Professional Documents

Culture Documents

20160323014501-20MnCr5 - 20MnCrS5

Uploaded by

singaravelan narayanasamy0 ratings0% found this document useful (0 votes)

270 views1 pageMaterial Chemical composiion for 20MnCrS5

Original Title

20160323014501-20MnCr5 - 20MnCrS5 (1)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMaterial Chemical composiion for 20MnCrS5

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

270 views1 page20160323014501-20MnCr5 - 20MnCrS5

Uploaded by

singaravelan narayanasamyMaterial Chemical composiion for 20MnCrS5

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

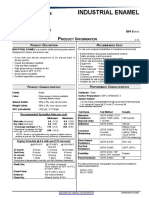

Material specification sheet

Saarstahl - 20MnCr5 - 20MnCrS5

Material No.: Former brand name: International steel grades:

1.7147 EC 100 BS:

AFNOR: 20MC5

1.7149 SAE: 5120

Material group: Case hardening steels according to DIN EN 10084

Chemical Steel C Si Mn Cr S other

composition:

(Typical analysis in %) 20MnCr5 0,20 0,25 1,25 1,15 <0,035 (Pb)

0,020

20MnCrS5 0,20 0,25 1,25 1,15 (Pb)

0,035

Application: Alloyed case hardening steel for parts with a required core tensile

strength of 1000 - 1300 N/mm and good wearing resistance as boxes,

piston bolts, spindles, camshafts, gears, shafts and other mechanical

controlling parts.

Hot forming and Forging or hot rolling: 1100 - 850C

heat treatment: Normalising: 840 - 870C/air

Soft annealing: 650 - 700C/furnace

Carburising: 880 - 980C

Core hardening: 860 - 900C/oil

Intermediate annealing: 650 - 700C

Case hardening: 780 - 820C/oil

Tempering: 150 - 200C

Mechanical Treated for cold shearability, +S: max. 255 HB

Properties: Soft annealed, +A: max. 217 HB

Treated for strength, +TH: 170 - 217 HB

Treated for ferrite and pearlite

structure and hardness range,

+FP: 152 - 201 HB

after hardening and tempering at 200C:

Diameter d [mm] d <= 16 16 <d <= 40 40 <d <= 100

Tensile strength Rm [N/mm] min. 1200 min. 1000 min. 800

You might also like

- Circlip For Bores-3075 - 2 PDFDocument12 pagesCirclip For Bores-3075 - 2 PDFRajasekaran MuruganNo ratings yet

- Trainee - Freshers Salary Breakup - HRDocument1 pageTrainee - Freshers Salary Breakup - HRAnuraagNo ratings yet

- Palm OilDocument8 pagesPalm OilAndy Wijaya HadrunNo ratings yet

- RGB Mounton Gear BoxDocument29 pagesRGB Mounton Gear BoxManojNo ratings yet

- Gearbox Instruction Manual: Control No.: GB-0207 - Rev 3.0Document19 pagesGearbox Instruction Manual: Control No.: GB-0207 - Rev 3.0Andre Brama AlvariNo ratings yet

- Tooth Gear SEW Linha KDocument7 pagesTooth Gear SEW Linha KSolver Manutenção IndustrialNo ratings yet

- Elecon Extruder Gear CatalogueDocument22 pagesElecon Extruder Gear CatalogueEnquiry Sg33% (3)

- Material Specification: Specification: Revision Date: Revision LevelDocument2 pagesMaterial Specification: Specification: Revision Date: Revision LevelReginaldo Santos100% (1)

- GOOGLEFINANCE - Docs Editors HelpDocument4 pagesGOOGLEFINANCE - Docs Editors HelpShakeel AhmedNo ratings yet

- PVC Granuels Making Machine-ChinaDocument12 pagesPVC Granuels Making Machine-Chinapratikgarg03No ratings yet

- Pen Brevini IndiaDocument1 pagePen Brevini Indiacia sin kwangNo ratings yet

- Book - Gears - IndiaDocument12 pagesBook - Gears - IndiadesetekNo ratings yet

- Equalent Material GradesDocument16 pagesEqualent Material GradesLesle GpNo ratings yet

