Professional Documents

Culture Documents

Vehicle Hoist Safe Work Procedure

Uploaded by

WiwinIndahSariEffendi0 ratings0% found this document useful (0 votes)

124 views2 pageslala

Original Title

SWP Vehicle Hoist AS559

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentlala

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

124 views2 pagesVehicle Hoist Safe Work Procedure

Uploaded by

WiwinIndahSariEffendilala

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 2

(Your Business Name Here) Safe Work Procedure

VEHICLE HOIST

DO NOT use this machine unless you have been instructed

in its safe use and operation and have been given permission

PERSONAL PROTECTIVE EQUIPMENT

Safety glasses must be worn at Long and loose hair must be Do not stand on hoist whilst

all times in work areas. contained. hoist is in operation.

Sturdy footwear must be worn Close fitting/protective Rings and jewellery must not

at all times in work areas. clothing must be worn. be worn.

PRE-OPERATIONAL SAFETY CHECKS

Leave the equipment and work area in a safe, clean

Locate and ensure you are familiar with all machine and tidy state.

operations and controls.

Ensure all guards are fitted, secure and functional.

Do not operate if guards are missing or faulty.

Ensure the vehicle hoist has operating and

maintenance instructions permanently located and

clearly visible.

Check the capacity of the hoist compared to the

weight of the vehicle. If vehicle is too heavy, do not

proceed.

Ensure the area is clean and clear of grease, oil.

Check workspaces and walkways to ensure no

slip/trip hazards are present.

Check that all safety devices are in good condition.

Ensure support arms are capable of being locked in

position.

Ensure rubber pads are in good condition on all load

points.

OPERATIONAL SAFETY CHECKS

Centre the vehicle on the hoist, ensuring the weight

is evenly distributed to the front and rear.

Identify the correct jacking points and place the lifting

pads under the vehicle at the front and rear on the

jacking points, ensuring contact.

Only one person shall operate the hoist at a time.

The hoist must not be operated unless it has a

current certificate of inspection.

Ensure the area is clear of people and equipment

before operating.

Check vehicle stability by looking at the jacking

points.

Engage manual lock.

ENDING OPERATIONS AND CLEANING UP

Lower the vehicle hoist and switch off machine when

work completed.

POTENTIAL HAZARDS AND INJURIES

Falling objects.

Trapping hazards.

Crushing hazards.

Hair/clothing getting caught in moving machine parts.

DONT

Do not use faulty equipment. Immediately report

suspect equipment.

Never leave the machine running unattended.

This SWP does not necessarily cover all possible hazards

associated with this equipment and should be used in

conjunction with other references. It is designed as a guide

to be used to compliment training and as a reminder to

users prior to equipment use.

This information is based on material published by the

South Australian Department of Education and Childrens

Services.

You might also like

- Lathe Wood SopDocument1 pageLathe Wood SopLucas BienertNo ratings yet

- Postnatal Assessment FormatDocument16 pagesPostnatal Assessment FormatValarmathi92% (13)

- SWP Metal Cutting Guillotine AS525Document2 pagesSWP Metal Cutting Guillotine AS525Riddhi SarvaiyaNo ratings yet

- SWP Grinder Bench AS520Document1 pageSWP Grinder Bench AS520Tosif AliNo ratings yet

- Safety Topic 863 - Working Under Suspended LoadsDocument2 pagesSafety Topic 863 - Working Under Suspended LoadsAshishNo ratings yet

- 14 - Method Statements For Erection of Steel PDFDocument1 page14 - Method Statements For Erection of Steel PDFAbdul RahmanNo ratings yet

- Hydrostatic Pressure Testing Procedure1 PWLDocument6 pagesHydrostatic Pressure Testing Procedure1 PWLYavannaNo ratings yet

- Duhok Polytechnic University College of Technical Engineering Department of PetrochemicalDocument17 pagesDuhok Polytechnic University College of Technical Engineering Department of PetrochemicalDll ZarNo ratings yet

