Professional Documents

Culture Documents

Axd Timing

Uploaded by

docrobb_Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Axd Timing

Uploaded by

docrobb_Copyright:

Available Formats

Instructions for:

DIESEL ENGINE SETTING/LOCKING KIT -

VOLKSWAGEN 2.5TDi - PUMP DSE -

GEAR DRIVE

MODEL No: VS5035

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions and properly

maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND CAUTIONS.

USE THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE

AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY INSTRUCTIONS

WARNING! Ensure Health and Safety, local authority Applications:

and general workshop practice regulations are adhered

to when using tools. VW GROUP 2.5 TDi Pump Dse Diesel engine (GEAR) in:

DO NOT use tools if damaged.

Maintain tools in good and clean condition for best and VOLKSWAGEN:

safest performance.

Ensure that a vehicle which has been jacked up is Transporter 03-08

adequately supported with axle stands. Touareg 03-08

Wear approved eye protection. A full range of personal Multivan 04-08

safety equipment is available from your Sealey dealer.

Wear suitable clothing to avoid snagging. DO NOT wear AXD, AXE, BAC, BLJ, BLK, BNZ, BPC, BPD and

jewellery and tie back long hair.

DO NOT attempt to start engine or move vehicle whilst BPE engines.

in gear with locking devices fitted.

Always display warning notification on steering wheel

when locking engine components.

Account for all tools, locking bolts, pins and parts being

used and do not leave them in or near the engine.

WARNING! Incorrect or out of phase camshaft timing

can result in contact between valve head and piston

crown causing damage to the engine.

IMPORTANT: These instructions are provided as a guide

only. Always refer to the vehicle manufacturers service

instructions, or a proprietary manual, to establish the

current procedure and data.

2. contents & applications

Suitable for timing gear drive engines where the camshaft,

crankshaft and auxiliary shafts are all linked by a series of

inter-meshed cogs.

Kit contents

Item Part Number Description

1 VS5031 Crankshaft TDC Position Tool

2 VS5032 Crankshaft Locking Tool

3 VS5033 Camshaft Locking Tool

4 VS5034 Camshaft Gear Clamp

5 VS5036 Eccentric Pin Holding Tool

6 VS5037 Camshaft Gear Adjuster

- VS5035-84 Case + Insert

Original Language Version VS5035 Issue No: 1 - 08/07/10

3. instructions

Introduced in 2003, the 2,5L TDi Pump Dse engines utilise

a helical-toothed spur gear set that drives the camshaft and

all engine auxiliaries from the crankshaft. The engine fan is

electrically driven.

NOTE: The tools in this timing kit are used in a specific

sequence, and it will save time and make selection of the

correct tools easier if the operator reads and becomes familiar

with the timing procedure beforehand.

3.1. Checking the Valve Timing.

IMPORTANT: To check the valve timing, the crankshaft is

positioned at TDC at cylinder number 1. fig.2

3.1.2. VS5032 Crankshaft Locking Tool.

VS5032 Locks the crankshaft in position with number 1

cylinder at TDC.

Fit VS5032 Crankshaft Locking Tool onto the crankshaft,

at the same time engaging the clamp pin through the

engine mounting in the cylinder block using the stepped

pin (fig.2).

NOTE: When the engine is removed from the vehicle, or

the engine mounting is removed, the alternative

straight pin is positioned directly into the cylinder

block.

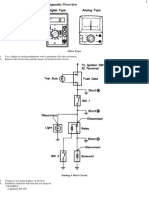

fig.1

3.1.1. VS5031 Crankshaft TDC Position Tool.

VS5031 is used to rotate the crankshaft to the timed

position.

Position VS5031 Crankshaft TDC Position Tool onto the

crankshaft (fig.1); turn the crankshaft in the direction of

engine rotation aligning the marks on VS5031 and the

sealing flange.

NOTE: The Crankshaft Locking Tool locates onto the

crankshaft in only one position.

The crankshaft is now timed in the correct position with fig.3

number 1 cylinder at TDC.

Remove VS5031 Position Tool

3.1.3. Attach the Crankshaft Locking Tool onto the crankshaft

with the screw provided (fig.3).

