Professional Documents

Culture Documents

Fiber Polishing Handbook2

Uploaded by

Berrezeg MahieddineCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fiber Polishing Handbook2

Uploaded by

Berrezeg MahieddineCopyright:

Available Formats

TEC NOTE #2 POLISHING TECHNIQUES FOR FIBER OPTIC

CONNECTORS

Critical to proper polishing is the applied process--the technique--that results in meeting

the various specifications. This TEC NOTE discusses various proven techniques for

maximized performance and suggests useful techniques than can be applied to maintain

these levels.

POLISHING TECHNIQUES

Early connectors were all produced with flat end-faces, which were specified to be close

(the linear tolerance on the SMA, for example, being 8 microns), but too specifically

avoid actual contact. As Polishing evolved the PC (Physical Contact) concept was

developed--spherical end-faces, with the fibers making actual physical contact--The PC

finish resulted in much improved performance because air-gap was eliminated which

allowed increased lightwave transmission.

The early PC connectors, preceding development of the now common pre-radiused

ferrules, required spherical forming of their flat end-faces as part of the polishing

process. These traditional polishing techniques, for singlemode PC connectors, involved

a four-step process: epoxy removal, ferrule forming, preliminary polish and a final polish.

These steps used aggressive materials for the epoxy removal and ferrule forming steps,

generally accomplished by using a diamond polishing film. Now, however, almost all

connectors are "pre-radiused", and the polishing process should avoid excessive

disruption of the spherical surface--the sort of thing a mechanized process can do well

(and a manual process poorly). As a result reducing the cycle time and changing the

film gradations to adapt to the current connector configurations has revitalized the

traditional polishing techniques. Now, the traditional four-step process is much improved

(epoxy removal, beginning polish, intermediate polish and final polish).

The following is a list of polishing techniques for singlemode & multimode polishing.

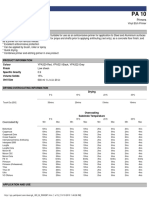

FOUR-STEP SINGLEMODE POLISHING TECHNIQUE

Step Description Film Type Timer Setting Lubrication

1 Epoxy Removal 15m Silicon Carbide 10 Seconds Dry

2 Beginning Polish m Diamond

5 30 Seconds D/I Water

3 Intermediate Polish 1m Diamond 60 Seconds D/I Water

4 Final Polish ULTRAFILM 5 10 Seconds D/I Water

MPC TECHNIQUE (new three step polishing technique for singlemode connectors)

Step Description Film Type Timer Setting Lubrication

1 Epoxy Removal 3um Silicon Carbide 5 Seconds Dry

2 Intermediate Polish 1um Diamond 45 Seconds D/I Water

3 Final Polish ULTRAFILM 5 10 Seconds D/I Water

TWO-STEP POLISHING TECHNIQUE for multimode connectors

Description Film Type Timer Setting Lubrication

1 Epoxy Removal 5m Silicon Carbide 5 Seconds Dry

2 Final Polish 1m Diamond 60 Seconds D/I Water

APC POLISHING TECHNIQUE

Step Description Film Type Timer Setting Lubrication

1 Epoxy Removal 15um Silicon Carbide 10 Seconds Dry

2 Beginning Polish 5um Diamond 30 Seconds D/I Water

3 Intermediate Polish 1um Diamond 60 Seconds D/I Water

4 Final Polish ULTRAFILM 5 10 Seconds D/I Water

COMMENTS ON POLISHING TECHNIQUE

More recent polishing techniques indicate that the aggressive epoxy removal and ferrule

forming steps that were previously popular should be minimized during the polishing

process, increasing reliance on the pre-formed radius. This can be accomplished by

using finer grades of silicon carbide for the epoxy removal and by replacing or even

eliminating the ferrule-forming step. The most current techniques use a three-step

process; epoxy removal, ferrule polishing and fiber polishing. This technique offers

higher levels of output while maintaining current performance standards, and results in

lower cost per connector.

Machine polishing is the only practical means available to meet the demands for

increased performance and production. To the extent that manual polishing can be

effective, it demands performance by highly skilled personnel (for a repetitive and

monotonous task), and, as the specifications become more difficult--SPC, UPC, APC--

manual polishing becomes an unreasonable (if not impossible) task. As in other "high

tech" fields, the ability of machines to perform repeatable ultra-precision tasks is the

answer.

