Professional Documents

Culture Documents

Nirosta 4104: Krupp Edelstahlprofile

Uploaded by

Luis MayorgaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nirosta 4104: Krupp Edelstahlprofile

Uploaded by

Luis MayorgaCopyright:

Available Formats

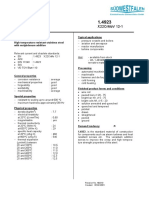

A ThyssenKrupp

Steel Company Krupp Edelstahlprofile

C: 0,10 - 0,17

Cr:

Mo:

15,5 - 17,5

0,20 - 0,40 NIROSTA 4104

S: 0,15 - 0,35 X14CrMoS 17

Typical applications

NIROSTA 4104 - automotive industry

- decorative applications and kitchen utensils

Chromium ferritic stainless steel with sulphur - electronic equipment

Hint: - available from stock

Relevant current and obsolete standards:

EN 10088-3 : 1.4104 X14CrMoS 17

AISI : 430 F Processing

BS :- - automated machining : yes

JIS : 430 F - machinable : yes

AFNOR : Z13CF 17 - hammer and die forging : seldom

DIN 17440 : 1.4104 - cold forming : yes

SIS : 2383 - cold heading : not common

- suited to polishing : no

General properties

- corrosion resistance : poor Finished product forms and conditions

- mechanical properties : good wire rod 5,5 - 27

- forgeability : average peeled bars 20 - 80

- weldability : poor bright bar h9, 3 - 80

- machinability : very good bright coils h9, 3 20

black bar 5,5 25

Special properties annealed

- ferromagnetic grade with good machinability tempered

pickled

Physical properties drawn

3

- density (kg/dm ) : 7,7 straightened

- electrical resistivity peeled

2

at 20C (W mm /m) : 0,70 ground

- magnetisable : yes

- thermal conductivity

at 20C (W/m K) : 25 Demand tendency

- specific heat capacity

at 20C (J/kg K) : 460

- thermal expansion

-6 -1

(10 K ) between

20 and 100C : 10

20 and 200C : 10,5

20 and 300C : 10,5

20 and 400C : 10,5

Revision No. 4104-0

Created: 04.05.2000

A ThyssenKrupp

Steel Company Krupp Edelstahlprofile

Properties, applications and processing

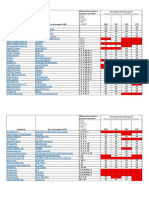

Property Spec. QT650 Typical

The machinability of NIROSTA 4104 is far supe- - yield strength (N/mm2) Rp0,2 : 500 525

- tensile strength (N/mm2) Rm : 650 850 725

rior to that of the ferritic 17% chromium steel,

NIROSTA 4016 as a result of the controlled - tensile elongation (%), A5 : 12, if d 60 19

sulphur addition to this grade of steel. The addi- : 10, if 60 <d 160

tion of sulphur however reduces the resistance to

corrosion, and as such NIROSTA 4016 is sig- Welding

nificantly more resistant to corrosion than NIRO-

In general, NIROSTA 4104 is not welded, other

STA 4104, despite their similar chromium con- than occasionally being friction or resistance

tents. welded.

Corrosion resistance (PRE = 16.16 to 19.48)* Forging

Although NIROSTA 4104, contains 17% chro- As a result of the high sulphur content and mixed

mium, the corrosion resistance of this steel is ferrite-austenite structure that exists at the forg-

severely compromised by the addition of sulphur. ing temperatures, care should be taken when

This is particularly true when exposed to envi- forging NIROSTA 4104. When forging is to be

ronments that promote pitting and crevice corro- performed, gradual heating to a temperature of

sion. about 850C is recommended prior to more rapid

* The range of PRE values that are possible for heating to a temperature of between 1100 and

this grade of steel thus have to be viewed with 1130C. Forging then takes place between 1130

some scepticism since the detrimental effects of - 1050C.