NOTE: The Crankshaft Locking Tool fits in only one

position on the crankshaft. If it is not possible to fit the

Locking Tool, re-fit VS5031 and turn the crankshaft one

revolution, in the direction of engine rotation, until the

marks on VS5031 and the sealing flange align again.

Original Language Version VS5035 Issue No: 1 - 08/07/10

fig.6

3.2.2. Position the crankshaft at TDC for cylinder number 1.

Position VS5031 Crankshaft TDC Position Tool onto

the crankshaft (fig.6); turn the crankshaft in the direction

fig.4

of engine rotation aligning the marks on VS5031 and

the sealing flange.

NOTE: The Crankshaft Locking Tool fits in only one

3.1.4. VS5033 Camshaft Locking Tool. position on the crankshaft.

VS5032 is used to accurately align a datum slot, located The crankshaft is now timed in the correct position with

in the end of the camshaft with a datum hole in the number 1 cylinder at TDC.

cylinder head, to hold the camshaft at the TDC position.

Fit the VS5033 Camshaft Locking Tool in position (fig.4).

fig.7

fig.5

3.2.3. VS5034 Camshaft Gear Clamp

VS5034 Camshaft Gear Clamp is used to support the

3.1.5. Check the position of the camshaft gear. camshaft gear to allow the camshaft gear fixing bolt to

The timing is correct when the marking arrow on the be removed.

sender wheel is aligned with the upper edge of the

cylinder head sealing surface as in fig.5. 3.2.4. Remove the outer bearing cap and position VS5034

If the marking arrow does not align, adjustment of the Camshaft Gear Clamp onto the camshaft gear and

valve timing will be necessary. tighten the four bolts to 40 Nm (fig.7).

3.2. Adjusting the Valve Timing. 3.2.5. Loosen the fixing bolt of the camshaft gear and remove

When adjusting the valve timing, removing and with the tandem pump shaft.

installing the cylinder head, removing and installing the

camshafts, it is necessary to remove the camshaft drive 3.2.6. Release the four bolts securing the Camshaft Gear

gear Clamp and remove VS5034.

3.2.1. Removing camshaft drive gear

3.2.7. Remove the camshaft gear from the camshaft.

It will be necessary to remove the acoustic cover,

cylinder head cover and the tandem pump. 3.2.8. Unbolt the sealing cover from the eccentric pin, removing

the securing bolt and pulling the eccentric pin out.

Original Language Version VS5035 Issue No: 1 - 08/07/10

3.2.9. Remove the camshaft drive gear.

IMPORTANT: Care must be taken when removing the

camshaft drive gear and the compensating link.

3.3. Installing Camshaft Drive Gear.

fig.9

3.3.3. Fit VS5032 Crankshaft Locking Tool onto the crankshaft

at the same time engaging the clamp pin through the

engine mounting on the cylinder block using the

stepped pin (fig.2).

NOTE: When the engine is removed from the vehicle,

fig.8 or the engine mounting is removed, the alternative

straight pin is positioned directly into the cylinder block.

3.3.4. Attach the Crankshaft Locking Tool onto the crankshaft

3.3.1. Position VS5031 Crankshaft TDC Position Tool onto with the screw provided.

the crankshaft (fig.8); turn the crankshaft in the direction

of engine rotation aligning the marks on VS5031 and the NOTE: The Crankshaft Locking Tool fits in only one

sealing flange. position on the crankshaft. If it is not possible to fit the

Locking Tool, re-fit VS5031 and turn the crankshaft one

NOTE: The Crankshaft Locking Tool fits in only one revolution, in the direction of engine rotation, until the

position on the crankshaft. marks on VS5031 and the sealing flange align again.

The crankshaft is now timed in the correct position with

number 1 cylinder at TDC.

3.3.2. Remove VS5031 Position Tool.

fig.10

3.3.5. Fit VS5033 Camshaft Locking Tool in position (fig.10).

Original Language Version VS5035 Issue No: 1 - 08/07/10

fig.11

3.3.6. Install the camshaft drive gear (fig11.1) onto the guide

sleeve (fig.11.2) ensuring all surfaces of the guide sleeve fig.13

are oiled.

3.3.7. Install the disc (fig.11.3) engaging the lugs in the grooves

of the guide sleeve (fig.11.2).

