Professional Documents

Culture Documents

Hardness Testing Notes

Uploaded by

JohnOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hardness Testing Notes

Uploaded by

JohnCopyright:

Available Formats

Hardness Testing

GENERAL

Hardness is not a bulk property of a material so hardness values are

arbitrary and have no standards of hardness.

Macro, micro, and nano tests are used to measure hardness of a material.

Macro is a larger measurement for bulk properties and is not suitable for

surface hardness or coatings like in the case of my research.

Micro indenting often done by Vickers or Knoop indenter is best for surface

hardness in my problem.

I. A tip is pressed into the sample

II. Constant measuring of applied load, penetration depth, and cycle time

Nano indentation usually involves very small indentation forces on the order

of nano-Newtons.

Typically used in the metal industry for accuracy are the Brinnell, Rockwell,

and Vickers hardness tests.

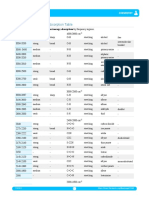

ROCKWELL HARDNESS TEST

ASTM Standard E 18, Standard Test Methods for Rockwell Hardness of

Metallic Materials.

Different scales available and has no units. However, the higher the number

in the relative scales indicates a harder material. According to University of

Maryland, the Rockwell hardness test is the most used and versatile of the

tests. For soft materials such as aluminum alloys, a 1/16 steel ball with a

100 kg load is used and the results are read from the B scale.

Measures difference between depth of first indent, minor indent (Used at

smaller load to seat the indenter correctly) and the second indent, major

indent (Heavy Load). It measures depth of immersion.

Reading Rockwell hardness numbers is done like so: 60 HRB stands for a

Rockwell Hardness of 60 on the B scale.

BRINNELL HARDNESS TEST (ASTM E-10?)

Does measurements by pressing a known diameter steel ball into the

surface under a known load and then measuring the diameter of the

resulting indentation. Numbers produced are found by dividing the load in

kg by the surface area of the indentation in mm^2. Unit is a pressure

measurement and units arent often used but are described as the Brinnell

Number. Typical loads for cast aluminum is 1500 kg and 3000 kg for iron

and steel for about 10-15 seconds.

Reading Brinnell hardness is done like so: 75 HB 10/500/30 stands for a

Brinnell Hardness of 75 was obtained used a 10 mm diameter ball with a

500 kg load for 30 seconds.

Brinnell tests make the largest and widest indentations so the test covers a

larger amount of material which will account for multiple grain structures,

irregularities, and more grains.

VICKERS HARDNESS TEST

Vickers is the standard for measuring hardness of metals, particularly

metals with extremely hard surfaces. A pyramid-shaped diamond tip is used

as the indenter.

Advantages of the Vickers hardness test is that there are no arbitrary

scales, measurements of indentations are more accurate, all measurements

are used with the same indenter.

KNOOP HARDNESS TEST

Similar to the Vickers hardness test but alls the hardness testing of brittle

materials.

http://www.calce.umd.edu/TSFA/Hardness_ad_.htm

Considerations for my selection of a hardness test:

Surface Finish - If I polish my surface then I lose some of the residual

stress from my casting. Brinnell and Rockwell need a smooth surface, not

necessarily polished.

You might also like

- Mohs Hardness TestDocument3 pagesMohs Hardness TestSelva KumarNo ratings yet

- Rockwell Hardness Test MethodDocument5 pagesRockwell Hardness Test MethodAnonymous gFcnQ4goNo ratings yet

- Hardness TestDocument8 pagesHardness TestFakhrul MuizzNo ratings yet

- Eng 45 Lab 2Document6 pagesEng 45 Lab 2Anonymous qOXAfbUONo ratings yet

- Vicker HardnessDocument3 pagesVicker HardnessEhsanulhaq786100% (1)

- Vickers Hardness Test Machine GuideDocument2 pagesVickers Hardness Test Machine GuideurwakhanNo ratings yet

- Tensile Test Lab 1Document30 pagesTensile Test Lab 1hanser100% (1)

- Engineering Lab Report StructureDocument7 pagesEngineering Lab Report StructureSana ButtNo ratings yet

- Brinell Hardness Test-2Document3 pagesBrinell Hardness Test-2addiwate67% (3)

