for lengths less than 8 feet and greater than 28 feet (maximum is 30 feet), ask for a quotation.

Racking -Standard end rack within 1" of each end or twist rack, our option. If end racking is used, any damage to the section within the 1" area is acceptable. Twist rock marks will be

away from the ends and two or more contacts will be required. Not all sections will accept the pressure of end racking and not all section are adaptable to twist racking. Such sections

should be reviewed for an acceptable racking method, special pricing may apply.

Packing - Repack bundles as received, bundles are to be bare, with layer separation, wood battens, steel straps and forklift protection. Bundle size to be 300 lbs. or more. Special

packing requires separate pricing.

Sheet, Brake: Prices are computed per square foot or per item where applicable. The anodized finish is on exposed surfaces only. Arcadia Inc., is not liable for costs involved in replacement material

Metal, and resulting from loss or damage sustained from the anodizing process. Replacement material supplied by the customer will be processed at no additional cost.

Fabricated

Parts

Size- The maximum width Arcadia Inc. can process is 12", the depth 60" and the length 24'. Any part over 12' long may require additional racking due to its flimsiness. For sheet and

brake metal a minimum thickness of 50 mils (0.05 inches) is required for processing.

Racking -Standard 1" rack marks on the ends of the material, some shapes may require additional rack marks due to the configuration of the part or due to the anodizing process itself.

Arcadia Inc. is not responsible for lost or damaged material that requires special racking (which includes all rack marks other than the standard 1" end or twist rack marks). The color range

is "best effort" only when special racking is required.

Packing - Material will be repacked as received if possible with paper or cardboard separation. Special packing is available upon request at additional cost.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- 310 Pid 0021 1994 01 - 2Document1 page310 Pid 0021 1994 01 - 2ValiNo ratings yet

- 7 International Commercial AgencyDocument22 pages7 International Commercial AgencyAntonio M. CitatiNo ratings yet

- Industrial Cyclones Brochure PDFDocument2 pagesIndustrial Cyclones Brochure PDFValiNo ratings yet

- VLT Series Daf SpecificationsDocument3 pagesVLT Series Daf SpecificationsValiNo ratings yet

- Ia - Ppa-003 - R7Document1 pageIa - Ppa-003 - R7ValiNo ratings yet

- Colornodic ChartDocument2 pagesColornodic ChartValiNo ratings yet

- En 10204-2004 Metallic Products - Types of Inspection DocumentsDocument10 pagesEn 10204-2004 Metallic Products - Types of Inspection DocumentsDalamagas KwnstantinosNo ratings yet

- Ir 5073 Ppa 005Document6 pagesIr 5073 Ppa 005ValiNo ratings yet

- Chapter (8) 99Document1 pageChapter (8) 99ValiNo ratings yet

- Chapter (8) 107Document1 pageChapter (8) 107ValiNo ratings yet

- Wemco 11 BrochureDocument8 pagesWemco 11 Brochuresalvador_10No ratings yet

- Pipe Selection Friction LossDocument26 pagesPipe Selection Friction Lossgoodspeed_ph100% (6)

- Multi Compartment AlDocument6 pagesMulti Compartment AlValiNo ratings yet

- Series 4000 Cyclosep Centrifugal SeparatorDocument7 pagesSeries 4000 Cyclosep Centrifugal SeparatorValiNo ratings yet

- Vane & Wire Mesh SeparatorsDocument2 pagesVane & Wire Mesh SeparatorsValiNo ratings yet

- Vane & Wire Mesh SeparatorsDocument2 pagesVane & Wire Mesh SeparatorsValiNo ratings yet

- Gas Filter SeparatorsDocument2 pagesGas Filter SeparatorsValiNo ratings yet

- Multicompartmental PDFDocument1 pageMulticompartmental PDFValiNo ratings yet

- OMG Controlled Volume Pumps - Selection Chart: EcodoxDocument1 pageOMG Controlled Volume Pumps - Selection Chart: EcodoxValiNo ratings yet

- Vane & Wire Mesh SeparatorsDocument2 pagesVane & Wire Mesh SeparatorsValiNo ratings yet

- BHI News 2004-3-1 CorporateDocument1 pageBHI News 2004-3-1 CorporateValiNo ratings yet

- Full Page PhotoDocument1 pageFull Page PhotoValiNo ratings yet

- Spec VCL PDFDocument4 pagesSpec VCL PDFValiNo ratings yet

- Easz 1Document6 pagesEasz 1ValiNo ratings yet

- VortClarex TDMDocument12 pagesVortClarex TDMValiNo ratings yet

- Fuel Gas Conditioning: Oil & Gas Systems LimitedDocument4 pagesFuel Gas Conditioning: Oil & Gas Systems LimitedValiNo ratings yet