3.3.9. Guide the link plate (fig.13.4) and the camshaft drive gear

3.3.8. Install the drive gear (fig.11.1) with disc (fig.11.3) and the

(fig.13.1) into the gear cavity from above.

guide sleeve (fig.11.2) on the compensating link plate

Refit the outer bearing cap and tighten hand tight.

(fig.11.4).

2

5

6

4 fig.12 fig.14

WARNING: The marks on the guide sleeve (fig.12.2)

and the link plate (fig.12.4) must align.

3.3.10. VS5036 Eccentric Pin Holding Tool

Install the eccentric pin (fig.14.5), oiling all surfaces,

ensuring that the marking on the eccentric pin (fig.14.5) is

vertical and uppermost; with the marking on the link plate

(fig.14.1) aligning with the sealing surface of the cylinder

head.

Original Language Version VS5035 Issue No: 1 - 08/07/10

fig.17

3.3.16. Position the camshaft gear wheel onto the camshaft

ensuring that the marking arrow on the sender wheel aligns

with the upper edge of the cylinder head sealing surface

(fig.17).

fig.15

fig.15

3.3.17. Using a new bolt secure the camshaft gear wheel and the

tandem pump shaft, tighten bolt finger tight. At this point the

3.3.11. VS5036 is used to turn and hold the eccentric pin in the

camshaft gear wheel can still turn.

installed position whilst securing with a new bolt (fig.15).

NOTE: Lubricate the gear wheel teeth with engine oil prior to

installation.

fig.16

3.3.12. Install a new securing bolt (fig.12.6) for the eccentric

pin (fig.12.5) and tighten by hand, then unscrew

back approximately one thread pitch.

fig.18

3.3.13. Position VS5036 Eccentric Pin Holding Tool with a torque

wrench into the holes of the eccentric, turning the eccentric

pin carefully anti-clockwise and tighten to 50Ncm 3.3.18. VS5037 Camshaft Gear Adjuster.

VS5037 is used to eliminate play in the gear train before

3.3.14. Whilst holding the eccentric pin in this position, tighten new

tightening the camshaft gear securing bolt.

securing bolt to 20Nm +90. Remove the outer bearing

cap. Position VS5037 Camshaft Gear Adjuster onto the camshaft

gear and tighten the three bolts to 70Nm to clamp the

3.3.15. Install the outer bearing cap using sealant and tighten with adjuster onto the camshaft gear (fig.18).

new bolts to 8Nm + 90.

Original Language Version VS5035 Issue No: 1 - 08/07/10

fig.19

3.3.19. Using a suitable torque wrench in the square drive of the

Camshaft Gear Adjuster, exert a force of 80 Nm in the fig.21

opposite direction of engine rotation to remove play

from the gear train (fig.19).

3.3.24. Using VS5031 Crankshaft TDC Positioning Tool (fig.21),

Whilst maintaining this force, tighten the camshaft gear rotate the engine in direction of engine rotation twice

securing bolt to 50 Nm. until the crankshaft is set again to TDC No.1 cylinder.

NOTE: Tightening this camshaft gear securing bolt will 3.3.25. Refit VS5032 Crankshaft Locking Tool and VS5033

require the assistance of a second mechanic. Camshaft Locking Tool to check the timing position -

as described in Checking valve timing.

3.3.20. Remove the Camshaft Gear Adjuster.

3.3.26. Remove all tools.

fig.20

3.3.21. Position VS5034 Camshaft Gear Clamp onto the

camshaft gear and tighten the four bolts to 40Nm.

NOTE: Ensure that the clamp plate fits fully onto the

surface of the cylinder head with no gap (fig.20).

3.3.22. Tighten camshaft gear securing bolt to 150 Nm + 90

Remove all tools.

3.3.23. Install the tandem pump, cylinder head cover and

acoustic cover.

