Professional Documents

Culture Documents

Piping Layout and Modelling Essentials

Uploaded by

HarishKumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Piping Layout and Modelling Essentials

Uploaded by

HarishKumarCopyright:

Available Formats

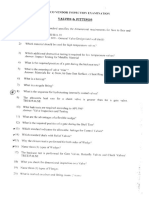

POINTS TO REMEMBER

FOR PIPING LAYOUT AND MODELLING

A.1 CHECK LIST FOR ISOMETRICS

1) LINE NO.

2) LINE SPEC

3) START POINT LOCATION

4) END POINT LOCATION

5) BRANCH CONNECTION

6) VALVE ACCESSIBILITY

7) SUPPORT

8) INSULATION (FOR INSULATED LINE ONLY)

9) INSTRUMENT END CONNECTION

10) FLOW DIRECTION

11) HIGH POINT VENT, LOW POINT DRAIN

12) HYDROTEST VENT AND DRAIN

13) NOZZLE CONNECTION

14) NOZZLE NOS.

15) EQUIPMENT NOS.

16) COORDINATES AND ELEVATIONS

17) ISO NORTH

18) BILL OF MATERIAL

19) VALVE TAG NOS.

20) INSTRUMENT TAG NOS.

21) CONTINUATION SHEETS OR ISO. NOS.

22) GRID LOCATION AND NOS.

A.2 DOCUMENTS FOR ISOMETRICS CHECKING

1) PIPING AND INSTRUMENT DIAGRAMS

2) PIPING LAYOUTS

3) SECTIONAL DRAWINGS

4) EQUIPMENT DRAWINGS

5) NOZZLE ORIENTATION

6) PIPING SPECIFICATION

7) SUPPORT STANDARD

8) SPECIAL ITEM DRAWINGS

9) STRESS ANALYSIS REPORT

A.3 POINTS TO REMEMBER IN ISOMETRICS CHECKING

1) PUMP SUCTION IS BIGGER THAN PUMP DISCHARGE.

2) ECCENTRIC REDUCER (FLAT SIDE TOP) USED FOR PUMP SUCTION. (This is used to avoid

cavitation.)

3) AVOID LOOPS IN PUMP SUCTION AND COMPRESSOR INLET LINES.

4) PSVs should be located always above flare header.

5) CHECK THE VALVE ACCESSIBILITY FOR MAINTENANCE PURPOSE. (VALVE OPERATING HEIGHT

MIN 750mm TO 1600mm FROM FLOOR LEVEL.)

6) CHECK VALVE CAN BE LOCATED IN VERTICAL RUN PROVIDED FLOW IS UPWARD.

7) CONTROL STATION OPERATING HEIGHT 500mm TO 750mm FROM FLOOR LEVEL.

8) SHOE NOT REQUIRED FOR TRUNION. (INSULATED LINES)

9) HEADROOM CLEARANCE MINIMUM 2.2M FROM GROUND/FLOOR LEVEL.

10) DRIP LEG REQUIRED FOR STEAM LINES ON PIPE RACK NEAR TO THE BLINDED END AND AT ALL

LOW POINTS

11) SHOE REQUIRED FOR INSULATED LINES (STEAM, CHILLED WATER, BRINE, STEAM

CONDENSATE).

12) SHOE NOT REQUIRED FOR CONDENSATE LINE WHEN LAID ON PIPE RACK AND APPLICABLE

FOR ALL LINES FOR WHICH INSULATION CATEGORY IS PP (PERSONEL PROTECTION).

13) NOZZLE ORIENTATIONS SHOULD BE KEPT AS PER PIPING REQUIREMENT.

14) PIPE ROUTING CLEAR OF TRIPPING HAZARDS.

15) LOCATE CONTROL STATION NEAR TO PIPE RACK COLUMNS.

16) BOTTOM OF PIPE IN CONTROL VALVE STATIONS TO BE MINIMUM 600mm FROM GRADE.

