Professional Documents

Culture Documents

EN 3-2005 Example 001

Uploaded by

Antonius AjalahCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EN 3-2005 Example 001

Uploaded by

Antonius AjalahCopyright:

Available Formats

Software Verification

PROGRAM NAME: SAP2000

REVISION NO.: 0

EN 3-2005 Example 001

WIDE FLANGE MEMBER UNDER COMBINED COMPRESSION & BENDING

EXAMPLE DESCRIPTION

The frame object axial strengths are tested in this example considering in-plane

behavior only.

A continuous column is subjected to factored load N = 210 kN and My,Ed = 43

kN-m. This example was tested using the Eurocode 3-2005 steel frame design

code. The design capacities are compared with independent hand calculated

results.

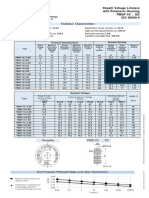

GEOMETRY, PROPERTIES AND LOADING

NEd

My,Ed

L

A A

Section A-A

L = 3.5 m

Material Properties Loading Design Properties

E = 210x103 MPa N = 210 kN fy = 235 MPa

v = 0.3 My,Ed = 43 kN-m Section: IPE 200

G = 80770 MPa

TECHNICAL FEATURES TESTED

Section compactness check (beam-column)

Member interaction capacities, D/C, Method 1

EN 3-2005 Example 001 - 1

Software Verification

PROGRAM NAME: SAP2000

REVISION NO.: 0

RESULTS COMPARISON

Independent results are taken from hand calculations based on the CSI steel

design documentation contained in the file SFD-EC-3-2005.pdf, which is

available through the program Help menu. This example was taken from "New

design rules in EN 1993-1-1 for member stability," Worked example 1 in section

5.2.1, page 151.

Percent

Output Parameter SAP2000 Independent Difference

Compactness Class 1 Class 1 0.00%

D/CAxial 0.334 0.334 0.00%

D/CBending 0.649 0.646 0.46%

COMPUTER FILE: EN 3-2005 EX001

CONCLUSION

The results show an acceptable comparison with the independent results.

EN 3-2005 Example 001 - 2

Software Verification

PROGRAM NAME: SAP2000

REVISION NO.: 0

HAND CALCULATION

Properties:

Material: S235

fy = 235 MPa

E = 210,000 MPa

G = 80,770 MPa

Section: IPE 200

A = 2848 mm2

h = 200 mm, bf = 100 mm, tf = 8.5 mm, tw = 5.6 mm, r = 12 mm

hw = h 2t f = 200 2 85 = 183mm

b f tw 2r 100 5.6 2 12

=c = = 35.2 mm

2 2

Iyy = 19,430,000 mm4

Wel,y = 194,300 mm3

Wpl,y = 220,600 mm3

Member:

Lyy = Lzz = 3,500 mm (unbraced length)

M 0 =

1

M1 =

1

y = 0.21

Loadings:

N Ed = 210, 000 N

M Ed , y ,Left = 0 N-m

M Ed , y ,Right = 43000 N-m

EN 3-2005 Example 001 - 3

Software Verification

PROGRAM NAME: SAP2000

REVISION NO.: 0

Section Compactness:

235 235

= = = 1

fy 235

1 N Ed

1 =

1 1

2 2htw f y

1 210, 000

=

1 = 0.6737

2 2 200 5.6 235

Localized Buckling for Flange:

For the tip in compression under combined bending and compression

9 9 1

cl .1 = = = 13.36

0.6737

c 35.2

e = = = 4.14

tf 8.5

=

e 4.14 < =

cl .1 13.36

So Flange is Class 1 in combined bending and compression

Localized Buckling for Web:

> 0.5, so

396 396 1

= = = 51.05 for combined bending & compression

13 1 13 0.6737 1

cl .1

d 183

e = = = 28.39

tw 5.6

=

e 32.68 < =

cl .1 51.05

So Web is Class 1 in combined bending and compression

Since Flange and Web are Class 1, Section is Class 1.

