Professional Documents

Culture Documents

Job Safety Analysis JSA

Uploaded by

mohame30dCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Job Safety Analysis JSA

Uploaded by

mohame30dCopyright:

Available Formats

P E TR OS ER V IC ES H SE D E PA R T ME N T

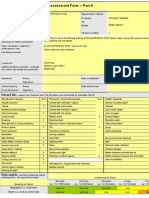

9.5.6.6. RISK ASSESSMENT WORKSHEET

A B C D E

Happens Happens

Incident has

Never several several

Heard of occurred in

heard of in times per in times per

in Industry our

the Industry our in a

Company

Company location

Improbable Remote Occasional Probable Likely

LEVEL VL L M H VH

S PEOPLE ASSETS ENVIRONMENT REPUTATION SCORE 0.1 0.2 0.3 0.4 0.5

No Injury or Health

1 Slight Damage Slight Effect Slight Impact VVL 0.1 0.2 0.3 0.4 0.5

Effect 1

Slight Injury or Health

2

Effect

Minor Damage Minor Effect Minor Impact VL 2 0.2 0.4 0.6 0.8 1.0

Major Injury or Health

3

Effect

Moderate Damage Moderate Effect Moderate Impact L 3 0.3 0.6 0.9 1.2 1.5

PTD or Up to 3

4

Fatalities

Major Damage Major Effect Major Impact M 4 0.4 0.8 1.2 1.6 2.0

More Than 3

5 Massive Damage Massive Effect Massive Impact H 5 0.5 1.0 1.5 2.0 2.5

Fatalities

Low (Range: 0.1 0.4).

Moderate (Range: 0.5 1.2).

High (Range: 1.5 2.5).

Chapter-9 "Risk Assessment & Classification of Hazards 56 May 2015

P E TR OS ER V IC ES H SE D E PA R T ME N T

9.5.6.7.0. In a JHA, each basic step of the job is to identify potential hazards and to recommend the safest way to do the job. The JHA is classified due to

9.5.6.7.1. Specific activity

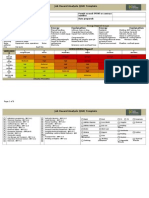

JOB HAZARD ANALYSIS WORKSHEET No. of Pages 1 Ref No. 01-0109

Task Name : Team Composition: Analysis Date:

Mobile cranes loading & unloading heavy equipment Crane Operator, Helper. 2015

BriefDescriptionoftheTask: AssumptionsMade : AbbreviationsUsedintheJHA:

Mobile cranes loading & unloading heavy equipment Falling of heavy objects may cause bone Low (Range: 0.1 0.4).

from truck into Base & Field (lifting Unit, tool box or fracture, cuttings or death. Moderate (Range: 0.5 1.2).

hydrogen bottle basket) Falling of H2 gas or C1-C5 cylinders may cause High (Range: 1.5 2.5).

gas choking, explosion, fire. PPE: personal protective equipments.

Step Description of Hazard Who or what might Severity Like- Ris Control measures/ Action &

No. Task step Potential incident be harmed lihood k Recovery measures Responsible party

1 Slinging the load Trapped fingers Operator, helper 3 0.2 0.6 Keep loads on Service engineer, Senior technical

Metal support, involved individuals wear engineer, technical manager, HSE

complete PPE. Officer, HSE manager, Branch

manager.

2 Picking up the load Load not balanced Operator, helper 3 0.2 0.6 Pick up a small distance & check

balance, involved individuals wear

complete PPE.

3 Move the load Trapped finger, collision with Operator/helper 3 0.1 0.3 Move slowly. Be aware of restricted area,

walls/other equipment Equipment damage if lifting high use tag line, involved

individuals wear complete PPE.

Lower load slowly, keep fingers clear,

4 Lowering the load Trapped finger Operator/helper 3 0.2 0.6 involved individuals wear complete PPE.

Involved individuals wear complete

PPE.

5 Objects falling from the Serious injury/death. Operator/helper 4 0.1 0.4

load Slack off weight & check before releasing

sling/tag line, involved individuals wear

6 Releasing the load Load moves on its support Operator/helper 2 0.2 0.4 complete PPE.

Equipment damage.

The bottle basket has metal supports to

fix the cylinders in the basket, involved

7 Loading bottle basket H2 gas cylinder may fall Operator, Helper, 4 0.1 0.4 individuals wear complete PPE.

Equipment damage.

Chapter-9 "Risk Assessment & Classification of Hazards 57 May 2015

P E TR OS ER V IC ES H SE D E PA R T ME N T

JOB HAZARD ANALYSIS WORKSHEET No. of Pages 1 Ref No. 01-0209

Task Name : Team Composition: Analysis Date:

Lifting Test Crane Operator, Helper. 2015

BriefDescriptionoftheTask: AssumptionsMade : AbbreviationsUsedintheJHA:

Mobile cranes loading & unloading heavy equipment Falling of heavy objects may cause bone Low (Range: 0.1 0.4).

(lifting test for Unit, tool box or hydrogen bottle fracture, cuttings or death. Moderate (Range: 0.5 1.2).

basket) Falling of H2 gas or C1-C5 cylinders may cause High (Range: 1.5 2.5).

gas choking, explosion, fire. PPE: personal protective equipments.

Step Description of Hazard Who or what might Severity Like- Ris Control measures/ Action &

No. Task step Potential incident be harmed lihood k Recovery measures Responsible party

1 Slinging the load Trapped fingers Operator, helper, Engineer 3 0.2 0.6 Keep loads on Service engineer, Senior technical

of lifting test company Metal support, involved individuals wear engineer, technical manager, HSE

complete PPE. Officer, HSE manager, Branch

Operator, helper, Engineer manager.

2 Picking up the load Load not balanced of lifting test company 3 0.2 0.6 Pick up a small distance & check

balance, involved individuals wear

Operator/helper complete PPE.

Equipment damage,

3 Move the load Trapped finger, collision with Engineer of lifting test 3 0.1 0.3 Move slowly. Be aware of restricted area,

walls/other equipment company. if lifting high use tag line, involved

individuals wear complete PPE.

Operator/helper

Lower load slowly, keep fingers clear,

4 Lowering the load Trapped finger 3 0.2 0.6 involved individuals wear complete PPE.

Operator/helper, Hardhats worn when working near a

Engineer of lifting test crane, involved individuals wear

5 Objects falling from the Serious injury/death. company. 4 0.1 0.4 complete PPE.

load

Operator/helper Slack off weight & check before releasing

Equipment damage, sling/tag line, involved individuals wear

6 Releasing the load Load moves on its support Engineer of lifting test 2 0.2 0.4 complete PPE.

company.

Operator, Helper, The bottle basket has metal supports to

Equipment damage. fix the cylinders in the basket, involved

7 Loading bottle basket H2 gas cylinder may fall 4 0.1 0.4 individuals wear complete PPE.

Chapter-9 "Risk Assessment & Classification of Hazards 58 May 2015

P E TR OS ER V IC ES H SE D E PA R T ME N T

JOB HAZARD ANALYSIS WORKSHEET No. of Pages 1 Ref No. 01-0309

Task Name : Team Composition: Analysis Date:

Transporting and Handling Hydrogen gas and C1- C5 gas Car Driver, Store Keeper, Helper. 2015

cylinders.

BriefDescriptionoftheTask: AssumptionsMade : AbbreviationsUsedintheJHA:

Transporting and Handling Hydrogen gas and C1- C5 Falling of H2 gas or C1-C5 cylinders may cause Low (Range: 0.1 0.4).

gas cylinders to and from the (store Rig) gas choking (to the involved personnel), Moderate (Range: 0.5 1.2).

explosion and fire. High (Range: 1.5 2.5).

PPE: personal protective equipments.