17) USE A DYKE WALL AROUND THE EQUIPMENTS FOR AVOID THE LIQUID TO SPREAD IN THE

PLANT AREA. THE VOLUME OF DIKE WALL IS 1.5 TIMES MORE THAN TOTAL CAPACITY OF

EQUIPMENTS.

18) USE WELDNECK FLANGE FOR PRESSURE PIPING.

B.1 TYPES OF CONTROL VALVE

1) PCV PRESSURE CONTROL VALVE

2) TCV TEMPERATURE CONTROL VALVE

3) FCV FLOW CONTROL VALVE

4) LCV LEVEL CONTROL VALVE

5) XV ISOLATION VALVE

6) XCV HIGH PRESSURE CONTROL VALVE

B.2 TYPES OF PUMPS

1) RECIPROCATING PUMP

2) ROTARY PUMP

3) CENTRIFUGAL PUMP

4) VACUUM PUMP

5) METERING PUMP

B.3 TYPES OF EXCHANGER

1) AIR COOLER EXCHANGER

2) PLATE TYPE EXCHANGER

3) SHELL & TUBE EXCHANGER

4) 2 PIPE EXCHANGER

5) SPIRAL EXCHANGER

B.4 TYPES OF COMPRESSOR

1) ELEVATED CENTRIFUGAL COMPRESSOR

2) GRADE-MOUNTED CENTRIFUGAL COMPRESSOR

3) RECIPROCATING COMPRESSOR

B.5 TYPES OF TOWER

1) TRAY TOWER

2) PACKED TOWER

3) VACUUM TOWER

B.6 TYPES OF VALVE

1) GATE VALVE

2) GLOBE VALVE

3) CHECK VALVE (NON RETURN VALVE)

4) BALL VALVE

5) BUTTERFLY VALVE

6) DIAFRAGME VALVE

7) PLUG VALVE

B.7 TYPE OF FLANGES

1) WELDNECK FLANGE (FLAT FACE, RAISED FACE)

2) SLIPON FLANGE DO

3) LAP JOINT FLANGE (FLAT FACE)

4) REDUCING FLANGE (FLAT FACE, RAISED FACE)

5) SCREWED FLANGE

6) BLIND FLANGE

7) SOCKETWELD FLANGE

B.7A PRESSURE TEMPERATURE RATTING

150#, 300#, 400#, 600#, 900#, 1500#, 2500#

B.7B FLANGES FACING

1) FF FLAT FACE

2) RF RAISED FACE

3) T/G TONGUE AND GROOVE FACE

4) M/F MALE AND FEMALE FACES

5) RTJ RING TYPE JOINT FACES

B.8 TYPES OF FITTINGS

1) 90 ELBOW, 45 ELBOW (BUTT WELDED, SOCKET WELDED, THREDED)

2) EQUAL TEE, REDUCING TEE DO

3) CAP, UNION, PLUG, HALF COUPLING, FULL COUPLING, LATERAL.

B.9 TYPES OF OLETS

1) LATEROLET

2) ELBOWLET

3) WELDOLET

4) SOCKOLET

5) THREADOLET

6) SWEEPOLET

7) NIPPOLET

B.10 TYPES OF REDUCER

1) ECCENTRIC REDUCER (BUTT WELDED)

2) CONCENTRIC REDUCER (BUTT WELDED)

3) SWAGES (SOCKET WELD, THREDED)

B.11 TYPES OF INSTRUMENTS

1) PSV PRESSURE SAFETY VALVE

2) LG LEVEL GUAGE

3) LI LEVEL INDICATOR

3) PG PRESSURE GUAGE

4) PI PRESSURE INDICATOR

4) CV CONTROL VALVE

5) TI TEMPERATURE INDICATOR

6) TW THERMOWELL

7) FE FLOW ELEMENTS

8) FI FLOW INDICATORS

9) FO FLOW ORIFICE FLANGES

A GENERAL PURPOSE

1) CONTROL VALVES (GLOBE, BALL, BUTTERFLY)

2) ON/OFF VALVES (BALL, BUTTERFLY)