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this equipment.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

Sole UKDistributor, Sealey Group, 01284 757500 www.sealey.co.uk

Kempson Way, Suffolk Business Park, Web

Bury St. Edmunds, Suffolk 01284 703534

IP32 7AR email sales@sealey.co.uk

Original Language Version VS5035 Issue No: 1 - 08/07/10

You might also like

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003From EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Rating: 5 out of 5 stars5/5 (1)

- Mitsubishi Engine F9Q Series Workshop ManualDocument48 pagesMitsubishi Engine F9Q Series Workshop ManualAlexandru sNo ratings yet

- Engine - 1.3L Duratec-8V (Rocam) /1.6L Duratec-8V (Rocam) - SpecificationsDocument59 pagesEngine - 1.3L Duratec-8V (Rocam) /1.6L Duratec-8V (Rocam) - SpecificationsAlexandr Kachenovsky100% (1)

- Patrol Y61 2.8 TD Ecu System Operation DiagramDocument9 pagesPatrol Y61 2.8 TD Ecu System Operation Diagramvali_nedelea100% (1)

- Common Rail System (CRS) : Subaru Ee20 EngineDocument47 pagesCommon Rail System (CRS) : Subaru Ee20 EngineJose Manuel PichardoNo ratings yet

- 2013 Volvo XC60Document186 pages2013 Volvo XC60Nestor YujraNo ratings yet

- EWD of Zace DR077W (VN)Document41 pagesEWD of Zace DR077W (VN)Binh Binh100% (1)

- 2AZ-FE FuelDocument43 pages2AZ-FE FuelAdedeji OluwatobilobaNo ratings yet

- Sect 1 Troubleshooting 1kd Engine Ce302Document330 pagesSect 1 Troubleshooting 1kd Engine Ce302Agustin Borge Garcia50% (2)

- Technical Specifications - EcoSportDocument1 pageTechnical Specifications - EcoSportBerg Auto Repairs100% (1)

- Motor Ford Ranger PDFDocument782 pagesMotor Ford Ranger PDFPedro AguileraNo ratings yet

- Installation & Timing of the VP44 Fuel Injection PumpDocument6 pagesInstallation & Timing of the VP44 Fuel Injection PumpAlberto AbarcaNo ratings yet

- Engine V9X NavaraDocument394 pagesEngine V9X Navaramichiganangola91% (11)

- Jaugar XJ X350 Electrical GuideDocument196 pagesJaugar XJ X350 Electrical GuideVolvej100% (1)

- Cruise Control, ECT and A/T IndicatorDocument29 pagesCruise Control, ECT and A/T IndicatorImam DedyNo ratings yet

- Toyota Land Cruiser Prado 150 Series Maintenance ScheduleDocument1 pageToyota Land Cruiser Prado 150 Series Maintenance ScheduleResty Remigio100% (1)

- Sec5a4 Abs AsrDocument94 pagesSec5a4 Abs AsrTadas PNo ratings yet

- Engine ControlDocument19 pagesEngine ControlBeymar Beltran SebastianNo ratings yet

- Dokumen - Tips Isuzu 07tf Immobilizer Training Ver1Document50 pagesDokumen - Tips Isuzu 07tf Immobilizer Training Ver1Chamila tharanga madushanNo ratings yet

- vnx.su x trail t30 sm - Часть2 PDFDocument1,770 pagesvnx.su x trail t30 sm - Часть2 PDFnssn1100% (4)

- Focus Data Systems / Mumbai Office: List of Ashok Leyland Vehicles SupportedDocument4 pagesFocus Data Systems / Mumbai Office: List of Ashok Leyland Vehicles SupportedDhruba Jyoti KumarNo ratings yet

- Mitsubishi Engine 6G7 E W Series Workshop ManualDocument68 pagesMitsubishi Engine 6G7 E W Series Workshop ManualJimmy Brian Kaifiti0% (1)

- ENGINE Timing 4ZZ-FEDocument31 pagesENGINE Timing 4ZZ-FEAriel100% (1)

- WarningDocument268 pagesWarningElguaro MecánicoNo ratings yet

- Cam Belt (M40)Document11 pagesCam Belt (M40)Metin OmerNo ratings yet

- Circ Electrico Eps-EtiosDocument4 pagesCirc Electrico Eps-EtiosAngel RodríguezNo ratings yet

- Nissan Y61 Engine MechanicalDocument65 pagesNissan Y61 Engine Mechanicalblumng100% (2)