- Digital Universal Hardness Tester BRV-187.5TDocument5 pagesDigital Universal Hardness Tester BRV-187.5T周记伟No ratings yet

- Lab7 Fatigue Testing MachineDocument13 pagesLab7 Fatigue Testing MachineHosam0% (1)

- Powder Metallurgy Process GuideDocument28 pagesPowder Metallurgy Process GuideAravindhan AnbalaganNo ratings yet

- JF 302 - Material Technology 1Document18 pagesJF 302 - Material Technology 1Arif AzizAnNo ratings yet

- Torsion TestDocument4 pagesTorsion TestankitsuchantiNo ratings yet

- Hardness Testing of Metallic MaterialsDocument4 pagesHardness Testing of Metallic MaterialsAshan Marambe100% (1)

- Nano-Mechanics and Thermal Phenomena at the Indian Institute of Technology RoorkeeDocument50 pagesNano-Mechanics and Thermal Phenomena at the Indian Institute of Technology RoorkeeAnkit VermaNo ratings yet

- Ceramics Tech #ElectroceramicsDocument51 pagesCeramics Tech #Electroceramicsnawa100% (2)

- Vickers Hardness TestDocument9 pagesVickers Hardness TestMazlin AzuraNo ratings yet

- Uniaxial TestDocument6 pagesUniaxial Testanil chejaraNo ratings yet

- Stress Intensity Factor and Fracture Toughness TestingDocument31 pagesStress Intensity Factor and Fracture Toughness TestingShahrul Azmin0% (1)

- Corrosion Measurement UNIT-5: CHE-545-172 DR Ime B.ObotDocument48 pagesCorrosion Measurement UNIT-5: CHE-545-172 DR Ime B.ObotArielNo ratings yet

- Basic Electrical Engineering LabDocument1 pageBasic Electrical Engineering LabchaitanyaNo ratings yet

- 11 Heat TreatmentDocument5 pages11 Heat TreatmentamokhtaNo ratings yet

- 1.0 TitleDocument10 pages1.0 TitlezackziffiNo ratings yet

- Impact Test Measures Material Toughness in 40 CharactersDocument5 pagesImpact Test Measures Material Toughness in 40 CharactersKamal JayarajNo ratings yet

- Recovery, Recrystallization, and Grain GrowthDocument12 pagesRecovery, Recrystallization, and Grain GrowthstevenwhittlNo ratings yet

- Week 10 - WeldingDocument133 pagesWeek 10 - WeldingFattihi EkhmalNo ratings yet

- Research On Tensile Testing of MaterialsDocument25 pagesResearch On Tensile Testing of MaterialskenechidukorNo ratings yet

- What Is The Difference Between The Hardness, Toughness, Resilience, and Stiffness of Materials - QuoraDocument5 pagesWhat Is The Difference Between The Hardness, Toughness, Resilience, and Stiffness of Materials - QuoraUdit AgarwalNo ratings yet

- Testing and Evaluation of Engineering MaterialsDocument5 pagesTesting and Evaluation of Engineering MaterialsFAHED AYYAD100% (1)

- Hardness TestDocument12 pagesHardness TestLola MeerazNo ratings yet

- Lab ManualDocument62 pagesLab ManualKhalid M. Hafez100% (1)

- Tensile TestDocument15 pagesTensile TestLilac ClassNo ratings yet

- Ce3481 Set1Document3 pagesCe3481 Set1THIRUMALAINo ratings yet

- Engineering Materials Lab ManualDocument14 pagesEngineering Materials Lab ManualHarood Nishat100% (1)

- HHP.fflo~.f..tpoo/'W S'06: 1 FN:AN201lAD301(1401Document14 pagesHHP.fflo~.f..tpoo/'W S'06: 1 FN:AN201lAD301(1401Bipin BabuNo ratings yet

- Engineering Plasticity: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionFrom EverandEngineering Plasticity: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNo ratings yet

- Deformation & StrengthDocument35 pagesDeformation & StrengthcolorofstoneNo ratings yet

- Chapter2 - AJMDocument13 pagesChapter2 - AJMravish kumarNo ratings yet

- ME2151 2 Metallography Lab 12/oct/2015Document8 pagesME2151 2 Metallography Lab 12/oct/2015Angelique PorterNo ratings yet

- Microstructure AnalysisDocument4 pagesMicrostructure AnalysissgarrabNo ratings yet