3) RELIEF VALVES (PRESSURE, THERMAL)

4) RAPTURE DISC

5) RESTRICTION ORIFICE

B FLOW MESSURING INSTRUMENTS

1) ORIFICE PLATE

2) VARIABLE AREA FLOW METER

3) MAGNETIC FLOW METER

4) TURBINE FLOW METER

5) POSITIVE DISPLACEMENT METER

C TEMPERATURE MEASURING INSTRUMENTS

1) THERMOCOUPLES

2) RESISTANCE TEMPERATURE DETACTORS

3) FILLED SYSTEM

4) BIMETALLIC THERMOMETRES

5) THERMOWELLS

D PRESSURE MESSURING INSTRUMENTS

1) MANOMETER

2) BOURDEN TYPE

3) BELLOW TYPE

4) DIAPHRAGM TYPE

E LEVEL MEASURING INSTRUMENTS

1) LEVEL GUAGE (DIRECT TYPE)

2) HYDROSTATIC HEAD (INFERENTIAL)

3) BUOYANCY

4) CONDUCTANCE

5) CAPACITANCE

6) RADIATION

7) FLOAT

B.12 SPECIAL ITEMS

1) STEAM TRAP (FLOAT TYPE, THERMODYNAMIC, BUCKET)

2) ORIFICE FLANGE

3) FLOW ELEMENTS

4) STRAINNER (Y TYPE SRAINNER, BUCKET TYPE STRAINNER)

B.13 TYPES OF PIPE ENDS

1) PBE PLAIN BOTH END

2) PLE PLAIN LARGE END

3) PSE PLAIN SMALL END

4) BLE BEVELLED LARGE END

5) TSE THREADED SMALL END

B.14 TYPES OF GASKETS

1) FLAT FACE

2) INSIDE BOLT CIRCLE

3) SPIRAL WOUND METTALIC

4) RING TYPE

5) METAL JACKETED

C.1 SERVICE CODE FOR UTILITY LINES

1) LPS LOW PRESSURE STEAM

2) HPS HIGH PRESSURE STEAM

3) MPS MEDIUM PRESSURE STEAM

4) CWS COOLING WATER SUPPLY

5) CWR COOLING WATER RETURN

6) CHWS CHILLED WATER SUPPLY

7) CHWR CHILLED WATER RETURN

8) BS BRINE SUPPLY

9) BR BRINE SUPPLY

10) IA INSTRUMENT AIR

11) CA COMPRESS AIR

12) DMW POTABLE WATER

13) PS PROCESS WATER

C.2 SERVICE CODE FOR PROCESS LINE

1) FG FUEL GAS

D.1 SHORT CODE

1) IBR INDIAN BOILER REGULATION ACT

2) ASTM AMERICAN SOCIETY OF TESTING MATERIAL

3) ANSI AMERICAN NATIONAL STANDARD INSTITUTE

4) SMLS SEAMLESS

5) THD THREDED

6) BW BUTT WELDED

8) SW SOCKET WELDED

9) ECC. RED. ECCENTRIC REDUCER

10) CONC.RED. CONCENTRIC REDUCER

11) EQ.TEE EQUAL TEE

12) RED. TEE REDUCING TEE

13) CLPG COUPLING

14) VLV VALVE

15) STR STRAINNER

16) T TRAP

17) EL ELBOW

18) FOF.EL. FINISH FLOOR ELEVATION

19) PTFL.EL. PLATFORM ELEVATION

20) GR.EL GROUND ELEVATION

21) SCH SCHEDULE

22) THK THICKNESS

23) EQPT EQUIPMENT

24) SORF SLIPON RAISE FACE

25) SOFF SLIPON FLAT FACE

26) WNRF WELDNECK RAISE FACE

27) WNFF WELDNECK FLAT FACE

28) BOP.EL. BOTTOM OF PIPE ELEVATION

29) CL.EL. CENTER LINE ELEVATION

30) PCD PITCH CIRCLE DIA.