sulphur are not taken into account in the determi-

nation of PRE values. Machining

The machinability of this grade of stainless steel

Heat treatment / mechanical properties is superior to other 12 and 17% chromium steels

Annealed condition: as a result of the sulphur addition. When ma-

NIROSTA 4104 may be annealed to a fully soft chining NIROSTA 4104, the following parame-

structure by holding the steel or component at a ters can be used as a guideline:

temperature of 800C followed by slow cooling in

air. Care must however be taken to ensure that a 1. Turning CNC

temperature of 825C is not exceeded during Tensile strengths Depth of cut (mm)

annealing. In this condition, the following me- Feed rate (mm/rev)

chanical properties can be expected: Rm in N/mm2 6 mm 3 mm 1 mm

0,5 mm/r 0,4 mm/r 0,2 mm/r

Property Specification Annealed (650 - 250 m/min 300 m/min 380 m/min

- tensile strength (N/mm2) Rm : 730 720)

- hardness HB : 220

Note: the HB values could be 60 units higher and the tensile 2. Automated machining

strengths 150 N/mm2 higher due to cold work during straight-

ening of profiles 35mm. Depth of cut (mm)

Tensile strengths Feed rate (mm/rev)

Rm in N/mm2 6 mm 3 mm 1 mm

Tempering: 0,5 mm/r 0,4 mm/r 0,2 mm/r

The mechanical properties may be improved by Annealed (650 - 720)

140 m/min 155 m/min 165 m/min

quenching and tempering, in which the steel is Quenched and tempered

first hardened by holding the steel at a tempera- (730-790) 125 m/min 140 m/min 150 m/min

ture between 950 and 1070C followed by

quenching in air, oil or polymer. The tempering General comments

temperature is dependent on the desired It should be noted that as a result of the sulphur

strength. In most cases, the QT 650 condition is addition, neither minimum impact properties, nor

specified and may be obtained by following the elevated temperature properties are specified.

hardening treatment with a tempering treatment

in the temperature range 550 to 650C / air

cooled. In this condition, the following mechanical

properties can be expected:

Revision No. 4104-0

Created: 04.05.2000

You might also like

- X17Crni 16-2: C: 0,19 - 0,22 CR: 15,5 - 17,0 Ni: 1,5 - 2,5Document2 pagesX17Crni 16-2: C: 0,19 - 0,22 CR: 15,5 - 17,0 Ni: 1,5 - 2,5Aadhya engineering ServicesNo ratings yet

- Datenblatt 4105 UKDocument2 pagesDatenblatt 4105 UKVahid SarfarazNo ratings yet

- 1.4742 enDocument2 pages1.4742 enGoran ErakovicNo ratings yet

- UntitledDocument2 pagesUntitledGyurmoooNo ratings yet

- 1.4742 en PDFDocument2 pages1.4742 en PDFArielNo ratings yet

- Chromium nickel martensitic stainless steel propertiesDocument2 pagesChromium nickel martensitic stainless steel propertiesZeljko68No ratings yet

- X65Cr13 C 0.58 - 0.70 CR 12.50 - 14.50 S Max. 0.015Document2 pagesX65Cr13 C 0.58 - 0.70 CR 12.50 - 14.50 S Max. 0.015Jim SmithNo ratings yet

- 1.4006 en PDFDocument2 pages1.4006 en PDFutkuNo ratings yet

- 420 Martensitic Stainless Steel BarDocument4 pages420 Martensitic Stainless Steel BarAHMED FATHINo ratings yet

- 1.4028 enDocument2 pages1.4028 ensandeep acharNo ratings yet

- 1.4057 Aisi 431 Data Sheet PDFDocument2 pages1.4057 Aisi 431 Data Sheet PDFGagat GongatNo ratings yet

- STAINLESS STEEL 431 / S43100/ 1.4057 SS 431: AvailabilityDocument3 pagesSTAINLESS STEEL 431 / S43100/ 1.4057 SS 431: Availabilitylir mNo ratings yet