- QAP-KGN-CIAL-001, Rev00Document2 pagesQAP-KGN-CIAL-001, Rev00iftekhar ahmedNo ratings yet

- Bs 970 Steel Numbers 1955 1991Document4 pagesBs 970 Steel Numbers 1955 1991sarath6725No ratings yet

- Zoho and Google Sheets IntegrationDocument11 pagesZoho and Google Sheets IntegrationAbhishek RastogiNo ratings yet

- Pristine Glory SDN BHD (353246-W) : Production FormDocument2 pagesPristine Glory SDN BHD (353246-W) : Production FormIkhwan AzizieNo ratings yet

- Spare Parts Catalogue: Gear ReducersDocument44 pagesSpare Parts Catalogue: Gear ReducersAio JumaNo ratings yet

- Is 14329 1995 PDFDocument13 pagesIs 14329 1995 PDFSriram Subramanian100% (1)

- 1570 (Part II)Document20 pages1570 (Part II)Kaushik SenguptaNo ratings yet

- SWRCH18A Steel DatasheetDocument2 pagesSWRCH18A Steel DatasheetHari SuthanNo ratings yet

- RFQ of C45 SteelDocument3 pagesRFQ of C45 Steelnhirpara1No ratings yet

- New Operator Training ManualDocument35 pagesNew Operator Training ManualBharat ChakravartinNo ratings yet

- Material Standards for Chinese Chemical and Mechanical AnalysisDocument2 pagesMaterial Standards for Chinese Chemical and Mechanical AnalysisHakim 'n BilalNo ratings yet

- National Standard for Eyelet Bolts GB 799-88Document6 pagesNational Standard for Eyelet Bolts GB 799-88zalabiNo ratings yet

- Shell Permeability PresentationDocument29 pagesShell Permeability Presentationbilalabbasi1990No ratings yet

- 1 Updated Section E - AxleDocument58 pages1 Updated Section E - AxleNibin OdukkathilNo ratings yet

- Stock Specifications - Plates - S355G10 MDocument2 pagesStock Specifications - Plates - S355G10 Macadjournals. comNo ratings yet

- Hammer Drive ScrewDocument1 pageHammer Drive ScrewNisa BN QANo ratings yet

- Application Blank FormDocument5 pagesApplication Blank FormSaiNo ratings yet

- ISOGradeDocument28 pagesISOGradeleo83No ratings yet

- Case-Hardening Steels RM16-RM16Pb Technical Data SheetDocument2 pagesCase-Hardening Steels RM16-RM16Pb Technical Data SheetJerzy RistujczinNo ratings yet

- Iso AnnealingDocument2 pagesIso AnnealingPurushottam Sutar100% (1)

- DATA SHEET Industrial Enamel BlancoDocument4 pagesDATA SHEET Industrial Enamel BlancoAlfredo OrellanaNo ratings yet

- Blackodizing CPDocument1 pageBlackodizing CPx yNo ratings yet

- Metric Insert Catalog SectionDocument4 pagesMetric Insert Catalog SectionvaseaNo ratings yet

- X65Cr13 C 0.58 - 0.70 CR 12.50 - 14.50 S Max. 0.015Document2 pagesX65Cr13 C 0.58 - 0.70 CR 12.50 - 14.50 S Max. 0.015Jim SmithNo ratings yet

- 16.0 Grade Wise Chemical CompositionDocument29 pages16.0 Grade Wise Chemical CompositionrohitNo ratings yet

- Jis G 0701 PDFDocument23 pagesJis G 0701 PDFNav TalukdarNo ratings yet

- Equivalent Grades and their Chemical CompositionDocument1 pageEquivalent Grades and their Chemical Compositionmini p shendeNo ratings yet

- Rivers of India PDFDocument1 pageRivers of India PDFV A Prem KumarNo ratings yet

- Bogie Technical RequirementsDocument8 pagesBogie Technical RequirementsAmit shahNo ratings yet

- John Deere Design, Process, and Assembly ReviewDocument33 pagesJohn Deere Design, Process, and Assembly ReviewcucuNo ratings yet