As described above, a Polishing Machine should have good instructions and a "recipe"

for producing polished connectors that meet all specifications. There are a number of

variables, however, which affect the process, about which the industry continues to learn

and develop. It is important that the machine selected has the capability to incorporate

new developments and that the manufacturer keeps you informed and is available for

support and advice.

ADDITIONAL POLISHING TIPS & PROCESS CONSIDERATIONS

In some cases, the machine user will become aware of some factors that involve

variables other than the polisher itself. The following are a few items that are commonly

overlooked.

1. Polishing Films

2. Epoxy

3. Cleanliness

4. Lubrication

1. Polishing Films--Films are the most significant factor in your polishing

operations. Quality and gradations vary from supplier to supplier. When a

polishing technique is developed the film type, make and particle size must be

chosen carefully. Excessively aggressive films can destroy a 125m fiber, and

the spherical radius can be disrupted beyond repair. Also, of critical importance

to real cost, is the initial cost of the polishing film as it relates to the cycle life that

the films provide--this can vary significantly from various manufacturers.

Tip--Clean each piece of polishing film before and after each use. Cleanliness

(discussed below) will increase the film life and decrease the cost per connector.

2. Epoxy--different types of epoxies can be removed more easily with specific

grades of silicon carbide polishing films. The films to use on this step depend on

the epoxy type and the size of the epoxy bead mounted on the connector end-

face. Different epoxies have varying levels of hardness--some are tacky, and

some are firm--Hard epoxies are removed easily with coarser particle sized films

(20 um, 30 um, etc.), while softer epoxies are better suited to smaller particle

sized films, i.e. 9 um, 5 um, etc.

Tip--The epoxy bead that remains on the connector before polishing should be

minimized (the size of a pinhead). This will extend the life of all the polishing

films. Also, try different gradations of silicon carbide until you find the epoxy

removal film that works best for your needs.

3. Cleanliness--A contamination free environment is essential when an optimum

connector polish is desired. Five items are needed to minimize contamination:

1. Deionized/Filtered Water

2. Isopropyl Alcohol

3. Lint Free Tissues

4. Lint Free Swabs

5. Canned Air

Deionized/Filtered Water--Clean water is needed to prevent foreign

particles from destroying the polish. Tap water and other water sources,

contain particles (dirt) that can be as large as 15 microns. Debris of this

size will destroy a polished connector. Deionized or Filtered Water will

eliminate this possibility.

Isopropyl Alcohol--The alcohol should be used to clean the polishing

films, connectors, and the surrounding area (inside the automatic

polisher) before and after each polishing step. This will virtually eliminate

any particles or debris from transferring to the next polishing step.

Lint-free Tissues--The tissues will be used to apply the alcohol to the

films, connectors and machine. The tissues will also be used to dry the

connector end-face before the testing and inspection stage of the

polishing process.

Lint-free Swabs--Always clean the reference meters and couplers will

the swabs soaked in alcohol. Measuring instruments and coupling

devices are the most overlooked pieces of equipment when creating a

contamination free environment. Test equipment cleaning should

become a habit. Repeated use of these instruments will result in debris

build-up. If maintained properly, correct results can be assured with

confidence, not to mention trouble shooting poor performance will be

minimized.

Canned Air--This is very useful for removing debris from connector

couplers. It can also be used as a general cleaning agent to remove dust

from connectors, films or the workstation.

Tip--Check the reference cable end-face periodically for end-face defects.

Connecting and de-connecting will result in debris build-up over a period of time.

Clean the end-face with alcohol using a lint free tissue. Also, at some point in

time the reference will need to be re-polished. After repeated re-polishing the

reference cable will need to be replaced.

4. Lubrication--deionized water, filtered water and suspensions, when used

correctly

can result in enhanced connector performance. The best solutions have very

small particle sizes 20-60nm. The solution particle size should be at least half

the size of the final polishing film. Solutions are used to decrease Return Loss

by as much as 5dB. Be careful of colloidal based solutions. They tend to dry

quickly and can destroy a polish if it is not removed from the connector end-face

quickly. Also, place the solution is a dry area at room temperature. Guard

solutions from cold temperatures. Many solutions loose their ability to improve

performance as they become more solid (dense).

Tip--Dilute the solution. Any range of 2 to 5 parts filtered/deionized water to one

part solution may improve your performance.