Step Description of Hazard Who or what might Severity Like- Ris Control measures/ Action &

No. Task step Potential incident be harmed lihood k Recovery measures Responsible party

1 Transporting the cylinders Falling, gas leak (gas Car driver. 5 0.1 0.5 The cylinder is checked at the vendor; Service engineer, Senior technical

from the vendor to our choking), explosion. also the car is equipped with wooden engineer, technical manager, HSE

company store. base to support the cylinders on the car, Officer, HSE manager, Branch

ensure the presence of the valve metallic manager.

cap.

2 Receiving the cylinders at Falling, gas leak (gas Helper, Store Keeper 5 0.1 0.5 The cylinders are put in trulli specifically

the store. choking), explosion, falling on design for handling the cylinder, then put

foot (leg). in secure metallic basket for storage,

placed in good ventilated area; involved

individuals must wear complete PPE,

ensure the presence of the valve metallic

cap.

3 Loading cylinders on the car. Falling, gas leak (gas Helper, Store Keeper 5 0.2 1.0 The cylinders are put in trulli specifically

choking), explosion, falling on design for handling the cylinder, involved

foot (leg). individuals wear complete PPE, ensure

the presence of the valve metallic cap.

Unloading cylinder in the rig Rechecking is made by the Unit Captain,

side (field). Falling, gas leak (gas Operation crew members. 5 0.1 0.5 must wear complete PPE

4

choking), explosion, falling on

foot (leg).

Loading empty cylinder to Involved individuals must wear complete

5 the car. Falling, gas leak (remaining Operation crew members. 3 0.1 0.3 PPE.

gas, very low pressure).

Chapter-9 "Risk Assessment & Classification of Hazards 59 May 2015

P E TR OS ER V IC ES H SE D E PA R T ME N T

JOB HAZARD ANALYSIS WORKSHEET No. of Pages 1 Ref No. 01-0409

Task Name: Team Composition: Analysis Date:

Handling and using Chemicals. Store Keeper, Helper, Crew members. 2015

BriefDescriptionoftheTask: AssumptionsMade : AbbreviationsUsedintheJHA:

Transporting chemicals, handling and using Chemicals may cause burns, allergy, irritation, Low (Range: 0.1 0.4).

chemicals. poisoning, carcinogenic, flammable cause fire, Moderate (Range: 0.5 1.2).

choking gasesetc. High (Range: 1.5 2.5).

PPE: personal protective equipments.

MSDS: material safety data sheet.

Step Description of Hazard Who or what might Severity Like- Ris Control measures/ Action &

No. Task step Potential incident be harmed lihood k Recovery measures Responsible party

Unloading chemicals from Corrosive, Irritant, Toxic Store keeper, Helper. 3 0.1 0.3 Involved individuals must wear complete Store manager, Unit Captain, HSE

1 the car, into the store. Flammable, Reactive PPE, providing MSDS; ensure sealing of officer, HSE manager, Branch

chemicalsetc the chemical container, good ventilation manager.

of the store, fire extinguishers are

present.

Loading chemicals on the

2 car, to send to the rig side Corrosive, Irritant, Toxic Store keeper, Helper 3 0.1 0.3 Involved individuals must wear complete

Flammable, Reactive PPE, chemical bottles are put in secured

chemicalsetc in cardboard box (prevent spillage of

chemicals inside the car).

Unloading chemicals from Involved individuals must wear complete

3 the car, into the Unit. Corrosive, Irritant, Toxic Crew members. 3 0.1 0.3 PPE, providing MSDS; ensure sealing of

Flammable, Reactive the chemical container.

chemicalsetc

Using chemicals. Involved individuals must wear complete

4 PPE, providing MSDS; ensure sealing of

Corrosive, Irritant, Toxic, Crew members. 3 0.3 0.9 the chemical container, ensure sealing of

Flammable, Reactive the chemical container, bottles used are

chemicalsetc labeled, fire extinguishers are present

and eye washer is present.

Chapter-9 "Risk Assessment & Classification of Hazards May 2015

P E TR OS ER V IC ES H SE D E PA R T ME N T

JOB HAZARD ANALYSIS WORKSHEET No. of Pages 2 Ref No. 01-0509

Task Name: Team Composition: Analysis Date:

Installing equipments, sensors and maintenance. Service Engineer, Technician, A.C Technician, Helper, Painter. 2015

BriefDescriptionoftheTask: AssumptionsMade : AbbreviationsUsedintheJHA:

Rig up and rig down. Electrical hazards, falling of heavy objects, Low (Range: 0.1 0.4).

Unit test. Choking due to gas leak, cuttings. Moderate (Range: 0.5 1.2).

Maintenance. High (Range: 1.5 2.5).

PPE: personal protective equipments.

MSDS: material safety data sheet.

Step Description of Hazard Who or what might Severit Like- Ris Control measures/ Action &

No. Task step Potential incident be harmed y lihoo k Recovery measures Responsible party

d

1 Connecting the power cable Electrical hazard Service engineer, 4 0.1 0.4 Electricity caution signs are present.

to the unit Technician, rig electrician.

Service engineer, Technical manager, HSE Officer,

2 Sensors installation. Electrical hazard, falling Technician, helper. 4 0.2 0.8 W ear hard hat and safety shoes. HSE manager, Branch manager.

objects. Read the instruction manual for every

equipment before installing it.

Service engineer, helper.

3 Installing equipments and Electrical hazard, falling 3 0. 2 0.6 Electricity caution signs, safety shoes.

sensors inside the unit. objects.

Service engineer, helper. Test the cylinder gauges, hydrocarbon

4 High pressure cylinders Gas leak, fire, explosion, 4 0.2 0.8 and H2S sensors are setup inside the

(hydrogen and C1-C5 gases) equipments damage, unit unit, providing MSDS, ensure the

installation. damage. presence of the valve metallic cap.

Service engineer,

5 Sensors maintenance Electrical hazard, mud splash Technician, helper. 3 0.3 0.9 Involved personnel must wear complete

(during drilling) to the eye, falling objects, PPE, providing MSDS.

noise, falling due to slippery

floor, exposure to H2S and

hydrocarbon gases.

Technician, helper,

Preparing the equipments to Falling objects, hand abrasion equipments damage. 2 0.3 0.6 Involved personnel must wear complete

6

put in or out the car and in PPE.

the unit.

Corrosives, Flammable, Technician, helper

7 Preparing chemicals to put Irritant, Toxic chemicals. 3 0.2 0.6 Involved personnel must wear complete

in the car and in the unit. PPE.

Chapter-9 "Risk Assessment & Classification of Hazards May 2015

P E TR OS ER V IC ES H SE D E PA R T ME N T

8 Preparing high pressure gas Falling objects, gas leak, fire, Technician, Helper 4 0.1 0.4 Involved personnel must wear safety

cylinders to put on the car explosion. shoes, gloves, goggles, and mask.

and in the unit.

9 Wiring, (laying cables, Electrical hazard, noise (Mud Technician, Helper. 3 0.3 0.9 Hard hat, safety shoes, electricity

connect power to the unit pumps), falling objects. caution signs,

and to the sensors).

Electrical hazard, fall from

10 Unit lighting ladder. Technician, Helper. 2 0.2 0.4 W ear gloves, safety shoes.

Crushed fingers, gas leak,

11 Maintenance of the electrical hazard, mud splash, Technician, Helper. 3 0.2 0.6 W ear complete PPE.

degasser motor (rotating noise, falling objects.

objects)

Small metal cuttings parts Technician, Helper. 3 0.2 0.6 W ear goggles and gloves; install safe

12 Using steel-cutting machine (hurt the eye and face), finger guard to the cutting machine.

and drills. or hand cut.

Electric hazards, falling of IT Engineer. 2 0.2 0.4 Electricity caution signs are present,

13 Setup computers. heavy objectsetc wear safety shoes.

Flammable chemicals (Paints, Painter, Helper 2 0.3 0.6 Involved individuals must wear complete

14 Painting the Unit. solvents), paint splashes (hurt PPE; guards equipped with the abrasion

the eye), falling objects, using machine, a competent person monitor

abrasion machine, falling from the painter while he is painting the Unit

Unit roof. roof.

