Professional Documents

Culture Documents

Us 6232274

Uploaded by

Lê Công0 ratings0% found this document useful (0 votes)

7 views9 pagesyehrtg3e

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentyehrtg3e

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views9 pagesUs 6232274

Uploaded by

Lê Côngyehrtg3e

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 9

2) United States Patent

Hughes et al.

a0) Patent No.:

106232274B1

US 6,232,274 BL

(45) Date of Patent:

May 15, 2001

(54) VISCOELASTIC SURFACTANT BASED

GELLING COMPOSITION FOR WELLBORI

SERVICE FLUIDS

(75) Inventors: ‘Trevor L. Hughes, Cambridge;

Timothy Gareth J. Jones, Cottenham;

Gary J. Tustin, Cambridge, all of (GB)

(73) Assignee: Schlumberger Technology

Corporation, Sugar Land, TX (US)

(*) Notice: Subject to any disclaimer, the term of this

patent is extended or adjusted under 35

U.S.C. 15440) by 0 days.

Appl: No. 09/209,906

Filed: Dee. 11, 1998

(30) Foreign Application Priority Data

Dee. 13,1997 (OB) oneas4

G1) Imt.cl? CO9K 3/00; E21B 43/27

(2) US.CL '507/240; 507/239; 507/276;

307/377; 507/921; 5071922; 507/925; 166/300

(58) Field of Seare 507/129, 130,

507/131, 145, 239, 240, 276, 277, 922,

921, 925; 1661308, 300,

56) References Cited

U.S, PATENT DOCUMENTS

4148736 4/1979 Meister

4.192753,

45532052

415,82:

44595,389

47253372

4735731

4975,482

5,036,136

(093,448

5,101,903

258.137

551516

929,002

5.064.205

59795357

3/1980,

7/1985

10/1986,

9/1987

2/1988

41988

1211990

ss

3/1992

‘992

11/1993

9/1996

= 771989

> 19/1990

> 11/1989

Pye eta

Weaver et a

Teot tal

Kubla

Teot eal

Rose et al

Peifer

Peifer

Peitfer

lave ot a

Bonekamp etal,

Norman el

Joyce et al

Brown eta

Card et al

I

07/269

SO7/3L

166/300

FOREIGN PATENT DOCUMENTS

(0835 983 A2

41998

* cited by examiner

er)

Primary Examiner—Philip Tucker

(74) Aitorney, Agent, or Firm—Robin C. Nava; William L

Wang

67)

Awellbore servi

ABSTRACT

¢ fluid comprising viscoelastic surfactants

in combination with means for controlling the concentration

of a least partially charged sites within the uid is deseribed,

11 Claims, 5 Drawing Sheets

ss ,

“

2 ‘

8

8

z

5 ‘

&

5

3 :

a

a

2

—o— casrumori coon

ow

“ '

. ew ae

‘TIME (hrs)

pH

U.S. Patent May 15, 2001 Sheet 1 of 5 US 6,232,274 BL

pH

GEL STRENGTH CODE

—O— GEL STRENGTH CODE

—o— pH

° 50 100 150 200 250

TIME (hrs)

FIG. 1A

U.S. Patent May 15, 2001 Sheet 2 of 5 US 6,232,274 BL

GEL STRENGTH CODE

25

15

05

TIME (hrs)

FIG. 1B

U.S. Patent May 15, 2001 Sheet 3 of 5 US 6,232,274 BL

35

GEL STRENGTH CODE

os

0 5 10 15 20

TIME (hrs)

FIG. 1C

U.S. Patent May 15, 2001 Sheet 4 of 5 US 6,232,274 BL

aA

ow 0

acid or base hydrolysis

FIG. 2

counter flow of

chloride ions

anion exchange

membrane

FIG. 3

U.S. Patent May 15, 2001 Sheet 5 of 5 US 6,232,274 BL

°

primary amine NHR’