You might also like

- Your Paint GuideDocument27 pagesYour Paint Guidemanox007No ratings yet

- Alcohol, Phenol and Ethers Digital Notes by Bharat PanchalDocument24 pagesAlcohol, Phenol and Ethers Digital Notes by Bharat Panchalzaid ansari86% (7)

- Symantec DLP 14.0 Admin GuideDocument1,569 pagesSymantec DLP 14.0 Admin GuideBerrezeg MahieddineNo ratings yet

- Choosing The Right Conformal Coating The Facts & MythsDocument4 pagesChoosing The Right Conformal Coating The Facts & Mythssdfdfs7253No ratings yet

- 3 - SWCC Specification M02 Polyethylene Coating Rev0Document30 pages3 - SWCC Specification M02 Polyethylene Coating Rev0EngineerSajidAlam100% (1)

- Waterborne Epoxy Curatives: High Performance. Low Emissions. Cost-EffectiveDocument12 pagesWaterborne Epoxy Curatives: High Performance. Low Emissions. Cost-EffectiverafchemNo ratings yet

- Robinair Bombas de Vacío 15401 601Document32 pagesRobinair Bombas de Vacío 15401 601MarcWorld100% (1)

- Arkema - Polymer Selection Guide For Liquid ResinsDocument28 pagesArkema - Polymer Selection Guide For Liquid ResinsYoNo ratings yet

- Bgas PaintingDocument85 pagesBgas PaintingDandaman92% (12)

- Asset Integrity Management PDFDocument155 pagesAsset Integrity Management PDFBouazizizi MOHAMEDNo ratings yet

- Coating Failure Presentation 01 PDFDocument32 pagesCoating Failure Presentation 01 PDFravi00098No ratings yet

- Den-Jet Ce20 Bosuns Manual 2019Document24 pagesDen-Jet Ce20 Bosuns Manual 2019Dario MackevicsNo ratings yet

- Resin AmberliteDocument2 pagesResin Amberlitegreat_1No ratings yet

- Dictionar Tehnic General / General Technical Dictionary: Romana/RomanianDocument62 pagesDictionar Tehnic General / General Technical Dictionary: Romana/RomanianAma81100% (17)

- GAP-015 - Rev D (2015 - 06 - 02 18 - 24 - 57 UTC)Document2 pagesGAP-015 - Rev D (2015 - 06 - 02 18 - 24 - 57 UTC)Epuran Liviu100% (2)

- 04-Cisco IOS-XR Overview PDFDocument90 pages04-Cisco IOS-XR Overview PDFBerrezeg MahieddineNo ratings yet

- 04-Cisco IOS-XR Overview PDFDocument90 pages04-Cisco IOS-XR Overview PDFBerrezeg MahieddineNo ratings yet

- Sika ShotcreteDocument8 pagesSika Shotcretefivehours5No ratings yet

- Firewall and Ips Design GuideDocument106 pagesFirewall and Ips Design GuideBerrezeg MahieddineNo ratings yet

- GLV - Drum Filter (PGS) LR PDFDocument8 pagesGLV - Drum Filter (PGS) LR PDFSamuel MushakaNo ratings yet

- AF Range BrochureDocument27 pagesAF Range Brochureboom10100% (1)

- Basic Info About Glaze FormulationsDocument3 pagesBasic Info About Glaze FormulationsThongMaVanNo ratings yet

- Seikoh Giken Seikoh Giken SFP 550CDocument2 pagesSeikoh Giken Seikoh Giken SFP 550Csleh_sbiNo ratings yet

- Automobile Body Materials Trim and MechanicsDocument8 pagesAutomobile Body Materials Trim and MechanicsHarshdeepsinh Padhiyar100% (1)

- Pa 10Document3 pagesPa 10LymeParkNo ratings yet

- Wet Slurry Blasting: ESOH NeedDocument3 pagesWet Slurry Blasting: ESOH NeedSamsu SamsNo ratings yet

- Car Body Painting ProcessDocument10 pagesCar Body Painting Processviksriram6782100% (1)

- Nozzle PowderDocument6 pagesNozzle PowdersossieNo ratings yet

- 1 Fisa Tehnica 2618Document7 pages1 Fisa Tehnica 2618Royal KingNo ratings yet

- Jotafloor: Traffic Deck SystemDocument12 pagesJotafloor: Traffic Deck SystemUnited Construction Est. TechnicalNo ratings yet