- Oilfield Inspection Services: Method Statement: Forklift Tubular & General Cargo HandlingDocument6 pagesOilfield Inspection Services: Method Statement: Forklift Tubular & General Cargo HandlingDheeraj MenonNo ratings yet

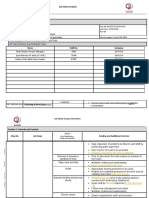

- Jobs Safety Analysis: Start DateDocument2 pagesJobs Safety Analysis: Start Dater afriantoNo ratings yet

- Changing Hydroulic Pump An Equipment (WS)Document6 pagesChanging Hydroulic Pump An Equipment (WS)John KalvinNo ratings yet

- Shop Safety Safe Work Procedure DRILL PRESSDocument1 pageShop Safety Safe Work Procedure DRILL PRESSTamoy CooreNo ratings yet

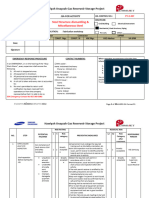

- How Chin Engineering: Job Safety AnalysisDocument5 pagesHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdNo ratings yet

- PT. Leighton Contractors Indonesia: Risk Assessment ReportDocument6 pagesPT. Leighton Contractors Indonesia: Risk Assessment ReportJohn KalvinNo ratings yet

- Grounding Rod Installation SafetyDocument5 pagesGrounding Rod Installation SafetyHow Chin Engineering Sdn BhdNo ratings yet

- Jacks and Vehicle Stands PDFDocument1 pageJacks and Vehicle Stands PDFcityofdarwingisNo ratings yet

- RA - SandblastingDocument2 pagesRA - Sandblasting721917114 47No ratings yet

- SWP Air Compressor Fixed - AS501Document1 pageSWP Air Compressor Fixed - AS501Perwez21No ratings yet

- 6-R A For Handling, Storage and Use of Gas CylindersDocument4 pages6-R A For Handling, Storage and Use of Gas CylindersMohamedSaidNo ratings yet

- SWP Plasma Cutter AS532Document2 pagesSWP Plasma Cutter AS532Adet WildanNo ratings yet

- IOCL Bench Cutting Machine ChecklistDocument2 pagesIOCL Bench Cutting Machine ChecklistmurthyNo ratings yet

- Guillotine (Metal) PDFDocument1 pageGuillotine (Metal) PDFcityofdarwingisNo ratings yet

- HPCL Madurai Welding Safety Work ProcedureDocument2 pagesHPCL Madurai Welding Safety Work Procedureanon_106345234100% (1)

- Hydraulic press safety procedureDocument2 pagesHydraulic press safety procedureARMANNo ratings yet

- For Electrical PannelDocument2 pagesFor Electrical Panneljithin shankarNo ratings yet

- Nail Gun Pnuematic Work Method Statement SWMS V8Document5 pagesNail Gun Pnuematic Work Method Statement SWMS V8ferny.51No ratings yet

- JSA Pressure TestingDocument1 pageJSA Pressure TestingScott Mills100% (1)

- Fixed Air Compressor: Do NotDocument1 pageFixed Air Compressor: Do NothainguyenbkvhvNo ratings yet

- HSE Work Practices GuideDocument27 pagesHSE Work Practices Guide5ad7100% (1)

- Lifting Tools & Tackle RegisterDocument1 pageLifting Tools & Tackle RegisterDth InfraNo ratings yet

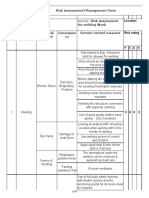

- Risk Assessment/Management FormDocument4 pagesRisk Assessment/Management FormNazriNo ratings yet

- Hazard Identification Risk AssessmentDocument5 pagesHazard Identification Risk Assessmentjithin shankarNo ratings yet

- Theme Based Safety Discussion (TBT) For Manual Grinding OperationDocument3 pagesTheme Based Safety Discussion (TBT) For Manual Grinding OperationMr. XNo ratings yet