EN 3-2005 Example 001 - 4

Software Verification

PROGRAM NAME: SAP2000

REVISION NO.: 0

Section Compression Capacity:

N c , Rk = Af y = 2.848 103 235 106 = 669 kN

Member Compression Capacity:

2 EI 22 2 210000 106 19.43 106

=

N cr ,22 = = 3287 kN

L2 3.52

Section Bending Capacity:

M pl , y , Rk= W pl , y f y= 220.6 106 235 106= 51.8 kN-m

Interaction Capacities - Method 1:

Member Bending & Compression Capacity with Buckling

Compression Buckling Factors

Af y 2.858 103 235 106

=

y = = 0.451

N cr , y 3287 103

y 0.5 1 + y ( y 0.2 ) + =

= 2

y

0.5 1 + 0.21 ( 0.451 0.2 ) + 0.451

=2

0.628

1 1

=

y = = 0.939 1

y y ( y ) (

+ 2 2 0.628 + 0.6282 0.4512

)

Auxiliary Terms

N Ed

1 1

210

N cr , y 3287

=y = = 0.996

N Ed 210

1 y 1 0.939

N cr , y 3287

W pl , y 220.6 106

=

wy = = 1.135 1.5

Wel , y 194.3 106

EN 3-2005 Example 001 - 5

Software Verification

PROGRAM NAME: SAP2000

REVISION NO.: 0

Cmo Factor

M Ed , y ,right 0

=

y = = 0

M Ed , y ,left 43 103

0.79 + 0.21 y + 0.36 ( y 0.33)

N Ed

Cmy=

,0

N cr , y

210

Cmy =

,0 0.79 + 0.21 0 + 0.36 ( 0 0.33) = 0.782

3287

=

Cmy C=

my ,0 0.782 because no LTB is likely to occur.

Elastic-Plastic Bending Resistance

Because LTB is prevented, bLT = 0 so aLT = 0

1.6 N

1 + ( wy 1) 2

1.6

C yy = Cmy 2 22 Cmy 2 y 2 Ed bLT

wy wy N c , Rk

M1

1.6 1.6 210 10

3

1 + (1.135 1) 2

C yy = 0.7822 0.451 0.7822 0.4512 0

1.135 669 10

3

1.135

1.0

Wel , y 194.3 106

C yy = 1.061 = = 0.881

W pl , y 220.6 106

N Ed 210 103

=

D / CAxial =

N c , Rk 669 103

y 0.939

M1 1

D / CAxial = 0.334

EN 3-2005 Example 001 - 6

Software Verification

PROGRAM NAME: SAP2000

REVISION NO.: 0

Cmy M Ed , y ,right 0.782 43 10 3

D / CBending =

y =

0.996

210 10

3

51.8 10 3

1 N Ed C M pl , y , Rk 1 3

1.061

N cr , y yy M 1 3287 10 1

D / CBending = 0.646

D / CTotal = 0.980

EN 3-2005 Example 001 - 7

You might also like

- Screenshot 20200113-160914Document1 pageScreenshot 20200113-160914Antonius AjalahNo ratings yet

- Kuota BESI BOQ - ALL Unit (17 Unit) : No. Uraian Pekerjaan UnitDocument10 pagesKuota BESI BOQ - ALL Unit (17 Unit) : No. Uraian Pekerjaan UnitAntonius AjalahNo ratings yet

- 4.Best Practise EloquentGitHub - Alexeymezenin_eloquent-SQL-reference_ SQL Queries Generated by Eloquent ORM ReferenceDocument11 pages4.Best Practise EloquentGitHub - Alexeymezenin_eloquent-SQL-reference_ SQL Queries Generated by Eloquent ORM ReferenceAntonius AjalahNo ratings yet