- Phoenix Water Based PrimerDocument5 pagesPhoenix Water Based PrimerbooklandNo ratings yet

- Jotafloor Traffic Deck System BrochureDocument12 pagesJotafloor Traffic Deck System BrochurehutuguoNo ratings yet

- Polishing Process For Heatcure Fiber Optic Connectors: 1. GeneralDocument4 pagesPolishing Process For Heatcure Fiber Optic Connectors: 1. GeneralAbNo ratings yet

- Carboguard 635 Thinned 50% - Sealer PDSDocument5 pagesCarboguard 635 Thinned 50% - Sealer PDSjakeNo ratings yet

- Silicon Wafer Manufacturing ProcessDocument8 pagesSilicon Wafer Manufacturing ProcessNur SaheerahNo ratings yet

- 03 35 00epmDocument14 pages03 35 00epmHan RodriguezNo ratings yet

- ECP TRB - Hassan AhmedDocument9 pagesECP TRB - Hassan AhmedHasan AhmedNo ratings yet

- Diamond Seal VoxDocument2 pagesDiamond Seal Voxpravi3434No ratings yet

- Kodak AA400Document4 pagesKodak AA400bikkelbobNo ratings yet

- Protect PCB Moisture GuideDocument2 pagesProtect PCB Moisture Guidemuti_khan20006003No ratings yet

- How Is The Vehicle PaintedDocument11 pagesHow Is The Vehicle PaintedredaelwanNo ratings yet

- Use of KODAK Brown Toner To Extend The Life of MicrofilmDocument5 pagesUse of KODAK Brown Toner To Extend The Life of Microfilmsabo6181No ratings yet

- Cleaning Pcbs in Electronics: Understanding Today'S NeedsDocument37 pagesCleaning Pcbs in Electronics: Understanding Today'S NeedsDelenzy CinoNo ratings yet

- Vinyl Primer: Technical Data SheetDocument4 pagesVinyl Primer: Technical Data SheetkarthickNo ratings yet

- METALLIC COATING FOR METAL, FIBERGLASSDocument2 pagesMETALLIC COATING FOR METAL, FIBERGLASSHFNo ratings yet

- Coating AluminiumDocument9 pagesCoating AluminiumNadangol DangolNo ratings yet

- Source Approval Kataline Part 2Document13 pagesSource Approval Kataline Part 2Arun KumarNo ratings yet

- Basic Process Requirement For PPG PVDF Approval Applicator EN Phuoc EditedDocument10 pagesBasic Process Requirement For PPG PVDF Approval Applicator EN Phuoc EditedTheAnh TranNo ratings yet

- Carapace Emp 110 LdiDocument8 pagesCarapace Emp 110 Ldidenivaldo2009No ratings yet

- Technical Paper MER - Effect of Leached LayerDocument4 pagesTechnical Paper MER - Effect of Leached LayerDanashekar SelvarajNo ratings yet

- SikaflexPRO TdsDocument6 pagesSikaflexPRO TdsidontlikeebooksNo ratings yet

- Macropoxy C400V3Document2 pagesMacropoxy C400V3nellyNo ratings yet

- Government of India Specification for Materials Used in Liquid Penetrate ExaminationDocument10 pagesGovernment of India Specification for Materials Used in Liquid Penetrate ExaminationphanthanhhungNo ratings yet

- How To Clean A Circuit Board Without AlcoholDocument10 pagesHow To Clean A Circuit Board Without AlcoholjackNo ratings yet

- Marine PDFDocument578 pagesMarine PDFNizar BouchaalaNo ratings yet

- Catalogue RTV EVDocument8 pagesCatalogue RTV EVSamar RashidNo ratings yet

- Jotun Penguard Express CF TDSDocument5 pagesJotun Penguard Express CF TDSnihad_mNo ratings yet

- Air Filter Leaflet 2009Document2 pagesAir Filter Leaflet 2009karthikraja21No ratings yet

- KENT Brochure 1Document42 pagesKENT Brochure 1cesar ucedaNo ratings yet

- Metallography Lab Polishing and EtchingDocument7 pagesMetallography Lab Polishing and EtchingAyeshaSiddiqaNo ratings yet