- Cruise Control (1VD-FTV W/o DPF) (Before Jan. 2013 Production), ECT and A/T Indicator (1VD-FTV W/o DPF) (Before Jan. 2013 Production), Engine Control (1VD-FTV W/o DPF) (Before Jan. 2013 Production)Document28 pagesCruise Control (1VD-FTV W/o DPF) (Before Jan. 2013 Production), ECT and A/T Indicator (1VD-FTV W/o DPF) (Before Jan. 2013 Production), Engine Control (1VD-FTV W/o DPF) (Before Jan. 2013 Production)Yannick de WalqueNo ratings yet

- VW Golf 7 Wiring Diagrams EngDocument1,698 pagesVW Golf 7 Wiring Diagrams EngExpress CarParts100% (2)

- or Read: Hino Ef750 Engine HP PDF EbookDocument4 pagesor Read: Hino Ef750 Engine HP PDF Ebookvadim vadim33% (3)

- Nissan NP 200Document13 pagesNissan NP 200anticoo0% (2)

- Overall Electrical Wiring Diagram for Toyota HiluxDocument2 pagesOverall Electrical Wiring Diagram for Toyota HiluxDanilo PierreNo ratings yet

- Overview CDNC, CDNB, Cada, Caeb and CdzaDocument17 pagesOverview CDNC, CDNB, Cada, Caeb and CdzaaritmeticsNo ratings yet

- Document SummaryDocument3 pagesDocument Summarypakiturbo2papeles100% (1)

- OM 460 LA: 6-Cylinder In-Line Diesel EngineDocument16 pagesOM 460 LA: 6-Cylinder In-Line Diesel EngineВлад Беломестнов100% (1)

- Clutch Hino 5.5Document5 pagesClutch Hino 5.5Yeam_90No ratings yet

- Ford Fiesta 1996 2002 Workshop ManualDocument357 pagesFord Fiesta 1996 2002 Workshop Manualעליזה שדמי50% (2)

- 1 9 Tdi PDDocument21 pages1 9 Tdi PDMohd Fairus100% (1)

- Nissa Patrol Engine Control SistemDocument192 pagesNissa Patrol Engine Control SistemblumngNo ratings yet

- 4m41 Pump160061130 Bomba VE VRZ EE14E 11162 VRZ Service ManualDocument117 pages4m41 Pump160061130 Bomba VE VRZ EE14E 11162 VRZ Service Manualesyjam67% (3)

- Common Rail Injector Tester CR-C +S60H Multifunction Test MachineDocument3 pagesCommon Rail Injector Tester CR-C +S60H Multifunction Test MachineAlen HuangNo ratings yet

- 4D33 4D34T4 MT - 6 PDFDocument1 page4D33 4D34T4 MT - 6 PDFwilmanesNo ratings yet

- Renault-Nissan V9X EngineDocument2 pagesRenault-Nissan V9X EngineRoberto Ortega MicalizziNo ratings yet

- Mazda l3 With TC Engine Workshop Manual PDFDocument70 pagesMazda l3 With TC Engine Workshop Manual PDFJuan Idrovo100% (1)

- Mercedes-Benz C-Class (W205) Fuse Diagram Fuse Diagram PDFDocument18 pagesMercedes-Benz C-Class (W205) Fuse Diagram Fuse Diagram PDFDevi Sharan PrajapatiNo ratings yet

- Comprobaciones en Hilux 2KD Sintoma Perdida de Potencia.Document18 pagesComprobaciones en Hilux 2KD Sintoma Perdida de Potencia.Norman Valle SáenzNo ratings yet

- Injection Pump Assy Parts List and DiagramDocument5 pagesInjection Pump Assy Parts List and DiagramElisio MarquesNo ratings yet

- 3736a G9T Common Rail System (001-068) PDFDocument68 pages3736a G9T Common Rail System (001-068) PDFIlija MihajlovićNo ratings yet

- Car wiring diagram color codesDocument1 pageCar wiring diagram color codesFabian Carrasco NaulaNo ratings yet

- Workshop Manual Puma 2.2LDocument152 pagesWorkshop Manual Puma 2.2LGaston Como100% (6)

- Engine ASZDocument52 pagesEngine ASZkalleanka00100% (1)

- TransitDocument15 pagesTransitRuanWheelingNo ratings yet

- Technical data on the Hyundai H1 2.5 TCI vehicleDocument22 pagesTechnical data on the Hyundai H1 2.5 TCI vehicleJesús AraizaNo ratings yet