- ThesisAA PDFDocument48 pagesThesisAA PDFziror11No ratings yet

- From Zero To A Pro Pemrograman Aplikasi Android: January 2014Document19 pagesFrom Zero To A Pro Pemrograman Aplikasi Android: January 2014subandiwahyudi08No ratings yet

- Aplikasi Aki ASPIRA PDFDocument1 pageAplikasi Aki ASPIRA PDFabu faizNo ratings yet

- Analisis Dan Desain Struktur Rangka Dengan SAP 2000 Versi StudentDocument8 pagesAnalisis Dan Desain Struktur Rangka Dengan SAP 2000 Versi StudentAntonius AjalahNo ratings yet

- Thesis AADocument1 pageThesis AAAntonius AjalahNo ratings yet

- Aisc Asd-89 Example 002Document5 pagesAisc Asd-89 Example 002Antonius AjalahNo ratings yet

- 04 ARCHICAD Calculation GuideDocument79 pages04 ARCHICAD Calculation GuideAntonius AjalahNo ratings yet

- Interaction DiagramDocument27 pagesInteraction DiagramAlfie Angelo ReyesNo ratings yet

- Aisc Lrfd-93 Example 002Document7 pagesAisc Lrfd-93 Example 002Antonius AjalahNo ratings yet

- Software verification of wide flange beam bending capacitiesDocument7 pagesSoftware verification of wide flange beam bending capacitiesAntonius AjalahNo ratings yet

- Telecommunication Tower Reinforced Concrete Foundation ACI318 14Document21 pagesTelecommunication Tower Reinforced Concrete Foundation ACI318 14Antonius AjalahNo ratings yet

- Syllabus PDFDocument40 pagesSyllabus PDFAntonius AjalahNo ratings yet

- AISC 360-05 Example 002Document6 pagesAISC 360-05 Example 002Antonius AjalahNo ratings yet

- ACI 318-08 Example 002 - Software Verification of P-M Interaction CheckDocument4 pagesACI 318-08 Example 002 - Software Verification of P-M Interaction CheckAntonius AjalahNo ratings yet

- Important Note PDFDocument1 pageImportant Note PDFMuhammad RizwanNo ratings yet

- Software Verification: NTC 2008 Example 002Document4 pagesSoftware Verification: NTC 2008 Example 002Antonius AjalahNo ratings yet

- AS 3600-2009 Ex002Document4 pagesAS 3600-2009 Ex002Antonius AjalahNo ratings yet

- Software Verification: Automating The Sap2000 Verification Checking ProcessDocument7 pagesSoftware Verification: Automating The Sap2000 Verification Checking ProcessAntonius AjalahNo ratings yet

- ACI 318-11 Ex001Document5 pagesACI 318-11 Ex001Antonius AjalahNo ratings yet

- ACI 318-08 Example 002 - Software Verification of P-M Interaction CheckDocument4 pagesACI 318-08 Example 002 - Software Verification of P-M Interaction CheckAntonius AjalahNo ratings yet

- AS 3600-2009 Ex002Document4 pagesAS 3600-2009 Ex002Antonius AjalahNo ratings yet

- AS 3600-2009 Ex001Document8 pagesAS 3600-2009 Ex001Antonius AjalahNo ratings yet

- ACI 318-11 Ex001Document5 pagesACI 318-11 Ex001Antonius AjalahNo ratings yet

- Software Verification: ConclusionsDocument5 pagesSoftware Verification: ConclusionsAntonius AjalahNo ratings yet

- CSIVerification PDFDocument1 pageCSIVerification PDFAntonius AjalahNo ratings yet

- ACI 318-11 Ex001Document5 pagesACI 318-11 Ex001Antonius AjalahNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Diagrama Hidraulico 906Document2 pagesDiagrama Hidraulico 906cris100% (1)

- Benshaw Low Voltage Starters PDFDocument16 pagesBenshaw Low Voltage Starters PDFRollyDuqueCampoverdeNo ratings yet