R—s—cl > nl ve + cr

FIG. 4A

H,0 or O17

R—s—a ee s— on ts cr

FIG. 4B

US 6,232,274 BL

1

VISCOELASTIC SURFACTANT BASED

GELLING COMPOSITION FOR WELLBORE,

SERVICE FLUIDS

‘The present invention relates to viscoelastic surfactant

based gelling compositions for weltbore service fluids, More

particularly it relates to viscoelastic surfactant based gelling

‘compositions for selectively reducing the flow of subterra-

rnean aqueous fluids into a well while maintaining the

hydrocarbon production,

BACKGROUND OF THE INVENTION

Various types of wellbore fluids are used in operations

related to the development, completion, and production of

‘natural hydrocarbon reservoirs. The operations include frac-

turing subterranean formations, modifying the permeability

Of subterranean formations, or sand control. Other applica-

tions comprise the placement of a chemical plug to isolate

zones or complement an isolating operation, ‘The fluids

employed by those operations are known as drilling fluids,

‘completion fluids, work over fluids, packer fluids, fracturing

fluids, conformance or permeability control fluids and the

like,

‘Of particular interest with regard to the present inventions,

are fluids for water cootol applications: During the life

cycle of a hydrocarbon well, e.g. a well for extracting oil or

natural gas from the Earth, the producing well commonly

also yields water. In these instances, the amount of water

prochiced from the well tends to increase over time with a

concomitant reduetion of hydrocarbon production,

Frequently, the production of water becomes so profuse that

remedial measures have to be taken to decrease the water!

hydrocarbon productioa ratio. As a final consequence of the

inereasing water production, the well has to be abandoned

In many cases, « principal component of wellbore service

fluids are gelling compositions, usually based on polymers

‘or viscoelastic surfactants,

Viscoelastic surfactant solutions are usually formed by the

addition of certain reagents to concentrated solutions of

surfactants, which most frequently consist of long-chain

‘quaternary ammonium salts such as cetyltrimetbylammo-

nium bromide (CTAB). Common reagents which generate

viscoelasticity in the surfactant solutions are salts such

sodium salicylate and sodium isocyanate and non-ionic

‘organic molecules such as chloroform. The electrolyte con-

tent of surfactant solutions is also an important control on

their viscoelastic behaviour.

Further references related to the use of viscoelastic sur-

factants as wellbore service fuids can be found for example

in US. Pat, Nos.4,695,389, 4,725,372, and 5,551,516.

‘There has been considerable interest in the viscoelastic

gels formed from the solutions of certain surfactants when

the concentration significantly exceeds the critical micelle

concentration, The surfactant molecules aggregate into

worm-like micelles which can become highly entangled at

these high concentrations to form a network exhibiting

clastic behaviour, These surfactant gels are of considerable

‘commercial interest, including application as oil well frac-

turing ids.

‘The viscoelasticity of the surfactant solutions appears

invariably to form rapidly on mixing the various compo-

rents. The resulting high viscosities ofthe viscoelastic gels

‘can make handling or placement difficult, For example,

placement of a uniform surfactant gel in a porous medium is

Lifficult since injection of the gel in the medium can lead to

the separation ofthe surfactant from the solute by a filtration

0

os

ss

ss

6s

2

process. Any application of viscoelastic surfactant solutions

which requires their transport or placement after their prepa~

ration would benefit from a method of controlling theit

viscosities and gel times,

‘The object of this present invention is therefore to provide

improved compositions for wellbore service fluids based on

viscoelastic suefactants, It is a specitic object of the inven-

tioa to provide means of controlling or delaying the build-up

of viscosity in such compositions. It is a further specific

‘object of the invention to provide such compositions for

‘water control operations in hydrocarbon wells

SUMMARY OF THE INVENTION

‘The objects ofthe invention are achieved by methods and

compositions as set forth in the appended independent

claims,

‘A composition ia accordance with the present invention

comprises viscoelastic surfactants and means of controlling

the concentration ofa least partially changed sites within the

composition. For the purpose of this description, the term

“partially charged sites” includes groups, molecules, of

atoms, whether or not attached to larger molecules, of polar

or ionie character. The concentration is used as a means to

control or delay the onset of gelation in surfactant based

viscoelastic fluids after the fluid has been mixed

The control can be achieved by at leas three diferent

mechanisms:

the delayed release of a specific counter-on such as the

formation of the salicylate anion by ester hydrolysis;

the controlled removal of a hydrogen bonding modifier

such a8 ures or guanidine hydrochloride in surfactant

systems where hydogen bonding provides a significant

interaction between the entangled micelles; or

the controlled change in the ionic composition of the

‘surfactant solution.