- Holden Alloytec Camshaft TimingDocument9 pagesHolden Alloytec Camshaft Timingducatiss900No ratings yet

- Hat Z InstructionDocument81 pagesHat Z InstructionAros IsaiasNo ratings yet

- Keihin KS2Document2 pagesKeihin KS2spotNo ratings yet

- Toyota Fortuner (EM3275E) - Relay LocationsDocument37 pagesToyota Fortuner (EM3275E) - Relay Locationsyudianto sugyty100% (2)

- Motores 4H Series MT-OrG (150-170)Document21 pagesMotores 4H Series MT-OrG (150-170)VictorNo ratings yet

- 05 - ECR Engine Control System (M9R)Document333 pages05 - ECR Engine Control System (M9R)Ady Lăscuș83% (6)

- Diesel Fuel Injector and System OperationDocument1 pageDiesel Fuel Injector and System Operationdocrobb_No ratings yet

- Ewj - 14a 5Document1 pageEwj - 14a 5docrobb_No ratings yet

- Diesel Fuel Injector and System OperationDocument1 pageDiesel Fuel Injector and System Operationdocrobb_No ratings yet

- Ac Compressor Oil Checking PDFDocument3 pagesAc Compressor Oil Checking PDFdocrobb_No ratings yet

- Eurocargo Tector 6-26t Electronic System PDFDocument192 pagesEurocargo Tector 6-26t Electronic System PDFRogério Moreno80% (15)

- Eurocargo Tector 6-26t Electronic SystemDocument1 pageEurocargo Tector 6-26t Electronic Systemdocrobb_No ratings yet

- General - PDF 1Document29 pagesGeneral - PDF 1Belinda Van NieuwenhuyzenNo ratings yet

- General - PDF 1Document29 pagesGeneral - PDF 1Belinda Van NieuwenhuyzenNo ratings yet

- VW Audi Vag K Can Commander 3.6 Install ManualDocument3 pagesVW Audi Vag K Can Commander 3.6 Install Manualdocrobb_No ratings yet

- Factory Cross Interchange NumbersDocument2 pagesFactory Cross Interchange Numbersdocrobb_No ratings yet

- Atmel 8271 8 Bit AVR Microcontroller ATmega48A 48PA 88A 88PA 168A 168PA 328 328P - Datasheet - Complete PDFDocument650 pagesAtmel 8271 8 Bit AVR Microcontroller ATmega48A 48PA 88A 88PA 168A 168PA 328 328P - Datasheet - Complete PDFNext MillNo ratings yet

- Samsung 5115 ManualDocument178 pagesSamsung 5115 Manualdocrobb_No ratings yet

- Data SheetDocument30 pagesData Sheetdocrobb_No ratings yet

- GaAs Infrared Emitter OPE5594A Specs & PerformanceDocument2 pagesGaAs Infrared Emitter OPE5594A Specs & Performancedocrobb_No ratings yet

- General Purpose Rectifiers: Absolute Maximum RatingsDocument3 pagesGeneral Purpose Rectifiers: Absolute Maximum Ratingsdocrobb_No ratings yet

- MM74HC00 Quad 2-Input NAND Gate: General Description FeaturesDocument7 pagesMM74HC00 Quad 2-Input NAND Gate: General Description Featuresdocrobb_No ratings yet

- MM74HC00 Quad 2-Input NAND Gate: General Description FeaturesDocument7 pagesMM74HC00 Quad 2-Input NAND Gate: General Description Featuresdocrobb_No ratings yet

- 1 N N4007Document3 pages1 N N4007Trương Quốc HưngNo ratings yet

- IC Engine Seminar ReportDocument25 pagesIC Engine Seminar Reportrupam_chanda75% (4)

- 1KR-FE Engine Control System Service DataDocument2 pages1KR-FE Engine Control System Service DataTiaanNo ratings yet

- Workshop Manual, Technical Data D16Document52 pagesWorkshop Manual, Technical Data D16Ramón Rafael León Osuna100% (2)

- Westerbeke Parts 8-15-2019 PDFDocument330 pagesWesterbeke Parts 8-15-2019 PDFjitmarineNo ratings yet

- ABC Dual Fuel Engines DatasheetDocument4 pagesABC Dual Fuel Engines DatasheetMartin KratkyNo ratings yet