- Leading Edge Semiconductor Wafer Surface Cleaning Technologies That Support The Next Generation of Semiconductor DevicesDocument4 pagesLeading Edge Semiconductor Wafer Surface Cleaning Technologies That Support The Next Generation of Semiconductor DevicesukalNo ratings yet

- Ngineering ATA: Protective Coating Guide For FansDocument7 pagesNgineering ATA: Protective Coating Guide For FansMohamed TahounNo ratings yet

- Tuff Stuff: Item #1284 & #1285Document3 pagesTuff Stuff: Item #1284 & #1285joeyNo ratings yet

- PVC, CPVC Solvent, Primer and CleanerDocument12 pagesPVC, CPVC Solvent, Primer and CleanerUmarSeddiqueNo ratings yet

- THE DRIVE OFF ROAD: THE FIRST REACH COMPLIANT PLATING ON PLASTIC FACILITY IN EUROPEDocument8 pagesTHE DRIVE OFF ROAD: THE FIRST REACH COMPLIANT PLATING ON PLASTIC FACILITY IN EUROPELukeNo ratings yet

- Electro CoatingDocument2 pagesElectro CoatingViswanathan SrkNo ratings yet

- Epoxy Coating 162 PWDocument2 pagesEpoxy Coating 162 PWANIBALLOPEZVEGANo ratings yet

- Nitoflor FC145: Constructive SolutionsDocument3 pagesNitoflor FC145: Constructive SolutionstalatzahoorNo ratings yet

- Eco - Crete Concrete Cleaner.Document2 pagesEco - Crete Concrete Cleaner.Hans JonesNo ratings yet

- Fiber Polishing Handbook1Document5 pagesFiber Polishing Handbook1Berrezeg MahieddineNo ratings yet

- 00 HadoopTrainingVM PDFDocument3 pages00 HadoopTrainingVM PDFBerrezeg MahieddineNo ratings yet

- DMD SystimaxDocument45 pagesDMD SystimaxBerrezeg MahieddineNo ratings yet

- Exomath 3apDocument96 pagesExomath 3apBerrezeg MahieddineNo ratings yet

- ISO/IEC 27002 Baseline Selection with Limited BudgetDocument55 pagesISO/IEC 27002 Baseline Selection with Limited BudgetBerrezeg MahieddineNo ratings yet

- Thales Training I3000 - 2Document1 pageThales Training I3000 - 2Berrezeg MahieddineNo ratings yet

- Alcatel-Lucent OmniPCX Office R7.1 Configuration GuideDocument11 pagesAlcatel-Lucent OmniPCX Office R7.1 Configuration GuideAdrian Petris100% (1)

- XST Bypasses Current Web Security Using TRACE and XSSDocument14 pagesXST Bypasses Current Web Security Using TRACE and XSSBerrezeg MahieddineNo ratings yet

- Asterisk - The Asterisk Handbook Version 2Document71 pagesAsterisk - The Asterisk Handbook Version 2Nobinel SuarezNo ratings yet

- TT - DLP Symantec PDFDocument22 pagesTT - DLP Symantec PDFBerrezeg MahieddineNo ratings yet

- Asterisk - The Asterisk Handbook Version 2Document71 pagesAsterisk - The Asterisk Handbook Version 2Nobinel SuarezNo ratings yet

- 2012 6th CodeEngn (Posquit0) Defcon 20th The Way To Go To LasVegasDocument141 pages2012 6th CodeEngn (Posquit0) Defcon 20th The Way To Go To LasVegasBerrezeg MahieddineNo ratings yet

- Sip Trunk Guide de Config r920 Tc1975en-Ed01Document28 pagesSip Trunk Guide de Config r920 Tc1975en-Ed01Berrezeg MahieddineNo ratings yet

- Extreme SIEM Admin GuideDocument304 pagesExtreme SIEM Admin GuideBerrezeg MahieddineNo ratings yet

- VOIP Basics Cheat SheetDocument1 pageVOIP Basics Cheat SheetDaniel Jiménez CórdovaNo ratings yet

- Forensics AppendicesDocument27 pagesForensics AppendicesBerrezeg MahieddineNo ratings yet

- Trixbox Without TearsDocument209 pagesTrixbox Without Tearsla9mechNo ratings yet

- $-Step Approach To SCADA SecurityDocument10 pages$-Step Approach To SCADA SecurityBerrezeg MahieddineNo ratings yet