31) NB NOMINAL BORE

32) NS NOMINAL SIZE

33) BE BEVELED END

34) ISI INDIAN STANDARD INSTITUTE

35) FST FLAT SIDE TOP

36) FSD FLAT SIDE DOWN

37) SUC. SUCTION

38) DISCH. DISCHARGE

39) WP.EL. WORK POINT ELEVATION

40) GA GENERAL ARRANGEMENT

41) P&ID PIPING AND INSTRUMENT DIAGRAMES

D.2 AMERICAN STANDARD

42) ASTM THE AMERICAN SOCIETY OF TESTING MATERIALS

43) API THE AMERICAL PETROLEUM INSTITUTE

44) AISI THE AMERICAN IRON AND STEEL INSTITUTE

45) ANSI THE AMERICAN NATIONAL STANDARD INSTITUTE

46) AWS THE AMERICAN WELDING SOCIETY

47) AWWA THE AMERICAN WATER WORKS ASSOCIATION

48) ASME THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS

D.3 API STANDARDS

1) API5L SPECIFICATION FOR PIPE LINE

2) API6D PIPE LINE VALVES, END CLOSERS, CONNECTORS, AND SWIVELS

3) API600 STEEL GATE VALVE

4) API 605 LARGE DIAMETRE CARBON STEEL FLANGES

D.4 ANSI STANDARDS

1) ANSI/ASME 31.1 POWER PIPING-1995

2) ANSI/ASME 31.2 FUEL GAS PIPING-1968

3) ANSI/ASME-31.3 CHEMICAL PETROLEUM REFINERY PIPING-1993

D.5 BRITISH STANDARD

1) BS10 FLANGES

2) BS806 PIPES AND FITTINGS FOR BOILER

3) BS916 BLACK BOLTS, NUTS AND SCREWS

4) BS1560 STEEL PIPE FLANGES

5) BS1414 GATE VALVES FOR PETROLEUM INDUSTRIES

6) BS1600 DIMENSIONS OF STEEL PIPES

7) BS1965 BUTT WELDING PIPE FITTINGS

8) BS2080 FACE TO FACE /END TO END DIMENSIONS OF VALVES

9) BS2598 GLASS PIPE LINES AND FITTINGS.