- Bicomdkplcc0023 PDFDocument2 pagesBicomdkplcc0023 PDFValiNo ratings yet

- 09floatingintake PDFDocument2 pages09floatingintake PDFValiNo ratings yet

- Company Profile: Oil & Gas Systems LimitedDocument6 pagesCompany Profile: Oil & Gas Systems LimitedValiNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 38 - Liquid Metal Assisted Cracking of Galvanized Structural Steel SectionsDocument7 pages38 - Liquid Metal Assisted Cracking of Galvanized Structural Steel SectionsMarjan SubanNo ratings yet

- Socketweldspacerrings SoluGapBrochureDocument2 pagesSocketweldspacerrings SoluGapBrochureRamzi BEN AHMEDNo ratings yet

- Elems 15Document101 pagesElems 15Reynald de VeraNo ratings yet

- E.2.2 Sheet Metal WorkingDocument18 pagesE.2.2 Sheet Metal WorkingMesfin SisayNo ratings yet

- Non-Conventional Materials Workshop SummaryDocument134 pagesNon-Conventional Materials Workshop SummaryAnupam SinghNo ratings yet

- T Ayt8579Document2 pagesT Ayt8579Vũ Khánh CườngNo ratings yet

- Material Testing Lab Virtual TourDocument13 pagesMaterial Testing Lab Virtual TourNirmal PanditNo ratings yet

- 6.01 MAS3000 Carbon Steel Pipe FittingsDocument17 pages6.01 MAS3000 Carbon Steel Pipe FittingsPaul StuttNo ratings yet

- Interior Fitting Out Works Bill of MaterialsDocument15 pagesInterior Fitting Out Works Bill of MaterialsAnn MoralesNo ratings yet

- Toplotna IzolacijaDocument12 pagesToplotna IzolacijaZdravko GrbićNo ratings yet

- Use of Plastic Waste in Road ConstructionDocument3 pagesUse of Plastic Waste in Road ConstructionriyaNo ratings yet

- Key To Steel-Stellite 6Document1 pageKey To Steel-Stellite 6Anonymous pmp0NyDNo ratings yet

- Astm 471Document6 pagesAstm 471JOSEPH REFUERZONo ratings yet

- Josefino D. Minguillan JR.: Block 51 Lot 11 Dela Costa Homes V Ph1 Brgy. Burgos, Rodriguez, RizalDocument2 pagesJosefino D. Minguillan JR.: Block 51 Lot 11 Dela Costa Homes V Ph1 Brgy. Burgos, Rodriguez, RizalCatherine RenanteNo ratings yet

- Steel View Tower Quantity Estimatev1.0Document14 pagesSteel View Tower Quantity Estimatev1.0Prayush RajbhandariNo ratings yet

- Informacion Tecnica Valvula Motora Gas de AltaDocument8 pagesInformacion Tecnica Valvula Motora Gas de AltaGuille MVNo ratings yet

- HS PDFDocument11 pagesHS PDFSawa Zayia MichaelNo ratings yet

- Thesis Proposal CHAPTER IIIDocument17 pagesThesis Proposal CHAPTER IIIJonathanNo ratings yet

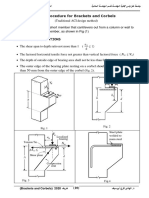

- Brackets and Corbels ACI 318 L # 1Document7 pagesBrackets and Corbels ACI 318 L # 1soran azizNo ratings yet

- Building Technology (ALE Review 5)Document1 pageBuilding Technology (ALE Review 5)Jehan MohamadNo ratings yet

- ASTM A 802 Standard Practice For Steel Castings, Iron Castings, Surface Acceptance, Visual ExaminationDocument10 pagesASTM A 802 Standard Practice For Steel Castings, Iron Castings, Surface Acceptance, Visual ExaminationlodraprabowoNo ratings yet

- Flexisecurit ER-SO Epoxy Underlayment Product DataDocument2 pagesFlexisecurit ER-SO Epoxy Underlayment Product DataLe Ngoc AnhNo ratings yet

- W623Document2 pagesW623Jebi Se0% (1)

- BPI-Company ProfileDocument19 pagesBPI-Company Profilesunny vachhaniNo ratings yet

- Use of Plastic Waste in Road Construction: Shweta N. Rokdey P. L. Naktode M. R. NikharDocument3 pagesUse of Plastic Waste in Road Construction: Shweta N. Rokdey P. L. Naktode M. R. NikharIndra AgraNo ratings yet

- Lecture 6 - BricksDocument28 pagesLecture 6 - BricksVanessa AlexanderNo ratings yet

- Commercial Roof Systems GuideDocument14 pagesCommercial Roof Systems GuidePatrickNo ratings yet

- Limit Values For LubricantsDocument28 pagesLimit Values For LubricantsSindley LimaferNo ratings yet

- Acid PipingDocument1 pageAcid Pipinghasan_676489616No ratings yet