The use of an internal delayed release (removal) of a

reagent which promotes (inhibits) the formation of vis-

coelastic gels from the surfactant solutions is seen asa now

feature of the present invention

‘These and other features of the invention, preferred

embodiments and variants thereof, and further advantages of|

the invention will become appreciated and understood by

those skilled in the art from the detailed description and

drawings following below.

BRIEF DESCRIPTION OF DRAWINGS

FIG. 1A shows the time dependence of gel strength and

pH of a concentrated surfactant solutions

FIGS, 1B and 1C show the time dependence of gel

strength of two further concentrated surfactant solutions;

FIG, 2 illustrtes the hydrolysis of a salicylate ester to

{orm the salicylate anion or salicylic aci

FIG. 3 shows a schematic of the proposed process using

the exchange of iodide for chloride in a solution of a

surfactant (¢.g., N-crucyl-N.N-bis(2 -hydroxyethyl)-N-

methylammonium chloride) and the electrolyte sodium

iodide;

FIGS. 44,B show two possible reactions in which chlo-

ride ions are released into the surfactant solution replacing

MODES) FOR CARRYING OUT THE

INVENTION,

‘Thrwe different methods for delaying the gelation of

concentrated surfactant solutions are described below.

US 6,232,274 BL

3

Firstly, the gelation process can be delayed by the con-

twolled reiease of the counter-ion into the suzTactant solution,

For example, an aqueous solution of the viscoelastic sur-

factaat cetyltrimethylammonium bromide (CTAB),

ea cus

Be Ycttgy—N—cr

cay

will immediately form a viscoelastic gl in the preseace of

the salicylate anon but not with salicylic acid or derivatives

of salicylic acid such as an ester or an amide. The salicylate

fnion can be released from derivatives by acid or alkaline

bydrolysis,

‘An example of the controlled development of viscoets-

ticity in concentrated surfactant solutions i the release of

counterion fora long-chain qusternary ammenium surfac-

tant. The initial low viscosity fluid coasised of a 30 g/l

solution of eetyrimethylammonium chloride with 20 wt

Salicylic aid, 6 g/l urea and 20 gil sodium chloride, The

Solution was heated to 60° C, whereupon the urea hydro

sed and raised the pH which, in tu, released the saliylate

anion from the salicylic acid and’ caused the surfactant

Solution to gel FIG. 1A shows the development ofthe gel

Strength of the surfactant solution over a period of 240

hours. The time dependence ofthe pH ofthe solution closely

follows the development of gel stength

‘A further variant of the controlled development of the

viseoelastiity in «concentrated surfactant solution through

the release of a counterion is by hydrolysis of an ester. FIG.

2'shows the release ofthe salicylate anion (or salicylic acid)