10) BS3351 PIPING SYSTEM FOR PETROLEUM REFINERIES

E.1 DRAWINGS

1) STUDY LAYOUT

2) GENERAL ARRANGEMENT DRAWINGS

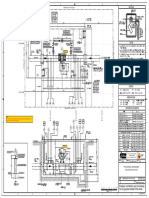

3) PIPING AND INSTRUMENT DIAGRAMS

4) SECTIONAL LAYOUTS

5) CIVIL LAYOUTS

6) EQUIPMENT LAYOUTS

7) FABRICATION DETAILS DRAWING

8) FOUNDATION DETAILS DRAWINGS

9) STRUCTURAL LAYOUT

10) ISOMETRICS

11) PIPING DETAILS LAYOUT

12) NOZZLE ORIENTATIONS

13) PLOT PLAN

14) FLOW DIAGRAME

F1 PROCESS DESIGN CODE FOR SERVICE

1) SULFER ASME B31.3

F2.PIPING MATERIAL CODE

1) BUTTWELDED FITTINGS A234-WP5, SCH.40, B16.9

BUTTWELD, 5CROM MOLYDENUM ALLOYSTEEL PER ASTM

GRADE WP5, SCHEDULE 40, PER ANSI B16.9

2) SPECTACLE BLIND A240-304H 600LB RF SMTH

STAINLESS STEEL, PER ASTM A240 GRADE 321, CLASS 600,

PER API 590

3) PIPING CS. A106 GR. B

4) VALVE CS A216 WCB

5) FLANGE ASME B16.5, CLASS 150 RATTING

6) SMALL FITTINGS AS A182 F5

7) GASKET SPIRAL WOUND

G.1 PIPE ENDS

1) BEVELLED ENDS

2) PLAIN ENDS

3) SCREWED ENDS

4) FLANGED ENDS

5) SPIGOT/SOCKET ENDS

6) BUTTRESS END

H.1 PIPE MATERIALS

1) ASTM A53 WELDED AND SEAMLESS PIPE

2) ASTM A106 SEAMLESS CS PIPE FOR HIGH TEMP. SERVICES

3) API 5L LINE PIPE

4) IS 1239 STEEL PIPES FOR GENERAL PURPOSE

5) IS 3589 STEEL PIPES FOR GENERAL SERVICES

H.2 DIMENSIONAL STANDARD

1) ANSI B16.1 CAST IRON FLANGED END FITTINGS

2) ANSI B16.3 MALLEABLE IRON THREDED FITTINGS

3) ANSI B16.4 CAST IRON THREDED FITTINGS

4) ANSI B16.5 STEEL FLANGED END FITTINGS

5) ANSI B16.9 BUTTWELDING END FITTINGS

6) ANSI B16.11 SOCKETWELD AND SCREWED END FITTINGS

H.3 SW/SCRD FITTING MATERIALS

1) ASTM 105 FORGED CARBON STEEL

2) ASTM A181 FORGED CARBON STEEL FOR GENERAL PURPOSES

3) ASTM A182 FORGED ALLOY STEEL AND STAINLESS STEEL

4) ASTM A234 WROUGHT CARBON STEEL AND ELEVATED ALLOY STEEL PIPE

FITTING FOR MODERATE AND ELEVATED TEMPERATURES

5) ASTM A350 FORGED ALLOY STEEL FOR LOW TEMPERATURE SERVICES

H.3 BUTTWELDED END FITTINGS

1) ASTM A234 CARBON STEEL FITTINGS

2) ASTM A403 AUSTENITIC STAINLESS STEEL FITTINGS

3) ASTM A420 ALLOY STEEL FOR LOW TEMPERATURE SERVICES.

H.4 FLANGED END FITTINGS

1) ASTM 216 CARBON STEEL CASTINGS

2) ASTM 351 STAINLESS STEEL CASTINGS

3) ASTM A352 ALLOY STEEL CASTINGS

4) ASTM F 1545 PLASTING LINED FITTINGS

5) IS 1538 CI FITTINGS.

You might also like

- Piping GuideDocument13 pagesPiping GuidemuraliNo ratings yet

- Piping GuideDocument14 pagesPiping Guideவிஷ்ணு ராஜசெல்வன்100% (1)

- Piping Guide ISO ChecklistDocument14 pagesPiping Guide ISO Checklistprince_lalNo ratings yet

- Check List For Iso and ValvesDocument13 pagesCheck List For Iso and ValvesNeeraj JanakiramanNo ratings yet

- Piping Guide Made by A.1 Check List For IsometricsDocument14 pagesPiping Guide Made by A.1 Check List For IsometricsSuresh Ram RNo ratings yet

- Short Codes and Standards Reference GuideDocument3 pagesShort Codes and Standards Reference GuideSaiKumarNo ratings yet

- Aramco Interview Questions PRDocument11 pagesAramco Interview Questions PRhemant1284100% (2)

- Piping QuestionsDocument13 pagesPiping QuestionsMani KantaNo ratings yet

- List of Jewelry Manufacture ToolsDocument2 pagesList of Jewelry Manufacture ToolsMellisa AllenNo ratings yet

- Cross Line CharolasDocument11 pagesCross Line CharolasMiguel FonsecaNo ratings yet

- Piping Commodities: 1 PipeDocument4 pagesPiping Commodities: 1 PipeDhakshina KNo ratings yet

- Pipe Sizing As Per Asme B 31.1Document3 pagesPipe Sizing As Per Asme B 31.1unibalaji_05No ratings yet

- Astm Nos For PipingDocument6 pagesAstm Nos For PipingJessica HerringNo ratings yet