- Machine Design Tutorial Sheet QuestionsDocument3 pagesMachine Design Tutorial Sheet Questionsabhishek chaurasiyaNo ratings yet

- Three Point Bend TestDocument3 pagesThree Point Bend TestShreyansh Shukla100% (1)

- Impact TestDocument8 pagesImpact TestRashid Mehmood100% (1)

- Iugaza Tom2012 - CH1-5 PDFDocument95 pagesIugaza Tom2012 - CH1-5 PDFaaima malikNo ratings yet

- ME3112-1 Lab Vibration MeasurementDocument8 pagesME3112-1 Lab Vibration MeasurementLinShaodunNo ratings yet

- SDQADocument4 pagesSDQAyaadhaviNo ratings yet

- Resistance WeldingDocument4 pagesResistance WeldingAjith GanjiNo ratings yet

- Forging Lab PresentationDocument39 pagesForging Lab PresentationAlpkan YılmazNo ratings yet

- Numerical in Electrical, Mechanical, Electronic, Optical Materials From Different Books Along With Previous Year Papers of GATE, ES, CS and Other Exams.Document24 pagesNumerical in Electrical, Mechanical, Electronic, Optical Materials From Different Books Along With Previous Year Papers of GATE, ES, CS and Other Exams.Rehan Sharma100% (1)

- Materials Engineering: Proceedings of the First International Symposium, University of the Witwatersrand, Johannesburg, South Africa, November 1985From EverandMaterials Engineering: Proceedings of the First International Symposium, University of the Witwatersrand, Johannesburg, South Africa, November 1985J. V. BeeNo ratings yet

- Ashok Leyland Placement PaperDocument57 pagesAshok Leyland Placement PaperPriyanka NegiNo ratings yet

- Material Lab Manual Experiments January2016 1Document47 pagesMaterial Lab Manual Experiments January2016 1gosaye desalegn100% (2)

- Toughness TestDocument25 pagesToughness TestNehaJainNo ratings yet

- Crystal Defects: Types, Origins and Impact on Material PropertiesDocument21 pagesCrystal Defects: Types, Origins and Impact on Material PropertiesAbhijeet Singh KatiyarNo ratings yet

- Bonding and Properties 2018 PDFDocument31 pagesBonding and Properties 2018 PDFJackNo ratings yet

- LAB NOTES ON STRUCTURAL BUCKLINGDocument11 pagesLAB NOTES ON STRUCTURAL BUCKLINGYousif SaidNo ratings yet

- Seismic Migration: Imaging of Acoustic Energy by Wave Field ExtrapolationFrom EverandSeismic Migration: Imaging of Acoustic Energy by Wave Field ExtrapolationNo ratings yet

- NIINOMI - Dissolution of Ferrous Alloys Into Molten AluminumDocument8 pagesNIINOMI - Dissolution of Ferrous Alloys Into Molten AluminumJohnNo ratings yet

- CHENG - Effect of Silicon On The Formation of Intermetallic Phases in Aluminide Coating On Mild SteelDocument6 pagesCHENG - Effect of Silicon On The Formation of Intermetallic Phases in Aluminide Coating On Mild SteelJohnNo ratings yet

- UCHIDA - Effects of Si in Coating Bath On The Reaction Between Molten Aluminum and Steel SheetDocument7 pagesUCHIDA - Effects of Si in Coating Bath On The Reaction Between Molten Aluminum and Steel SheetJohnNo ratings yet

- An - Effect of Si On The Interfacial Bonding Strength of Al-Pb Alloy Strips and Hot Dip Aluminized Steel Sheets by Hot RollingDocument7 pagesAn - Effect of Si On The Interfacial Bonding Strength of Al-Pb Alloy Strips and Hot Dip Aluminized Steel Sheets by Hot RollingJohnNo ratings yet

- Influence of Ambient Air and Different Surface Treatments On The Bonding Performance of A CAD CAM Composite Block. Alghamdi Ali. 2018. J Adhes DentDocument8 pagesInfluence of Ambient Air and Different Surface Treatments On The Bonding Performance of A CAD CAM Composite Block. Alghamdi Ali. 2018. J Adhes DentValeria CrespoNo ratings yet