- AEG - JSA - 107 - Oxygen Acetylene Torch PDFDocument2 pagesAEG - JSA - 107 - Oxygen Acetylene Torch PDFanon_421433640No ratings yet

- Risk assessment form for forklift operationsDocument5 pagesRisk assessment form for forklift operationsFachri HidayatNo ratings yet

- Bolt TorquingDocument2 pagesBolt TorquingREHAN IQBALNo ratings yet

- Compulsory Ppe As Needed Ppe: Safe Operating Procedures SOP 02 - Bench GrinderDocument2 pagesCompulsory Ppe As Needed Ppe: Safe Operating Procedures SOP 02 - Bench GrinderMuhammad Oji L100% (1)

- Jsa Bearing Replacement-OverhaulingDocument2 pagesJsa Bearing Replacement-Overhaulingashish engineeringNo ratings yet

- Milling MachineDocument1 pageMilling MachineJeannie TimothyNo ratings yet

- Machineguardingsoptech 12Document1 pageMachineguardingsoptech 12api-200253170No ratings yet

- 1.tech Pneumatic Tool Safety 20180207Document2 pages1.tech Pneumatic Tool Safety 20180207Ku RatheeshNo ratings yet

- Safe Working PracticesDocument7 pagesSafe Working PracticesDiana ParkerNo ratings yet

- Theme Based Safety Discussion - Gas Cylinder Storage & HandlingDocument2 pagesTheme Based Safety Discussion - Gas Cylinder Storage & HandlingMr. XNo ratings yet

- JSA Forklift PDFDocument2 pagesJSA Forklift PDFfauziNo ratings yet

- Air CompressorDocument4 pagesAir CompressorLajapathi RaiNo ratings yet

- SWP Air CompressorDocument2 pagesSWP Air Compressormyn maliQueNo ratings yet

- 16.18 TBT - Gas Welding and CuttingDocument2 pages16.18 TBT - Gas Welding and Cuttinggrant100% (1)

- Jsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007Document30 pagesJsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007elmsm14No ratings yet

- Machine Shop SafetyDocument10 pagesMachine Shop SafetySreedhar Patnaik.MNo ratings yet

- Bench GrinderDocument1 pageBench GrinderSreejith S NairNo ratings yet

- SOP - Stick WeldingDocument1 pageSOP - Stick WeldingMALLADI PRADEEPNo ratings yet

- Welder SpotDocument1 pageWelder SpotShubham NayakNo ratings yet

- SWP Welder Gas Metal Arc AS560Document2 pagesSWP Welder Gas Metal Arc AS560Amirul Haris100% (1)

- Abrasive CutDocument1 pageAbrasive CutWahyu Haidar PratamaNo ratings yet

- Caretaker Risk Assessment - Working at HeightDocument8 pagesCaretaker Risk Assessment - Working at HeightLina MarcelaNo ratings yet

- SWP Welder Manual Metal Arc AS562Document2 pagesSWP Welder Manual Metal Arc AS562Jonathan BajelaNo ratings yet

- UNC Hot Work Safety PolicyDocument19 pagesUNC Hot Work Safety Policytheblues2708No ratings yet

- Risk assessment for changing hydraulic cylindersDocument4 pagesRisk assessment for changing hydraulic cylindersJohn KalvinNo ratings yet

- Changing & Charging of Batteries (WS)Document4 pagesChanging & Charging of Batteries (WS)John KalvinNo ratings yet

- 020.abrasive Blasting Rev.0 PDFDocument12 pages020.abrasive Blasting Rev.0 PDFYounis KhanNo ratings yet

- 16 Daftar PustakaDocument4 pages16 Daftar PustakaWiwinIndahSariEffendiNo ratings yet

- DsesDocument4 pagesDsesWiwinIndahSariEffendiNo ratings yet

- With Your HabitualDocument1 pageWith Your HabitualWiwinIndahSariEffendiNo ratings yet

- With Your HabitualDocument1 pageWith Your HabitualWiwinIndahSariEffendiNo ratings yet

- With Your HabitualDocument1 pageWith Your HabitualWiwinIndahSariEffendiNo ratings yet