- Datasheet PompaDocument8 pagesDatasheet PompaagusnnnNo ratings yet

- Piping Interview QuestionsDocument6 pagesPiping Interview QuestionsCalvin Hobbes100% (1)

- Valves & Fittings Question - 02Document3 pagesValves & Fittings Question - 02mohamed elmasry100% (1)

- ABBREVIATIONSDocument13 pagesABBREVIATIONSSubash Gold KingNo ratings yet

- Geotechnical Department List of Geotechnical Equipments/ Instruments & ToolsDocument3 pagesGeotechnical Department List of Geotechnical Equipments/ Instruments & ToolstasaddaqYounasNo ratings yet

- Water SystemDocument9 pagesWater SystemArun GuptaNo ratings yet

- QM 07 - ValvesDocument6 pagesQM 07 - Valvesmohamed elmasryNo ratings yet

- 143 Yer Pe MJ3 0004Document9 pages143 Yer Pe MJ3 0004Janakiraman MalligaNo ratings yet

- MDCC Status Thermax CompareDocument35 pagesMDCC Status Thermax Comparesdhall_iitdNo ratings yet

- Unit 9 ReviewDocument11 pagesUnit 9 ReviewDr. Amr ArafaNo ratings yet

- Spiral Wound Gasket CalculatorDocument11 pagesSpiral Wound Gasket Calculatorbhaveshshukla1698No ratings yet

- 3.4.b.01 Air BlowerDocument2 pages3.4.b.01 Air BlowerGohar KhokharNo ratings yet

- 11Document5 pages11MOHAMEDNo ratings yet

- Celdas Wemco de 60 m3 - Planos IdDocument17 pagesCeldas Wemco de 60 m3 - Planos IdFrancisco Gil100% (1)

- Piping Code ComparisonDocument5 pagesPiping Code ComparisonAndy Hakim83% (6)

- EGE32B2Document7 pagesEGE32B2Jhonny Rafael Blanco CauraNo ratings yet

- Piping Final ExamDocument11 pagesPiping Final ExamAhmed HaridiNo ratings yet

- 8931 PDFDocument27 pages8931 PDFPawan Kumar100% (1)

- Proporcionador D10D03121Document6 pagesProporcionador D10D03121monchiss21No ratings yet

- EGE13B10Document46 pagesEGE13B10Jhonny Rafael Blanco CauraNo ratings yet

- Design Practice For General Piping DesignDocument28 pagesDesign Practice For General Piping DesignAnanto Yusuf WNo ratings yet

- API 610 11th Ed DatasheetDocument13 pagesAPI 610 11th Ed DatasheetHatem ShawkiNo ratings yet

- PROJECT UNITS DATA SHEETDocument7 pagesPROJECT UNITS DATA SHEETHatem ShawkiNo ratings yet

- PWD Make List 2015 16Document6 pagesPWD Make List 2015 16Bu ManNo ratings yet

- RFQ - GZ0200162A Wellhead X-Mas Tree SpoolsDocument1 pageRFQ - GZ0200162A Wellhead X-Mas Tree SpoolsHarryNo ratings yet

- BOQ Air Liquide Project (Diesel Tank)Document19 pagesBOQ Air Liquide Project (Diesel Tank)Remmo S Ardiansyah100% (1)

- Piping Code ComparisonDocument7 pagesPiping Code ComparisonRenjith GopanNo ratings yet

- Well ControlDocument70 pagesWell ControlAbd EnnacerNo ratings yet

- NSL Loler MatrixDocument1 pageNSL Loler MatrixJogi Oscar SinagaNo ratings yet

- App B Piping Specifications PDFDocument4 pagesApp B Piping Specifications PDFirawan_epNo ratings yet

- API STD 676-2009 - Hoja de RequisiciónDocument28 pagesAPI STD 676-2009 - Hoja de RequisiciónRicardo CastroNo ratings yet

- TDS For Basket StrainerDocument2 pagesTDS For Basket StrainerRAGHVENDRA PRATAP SINGHNo ratings yet