by the acidor alkane hydrolysis of slicylate ester where

R is a suitable chemical group. The rate of hydrolysis (and

thence the release ofthe anion or acid can be controlled by

the pH of the solution andor the choice of the functional

group R. In the case of acid hydrolysis, raising the pH by the

controlled hydrolysis of a second reagent will form the

Salicylate anion, In an example, the surfactant solution

consisted of 30 gl cetylrimethylammonium chloride with

20 alethylsalicvlite, 61 urea and 5 1 sodium hydroxide

‘The solution was maintained a 80°C. and the release of the

salicylate anion ftom the salicylate ester caused the surfac-

tant solution to gel. FIG, 1B shows the development of gel

‘strength in the surfactant solution over a time period of 120

hours

“The scoond method of controlling the development of

viscoelasticity is based onthe contol of hydrogen bonding

between the entangled worm-like micelles. It has been

‘observed that some surfactants sich as Neemiey/-NN-bis(2-

hydroxyethyl)-N-methylammonium chloride,

cr

=

ad

on

do not require the presence of a Iaege organic anion such as

salicylate to form viscoelastic solutions. At ambient tem-

perature N-erueyl-N,N-bis(2-hydroxyethyl)-N-

‘methylammonium chloride forms a viscoelastic solution

0

as

os

ss

4s

ss

6s

4

when the concentration of a suitable electrolyte isin excess

of about 0.5 weiaht pereent

It is assumed that hydrogen bonding between the —OH

groups on the quaternary ammonium groups plays a major

role in the biading of the surfactant micelles to form a

viscoelastic gel. The presence of hydrogen bonding modi-

fers should therefore inhibit viscoelasticiy in such surfac-

tant systems. It is observed thatthe addition of hydrogen

bonding modifiers such as urea, guanidine hydrochloride

and urethane do inhibit viscoelasticity:

‘The additives urea, guanidine hydrochloride and urethane

can be broken down by temperature or either base or acid

hydrolysis whereupon the viscoelasticity of the surfactant

solution ean develop. The inhibitor urea can also be broken

down using enzymes such as urease to yield ammonia and

carbon dioxide; enzymes such as urease can decompose urea

very rapidly at ambient temperatures. The use of guanidine

hydrochloride may be particularly convenient since in aque

oils solution the hydrogen chloride can catalyse the acid

hydrolysis of the guanidine

‘An Surfactant solution to illustrate this variant consists of

30 go the suefactant N-orucyl-N,N-bis2-hydroxyethy-

Nemethylammonium chloride in an aqueous solution con-

taining 0.5 molar urea, 10 gil potassium chloride and 40 gy

3-chloropropionie acid. FIG. IC shows the development of

gel strength inthe solution at 60° C. The presence ofthe urea

in the inal solution significantly weakened the hydrogen

bonding between the micelles in the agueous solution and

the surfactant solution could not gel The urea hydrolysed

rapidly at clevated temperature and its decomposition

allowed hydrogen bonding between the surfactant micelles

to gel the solution

The third method of controlling the onset of viscoelas-

ticity in surfactant solutions uses the sensitivity of viscoelas-

tic behavior tothe ionic environment of the solution. One

method of triggering the gelation of the surfactant solution

is by formulating it with « low electolyte concentration and

then subsequently adding electrolyte to achieve the required

viscosity. However, the external alton of electrolyte may

not always be possible

‘Asecontl example ofthis variant involves the exchange of

4 salt which inhibits gelation With one which promotes it

For example, solutions of the surfactant N-erucyl-N,N-bis

(@-hydroxyethyl)-N-methylammonium chloride will not gel

in the presence of electolytes containing carbonate, ice,

hydroxide of acetate ions but wil form gels in the presence

of electrolytes containing chloride, bromide, sulphate and

nitgate ions.

‘Two techniques are proposed for the controlled gelation

of surfactant solutions using changes in their ionie environ-

iments. Firily, itis proposed to exchange the anions in the

surfactant solution by replacing an anion which iabibits

gelation with one which promotes i, The anion exchange

tan be achieved by flowing the surfactant solution through

4 pipe or tube, the walls of which consist of an anion

exchange membrane; a counter-flow of an electrolyte con-

taining the exchange anion is flowed on the ether side ofthe

membrane

FIG. 3 shows a schematic ofthe proposed process using

the exchange of iodide for eblorde in a solution of a

surfactant (¢.g., N-erucyl-N,N-bis(2-hydroxyethyl)-N-

methylammonium chloride) and the electrolyte sodium

‘iodide. The rate of anion exchange, and bence gelation, can

be controlled by the flow rates ofthe two solutions and the

anion diffusion rate through the anion exchange membrane

‘Secondly, the anions can be exchanged directly in the

surfactant solution by a conteoled reaction, For example,

US 6,232,274 BL

5

‘chloride ions can be released into solution by the hydrolysis

(or other reaction) of a suitable sulphonyl chloride.