Chapter-9 "Risk Assessment & Classification of Hazards 62 May 2015

P E TR OS ER V IC ES H SE D E PA R T ME N T

JOB HAZARD ANALYSIS WORKSHEET No. of Pages 1 Ref No. 01-0609

Task Name: Team Composition: Analysis Date:

The Office work. Admin. Employees, Office boys, Helpers. 2015

BriefDescriptionoftheTask: AssumptionsMade : AbbreviationsUsedintheJHA:

Computer work, Office boy work. Falling from stairs, Long time Computer Low (Range: 0.1 0.4).

worketc. Moderate (Range: 0.5 1.2).

High (Range: 1.5 2.5).

PPE: personal protective equipments.

MSDS: material safety data sheet.

Step Description of Hazard Who or what might Severity Like- Ris Control measures/ Action &

No. Task step Potential incident be harmed lihood k Recovery measures Responsible party

Admin. Employees, Office 3 0.1 0.3 -The stairs are always maintained from Department Manager, HSE officer,

Falling from stairs. Injury boys, Helpers. any breaks or slippery surfaces. HSE manager, Branch manager.

1

2 Admin. Employees, Office 1 0.1 0.1 -The furniture is arranged in such way

Furniture obstructs the way. Injury boys, Helpers. not to obstruct the way.

-The lighting inside the offices is

regularly maintained, providing good

lighting in the work place.

Computer work: 0.1 0.2 -The computer screens are anti flare with

2

3 Long time CPU work. -Exhaust of the eye. -Admin. Employees. 0.1 0.2 low radiation.

2 -Employees must take 5 minutes break

Long time CPU work. -Neck, shoulders and back -Admin. Employees.

every 2 hours CPU work.

bone pain.

CPU cables obstruct the

4 way. -Injury or CPU damage. - Admin. Employees, 0.2 0.6 -CPU cables are collected in a duct or

3

fixed with tie wraps.

Office boys.

Office boy kitchen work:

5 Hot plate. 3 0.1 0.3

-Injury. - Office boys, Helpers.

Using cleaners. - Office boys, Helpers. 3 0.2 0.6 -Office boy must not spill liquid on the

-irritant hotplate and switch it off immediately

Lifting heavy - Office boys, Helpers. 3 0.2 0.6

-Foot injury. after use.

objects. -Must wear gloves while using cleaners

and be sure not to contact the skin and

not leaving any cleaners traces.

-Must wear cotton gloves and safety

shoes before lifting heavy objects.

Chapter-9 "Risk Assessment & Classification of Hazards May 2015

P E TR OS ER V IC ES H SE D E PA R T ME N T

9.5.6.7.2. Job:

JOB HAZARD ANALYSIS WORKSHEET No. of Pages 1 Ref No. 01-0709

Job title: Pressure engineer. Team Composition: Analysis Date:

2015

BriefDescriptionoftheTask: AssumptionsMade : AbbreviationsUsedintheJHA:

Checking the mud at the shale shaker, Testing the Mud splashes, falling, electrical hazards, H2S Low (Range: 0.1 0.4).

sensors, Using chemicals. gas, using chemicalsetc. Moderate (Range: 0.5 1.2).

High (Range: 1.5 2.5).

PPE: personal protective equipments.

MSDS: material safety data sheet.

Step Description of Hazard Who or what might Severity Like- Ris Control measures/ Action &

No. Task step Potential incident be harmed lihood k Recovery measures Responsible party

1 Checking the mud at the Mud splash to the eye, falling Pressure engineer. 3 0.2 0.6 W ear complete personal protective Unit captain, HSE officer, HSE

shale shaker, tanks and objects, noise, falling due to equipments PPE, providing MSDS, H2S manager, Branch manager.

pumps. slippery floor, exposure to H2S and hydrocarbon sensors are present

and hydrocarbon gases. and the Unit is pressurized.

2 Electrical, mud splash to the

Testing the sensors. eye, falling objects, noise, Pressure engineer. 3 0.2 0.6 W ear complete personal protective

falling due to slippery floor, equipments PPE, providing MSDS, H2S

exposure to H2S and and hydrocarbon sensors are present

hydrocarbon gases. and the Unit is pressurized.

Corrosive, toxic, irritantetc.

3

Using chemicals. Skin burns, fire (if using oil Pressure engineer. 3 0.2 0.6 W ear complete personal protective

base mud it's more probable). equipments PPE, providing MSDS.

4

Using oven for sample Highly flammable gas leak, Pressure engineer, 2 0.2 0.4 W ear complete personal protective

preparation. explosion, fire. equipment damage. equipments PPE, fire extinguishers are

present, smoke detector is setup.

5

High pressure gas cylinders Pressure engineer, gas 4 0.1 0.4 Test the cylinder gauges (periodically

(hydrogen gas, C1-C5 leak, fire, explosion, tested), hydrocarbon senor is setup

gases) exchange. equipment damage, unit inside the unit, providing MSDS, ensure

damage. the presence of the valve metallic cap.

Chapter-9 "Risk Assessment & Classification of Hazards 64 May 2015

P E TR OS ER V IC ES H SE D E PA R T ME N T

JOB HAZARD ANALYSIS WORKSHEET No. of Pages 1 Ref No. 01-0809

Job title: Data engineer. Team Composition: Analysis Date:

2015

BriefDescriptionoftheTask: AssumptionsMade : AbbreviationsUsedintheJHA:

Taking sample of mud from the shale shaker, Testing Mud splashes, falling, electrical hazards, H2S Low (Range: 0.1 0.4).

the sensors, Using chemicals. gas, using chemicalsetc. Moderate (Range: 0.5 1.2).

High (Range: 1.5 2.5).

PPE: personal protective equipments.

MSDS: material safety data sheet.

Step Description of Hazard Who or what might Severity Like- Ris Control measures/ Action &

No. Task step Potential incident be harmed lihood k Recovery measures Responsible party

1 Taking sample of mud from Mud splash to the eye, falling Data engineer. 3 0.2 0.6 W ear complete personal protective Unit captain, HSE officer, HSE

the shale shaker. objects, noise, falling due to equipments PPE, providing MSDS, H2S manager, Branch manager.

slippery floor, exposure to H2S and hydrocarbon sensors are present

and hydrocarbon gases. and the Unit is pressurized.

Electrical, mud splash to the

2 Testing the sensors. eye, falling objects, noise, Data engineer. 3 0.2 0.6 W ear complete personal protective

falling due to slippery floor, equipments PPE, providing MSDS, H2S

exposure to H2S and and hydrocarbon sensors are present

hydrocarbon gases. and the Unit is pressurized.

Corrosive, toxic, Flammable,

3 Using chemicals. Reactive, irritantetc. Data engineer. 3 0.2 0.6 W ear complete personal protective

equipments PPE , providing MSDS

Skin burns, fire (if using oil

4 Using oven for sample base mud it's more probable).

preparation. Data engineer, equipments 2 0.2 0.4 W ear complete personal protective

damage. equipments PPE, providing MSDS,

fire extinguishers are present, smoke

Highly flammable gas leak, detector is setup.

explosion, fire.

5 High pressure gas cylinders Data engineer, gas leak, 4 0.1 0.4 Test the cylinder gauges (periodically

(hydrogen gas, C1-C5 fire, explosion, unit tested), hydrocarbon senor is setup

gases) exchange. damage. inside the unit; ensure the presence of

the valve metallic cap.

Chapter-9 "Risk Assessment & Classification of Hazards 65 May 2015

P E TR OS ER V IC ES H SE D E PA R T ME N T

JOB HAZARD ANALYSIS WORKSHEET No. of Pages 1 Ref No. 01-0909

Job title: Mud logger. Team Composition: Analysis Date:

2015

BriefDescriptionoftheTask: AssumptionsMade : AbbreviationsUsedintheJHA:

Taking sample of mud from the shale shaker, Testing Mud splashes, falling, electrical hazards, H2S Low (Range: 0.1 0.4).

the sensors, Using chemicals. gas, using chemicalsetc. Moderate (Range: 0.5 1.2).