- WooDocument1 pageWooWiwinIndahSariEffendiNo ratings yet

- Speech Disorders - ChildrenDocument2 pagesSpeech Disorders - ChildrenAmanda Kenshi NurfitriNo ratings yet

- 004 General Consent English (Front)Document2 pages004 General Consent English (Front)عبدالله الرعويNo ratings yet

- Loxapine Drug StudyDocument5 pagesLoxapine Drug Studyshadow gonzalezNo ratings yet

- Test 4Document4 pagesTest 4Hiếu Nguyễn HữuNo ratings yet

- Waiver For Turkey TrotDocument1 pageWaiver For Turkey Trotapi-85191986No ratings yet

- Confirmation 1068409Document3 pagesConfirmation 1068409ankiosaNo ratings yet

- D A Up To 2 YearDocument7 pagesD A Up To 2 YearNischitha G CNo ratings yet

- Chapter 18Document36 pagesChapter 18hussein harbNo ratings yet

- Uttarakhand Dealers Data, JanviDocument8 pagesUttarakhand Dealers Data, JanviVAISHNAVI TAYALNo ratings yet

- Sma - Ma Bahasa Inggris Ipa - Ips - Bahasa SecuredDocument39 pagesSma - Ma Bahasa Inggris Ipa - Ips - Bahasa SecuredJohnson LiuNo ratings yet

- Challenges and Opportunities in Preventive and Social MedicineDocument3 pagesChallenges and Opportunities in Preventive and Social MedicineIJAR JOURNALNo ratings yet

- 1 s2.0 S2772569323000026 MainDocument8 pages1 s2.0 S2772569323000026 MainAditya RizkyNo ratings yet

- Labor and Delivery QuizDocument7 pagesLabor and Delivery QuizAmy50% (2)

- Respiratory MechanicsDocument27 pagesRespiratory MechanicsKarla Hernandez100% (1)

- 02 2 Internal OrgansDocument1 page02 2 Internal OrgansgabrielaNo ratings yet

- Mary Law PEO Model PDFDocument15 pagesMary Law PEO Model PDFalepati29No ratings yet

- Nursing Process in Drug TherapyDocument60 pagesNursing Process in Drug TherapyYra JhaneNo ratings yet

- Tugas Jurnal TeksolDocument6 pagesTugas Jurnal TeksolNovita IndahNo ratings yet

- Slide PPT PrismaDocument31 pagesSlide PPT PrismaUlul Azmi AdnanNo ratings yet

- Ethical Decision Making in ResearchDocument2 pagesEthical Decision Making in ResearchChandraKurniawanNo ratings yet

- Mdbsis09 CA A III 2017Document4 pagesMdbsis09 CA A III 2017Guneyden GuneydenNo ratings yet

- Effect of Smoking On HalitosisDocument5 pagesEffect of Smoking On HalitosisMaria JabbarNo ratings yet

- Review Article On Chemical Constituents and Uses of Turmeric PlantDocument8 pagesReview Article On Chemical Constituents and Uses of Turmeric PlantEditor IJTSRDNo ratings yet

- PamphletDocument1 pagePamphletAldenn MinotaurNo ratings yet

- Paedo Don TicsDocument103 pagesPaedo Don TicsIana RusuNo ratings yet

- Nursing Care Plan UlcerDocument2 pagesNursing Care Plan Ulcerxrampley2100% (2)

- APSACS Summer Holiday Homework Guide Warm Region 2023 24 Dated 02 June 2023 - CompressedDocument17 pagesAPSACS Summer Holiday Homework Guide Warm Region 2023 24 Dated 02 June 2023 - CompressedGaming 7HawkNo ratings yet

- Inflammation - The Silent Killer - Terra Health EssentialsDocument6 pagesInflammation - The Silent Killer - Terra Health EssentialshighlanderoneNo ratings yet

- Cardiovascular ADocument3 pagesCardiovascular AAutumn AllisonNo ratings yet