FIG, 4 shows two possible reactions in which chloride

fons are released into the surfactant solution replacing

anions such as carbonate and hydroxide and causing gela-

tion, One example is the reaction of a sulphonyl chloride

with a primary amine (FIG. 4A) and the second example

(FIG. 4B) is water or hydroxide ions to release chloride ions

into a surfactant solution for the purposes of gelation.

‘Other examples of surfactants which could be use for the

purpose of the present invention include cetylpyridinium

chloride

mcr

‘or sodium perfluorooctane1 sulphonate

F,C-(CR,) SON

‘What is claimed is:

1. A wellbore service fluid comprising viscoelastic sur-

factants having an intemal mechanism that controls the

‘concentration of at least partially charged sites within the

fluid, thereby delaying the onset of gelation of said fluid

2. The fluid of claim 1, wherein said internal mechanism

is a delayed release of a Specific counter-in,

0

as

os

6

3. The fluid of claim 1, wherein said intemal mechanism

is the controlled removal of a hydrogen bonding moditier.

4. The fluid of claim 1, wherein said intemal mechanism

is a controlled change in the ionic composition of the said

surfactant

‘5. The fluid of claim 2, wherein said delayed release of a

specific counter-ion isthe formation of a salicylate anion by

ester hydrolysis,

(6. The fluid of claim 3, wherein said hydrogen bonding,

modifier is selected from the group consisting of urea,

guanidine hydrochloride, and urethane.

7. The fluid of claim 4, wherein said controlled change is

by exchange of an electrolyte.

'8. The fluid of claim 4, wherein said controlled change is

by exchange of a salt

9. The fluid of claim 4, wherein said controlled change is

by a controlled reaction that releases chloride ions.

10. The fluid of claim 1, wherein the internal mechanism

exchanges ions in the fuid.

IL, A method of treating a subterranean formation pen-

trated by a wellbore, said method comprising the steps of

injecting through the wellbore into said formation a Muid

comprising viscoelastic surfactants in the presence of an

internal mechanism that controls the concentration of atleast

partially charged sites withia the fluid, thereby delaying the

‘onset of gelation of said fluid.

You might also like

- Clay Guard: Product Data Sheet (PDS)Document1 pageClay Guard: Product Data Sheet (PDS)Lê CôngNo ratings yet

- Wo2016187364 Pamph 20161124 3002Document32 pagesWo2016187364 Pamph 20161124 3002Lê CôngNo ratings yet

- Us2016033163 IasrDocument2 pagesUs2016033163 IasrLê CôngNo ratings yet

- Product Data SummaryDocument11 pagesProduct Data SummaryLê CôngNo ratings yet

- Review On Chemical Stimulation Techniques in Oil IDocument35 pagesReview On Chemical Stimulation Techniques in Oil IJesseNo ratings yet

- DFS14-007. Benvis-Pds-EnDocument1 pageDFS14-007. Benvis-Pds-EnLê CôngNo ratings yet

- Driscal D™: Product Data Sheet (PDS)Document1 pageDriscal D™: Product Data Sheet (PDS)Lê CôngNo ratings yet

- Zoran Krilov, Boris Kaved Ija, Tomislav BukovacDocument12 pagesZoran Krilov, Boris Kaved Ija, Tomislav BukovacLê CôngNo ratings yet

- Energies: Development of Selective Acidizing Technology For An Oil Field in The Zechstein Main DolomiteDocument18 pagesEnergies: Development of Selective Acidizing Technology For An Oil Field in The Zechstein Main DolomiteLê CôngNo ratings yet

- Flowsolve ™ 150: An Asphaltene InhibitorDocument1 pageFlowsolve ™ 150: An Asphaltene InhibitorLê CôngNo ratings yet

- Scale Dissolver: Product Data Sheet (PDS)Document1 pageScale Dissolver: Product Data Sheet (PDS)Lê CôngNo ratings yet