- AISI 440 Martensit PDFDocument4 pagesAISI 440 Martensit PDFJimmyVargasNo ratings yet

- Data Sheet Aluminium 6061 t6 Group (H)Document7 pagesData Sheet Aluminium 6061 t6 Group (H)احمد نعيمNo ratings yet

- Remanit: Stainless, Acid and Heat-Resistant Special Steel Grades À La CarteDocument36 pagesRemanit: Stainless, Acid and Heat-Resistant Special Steel Grades À La Cartepipedown456No ratings yet

- 1.4006 en PDFDocument2 pages1.4006 en PDFdiego.peinado8856No ratings yet

- 17 4 PHDocument2 pages17 4 PHzaranrajputNo ratings yet

- Stick Electrodes For Welding of Stainless Steels: Part NumberDocument19 pagesStick Electrodes For Welding of Stainless Steels: Part NumberAyman RiyadhNo ratings yet

- Ferrotherm 4742Document2 pagesFerrotherm 4742Özlem KarataşNo ratings yet

- 4140 High Tensile Steel PDFDocument3 pages4140 High Tensile Steel PDFFikri SiplhoNo ratings yet

- High Tensile: Voestalpine High Performance Metals (Australia) Pty LTDDocument5 pagesHigh Tensile: Voestalpine High Performance Metals (Australia) Pty LTDSinan YıldızNo ratings yet

- Boehler CN 13 4-MC - SWDocument1 pageBoehler CN 13 4-MC - SWSebastian AcostaNo ratings yet

- E 8018 B2Document1 pageE 8018 B2ElMacheteDelHuesoNo ratings yet

- 1564 Fox Ev 85 ElettrodoDocument1 page1564 Fox Ev 85 ElettrodoAminNo ratings yet

- 5 - Duplex Stainless Steels and Nickel AlloysDocument44 pages5 - Duplex Stainless Steels and Nickel AlloysdennykvgNo ratings yet

- X5CrNiCuNb 16-41.4542Document2 pagesX5CrNiCuNb 16-41.4542nuesteNo ratings yet

- 1 4021 PDFDocument2 pages1 4021 PDFSarah FitzgeraldNo ratings yet

- 17-4 Fi Us enDocument10 pages17-4 Fi Us ennaeem akramNo ratings yet

- Nicrofer 3220 3220h eDocument15 pagesNicrofer 3220 3220h eKevinCollinNo ratings yet

- Aerospace Standard Materials - Mechanical Properties - Issue 12 - 2015Document6 pagesAerospace Standard Materials - Mechanical Properties - Issue 12 - 2015Leandro González De CeccoNo ratings yet

- Type and Selection of Welding ConsumablesDocument11 pagesType and Selection of Welding ConsumablesMohit SharmaNo ratings yet

- GB235 MetalsDocument12 pagesGB235 MetalsAhmet HamamcıoğluNo ratings yet

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocument2 pagesDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelHugo RodriguezNo ratings yet

- SS 1.4122Document2 pagesSS 1.4122Bipin Sadasivan100% (2)

- Betachrome 17cr Welding ElectrodeDocument1 pageBetachrome 17cr Welding ElectrodeSatyendra SinghNo ratings yet

- P P P P: Alloy 416 Specifications: UNS S41600Document2 pagesP P P P: Alloy 416 Specifications: UNS S41600AVINASHRAJNo ratings yet

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocument2 pagesDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelBo WangNo ratings yet

- Carbo 4842 Ac-E310Document1 pageCarbo 4842 Ac-E310ali torabiNo ratings yet

- Amie Material Science Notes PDFDocument276 pagesAmie Material Science Notes PDFAlok KulkarniNo ratings yet

- 1.4462 SpecificationDocument2 pages1.4462 SpecificationSergeyNo ratings yet

- High temperature resistant stainless steel properties, applications and processingDocument2 pagesHigh temperature resistant stainless steel properties, applications and processingPrasad RvsNo ratings yet