- Lampiran A: Cycle Time Exavator Hyundai 480Document15 pagesLampiran A: Cycle Time Exavator Hyundai 480Harry MartaNo ratings yet

- Electric Wiring and Basic Electricity 2003Document163 pagesElectric Wiring and Basic Electricity 2003walkerproductions20009116No ratings yet

- OSBI account statement for Zoya Jeans from Jan 2021 to Mar 2021Document18 pagesOSBI account statement for Zoya Jeans from Jan 2021 to Mar 2021Jamaluddin GauriNo ratings yet

- 2006 Volvo XC90Document204 pages2006 Volvo XC90St Julian Lloyd33% (3)

- M105H Series1 ManualDocument46 pagesM105H Series1 ManualS2gizzle100% (1)

- Ir ADV C5051/5045/5035/5030 Parts CatalogDocument268 pagesIr ADV C5051/5045/5035/5030 Parts Catalog-TT-67% (3)

- TG12-4 Thermoelectric Generator Technical Data SheetDocument2 pagesTG12-4 Thermoelectric Generator Technical Data SheetcrushqazNo ratings yet

- Radical Centrifugal Fans en PDFDocument184 pagesRadical Centrifugal Fans en PDFMohd AidilNo ratings yet

- BSRM Corporate Business Strategies RecommendationsDocument13 pagesBSRM Corporate Business Strategies RecommendationsNayeem MahmudNo ratings yet

- Road condition index reportDocument1 pageRoad condition index reportndieniNo ratings yet

- Inventaris Ruang MesinDocument14 pagesInventaris Ruang MesinMoh Nurilfatur AprilianzahNo ratings yet

- JSBDocument4 pagesJSBRiddho Perdana PutraNo ratings yet

- Tr05!09!1e Vibration Dampers For 220 KV and 400 KV Oh Lines Revision 3Document27 pagesTr05!09!1e Vibration Dampers For 220 KV and 400 KV Oh Lines Revision 3Agus Nur SetiawanNo ratings yet

- SDBNDIAIntlA-GSymposiumFinal ForNDIADropboxDocument14 pagesSDBNDIAIntlA-GSymposiumFinal ForNDIADropboxamenendezamNo ratings yet

- C16 C18 AdbacDocument6 pagesC16 C18 AdbachopemarineNo ratings yet

- EST2 System Operations ManualDocument84 pagesEST2 System Operations ManualVillamarimjuniorNo ratings yet

- CRP D 200 Manual EngDocument16 pagesCRP D 200 Manual EngAbbode Horani100% (2)

- Fire Safety EssentialsDocument9 pagesFire Safety EssentialsLouis MontenegroNo ratings yet

- RCD Lecture 1Document47 pagesRCD Lecture 1MohsinNo ratings yet

- Encoder Pepperl N Fuchs TV150N-09BK0RGTN-0100Document4 pagesEncoder Pepperl N Fuchs TV150N-09BK0RGTN-0100solutioncenter3No ratings yet

- PMSP DDDocument1 pagePMSP DDpablodcabreraNo ratings yet

- R-290 Safety Data SheetDocument6 pagesR-290 Safety Data SheetFathurrahman Yudhi NugrahaNo ratings yet

- New Scroll - IntroducciónDocument9 pagesNew Scroll - IntroducciónNicole SmithNo ratings yet

- Pin ConnectionDocument10 pagesPin ConnectionngocnnNo ratings yet

- EE593Document4 pagesEE593hassanNo ratings yet

- Vindicator Surveillances RadarDocument8 pagesVindicator Surveillances RadarFadli BadarudinNo ratings yet

- Quadcopter For Pesticide SprayingDocument3 pagesQuadcopter For Pesticide SprayingVivek SinghNo ratings yet

- Wyvern S.4 Pilot's NotesDocument63 pagesWyvern S.4 Pilot's NotesERIC WANGNo ratings yet