High (Range: 1.5 2.5).

PPE: personal protective equipments.

MSDS: material safety data sheet.

Step Description of Hazard Who or what might Severity Like- Ris Control measures/ Action &

No. Task step Potential incident be harmed lihood k Recovery measures Responsible party

1 Taking sample of mud from Mud splash to the eye, falling Mud logger 3 0.3 0.9 W ear complete personal protective Unit captain, HSE officer, HSE

the shale shaker. objects, noise, falling due to equipments PPE, providing MSDS, H2S manager, Branch manager.

slippery floor, exposure to H2S and hydrocarbon sensors are present

and hydrocarbon gases. and the Unit is pressurized.

2 Electrical, mud splash to the

Testing the sensors. eye, falling objects, noise, Mud logger. 3 0.2 0.6 W ear complete personal protective

falling due to slippery floor, equipments PPE, providing MSDS, H2S

exposure to H2S and and hydrocarbon sensors are present

hydrocarbon gases. and the Unit is pressurized.

Corrosive, toxic, irritantetc.

3

Using chemicals. Skin burns, fire (if using oil Mud logger. 3 0.2 0.6 W ear complete personal protective

base mud it's more probable). equipments PPE, providing MSDS.

4

Using oven for sample Mud logger, equipment W ear complete personal protective

preparation. Highly flammable gas leak, damage. 2 0.2 0.4 equipments PPE, fire extinguishers are

explosion, fire. present, smoke detector is setup.

5 High pressure gas cylinders Mud logger, gas leak, fire, 4 0.1 0.4 Test the cylinder gauges (periodically

(hydrogen gas, C1-C5 explosion, equipment tested), hydrocarbon senor is setup

gases) exchange. damage, unit damage. inside the unit, providing MSDS, ensure

the presence of the valve metallic cap.

Chapter-9 "Risk Assessment & Classification of Hazards 66 May 2015

P E TR OS ER V IC ES H SE D E PA R T ME N T

JOB HAZARD ANALYSIS WORKSHEET No. of Pages 1 Ref No. 01-1009

Job title: Sample catcher (trainee). Team Composition: Analysis Date:

2015

BriefDescriptionoftheTask: AssumptionsMade : AbbreviationsUsedintheJHA:

Taking sample of mud from the shale shaker, Testing Mud splashes, falling, electrical hazards, H2S Low (Range: 0.1 0.4).

the sensors, Using chemicals. gas, using chemicalsetc. Moderate (Range: 0.5 1.2).

High (Range: 1.5 2.5).

PPE: personal protective equipments.

MSDS: material safety data sheet.

Step Description of Hazard Who or what might Severity Like- Ris Control measures/ Action &

No. Task step Potential incident be harmed lihood k Recovery measures Responsible party

1 Taking sample of mud from Mud splash to the eye, falling Sample catcher. 3 0.3 0.9 W ear complete personal protective Unit captain, HSE officer, HSE

the shale shaker. objects, noise, falling due to equipments PPE, providing MSDS. manager, Branch manager.

slippery floor, exposure to H2S H2S and hydrocarbon sensors are

and hydrocarbon gases. present and the Unit is pressurized.

Electrical, mud splash to the

2 Testing the sensors. eye, falling objects, noise, Sample catcher. 3 0.3 0.9 W ear complete personal protective

falling due to slippery floor, equipments PPE, providing MSDS, H2S

exposure to H2S and and hydrocarbon sensors are present

hydrocarbon gases. and the Unit is pressurized.

Corrosive, toxic, irritantetc.

3 Using chemicals. Sample catcher. 3 0.2 0.6 W ear complete personal protective

Skin burns, fire (if using oil equipments PPE, providing MSDS.

base mud it's more probable).

4 Using oven for sample Sample catcher, 2 0.2 0.4 W ear complete personal protective

preparation. Highly flammable gas leak, equipment damage. equipments PPE, fire extinguishers are

explosion, fire. present, smoke detector is setup.

5 High pressure gas cylinders Sample catcher, gas leak, 4 0.1 0.4 Test the cylinder gauges (periodically

(hydrogen gas, C1-C5 fire, explosion, equipment tested), hydrocarbon senor is setup

gases) exchange. damage, unit damage. inside the unit, providing MSDS, ensure

the presence of the valve metallic cap.

Chapter-9 "Risk Assessment & Classification of Hazards 67 May 2015

P E TR OS ER V IC ES H SE D E PA R T ME N T

JOB HAZARD ANALYSIS WORKSHEET No. of Pages 1 Ref No. 01-1109

Job title: Service engineer (Technical engineer). Team Composition: Analysis Date:

2015

BriefDescriptionoftheTask: AssumptionsMade : AbbreviationsUsedintheJHA:

Rig up and rig down. Electrical hazards, falling of heavy objects, Gas Low (Range: 0.1 0.4).

Unit test. leak, explosion and fire, Mud splashes. Moderate (Range: 0.5 1.2).

Maintenance. High (Range: 1.5 2.5).

PPE: personal protective equipments.

MSDS: material safety data sheet.

Step Description of Hazard Who or what might Severity Like- Ris Control measures/ Action &

No. Task step Potential incident be harmed lihood k Recovery measures Responsible party

Duringunitinstallation:

Connecting the power cable Electrical hazard Service engineer, rig 3 0.1 0.3 Electricity caution signs. Technical manager, HSE Officer,

1

to the unit electrician. HSE manager, Branch manager.

2

Sensors installation. Electrical, falling objects. Service engineer, helper. 3 0.2 0.6 W ear hard hat and safety shoes.

Installing equipments and Electrical hazard, falling Service engineer, helper. 3 0.2 0.6 Electricity caution signs, safety shoes.

3

sensors inside the unit. objects.

High pressure cylinders Gas leak, fire, explosion, Service engineer, helper. 4 0.1 0.4 Test the cylinder gauges, hydrocarbon

4 equipments damage, unit

(hydrogen and C1-C5 gases) senor is setup inside the unit, providing

installation. damage. MSDS, ensure the presence of the valve

metallic cap.

Sensors maintenance Electrical, mud splash to the Service engineer, helper. 3 0.2 0.6 W ear complete PPE, providing MSDS.

5 (during drilling) eye, falling objects, noise,

falling due to slippery floor,

exposure to

H2S and hydrocarbon gases.

Crushed fingers, gas leak, Service engineer, helper. 3 0.2 0.6 W ear complete PPE.

Maintenance of the degasser electrical hazard, mud splash,

6 motor (rotating objects) noise, falling objects.

Chapter-9 "Risk Assessment & Classification of Hazards 68 May 2015

P E TR OS ER V IC ES H SE D E PA R T ME N T

JOB HAZARD ANALYSIS WORKSHEET No. of Pages 1 Ref No. 01-1209

Job title: Technician (electrical and mechanical). Team Composition: Analysis Date:

2015

BriefDescriptionoftheTask: AssumptionsMade : AbbreviationsUsedintheJHA:

Preparing and installing equipments, maintenance. Falling objects, chemical hazards, Electrical Low (Range: 0.1 0.4).

hazards, cuttings, bone fracture. Moderate (Range: 0.5 1.2).

High (Range: 1.5 2.5).

PPE: personal protective equipments.

MSDS: material safety data sheet.

Step Description of Hazard Who or what might Severity Like- Ris Control measures/ Action &

No. Task step Potential incident be harmed lihood k Recovery measures Responsible party

1 Installing equipments inside Falling objects, hand abrasion, Technician, helper, 3 0.2 0.6 Involved personnel must wear complete Senior technical engineer, Technical

the unit. Electrical hazard. equipments damage. PPE. manager, service engineer, HSE

officer, HSE manager, Branch

Preparing chemicals to put Corrosives, Flammable, Technician, helper. 3 0.1 0.3 Involved personnel must wear complete manager.