- Kemelix ™ D501: A DemulsifierDocument1 pageKemelix ™ D501: A DemulsifierLê CôngNo ratings yet

- Interox® Hydrogen Peroxide Chemical Grade 50%Document20 pagesInterox® Hydrogen Peroxide Chemical Grade 50%Lê CôngNo ratings yet

- Synthetic Lubricants & Engineered Fluids: Smooth Operations To Improve Your Bottom LineDocument12 pagesSynthetic Lubricants & Engineered Fluids: Smooth Operations To Improve Your Bottom LineLê CôngNo ratings yet

- Autoref Razrabotka Tekhnologii I Tekhnicheskikh Sredstv Dlya Ochistki Gazovykh Skvazhin Ot GlinistoDocument26 pagesAutoref Razrabotka Tekhnologii I Tekhnicheskikh Sredstv Dlya Ochistki Gazovykh Skvazhin Ot GlinistoLê CôngNo ratings yet

- Autoref Sokhranenie I Vosstanovlenie Estestvennoi Pronitsaemosti Produktivnykh Plastov V Gazovykh IDocument28 pagesAutoref Sokhranenie I Vosstanovlenie Estestvennoi Pronitsaemosti Produktivnykh Plastov V Gazovykh ILê CôngNo ratings yet

- Neoflo 1 58 bản tiếng việtDocument18 pagesNeoflo 1 58 bản tiếng việtLê CôngNo ratings yet

- Neoflo 1-58: Olefin & Paraffin Drilling FluidsDocument4 pagesNeoflo 1-58: Olefin & Paraffin Drilling FluidsLê CôngNo ratings yet

- US20120196836A1Document5 pagesUS20120196836A1Lê CôngNo ratings yet

- Sulfate Reducing Bacteria, Nitrate Reducing Bacteria and Their Interactions in A Souring Offshore Oil Reservoir SystemDocument282 pagesSulfate Reducing Bacteria, Nitrate Reducing Bacteria and Their Interactions in A Souring Offshore Oil Reservoir SystemUmar FarouqNo ratings yet

- Global Oilfield Solutions: Performance Chemicals For ProductionDocument6 pagesGlobal Oilfield Solutions: Performance Chemicals For ProductionLê CôngNo ratings yet

- Middle East Journal of Applied Sciences 4(2): 373-384, 2014Document11 pagesMiddle East Journal of Applied Sciences 4(2): 373-384, 2014Lê CôngNo ratings yet

- The Use of Alcohol in Gas Well StimulationDocument13 pagesThe Use of Alcohol in Gas Well StimulationLê CôngNo ratings yet

- Acid Corrosion Inhibitor (Se-Ci 1021) : Product Data SheetDocument2 pagesAcid Corrosion Inhibitor (Se-Ci 1021) : Product Data SheetLê CôngNo ratings yet

- Study On The Mechanism of Nanoemulsion Removal of WaterDocument10 pagesStudy On The Mechanism of Nanoemulsion Removal of WaterLê CôngNo ratings yet

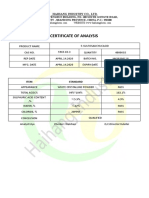

- Certificate of Analysis: Haihang Industry Co., LTDDocument1 pageCertificate of Analysis: Haihang Industry Co., LTDLê CôngNo ratings yet

- Lubrizol Well Stimulation: Acidizing Additives Application GuideDocument2 pagesLubrizol Well Stimulation: Acidizing Additives Application GuideLê CôngNo ratings yet

- Water Dispersible Drilling Fluid Lubricant Reduces Torque & DragDocument1 pageWater Dispersible Drilling Fluid Lubricant Reduces Torque & DragLê CôngNo ratings yet

- (Vanbanphapluat - Co) tcvn11115-2015Document10 pages(Vanbanphapluat - Co) tcvn11115-2015Lê CôngNo ratings yet

- NEOFLO 1-58 SDS Safety DataDocument17 pagesNEOFLO 1-58 SDS Safety DataLê CôngNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)