- SIS-S 501 50 AG Hot Rolled Steel Rounds (Up To Dia 180mm)Document5 pagesSIS-S 501 50 AG Hot Rolled Steel Rounds (Up To Dia 180mm)Rajoo PrajapatiNo ratings yet

- Hes B008-03 Hexagon NutsDocument5 pagesHes B008-03 Hexagon NutsPreetam KumarNo ratings yet

- Parallel Key Calculation According To DIN 6892Document21 pagesParallel Key Calculation According To DIN 6892zahirshah1436923No ratings yet

- Steel grade 1.2312 propertiesDocument4 pagesSteel grade 1.2312 propertiesFrancisco CarrascoNo ratings yet

- C43Document1 pageC43rudramansingh123No ratings yet

- PARAMAX NEW Copy Rev2Document281 pagesPARAMAX NEW Copy Rev2Waris La Joi WakatobiNo ratings yet

- Controlling Heat Treatment Distortion in Gear Rings - MachineMfgDocument37 pagesControlling Heat Treatment Distortion in Gear Rings - MachineMfgxiao mingNo ratings yet

- BS 970-3 1991 PDFDocument38 pagesBS 970-3 1991 PDFNav TalukdarNo ratings yet

- JIS B 2711-2005 Shot PeeningDocument30 pagesJIS B 2711-2005 Shot PeeningtsengccNo ratings yet

- Salt Bath FurnaceDocument7 pagesSalt Bath FurnacehavejsnjNo ratings yet

- Corewire Weldclad 01 PDFDocument31 pagesCorewire Weldclad 01 PDFRaviTeja BhamidiNo ratings yet

- Top stainless steel grades comparison chartDocument1 pageTop stainless steel grades comparison chartRajput PratiksinghNo ratings yet

- Bearing, Roller, Thrust, Two Channeled Race Surface, Rigid or Flat Seat TypeDocument4 pagesBearing, Roller, Thrust, Two Channeled Race Surface, Rigid or Flat Seat TypeAhmad Zubair RasulyNo ratings yet

- JSG 0116-1996Document158 pagesJSG 0116-1996Loknath MathnikarNo ratings yet

- Bluefracturemnm 2018Document8 pagesBluefracturemnm 2018Gomathi RNo ratings yet

- 20160323014547-16MnCr5 - 16MnCrS5Document1 page20160323014547-16MnCr5 - 16MnCrS5Chaitanya DattaNo ratings yet

- 20160401114119-6566 6569 6571 17NiCrMo64 17NiCrMoS64 20NiCrMoS64Document1 page20160401114119-6566 6569 6571 17NiCrMo64 17NiCrMoS64 20NiCrMoS64Önder YontarNo ratings yet

- IS-1730 1989 Reff2019Document11 pagesIS-1730 1989 Reff2019singaravelan narayanasamyNo ratings yet

- IS 1852 - 1985 - Reff2022Document28 pagesIS 1852 - 1985 - Reff2022singaravelan narayanasamy100% (1)

- IS 1173 - 1978 - Reff2019Document9 pagesIS 1173 - 1978 - Reff2019singaravelan narayanasamyNo ratings yet

- Astm A193-2020Document14 pagesAstm A193-2020singaravelan narayanasamyNo ratings yet

- Is 9879-1998 (Ra-2021)Document8 pagesIs 9879-1998 (Ra-2021)singaravelan narayanasamyNo ratings yet

- WCS 15 - Rev 4 Updations-15.02.2016 - Final Uploaded To DMSDocument9 pagesWCS 15 - Rev 4 Updations-15.02.2016 - Final Uploaded To DMSsingaravelan narayanasamyNo ratings yet

- Chemical and Mechanical Test Results for Cast Iron ComponentsDocument4 pagesChemical and Mechanical Test Results for Cast Iron Componentssingaravelan narayanasamyNo ratings yet

- ASTM A194-A194M-20aDocument12 pagesASTM A194-A194M-20aViviana Leon100% (8)