- Pemex Refinacion Plantas Desulfuradoras (ULSG) de Gasolinas CataliticasDocument5 pagesPemex Refinacion Plantas Desulfuradoras (ULSG) de Gasolinas CataliticasEmmanuelle David MoraNo ratings yet

- I S 0 13709 (Api 610 10Th) Centrifugal Pump: IslenclosureDocument9 pagesI S 0 13709 (Api 610 10Th) Centrifugal Pump: IslenclosureJanakiraman MalligaNo ratings yet

- Datasheet of Deluge ValveDocument2 pagesDatasheet of Deluge ValveAlvin SmithNo ratings yet

- KOGAS Natural Gas Ball Valve SpecificationDocument25 pagesKOGAS Natural Gas Ball Valve Specification윤병택No ratings yet

- 6oilccopdngglobal2152008 Voll III 20piping 20 20 MechanicalDocument643 pages6oilccopdngglobal2152008 Voll III 20piping 20 20 Mechanicaldinesh2u85No ratings yet

- A2 1 16junDocument2 pagesA2 1 16junamitrai86No ratings yet

- Approximate RT Calculation For API 650 TankDocument2 pagesApproximate RT Calculation For API 650 Tankjayaarnav100% (6)

- Bell & Gossett SuctionDiffusersDocument4 pagesBell & Gossett SuctionDiffusersAnonymous 7xHNgoKE6eNo ratings yet

- Piping Question and AnswerDocument7 pagesPiping Question and AnswerMohammed Abdul Moqeet100% (10)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Fundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationFrom EverandFundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationNo ratings yet

- EIL Material Selection ChartDocument1 pageEIL Material Selection ChartshamashergyNo ratings yet

- Piping Layout and Modelling EssentialsDocument7 pagesPiping Layout and Modelling EssentialsHarishKumarNo ratings yet

- Training Module: Piping Discipline Activities - InductionDocument1 pageTraining Module: Piping Discipline Activities - InductionHarishKumarNo ratings yet

- EIL Material Selection ChartDocument1 pageEIL Material Selection ChartshamashergyNo ratings yet

- Material 1 JacobsDocument1 pageMaterial 1 JacobsHarishKumarNo ratings yet

- EIL Material Selection ChartDocument1 pageEIL Material Selection ChartshamashergyNo ratings yet

- API Trim ChartDocument1 pageAPI Trim Charthassaanzafar7No ratings yet

- Employer Is Entitled To Use This Drawing For Any Purpose Related To The WorksDocument1 pageEmployer Is Entitled To Use This Drawing For Any Purpose Related To The WorksHarishKumarNo ratings yet

- Material 2 JacobsDocument1 pageMaterial 2 JacobsHarishKumarNo ratings yet

- GB090 2614 250 Pi DS 0001Document661 pagesGB090 2614 250 Pi DS 0001HarishKumarNo ratings yet

- P&ID Gas Heat ExchangerDocument1 pageP&ID Gas Heat ExchangerHarishKumarNo ratings yet

- HDFC Weekly May20Document18 pagesHDFC Weekly May20HarishKumarNo ratings yet

- UntitledDocument128 pagesUntitledapi-61200414No ratings yet

- Weekly Call: Research Analysts Research AnalystsDocument16 pagesWeekly Call: Research Analysts Research AnalystsHarishKumarNo ratings yet

- THREADING MACHINES FOR PIPES AND BOLTSDocument18 pagesTHREADING MACHINES FOR PIPES AND BOLTShendrobamaNo ratings yet

- 295051Document4 pages295051Denis MartiniNo ratings yet

- JaajajjaDocument862 pagesJaajajjaCarloz JozeNo ratings yet

- For Unit 4 & 9Document1 pageFor Unit 4 & 9Renzo GuevarraNo ratings yet

- Closed Conduits Through Which Fluids Flow A Tubular Section or Hollow Cylinder, Usually But Not Necessarily of Circular Cross-SectionDocument9 pagesClosed Conduits Through Which Fluids Flow A Tubular Section or Hollow Cylinder, Usually But Not Necessarily of Circular Cross-SectionTimothy GregoireNo ratings yet