- Disperse BoyamaDocument11 pagesDisperse Boyamasedat kumartaşlıNo ratings yet

- Pharmacognosy Lecture # 5+6 (Tannins) (By, Sir Tanveer Khan)Document31 pagesPharmacognosy Lecture # 5+6 (Tannins) (By, Sir Tanveer Khan)Arslan Abdullah85% (13)

- 0620 s19 QP 22 PDFDocument20 pages0620 s19 QP 22 PDFShemelis AragawNo ratings yet

- Thermodynamics and Kinetics of Water-Rock Interaction. Reviews in Mineralogy and GeochemistryDocument586 pagesThermodynamics and Kinetics of Water-Rock Interaction. Reviews in Mineralogy and GeochemistryFikri Adam Dermawan100% (1)

- Phase Transfer CatalystDocument6 pagesPhase Transfer CatalystPMH100% (3)

- An Evaluation of Desulfurization Technologies For Sulfur Removal From Liquid FuelsDocument25 pagesAn Evaluation of Desulfurization Technologies For Sulfur Removal From Liquid FuelsManoj KumarNo ratings yet

- Jcpds CardDocument148 pagesJcpds CardSanchit100% (3)

- Redken Color HandbookDocument40 pagesRedken Color HandbookVane Vane100% (3)

- Determination of Sugar Alcohols in Confectioneries byDocument6 pagesDetermination of Sugar Alcohols in Confectioneries byxacvierNo ratings yet

- Lab 3Document6 pagesLab 3Anonymous eGc6IFJc8GNo ratings yet

- Vinyl Ester ThesisDocument7 pagesVinyl Ester Thesisbethhalloverlandpark100% (2)

- Lecture 22Document16 pagesLecture 22imania shaumiNo ratings yet

- Filtration Control: Potential Problems From Excessive Filtrate InvasionDocument21 pagesFiltration Control: Potential Problems From Excessive Filtrate InvasionHanif Budhi CundomanikNo ratings yet

- Discover the functions and properties of lipids through experimentsDocument8 pagesDiscover the functions and properties of lipids through experimentsJasper Ian Tan JumalaNo ratings yet

- Effect of Thermal Pasteurization and Concentration OnDocument5 pagesEffect of Thermal Pasteurization and Concentration OnAmparitoxNo ratings yet

- Tablas de Nomenclatura Con S N PDocument13 pagesTablas de Nomenclatura Con S N PLucero RamirezNo ratings yet

- Determination of Hardness of WaterDocument2 pagesDetermination of Hardness of WaterNitinSrivastavaNo ratings yet

- Bảng phổ IRDocument5 pagesBảng phổ IRĐan KhanhNo ratings yet

- Thermochemical Conversion of Plastic Waste Into Fuels, Chemicals, and Value-Added Materials: A Critical Review and OutlooksDocument39 pagesThermochemical Conversion of Plastic Waste Into Fuels, Chemicals, and Value-Added Materials: A Critical Review and OutlooksMohamed FateemNo ratings yet

- Nucleic AcidDocument28 pagesNucleic AcidStellar OutputsNo ratings yet

- Waste Water TreatmentDocument10 pagesWaste Water TreatmentOms LdnsNo ratings yet

- Armor Piercing Bullets With Sintered Carbide Cores PDFDocument137 pagesArmor Piercing Bullets With Sintered Carbide Cores PDFfogdartNo ratings yet

- Calvin CycleDocument6 pagesCalvin CycleAtika ZulfiqarNo ratings yet

- Multiple Choice Questions D AN BLOCKDocument11 pagesMultiple Choice Questions D AN BLOCKMahrishiShukla100% (1)

- Lesson A1 - States of Matter PDFDocument15 pagesLesson A1 - States of Matter PDFOsmany MadrigalNo ratings yet

- A-Sch 102 Introduction To Organic ChemistryDocument49 pagesA-Sch 102 Introduction To Organic ChemistryLes Chikadoras100% (1)

- Textile ProcessingDocument13 pagesTextile ProcessingSivaraj PadmanabanNo ratings yet

- Mole Concept Numericals For PracticeDocument1 pageMole Concept Numericals For PracticemayurbuddyNo ratings yet

- IOM 2017 (2074) Reexam With Solution 1 - 30Document6 pagesIOM 2017 (2074) Reexam With Solution 1 - 30IneshNo ratings yet