2 inside the unit. Irritant, Toxic chemicals. PPE, providing MSDS.

3 Installing high pressure gas Falling objects, gas leak, fire, Technician. 4 0.1 0.4 Involved personnel must wear safety

cylinders inside the unit. explosion. shoes, gloves, goggles, mask, ensure

the presence of the valve metallic cap.

4 Wiring, (laying cables, Electrical hazard, noise

connect power to the unit (generator), falling objects. Technician. 3 0.2 0.6 Hard hat, safety shoes, electricity caution

and to the sensors). signs are present.

5 Unit lighting Electrical hazard, fall from Technician, Helper. 3 0.1 0.3 W ear gloves, safety shoes.

ladder.

6 Installing sensors Electrical, falling objects, noise Technician. 3 0.2 0.6 W ear complete PPE (ear plugs)

(pumps).

7 Maintenance of the degasser Crushed fingers, gas leak, Technician. 3 0.2 0.6 W ear complete PPE.

motor (rotating objects) electrical hazard, mud splash,

noise, falling objects.

Using steel-cutting machine

8 and drills. Small metal cuttings parts Technician, Helper. 3 0.3 0.9 W ear goggles and gloves; install safe

(hurt the eye and face), finger guard to the cutting machine.

or hand cut.

Air Conditioner maintenance. W ear goggles, plastic mask and gloves,

9 Electrical hazard, dust, falling 3 0.2 0.6 safety shoes.

Technician.

objects.

Chapter-9 "Risk Assessment & Classification of Hazards 69 May 2015

P E TR OS ER V IC ES H SE D E PA R T ME N T

JOB HAZARD ANALYSIS WORKSHEET No. of Pages 1 Ref No. 01-1309

Job title: IT Engineer. Team Composition: Analysis Date:

2015

BriefDescriptionoftheTask: AssumptionsMade : AbbreviationsUsedintheJHA:

Installing computers. Electrical Hazards, falling objects. Low (Range: 0.1 0.4).

Computer maintenance. Moderate (Range: 0.5 1.2).

High (Range: 1.5 2.5).

PPE: personal protective equipments.

MSDS: material safety data sheet.

Step Description of Hazard Who or what might Severity Like- Ris Control measures/ Action &

No. Task step Potential incident be harmed lihood k Recovery measures Responsible party

Intheyard:

Installing the computers. Electrical hazard, falling IT Engineer 2 0.1 0.2 Electricity caution signs, safety shoes. Technical manager, HSE Officer,

1

objects. HSE manager, Branch manager.

Computer maintenance. Electrical hazard, falling IT Engineer 2 0.2 0.4 Electricity caution signs, safety shoes.

2

objects, dust.

Complete PPE is provided if the job is in

the field (Rig site).

Chapter-9 "Risk Assessment & Classification of Hazards 70 May 2015

P E TR OS ER V IC ES H SE D E PA R T ME N T

JOB HAZARD ANALYSIS WORKSHEET No. of Pages 1 Ref No. 01-1409

Job title: Store keeper. Team Composition: Analysis Date:

2015

BriefDescriptionoftheTask: AssumptionsMade : AbbreviationsUsedintheJHA:

Storing stationary materials, wooden boxes, Falling objects, Chemical hazards, gas leak, Low (Range: 0.1 0.4).

chemicals, Hydrogen gas and C1-C5 gas cylinders, explosion and fire. Moderate (Range: 0.5 1.2).

equipments..etc. High (Range: 1.5 2.5).

PPE: personal protective equipments.

MSDS: material safety data sheet.

Step Description of Hazard Who or what might Severity Like- Ris Control measures/ Action &

No. Task step Potential incident be harmed lihood k Recovery measures Responsible party

1 Chemicals storing. Corrosive, irritant, toxic Store keeper, helper. 3 0.2 0.6 W ear gloves and safety shoes, providing Store manager, HSE officer, HSE

chemicalsetc, falling objects. MSDS; ensure sealing of the chemical manager, Branch manager.

container, good ventilation of the store,

and put container on wooden step,

smoke detectors, fire extinguishers are

present.

Falling objects, skin abrasion

2 Equipments storing. or cut, equipment breaking or Store keeper, equipments 2 0.2 0.4 W ear gloves and safety shoes, put

damage due to bad storing. damage equipments- especially electric equip.- in

safe boxes on wooden step in secure

position, smoke detectors, fire

Flammable gases, Falling extinguishers are present.

objects, gas leak, fire,

3 High pressure cylinders explosion. Store keeper, equipments 4 0.1 0.4 W ear safety shoes and gloves, high

(hydrogen, C1-C5 gases). damage, store damage. pressure gas sign, put cylinders in good

ventilated place, keep away from heat

sources, smoke detectors, fire

extinguishers are present, ensure the

Damage, fire presence of the valve metallic cap.

4 Plastic and paper and Store keeper, equipments 1 0.1 0.1 Keep in good place, smoke detectors,

stationery materials. and stationery damage. fire extinguisher are present.

Chapter-9 "Risk Assessment & Classification of Hazards 71 May 2015

P E TR OS ER V IC ES H SE D E PA R T ME N T

JOB HAZARD ANALYSIS WORKSHEET No. of Pages 1 Ref No. 01-1509

Job title: Administration Employees. Team Composition: Analysis Date:

2015

BriefDescriptionoftheTask: AssumptionsMade : AbbreviationsUsedintheJHA:

Office work. Musco-skeletal disorder, eye stress (due to time Low (Range: 0.1 0.4).

office work). Moderate (Range: 0.5 1.2).

High (Range: 1.5 2.5).

PPE: personal protective equipments.

MSDS: material safety data sheet.

Step Description of Hazard Who or what might Severity Like- Ris Control measures/ Action &

No. Task step Potential incident be harmed lihood k Recovery measures Responsible party

1 Admin. Employees. 3 0.1 0.3 -The stairs are always maintained from

Falling from stairs. Injury any breaks or slippery surfaces. Department Manager, HSE officer,

HSE manager, Branch manager.

Injury Admin. Employees. 1 0.1 0.1 -The furniture is arranged in such way

2 Furniture obstructs the way. not to obstruct the way.

-The lighting inside the offices is

regularly maintained, providing good

lighting in the work place.

Computer work:

Long time CPU work. -Exhaust of the eye. -Admin. Employees. 2 0.1 0.2 -The computer screens are anti flare with

3

Long time CPU work. 2 0.1 0.2 low radiation.

-Neck, shoulders and back -Admin. Employees.

CPU cables obstruct the -Employees must take 5 minutes break

bone pain. 3 0.6 every 2 hours CPU work.

way. - Admin. Employees. 0.2

-Injury or CPU damage. -CPU cables are collected in a duct.

Chapter-9 "Risk Assessment & Classification of Hazards 72 May 2015

P E TR OS ER V IC ES H SE D E PA R T ME N T

JOB HAZARD ANALYSIS WORKSHEET No. of Pages 1 Ref No. 01-1609

Job title: Painter. Team Composition: Analysis Date:

2015

BriefDescriptionoftheTask: AssumptionsMade : AbbreviationsUsedintheJHA:

Using paints, Using abrasion machine. Irritation of (skin, eye), cuttings, falling from Low (Range: 0.1 0.4).

height. Moderate (Range: 0.5 1.2).

High (Range: 1.5 2.5).

PPE: personal protective equipments.

MSDS: material safety data sheet.

Step Description of Hazard Who or what might Severity Like- Ris Control measures/ Action &

No. Task step Potential incident be harmed lihood k Recovery measures Responsible party

1 Use paints Flammable chemicals (Paints, Painter 3 0.3 0.9 W ear complete PPE Unit captain, HSE officer, HSE

solvents), paint splashes (hurt manager, Branch manager.

the eye), noise (during

drilling), falling objects.