- Drill Pipe Ad 68 Not# 200000708382Document5 pagesDrill Pipe Ad 68 Not# 200000708382Arun SidharthNo ratings yet

- Mixed-Use Development One Binondo: Moriones St. Cor. Juan Luna St. Binondo, ManilaDocument1 pageMixed-Use Development One Binondo: Moriones St. Cor. Juan Luna St. Binondo, ManilaedwinNo ratings yet

- The difference is qualityDocument16 pagesThe difference is qualityninatenaNo ratings yet

- Fleck 9000 9100 9500 Service Manual 40944Document52 pagesFleck 9000 9100 9500 Service Manual 40944rhusseinpos4765No ratings yet

- Mfna70 So00012742raDocument41 pagesMfna70 So00012742rasudhansu8beheraNo ratings yet

- Bill of Materials: Construction of 2 Storey ResidenceDocument4 pagesBill of Materials: Construction of 2 Storey ResidenceJan Emilyn Chavez CatindigNo ratings yet

- Flow, KV Values and Zeta Values For Gate Valves, Resilient Seated Appendix 6Document3 pagesFlow, KV Values and Zeta Values For Gate Valves, Resilient Seated Appendix 6Imtiyaz KhanNo ratings yet

- Pump - Detail Calculation Sheet (Warman Style)Document2 pagesPump - Detail Calculation Sheet (Warman Style)Sai KrishNo ratings yet

- Manufaktur Dan Test Sertifikat PDFDocument2 pagesManufaktur Dan Test Sertifikat PDFYor DanBa NiaraNo ratings yet

- Cive4307 LecturesDocument374 pagesCive4307 Lecturesrizwan ghafoor100% (1)

- Drawings of BoilerDocument10 pagesDrawings of Boilerramnath008100% (1)

- AMC FormatDocument4 pagesAMC FormatGroup RMRNo ratings yet

- 4Way-valve-operationsDocument16 pages4Way-valve-operationsHerman100% (1)

- Basic Plumbing WrittenDocument8 pagesBasic Plumbing WrittenJullie Ann SolanoNo ratings yet

- Calc. Hid. ManguerasDocument8 pagesCalc. Hid. ManguerasJonahtan A. Navas G.No ratings yet

- Dayco Idler/Tensioner Pulley Dimensions and ConfigurationDocument2 pagesDayco Idler/Tensioner Pulley Dimensions and ConfigurationKhoirulHakimNo ratings yet

- Drawing Receiver Tank by DayasaDocument1 pageDrawing Receiver Tank by DayasaMohammad AnshoryNo ratings yet

- RF Valves Descripcion General Valvula Pinch Con Actuador NeumaticoDocument5 pagesRF Valves Descripcion General Valvula Pinch Con Actuador NeumaticoRonulfo GutierrezNo ratings yet

- 6 Series Weld FittingsDocument10 pages6 Series Weld FittingsNilesh MistryNo ratings yet

- Storm Water Detention & Retention Installation Instructions & Technical InformationDocument24 pagesStorm Water Detention & Retention Installation Instructions & Technical InformationBarrasons Engineers TeamNo ratings yet

- PLDT Bacoor Plumbing Technical SpecificationsDocument205 pagesPLDT Bacoor Plumbing Technical Specificationsrerenz musniNo ratings yet

- FME 002 Fluid Mechanics TrainerDocument1 pageFME 002 Fluid Mechanics TrainerInquiry XEEPLNo ratings yet

- Dkrci - Pd.if0.a7.02 SfaDocument10 pagesDkrci - Pd.if0.a7.02 Sfaali_irvNo ratings yet

- Tubing Pipe Dimensions Weight ChartDocument1 pageTubing Pipe Dimensions Weight ChartTahiruddin AhmedNo ratings yet

- ME2134 NUS PipeflowDocument47 pagesME2134 NUS PipeflowMohammad TahaNo ratings yet