- INTERNET STANDARDSDocument18 pagesINTERNET STANDARDSDawn HaneyNo ratings yet

- Astm F606.F606M-2021Document19 pagesAstm F606.F606M-2021singaravelan narayanasamyNo ratings yet

- Astm A262-2015 (R2021)Document20 pagesAstm A262-2015 (R2021)singaravelan narayanasamyNo ratings yet

- Astm E1077-2021Document10 pagesAstm E1077-2021Anonymous tIwg2AyNo ratings yet

- Pulley PartsDocument3 pagesPulley Partssingaravelan narayanasamyNo ratings yet

- Methods of Samrling and Test For Paints, VarnishesDocument9 pagesMethods of Samrling and Test For Paints, Varnishessingaravelan narayanasamyNo ratings yet

- Q/Lam&Ijfiij E@ Rmf5 ?M - : Fa-DwDocument5 pagesQ/Lam&Ijfiij E@ Rmf5 ?M - : Fa-Dwsingaravelan narayanasamyNo ratings yet

- Din en Iso 7090 PDFDocument8 pagesDin en Iso 7090 PDFsingaravelan narayanasamyNo ratings yet

- Is 8811-1998 (Ra-2018)Document8 pagesIs 8811-1998 (Ra-2018)singaravelan narayanasamy100% (1)

- Methods For'Measuring Case Depth of Steel: Indian StandardDocument7 pagesMethods For'Measuring Case Depth of Steel: Indian Standardsingaravelan narayanasamyNo ratings yet

- 23-Grade 8.8 Bolt & Nut (Iso)Document1 page23-Grade 8.8 Bolt & Nut (Iso)anoordheen100% (2)

- Is 513 2016Document16 pagesIs 513 2016santosh kumar50% (14)

- LSS - 04 - 19 - 20 - 060419 PDFDocument1 pageLSS - 04 - 19 - 20 - 060419 PDFsingaravelan narayanasamyNo ratings yet

- ASTM E1251 2017 Ver A PDFDocument10 pagesASTM E1251 2017 Ver A PDFaizaz65No ratings yet

- Aluminium Alloy Ingots PDFDocument1 pageAluminium Alloy Ingots PDFsingaravelan narayanasamyNo ratings yet

- Hardox 400 UkDocument2 pagesHardox 400 Uksingaravelan narayanasamyNo ratings yet

- A940Document4 pagesA940singaravelan narayanasamyNo ratings yet

- 080m40 En8 BlackDocument3 pages080m40 En8 BlackAbhishek SharmaNo ratings yet

- E 123 - 02 - RteymwDocument5 pagesE 123 - 02 - Rteymwsingaravelan narayanasamyNo ratings yet

- Hardox 400 UkDocument2 pagesHardox 400 Uksingaravelan narayanasamyNo ratings yet

- A 498 - 98 Qtq5oc1sruqDocument4 pagesA 498 - 98 Qtq5oc1sruqsingaravelan narayanasamyNo ratings yet

- Cold Rolled Steel Sheets SpecificationDocument10 pagesCold Rolled Steel Sheets Specificationsingaravelan narayanasamyNo ratings yet

- ASTM's Steel Standards GuideDocument63 pagesASTM's Steel Standards GuideNagarjun ReddyNo ratings yet

- Reinforced Brickwork Strengths and UsesDocument35 pagesReinforced Brickwork Strengths and Usesthushara100% (1)

- Improving The Quality and Durability of Restorative Coatings by Arc Deposition and Modification With Natural Additive Bentonite ClayDocument8 pagesImproving The Quality and Durability of Restorative Coatings by Arc Deposition and Modification With Natural Additive Bentonite ClayVelumani sNo ratings yet

- Spot WeldDocument8 pagesSpot Weld0502raviNo ratings yet

- Bud Chpper Machine DetailsDocument18 pagesBud Chpper Machine DetailsSanket Malunje100% (1)

- H44H Check ValveDocument3 pagesH44H Check ValveMoon RdrNo ratings yet

- Mahalaxmi Quality Plan For FabricationDocument1 pageMahalaxmi Quality Plan For FabricationAnonymous RXXdbl36ANo ratings yet