Electric, small metal cuttings,

2 Steel-cutting machine (for skin cuttings. Painter 3 0.2 0.6 W ear goggles and gloves; install safe

cleaning rust from the steel guard to the cutting machine.

before painting)

Falling from the roof

3 Painting on the roof of the Painter. 3 0.1 0.3 W ear complete PPE and a competent

unit. person monitoring him

Chapter-9 "Risk Assessment & Classification of Hazards 73 May 2015

P E TR OS ER V IC ES H SE D E PA R T ME N T

JOB HAZARD ANALYSIS WORKSHEET No. of Pages 1 Ref No. 01-1709

Job title: Office boy. Team Composition: Analysis Date:

2015

BriefDescriptionoftheTask: AssumptionsMade : AbbreviationsUsedintheJHA:

Using hot plate and heater, cleaning with chemicals, Electric hazards, burns, irritation, fire, falling Low (Range: 0.1 0.4).

lifting heavy objects. objects. Moderate (Range: 0.5 1.2).

High (Range: 1.5 2.5).

PPE: personal protective equipments.

MSDS: material safety data sheet.

Step Description of Hazard Who or what might Severity Like- Ris Control measures/ Action &

No. Task step Potential incident be harmed lihood k Recovery measures Responsible party

1 Hot plate and heater (for Electric hazard, hot surface Office boy 2 0.2 0.4 Electrical cables are checked, increase HSE officer, HSE manager, Branch

heating liquid). office boy awareness of hot surface manager.

risks.

Cleaning with chemical Flammable, irritant to eyes Office boy 2 0.2 0.4 W ear goggles and gloves.

2

cleaners. and skin chemicals.

3

Lifting heavy loads Trapped fingers, Office boy 3 0.2 0.6 W earing safety shoes, gloves.

Musculoskeletal disorder.

Chapter-9 "Risk Assessment & Classification of Hazards 74 May 2015

P E TR OS ER V IC ES H SE D E PA R T ME N T

JOB HAZARD ANALYSIS WORKSHEET No. of Pages 1 Ref No. 01-1809

Job title: Driver. Team Composition (Name & Positions): Analysis Date:

2015

BriefDescriptionoftheTask: AssumptionsMade : AbbreviationsUsedintheJHA:

Car malfunction, high speed crash, fire, lost in Low (Range: 0.1 0.4).

Equipments transportation. the desert, unpaved road, robbery Moderate (Range: 0.5 1.2).

Crew transportation. High (Range: 1.5 2.5).

Chemicals transportation PPE: personal protective equipments.

MSDS: material safety data sheet.

Step Description of Hazard Who or what might Severity Like- Ris Control measures/ Action &

No. Task step Potential incident be harmed lihood k Recovery measures Responsible party

1 During the trip (on the road). Car malfunction, high speed Driver, Passengers, 2 0.2 0.4 Checking the car before trip, ensure Senior driver, HSE officer, HSE

crash, fire, lost in the desert, equipments damage or presence of enough fuel, fire manager, Branch manager.

unpaved road, robbery. lost. extinguisher, first aid box, regular time

reporting, dont exceed the road speed

limits.

2 Leakage of gases Gas chocking, explosion, fire.

(Hydrocarbon or hydrogen Driver, Passengers, 4 0.1 0.4 Check the gas cylinders valves before

gas). equipments damage. starting the trip and ensure the presence

of the valve metallic cap.

Chemical spill in the car Corrosive, Irritant, Toxic

trunk. Flammable, Reactive Driver, Passengers, 3 0.2 0.6 Ensure that the cardboard containing

3

chemicalsetc equipments damage. chemicals are in good packing and

secured.

Chapter-9 "Risk Assessment & Classification of Hazards 75 May 2015

P E TR OS ER V IC ES H SE D E PA R T ME N T

JOB HAZARD ANALYSIS WORKSHEET No. of Pages 2 Ref No. 01-1909

Job title: Helper. Team Composition: Analysis Date:

2015

BriefDescriptionoftheTask: AssumptionsMade : AbbreviationsUsedintheJHA:

Preparing equipments & chemicals on the car, lifting Falling objects, Chemical hazards. Low (Range: 0.1 0.4).

heavy objects. Moderate (Range: 0.5 1.2).

High (Range: 1.5 2.5).

PPE: personal protective equipments.

MSDS: material safety data sheet.

Step Description of Hazard Who or what might Severity Like- Ris Control measures/ Action &

No. Task step Potential incident be harmed lihood k Recovery measures Responsible party

1 Preparing the equipments to Falling objects, hand abrasion Helper, equipments 2 0.2 0.4 Involved personnel must wear complete Senior technical engineer, Technical

put in or out the car and in damage. PPE. manager, service engineer, HSE

the unit. officer, HSE manager, Branch

Corrosives, Flammable, manager.

2 Preparing chemicals to put in Irritant, Toxic chemicals.. Helper 3 0.2 0.6 Involved personnel must wear complete

the car and in the unit. PPE, providing MSDS.

Falling objects, gas leak, fire,

3 Preparing high pressure gas explosion. Helper 4 0.1 0.4 Involved personnel must wear safety

cylinders to put on the car shoes, gloves, goggles, mask, ensure

and in the unit. the presence of the valve metallic cap.

Electrical hazard, noise

4 Wiring, (laying cables, (generator), falling objects. Helper 3 0.2 0.6 Hard hat, safety shoes, electricity caution

connect power to the unit signs are present.

and to the sensors).

Electrical hazard, fall from

5 Unit lighting ladder. Helper. 2 0.2 0.4 W ear gloves, safety shoes. W

Electrical, falling objects, noise

Installing sensors (pumps). Helper. 3 0.2 0.6 ear complete PPE (ear plugs)

6

Crushed fingers, gas leak, Helper.

electrical hazard, mud splash, 3 0.2 0.6 W ear complete PPE.

7 Maintenance of the degasser

motor (rotating objects) noise, falling objects.

Using steel-cutting machine Small metal cuttings parts

(hurt the eye and face), finger 3 0.3 0.9 W ear goggles and gloves; install safe

8 and drills. Helper.

or hand cut. guard to the cutting machine.

Chapter-9 "Risk Assessment & Classification of Hazards 76 May 2015

P E TR OS ER V IC ES H SE D E PA R T ME N T

9 Chemicals storing. Corrosive, irritant, toxic Helper. 3 0.1 0.4 W ear gloves and safety shoes, providing

chemicalsetc, falling objects. MSDS; ensure sealing of the chemical

container, good ventilation of the store,

and put container on wooden step,

smoke detectors, fire extinguishers are

present.

Falling objects, skin abrasion

10 Equipments storing. or cut, equipment breaking or Helper, equipments 2 0.2 0.6 W ear gloves and safety shoes, put

damage due to bad storing. damage equipments- especially electric equip. - in

safe boxes on wooden step in secure

position, smoke detectors, fire

Flammable gases, Falling extinguishers are present.

objects, gas leak, fire,

11 High pressure cylinders explosion. Helper, equipments 4 0.1 0.4 W ear safety shoes and gloves, high

(hydrogen, C1-C5 gases). damage, store damage. pressure gas sign, put cylinders in good

ventilated place, keep away from heat

sources, smoke detectors, fire

extinguishers are present, ensure the

presence of the valve metallic cap.