- Worm Gear Sets CatalogueDocument29 pagesWorm Gear Sets Cataloguemohammad khoraminiaNo ratings yet

- Worm Gear Sets CatalogueDocument30 pagesWorm Gear Sets Cataloguefog900No ratings yet

- Nickel Alloys Monel 400 N04400Document4 pagesNickel Alloys Monel 400 N04400David Balboa VillenasNo ratings yet

- Electrode Booklet F Web 100Document1 pageElectrode Booklet F Web 100satnamNo ratings yet

- Butterfly Valve AMRIDocument20 pagesButterfly Valve AMRIMASOUDNo ratings yet

- Martensitic-Austenitic Stainless Steel EN 1.4418 Properties and ApplicationsDocument2 pagesMartensitic-Austenitic Stainless Steel EN 1.4418 Properties and ApplicationsLebasNo ratings yet

- Cartech Trimrite® Stainless: IdentificationDocument7 pagesCartech Trimrite® Stainless: IdentificationYassinSalahNo ratings yet

- 20160323014501-20MnCr5 - 20MnCrS5Document1 page20160323014501-20MnCr5 - 20MnCrS5singaravelan narayanasamyNo ratings yet

- 1 4418Document2 pages1 4418cristi_molinsNo ratings yet

- Steel Casting Handbook Supplement 8 - High Alloy Data Sheets - Corrosion SeriesDocument93 pagesSteel Casting Handbook Supplement 8 - High Alloy Data Sheets - Corrosion SeriesjosemiguelzuNo ratings yet

- The Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20From EverandThe Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20No ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesFrom EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNo ratings yet

- Knockout DrumsDocument1 pageKnockout DrumsCheng Kai CongNo ratings yet

- Knockout DrumsDocument1 pageKnockout DrumsCheng Kai CongNo ratings yet

- Flowcomputer Tutorial PDFDocument1 pageFlowcomputer Tutorial PDFLuis MayorgaNo ratings yet

- Knockout DrumsDocument1 pageKnockout DrumsCheng Kai CongNo ratings yet

- Flowcomputer Tutorial PDFDocument1 pageFlowcomputer Tutorial PDFLuis MayorgaNo ratings yet

- 4WI Operation and Maintenance GuideDocument216 pages4WI Operation and Maintenance GuideJohan Paul ValladaresNo ratings yet

- Density Measurement - System OverviewDocument20 pagesDensity Measurement - System OverviewLuis MayorgaNo ratings yet

- KF Series F Catalog PDFDocument16 pagesKF Series F Catalog PDFLuis MayorgaNo ratings yet

- Catalog High Performance 2 EN PDFDocument144 pagesCatalog High Performance 2 EN PDFLuis MayorgaNo ratings yet

- Catálogo Bomba NEMO BY PDFDocument2 pagesCatálogo Bomba NEMO BY PDFbohormitaNo ratings yet

- Pacific Steel Locations GuideDocument70 pagesPacific Steel Locations Guidekimyt250651No ratings yet

- Hal Helicopter Division Training ReportDocument41 pagesHal Helicopter Division Training ReportMayank Gupta67% (9)

- Bends Requirement As Ibr & AsmeDocument3 pagesBends Requirement As Ibr & AsmeSimbu ArasanNo ratings yet

- Kapitel 04 DINO Techn Teil PDFDocument4 pagesKapitel 04 DINO Techn Teil PDFManjunath NakkundiNo ratings yet

- IENG 475 - Lathe OperationsDocument27 pagesIENG 475 - Lathe OperationsJohn VincentNo ratings yet

- Shell Molding: Presented By: Suraj Kute. Ambarish BhogaDocument61 pagesShell Molding: Presented By: Suraj Kute. Ambarish Bhogasooraj67% (3)

- MIME 2130 MANUFACTURING PROCESSESDocument23 pagesMIME 2130 MANUFACTURING PROCESSESKumaradhas PaulianNo ratings yet