- Advanced IPSLADocument92 pagesAdvanced IPSLABerrezeg MahieddineNo ratings yet

- Master Thesis - Jurica BabicDocument103 pagesMaster Thesis - Jurica BabicBerrezeg MahieddineNo ratings yet

- Electronic voting: current challenges and potential solutionsDocument9 pagesElectronic voting: current challenges and potential solutionsBerrezeg MahieddineNo ratings yet

- Administrator Guide For OpenQRM 5Document59 pagesAdministrator Guide For OpenQRM 5Muhammad IkbalNo ratings yet

- ForeScout-TechnicalBrief DeviceHostDetectionMethods 5.5.11Document8 pagesForeScout-TechnicalBrief DeviceHostDetectionMethods 5.5.11Berrezeg Mahieddine100% (1)

- Conception de La Securite 02-PrinciplesDocument52 pagesConception de La Securite 02-PrinciplesBerrezeg MahieddineNo ratings yet

- E-voting security lecture focuses on JCJ/Civitas systemDocument40 pagesE-voting security lecture focuses on JCJ/Civitas systemBerrezeg MahieddineNo ratings yet

- Ficha Tecnica Astm 514Document1 pageFicha Tecnica Astm 514Ruben Dario Mamani ArellanoNo ratings yet

- Preliminary Technical Program HMnS2016Document33 pagesPreliminary Technical Program HMnS2016manjumv27No ratings yet

- Metal ExerciseDocument3 pagesMetal ExercisemattyamaniNo ratings yet

- Act-70ga (Xla-60) TDSDocument1 pageAct-70ga (Xla-60) TDSFairmont Ind Quality DivisionNo ratings yet

- Nitoseal MS600 sealant for immersed conditionsDocument4 pagesNitoseal MS600 sealant for immersed conditionsmilanbrasinaNo ratings yet

- Load CalculationsDocument3 pagesLoad CalculationsWilkenn TuazonNo ratings yet

- Synthetic Oils: E-Books Download Weblog: Water Engineering WeblogDocument11 pagesSynthetic Oils: E-Books Download Weblog: Water Engineering WeblogalbertofgvNo ratings yet

- Atomic Absorption Analysis Cookbook Section 10 Analysis of Medicines and Biological SubstancesDocument42 pagesAtomic Absorption Analysis Cookbook Section 10 Analysis of Medicines and Biological SubstancesLe HuyNo ratings yet

- Inorganic Salt Analysis Record WritingDocument20 pagesInorganic Salt Analysis Record WritingDineshNo ratings yet

- Unit 5 InfographicsDocument1 pageUnit 5 Infographicsgwy jianNo ratings yet

- Introduction To Composite Materials (Laminated Composite Materials)Document60 pagesIntroduction To Composite Materials (Laminated Composite Materials)soma_durga6606No ratings yet

- PS1 Without AnswerDocument3 pagesPS1 Without Answerbrian galangNo ratings yet

- Nozzle Liners and Dip PipesDocument6 pagesNozzle Liners and Dip PipesHedi Ben MohamedNo ratings yet

- Quantitative Analysis of PGM Using XRFDocument6 pagesQuantitative Analysis of PGM Using XRFGrigorescuVeronica100% (1)

- Leaflet SPM and SOPDocument4 pagesLeaflet SPM and SOPAbdullah Al-ZahraniNo ratings yet

- Recent Patents On EngineeringDocument67 pagesRecent Patents On EngineeringmarcomtnNo ratings yet

- Railways: Mechanical Stabilisation of Track Ballast and Sub-BallastDocument12 pagesRailways: Mechanical Stabilisation of Track Ballast and Sub-BallastJohn Archie Dela CruzNo ratings yet

- Loctite 510™: Technical Data SheetDocument4 pagesLoctite 510™: Technical Data SheetYasser RezkNo ratings yet

- Aalco Metals LTD Copper Brass Bronze CW712R Naval Brass CZ112Document2 pagesAalco Metals LTD Copper Brass Bronze CW712R Naval Brass CZ112kriskee13No ratings yet

- Visco Elastic DamperDocument4 pagesVisco Elastic DampergauravNo ratings yet

- 1ST Law of ThermodynamicsDocument7 pages1ST Law of ThermodynamicsKen BorjaNo ratings yet

- Wheels EspecificationsDocument26 pagesWheels Especificationsdavid rosarioNo ratings yet