- Subaru Justy L3-1.2 2wd Carb Repair PDFDocument557 pagesSubaru Justy L3-1.2 2wd Carb Repair PDFThezoharKabbalahNo ratings yet

- Engine Control Module (ECM) TitleDocument10 pagesEngine Control Module (ECM) TitleMiguel ruiz100% (2)

- Technical Documentation: M57TU EngineDocument89 pagesTechnical Documentation: M57TU EngineIongornistu100% (4)

- List of Recommended Parts N45 100Document1 pageList of Recommended Parts N45 100kartikago234No ratings yet

- Unit 2 Fuel System For SI & CI EngineDocument75 pagesUnit 2 Fuel System For SI & CI EngineShalom UndefinedNo ratings yet

- Chapter 5 6 Mixture Formation in SI & CI EngineDocument12 pagesChapter 5 6 Mixture Formation in SI & CI Engineahmed jemalNo ratings yet

- Fuel Induction Techniques For A H Y D R O G E N Operated EngineDocument10 pagesFuel Induction Techniques For A H Y D R O G E N Operated Engineshivang36No ratings yet

- Puma Race Engines - Cylinder Head Modifications - Part 1: Valve SeatsDocument4 pagesPuma Race Engines - Cylinder Head Modifications - Part 1: Valve SeatsRobert DennisNo ratings yet

- M30B35M 6 Cyl.: The O.E.M Trade Mark Is Property O.E.M Supplier Company O.E.M Part No. Are Used For Reference OnlyDocument3 pagesM30B35M 6 Cyl.: The O.E.M Trade Mark Is Property O.E.M Supplier Company O.E.M Part No. Are Used For Reference OnlyЕвгений ДынникNo ratings yet

- Daelim S2 125cc Motorcycle Parts CatalogDocument88 pagesDaelim S2 125cc Motorcycle Parts CatalogHelpdesk TrpNo ratings yet

- 5 Cce 42 Ca 482 DF 8775Document10 pages5 Cce 42 Ca 482 DF 8775Purnama AbhieNo ratings yet

- HDocument46 pagesHchris_skyanNo ratings yet

- Fuel Filter Ve TypeDocument2 pagesFuel Filter Ve Typeparahu ariefNo ratings yet

- CATERPILLAR 3508 Genset TEST SPECDocument3 pagesCATERPILLAR 3508 Genset TEST SPECHendra MechanicNo ratings yet

- Fa20 Engine Control - Sfi System - Diagnostic Trouble Code Chart (2013 FR-S)Document9 pagesFa20 Engine Control - Sfi System - Diagnostic Trouble Code Chart (2013 FR-S)Bruce LyndeNo ratings yet

- KohlerDocument4 pagesKohlerAngga ClevneztNo ratings yet

- Jhon Sammuel - 110401044 - Tugas Motor BakarDocument5 pagesJhon Sammuel - 110401044 - Tugas Motor BakarAkhun NastiNo ratings yet

- 3512B Generator Set YAM00001-UP (SEBP5402 - 26) - DocumentationDocument11 pages3512B Generator Set YAM00001-UP (SEBP5402 - 26) - Documentationkrisari9No ratings yet

- 9L Plus Series PFD - PFG18, 20, 25, 30, 35 & 18C, 25C, 30C @@@Document191 pages9L Plus Series PFD - PFG18, 20, 25, 30, 35 & 18C, 25C, 30C @@@Michael AkhramovichNo ratings yet

- 4le1da07 DGK25B 01Document46 pages4le1da07 DGK25B 01Leo BurnsNo ratings yet

- Tss Crankshafts 2strokeDocument10 pagesTss Crankshafts 2strokeyusef2005No ratings yet

- Bloque y CiguenalDocument15 pagesBloque y CiguenalAlejandro ValenzuelaNo ratings yet

- Calibracion de Valvulas Honda K24 - 0Document6 pagesCalibracion de Valvulas Honda K24 - 0Willy MotorsNo ratings yet

- Auto 12.module q.2 Module 1 XDocument22 pagesAuto 12.module q.2 Module 1 XNomer PacilanNo ratings yet

- Waukesha Valve Adjustment All VHP EnginesDocument6 pagesWaukesha Valve Adjustment All VHP EnginesJoe Huff100% (1)