- Sutherland S Handbook For Bicycle Mechanics 6th EditionDocument593 pagesSutherland S Handbook For Bicycle Mechanics 6th Editionstarengineer3473100% (7)

- Is 316 Stainless Steel Worth The Extra Cost Over 304?Document11 pagesIs 316 Stainless Steel Worth The Extra Cost Over 304?francisNo ratings yet

- Historical Industry OverviewDocument2 pagesHistorical Industry OverviewSyed FaridNo ratings yet

- Iso 3834-5 - 2015Document14 pagesIso 3834-5 - 2015raghulramasamy100% (1)

- Analysis of Current Problems Caused by Localized Corrosion. Study of Their Idustrial Impact and Proposals For ActionDocument164 pagesAnalysis of Current Problems Caused by Localized Corrosion. Study of Their Idustrial Impact and Proposals For ActionRuth Noemi Ballena GuerreroNo ratings yet

- ArcelorMittal SWOT AnalysisDocument2 pagesArcelorMittal SWOT AnalysisUmer RazzaqNo ratings yet

- WQT Visual Inspection Report ASTRON-22Document1 pageWQT Visual Inspection Report ASTRON-22sasikumarNo ratings yet

- Katalog ARITA - 2019Document68 pagesKatalog ARITA - 2019Sugeng Arief Van'tbowoNo ratings yet

- Home Work 01 - 1106071643Document3 pagesHome Work 01 - 1106071643Rifqi AdzkaroNo ratings yet

- Effect of Drawing Angle Size of A Die On Wire Drawing and Bunching ProcessDocument6 pagesEffect of Drawing Angle Size of A Die On Wire Drawing and Bunching ProcessRaghavendra BetakerurNo ratings yet

- METALLURGICAL DAMAGE MECHANISM AND ASSESSMENTDocument61 pagesMETALLURGICAL DAMAGE MECHANISM AND ASSESSMENTSACHIN PETKARNo ratings yet

- Paper & Board Machine Doctoring Training CourseDocument32 pagesPaper & Board Machine Doctoring Training Coursetao dao ngocNo ratings yet

- Grove G9 Wafer Gate ValveDocument9 pagesGrove G9 Wafer Gate Valvetxlucky80No ratings yet

- GMAW Butt Joint Project ReportDocument43 pagesGMAW Butt Joint Project ReportahmedNo ratings yet

- HGFGHDocument21 pagesHGFGHajit1130No ratings yet

- Design Guide Galvanized Steel StructuresDocument28 pagesDesign Guide Galvanized Steel StructuresLuis MundacaNo ratings yet

- Outokumpu Semifinished MaterialsDocument12 pagesOutokumpu Semifinished MaterialsvgestantyoNo ratings yet

- Asme Section Ix-Welding - Practice Quest PDFDocument3 pagesAsme Section Ix-Welding - Practice Quest PDFRajesh KumarNo ratings yet

- Investors PDF Investor Presentation Apr 2011Document136 pagesInvestors PDF Investor Presentation Apr 2011Deepak SinghNo ratings yet

- Product List: Agglomerated Flux (/Product/Agglomerated-Flux/)Document5 pagesProduct List: Agglomerated Flux (/Product/Agglomerated-Flux/)ArfanAliNo ratings yet

- Certificate: Shri Leeladhar Pal, JR - Officer Plate Mill (Elect.), Bhilai Steel Plant, BhilaiDocument51 pagesCertificate: Shri Leeladhar Pal, JR - Officer Plate Mill (Elect.), Bhilai Steel Plant, BhilaiAditya SinghNo ratings yet

- 2017 - Lin - Pyrometallurgical Recycling of Electric Arc Furnace DustDocument92 pages2017 - Lin - Pyrometallurgical Recycling of Electric Arc Furnace DustNancy Carolina Prieto MartinezNo ratings yet

- CastroLHD-AGBE2613-Machine Design-Assesment 1Document3 pagesCastroLHD-AGBE2613-Machine Design-Assesment 1Lee CastroNo ratings yet