Chapter-9 "Risk Assessment & Classification of Hazards 77 May 2015

You might also like

- Hot Work Program PDFDocument49 pagesHot Work Program PDFAnonymous wtK1AZBiNo ratings yet

- Hova Production Risk Assessment Form - Part A: Summary of What Is ProposedDocument2 pagesHova Production Risk Assessment Form - Part A: Summary of What Is ProposedfatumaNo ratings yet

- Boc India Limited: Induction ProgrammeDocument83 pagesBoc India Limited: Induction ProgrammeAyah'e BhinoNo ratings yet

- EHS ManagerDocument3 pagesEHS Managerapi-121631565No ratings yet

- Fatigue Risk Management ChartDocument1 pageFatigue Risk Management ChartMurali DharNo ratings yet

- Cold weather safetyDocument11 pagesCold weather safetyotak04No ratings yet

- Risk AssesmentDocument2 pagesRisk Assesmentsabu1995No ratings yet

- Job Safety AnalysisDocument9 pagesJob Safety AnalysisazerNo ratings yet

- Effective Safety Committee MeetingsDocument25 pagesEffective Safety Committee Meetingsyawikhan100% (1)

- Safety Pre-Task AssignmentDocument2 pagesSafety Pre-Task AssignmentSathiya SeelanNo ratings yet

- JHA # 009 - Hot WorkDocument7 pagesJHA # 009 - Hot WorkkumarNo ratings yet

- Fall Protection English 10-10-07Document187 pagesFall Protection English 10-10-07Richard BurtonNo ratings yet

- CPWR Confined Spaces 1 PDFDocument2 pagesCPWR Confined Spaces 1 PDFIgnacio RomeroNo ratings yet

- JSA TemplateDocument2 pagesJSA TemplateRassie ErasmusNo ratings yet

- Silica Awareness Toolbox TalkDocument2 pagesSilica Awareness Toolbox TalkSamar Husain0% (1)

- Training Requirements in OSHADocument3 pagesTraining Requirements in OSHAXozanNo ratings yet

- Hand Safety and Injury Prevention TBTDocument5 pagesHand Safety and Injury Prevention TBTAlok SinghNo ratings yet

- JHA Job Hazard AnalysisDocument9 pagesJHA Job Hazard Analysisamtris406100% (1)

- Corporate Safety - Template: Job Safety & Environmental Analysis (JSEA) / Safe Work Method Statement (SWMS)Document6 pagesCorporate Safety - Template: Job Safety & Environmental Analysis (JSEA) / Safe Work Method Statement (SWMS)yyyyyuil100% (1)

- Pinch Points V1110.1Document1 pagePinch Points V1110.1bob geldofNo ratings yet

- Initial & Re-CertificationDocument107 pagesInitial & Re-CertificationSatya PrabhatNo ratings yet

- Job Safety Analysis PSA-MailDocument50 pagesJob Safety Analysis PSA-MailechaNo ratings yet

- Pre-Job Safety Assessment ChecklistDocument2 pagesPre-Job Safety Assessment Checklistgueettaf faresNo ratings yet

- Training Program: By: Rahul AhujaDocument17 pagesTraining Program: By: Rahul Ahujakei HoinaNo ratings yet

- RA Folder Jan 12Document83 pagesRA Folder Jan 12mouben100% (2)

- KBR It It Sti InstructionsDocument2 pagesKBR It It Sti InstructionsbotahraNo ratings yet

- SWMS 71 - Use of Curing ChemicalDocument2 pagesSWMS 71 - Use of Curing ChemicaleastNo ratings yet

- JSA Formet New Structural Steel FabricationDocument7 pagesJSA Formet New Structural Steel Fabricationsakthi venkatNo ratings yet

- Aerial Lift Inspection FormsDocument15 pagesAerial Lift Inspection FormsianNo ratings yet

- Health and Safety Risks on School Farm VisitsDocument46 pagesHealth and Safety Risks on School Farm Visitsshan123455555555No ratings yet

- 07.03.09 Rig Move (Working at Height)Document1 page07.03.09 Rig Move (Working at Height)Hamdi RafiekNo ratings yet

- Proper Lifting Techniques Toolbox Talk #13Document1 pageProper Lifting Techniques Toolbox Talk #13kimlynroseNo ratings yet

- JHA For Welding ShopDocument34 pagesJHA For Welding ShopRadhaKrishnan RNo ratings yet

- Kitchen Safety: Preventing Cuts, Burns, Spills & MoreDocument21 pagesKitchen Safety: Preventing Cuts, Burns, Spills & MoreTara NahNo ratings yet

- Overhead Crane Safety GuideDocument11 pagesOverhead Crane Safety GuideAhsan Farooq100% (1)

- Surface Blasting Safety Procedures ManualDocument21 pagesSurface Blasting Safety Procedures ManualRajanbabu100% (1)

- Health Safety Environmental Manager in Houston TX Resume Fabian Gregory WomacDocument2 pagesHealth Safety Environmental Manager in Houston TX Resume Fabian Gregory WomacFabianGregoryWomacNo ratings yet

- Safe Operating Procedures 03 Chainsaw OperationDocument2 pagesSafe Operating Procedures 03 Chainsaw OperationVictorNo ratings yet

- SWP Work at Height CBTDocument52 pagesSWP Work at Height CBTRasLDK100% (1)

- How To Run Toolbox TalksDocument2 pagesHow To Run Toolbox TalksRoshin99No ratings yet

- Good Catch Safety Program ConstructionDocument3 pagesGood Catch Safety Program ConstructionStephanie0% (1)

- Using This Template: Lockout/Tagout ProgramDocument14 pagesUsing This Template: Lockout/Tagout ProgramAhmad KharisNo ratings yet

- Toolbox Talk - Mounting and Dismounting EquipmentDocument1 pageToolbox Talk - Mounting and Dismounting Equipmentsl1828No ratings yet

- EHS is Everyone’s ResponsibilityDocument88 pagesEHS is Everyone’s ResponsibilityMarthaNo ratings yet

- PPE PolicyDocument4 pagesPPE PolicyalbertNo ratings yet

- Job Safety Analysis Sheet: Arc Welding, Cutting, GrindingDocument1 pageJob Safety Analysis Sheet: Arc Welding, Cutting, GrindingalekyaNo ratings yet

- Process and Risk Assessment Template All Faculty January 2015Document6 pagesProcess and Risk Assessment Template All Faculty January 2015hungonline07No ratings yet

- JSA ScaffoldingDocument2 pagesJSA Scaffoldingmyco samNo ratings yet

- Worksite Hazard Analysis Techniques (39Document113 pagesWorksite Hazard Analysis Techniques (39parapencarituhanNo ratings yet

- Clearing Brush With Weed Trimmer: Job Safety AnalysisDocument2 pagesClearing Brush With Weed Trimmer: Job Safety AnalysisRetselisitsoe100% (1)

- ISBN Sample OHS Action Plan For Community Services Sector 2007 01 PDFDocument5 pagesISBN Sample OHS Action Plan For Community Services Sector 2007 01 PDFpurva02No ratings yet

- Hse Audit Checklist PDFDocument6 pagesHse Audit Checklist PDFnorlieNo ratings yet

- 2010 Safety ManualDocument290 pages2010 Safety ManualPaul Januario G. RostrataNo ratings yet

- Job Safety Analysis for Loading/Unloading DrumsDocument4 pagesJob Safety Analysis for Loading/Unloading DrumsRimNo ratings yet

- 49 Roofing safety-JOB PROCEDUREDocument2 pages49 Roofing safety-JOB PROCEDUREmalimsaidi_160040895No ratings yet

- Amplitude Balancing 6409351 01 6409351 01Document8 pagesAmplitude Balancing 6409351 01 6409351 01mohame30dNo ratings yet

- Gardosh 2010Document29 pagesGardosh 2010mohame30dNo ratings yet

- Tutorial Trajectories 5876161 01 5876161 01Document13 pagesTutorial Trajectories 5876161 01 5876161 01mohame30dNo ratings yet

- Nanno Zonations1Document12 pagesNanno Zonations1mohame30dNo ratings yet

- Petrel Guided Workflow: Fault Interpretation - Surface IntersectionsDocument4 pagesPetrel Guided Workflow: Fault Interpretation - Surface Intersectionsmohame30dNo ratings yet

- Ikon Science SGreen Hydrodynamics AAPG2014Document10 pagesIkon Science SGreen Hydrodynamics AAPG2014Jhonatan_Valdi_8987No ratings yet

- 10 1190@segam2017-17701303 1Document5 pages10 1190@segam2017-17701303 1mohame30dNo ratings yet