- A Micro Project On: Industrial Components Which Are Produced Through Non Conventional Machining ProcessesDocument26 pagesA Micro Project On: Industrial Components Which Are Produced Through Non Conventional Machining Processesrajnish patilNo ratings yet

- Hobby Metal Casting Made Easy - Melting Metal and Hobby Metalcasting Information How To Build Homebuilt Backyard Foundry How To Build Furnace Plans Step by STDocument9 pagesHobby Metal Casting Made Easy - Melting Metal and Hobby Metalcasting Information How To Build Homebuilt Backyard Foundry How To Build Furnace Plans Step by STFernando SotoNo ratings yet

- Blastrite BeadsDocument1 pageBlastrite BeadsAsad AhmedNo ratings yet

- 31CrMo23 Data SheetDocument2 pages31CrMo23 Data SheetOrnella MancinelliNo ratings yet

- Mini Farmhouse Bedside Table Plans - Ana WhiteDocument16 pagesMini Farmhouse Bedside Table Plans - Ana WhiteVerlaine RozefortNo ratings yet

- MF7203 Theory of Metal FormingDocument4 pagesMF7203 Theory of Metal FormingKanagarajanNo ratings yet

- ASME B 31.3 Table A 1B Weld Joint Quality Factor (E)Document3 pagesASME B 31.3 Table A 1B Weld Joint Quality Factor (E)groshan20No ratings yet

- Nontraditional Machining and Thermal Cutting Processes OverviewDocument26 pagesNontraditional Machining and Thermal Cutting Processes OverviewanilmechNo ratings yet

- Brochure Wheels Convolute Generalpurpose Rapidfinish Norton 8645Document6 pagesBrochure Wheels Convolute Generalpurpose Rapidfinish Norton 8645ISVARAN RAMAKRISHNANo ratings yet

- All Polyurea SystemsDocument20 pagesAll Polyurea SystemsRaheel AsgharNo ratings yet

- Proses Manufaktur - Extrusion and DrawingDocument27 pagesProses Manufaktur - Extrusion and DrawingRandy NainggolanNo ratings yet

- Machining Operations OptimizationDocument26 pagesMachining Operations OptimizationMuhmmad AliNo ratings yet

- Influence of Film Thickness and Porosity on FBE Coating PerformanceDocument6 pagesInfluence of Film Thickness and Porosity on FBE Coating PerformanceOwais MalikNo ratings yet

- MECH1210 LEC04 Material Removal Processes TurningDocument60 pagesMECH1210 LEC04 Material Removal Processes Turningmaryam.saleh.alyamani2204971No ratings yet

- Drawing Flowchart Trafilix: Steel MillDocument4 pagesDrawing Flowchart Trafilix: Steel MillSaveli Paul FlorinNo ratings yet

- TDS Pt950ir-S 950 EngDocument2 pagesTDS Pt950ir-S 950 Eng香油费No ratings yet

- Formato de Troca de Arquivo Suportado Por Software CAMDocument2 pagesFormato de Troca de Arquivo Suportado Por Software CAMJonatas PietrNo ratings yet

- Experimental Investigations On Heat Treatment of Cold WorkDocument11 pagesExperimental Investigations On Heat Treatment of Cold WorkJarek PlaszczycaNo ratings yet

- Microstructure of Metals and Materials PDFDocument70 pagesMicrostructure of Metals and Materials PDFAdriene SantosNo ratings yet

- How Mine Milling Section ReportDocument16 pagesHow Mine Milling Section ReporttkubvosNo ratings yet

- Zinc Plating InformationDocument4 pagesZinc Plating Informationankur panwarNo ratings yet

- Proje TakvimiDocument4 pagesProje TakvimiYalçın ÖzaygünNo ratings yet

- Lec 10 Commonly Used FurnacesDocument35 pagesLec 10 Commonly Used FurnacesSakunaPappuNo ratings yet