- Reservoir Characterization and Depositional PatternsDocument4 pagesReservoir Characterization and Depositional PatternsMahmoud EloribiNo ratings yet

- Yamada 2003Document6 pagesYamada 2003mohame30dNo ratings yet

- Reservoir ModelerDocument1 pageReservoir Modelermohame30dNo ratings yet

- SCM Workflow Tips Petrel 2010Document13 pagesSCM Workflow Tips Petrel 2010TanaskumarKanesanNo ratings yet

- Type Byte Position Seg YDocument12 pagesType Byte Position Seg Ymohame30dNo ratings yet

- Application of geometric models to inverted listric fault systemsDocument10 pagesApplication of geometric models to inverted listric fault systemsFrancisco AlfaroNo ratings yet

- NDX LiDocument4 pagesNDX Limohame30dNo ratings yet

- Safety Risk AssessmentDocument2 pagesSafety Risk Assessmentmohame30dNo ratings yet

- Application of Time Lapse (4D) Seismic For Petroleum Reservoir Monitoring and Management-A Review PDFDocument7 pagesApplication of Time Lapse (4D) Seismic For Petroleum Reservoir Monitoring and Management-A Review PDFAlexander DeckerNo ratings yet

- Lithofacies, Environments of Deposition and Provenance of The Upper Carboniferous Abu Durba Formation, Southwest Sinai, Egypt Hosny E. SolimanDocument23 pagesLithofacies, Environments of Deposition and Provenance of The Upper Carboniferous Abu Durba Formation, Southwest Sinai, Egypt Hosny E. Solimanmohame30dNo ratings yet

- Nos Volume 35 Number 3 p181-187 On The Extinction of Costate Buliminas in The Egyptian Eocene Rocks 86436Document1 pageNos Volume 35 Number 3 p181-187 On The Extinction of Costate Buliminas in The Egyptian Eocene Rocks 86436mohame30dNo ratings yet

- Contribution to the Mineralogy and Geochemistry of the Upper Cretaceous Matulla Formation and Sudr ChalkDocument31 pagesContribution to the Mineralogy and Geochemistry of the Upper Cretaceous Matulla Formation and Sudr Chalkmohame30dNo ratings yet

- Lithofacies, Environments of Deposition and Provenance of The Upper Carboniferous Abu Durba Formation, Southwest Sinai, Egypt Hosny E. SolimanDocument23 pagesLithofacies, Environments of Deposition and Provenance of The Upper Carboniferous Abu Durba Formation, Southwest Sinai, Egypt Hosny E. Solimanmohame30dNo ratings yet

- Egypt 1Document1 pageEgypt 1mohame30dNo ratings yet

- 61Document1 page61mohame30dNo ratings yet

- Stateview Install Guide9 XDocument39 pagesStateview Install Guide9 Xmohame30dNo ratings yet

- RavenDocument2 pagesRavenmohame30dNo ratings yet

- Weissbrod-2004 IJES 53Document12 pagesWeissbrod-2004 IJES 53mohame30dNo ratings yet

- 10.1016@0040 19518890004 2 PDFDocument2 pages10.1016@0040 19518890004 2 PDFmohame30dNo ratings yet

- 61Document1 page61mohame30dNo ratings yet

- Shallow Nile Delta: Data Challenges and Possible SolutionsDocument1 pageShallow Nile Delta: Data Challenges and Possible Solutionsmohame30dNo ratings yet

- SS02Document3 pagesSS02mohame30dNo ratings yet

- Animal Cell Vs Plant CellDocument4 pagesAnimal Cell Vs Plant CellRizza Mae Samalca100% (2)

- BdeM Taller No. 2Document2 pagesBdeM Taller No. 2Luisfer PriceNo ratings yet

- Astm D5322 92 97Document6 pagesAstm D5322 92 97Ahmed AbidNo ratings yet

- Plastic ExtrusionDocument35 pagesPlastic ExtrusionOff Campus100% (2)

- 1 - Bhattiacademy - Com - Physics - 6. Azeem Acadmy (Objective) PDFDocument14 pages1 - Bhattiacademy - Com - Physics - 6. Azeem Acadmy (Objective) PDFAwaisNo ratings yet

- Madharasathul Ahmadhiyya: First Term ExaminationDocument9 pagesMadharasathul Ahmadhiyya: First Term Examinationafoo1234No ratings yet

- 1 4713 4724 4742 4762Document4 pages1 4713 4724 4742 4762Ján KožičkaNo ratings yet

- Lenox Insight Application Solutions - Cement Rotary Kiln MonDocument2 pagesLenox Insight Application Solutions - Cement Rotary Kiln MonRaden Pambudi PratamaNo ratings yet

- Mil DTF 5541fDocument12 pagesMil DTF 5541fMarcos PerezNo ratings yet

- Mil F 25173a DzusDocument19 pagesMil F 25173a DzusacparaujoNo ratings yet

- Karkim Kar Ben enDocument1 pageKarkim Kar Ben enIqbal batchaNo ratings yet

- Design of Compression MembersDocument22 pagesDesign of Compression MembersChee Fong MakeNo ratings yet

- Cell Membrane Transport: A Guide to Passive and Active ProcessesDocument2 pagesCell Membrane Transport: A Guide to Passive and Active ProcessesZei-chen LocabenNo ratings yet

- Fujikura 12S CDocument2 pagesFujikura 12S CCristian BolañosNo ratings yet

- Understanding Redox Titration CurvesDocument79 pagesUnderstanding Redox Titration CurvesSiti AmirahNo ratings yet

- EOR ReportDocument119 pagesEOR Reportrarunr1100% (2)

- Pengaruh Rentang Suhu Distilasi Fraksinasi Terhadap Kadar Patchouli Alcohol (PA) Pada Minyak NilamDocument7 pagesPengaruh Rentang Suhu Distilasi Fraksinasi Terhadap Kadar Patchouli Alcohol (PA) Pada Minyak NilamBagusSatriyaNo ratings yet

- RetroSled OverviewDocument1 pageRetroSled OverviewdigdreamNo ratings yet

- Thermodynamics in The News... : Airborne Soot Adds To Weather Woes, Some SayDocument13 pagesThermodynamics in The News... : Airborne Soot Adds To Weather Woes, Some SayJames Patrick TorresNo ratings yet

- Chris DeArmitt PHD ThesisDocument160 pagesChris DeArmitt PHD Thesisalinbu2007No ratings yet

- Set 1 Section A (45 MARKS) : X X y X DX DyDocument2 pagesSet 1 Section A (45 MARKS) : X X y X DX DyMuhammad SaifudinNo ratings yet

- FIB Full Paper Final Rev1Document9 pagesFIB Full Paper Final Rev1Anonymous cPhfqzNo ratings yet

- (Semiconductors and Semimetals 56) Robert Hull and John C. Bean (Eds.) - Germanium Silicon - Physics and Materials-Elsevier, Academic Press (1998)Document459 pages(Semiconductors and Semimetals 56) Robert Hull and John C. Bean (Eds.) - Germanium Silicon - Physics and Materials-Elsevier, Academic Press (1998)Domenico BarillariNo ratings yet

- Foodpharma MaterialoverviewpdfDocument2 pagesFoodpharma MaterialoverviewpdfJai BhandariNo ratings yet

- Submerged PumpDocument8 pagesSubmerged Pumpbramantiya100% (1)

- Astm A 1084 2013 PDFDocument17 pagesAstm A 1084 2013 PDFjoao carlos protzNo ratings yet

- A Study of Radiator Cooling Fan With Labyrinth SealDocument9 pagesA Study of Radiator Cooling Fan With Labyrinth SealDarel DalmassoNo ratings yet

- Earth Pressure Calculation Web PDFDocument273 pagesEarth Pressure Calculation Web PDFKumaranNo ratings yet

- LDH Pointe ScientificDocument2 pagesLDH Pointe ScientificDaria Vîrtic100% (1)

- 9701 w14 QP 53Document12 pages9701 w14 QP 53CindyVortexNo ratings yet