Professional Documents

Culture Documents

GASOLINE STORAGE TANK INSPECTION AND TEST PLAN

Uploaded by

Amer Y KOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GASOLINE STORAGE TANK INSPECTION AND TEST PLAN

Uploaded by

Amer Y KCopyright:

Available Formats

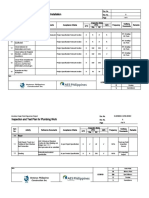

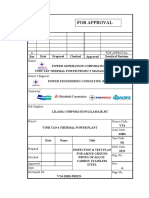

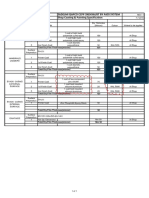

INSPECTION AND TEST PLAN For Gasoline Products Storage Tanks Painting

Rev : 0

Date 30/07/2016

Contractor: OHL-MID JV Page 1 Of 1

Project Title : AMMAN STRATEGIC RESERVE TERMINAL FOR PETROLEUM PRODUCTS Purchase Order No E00014B002

OWNER : Ministry of Energy and Mineral Resources Subcontractor : Quality International

ITP No: QICL-J810-QA&I-ITP-011

Item No. Quality Control Activity Frequency of Tests Technique/ Instrument Reference Acceptance Criteria Quality International Surveillance OMJ Surveillance MEMR/ILF Surveillance

OMJ inspection MEMR/ILF

PREPARATION ACTIVITIES QICL QICL OMJ sign & date MEMR/ILF sign & date

type inspection type

1 Painting Procedure H H H

2 Material reciving at site H H H

3 Calibration list H H R

- Air & temperature temp :10-50C

Ambient conditions & surface - RH < 70%

4 Daily Dew meter (Elcometer 319) BS 7079-B4 / ISO 8502-4 H W R

temperature - Surface Temp at least 3C above the dew

point

5 Pre-blast surface cleanliness 100% of surface Visual SSPC SP1 Removal of all visible grease &oil H S S

According to Jotun BRESLE CONDUCTIVITY KIT

6 Salt contamination ISO 8502-6 / ISO 8502-9 Salt contamination < 80 mg/m 2 H W S

specification (Elcometer 138)

Before start of each shift

absorbent or nonabsorbent Free from oil, grease & moisture and

7 Air Quality or change in compressed ASTM D4285 H R R

collector pressure at blasting nozzle is as 7 bars.

air source

8 Cleanliness of sand Each lot of sand Visual SSPC AB1 Expendable , angular slag , no visible oil H W S

Prior to primer

9 Post-blast surface cleanliness Visual ISI 8501-1 Cleanliness to be Sa 2.5 H W S

application

Prior to primer

10 Dust removal Visual ISO 85023 No visible dust H W S

application

Painting ACTIVITIES

1 Paint Starting Notification Prior to Start Painting / System H W W

Product label matches product name in

2 Painting material Visual (label) Prior to paint application Technical Submittal H R R

technical submittal

3 Material mixing Visual During mixing Product Application Guide Homogenous color , no lumps H N/A N/A

4 Proper thinning Visual During mixing Technical Submittal Type & amount as per TDS H N/A N/A

Maximum local DFT 120% of the required

Dry film thickness gage

6 Painting dry thickness After each coat when dry SSPC PA 2 / ASTM D7091 reading & Minimum local DFT 80% of the H R S

(Elcometer 456)

required reading

7 Repaint intervals Visual Prior to each successive coat Technical data sheet Technical data sheet H S S

POST PAINTING ACTIVITIES

1 Final appearance Visual After application of final coat ISO 4628 No runs, drips, sags or misses H H W

Dry film thickness gage According to DFT defined in technical

2 Verify Total DFT After each coat when dry SSPC PA 2 / ASTM D7091 H H W

(Elcometer 456) submittal

Pull Off Adhesion Test

3 Adhesion After full curing ISO 4624 Minimum 3 MPa H H W

(Elcometer 108)

* Inspection type H: Hold point S: Surveillance W: Witness N/A: Not Apply R: Review

* Material safety data sheet MSDS will be available and followed on site.

You might also like

- Inspection Test PlanDocument2 pagesInspection Test PlanBalaji Guru90% (10)

- ITP - Painting & SandBlasting Rev00Document2 pagesITP - Painting & SandBlasting Rev00Sulist N Wahyudie80% (5)

- INSPECTION AND TEST PLAN FOR PIPE RACK AND PIPING PAINTING WORKSDocument2 pagesINSPECTION AND TEST PLAN FOR PIPE RACK AND PIPING PAINTING WORKSRanjan KumarNo ratings yet

- ITP For Painting WorksDocument27 pagesITP For Painting Workssree50% (2)

- ITP Blasting Painting.Document2 pagesITP Blasting Painting.mohd as shahiddin jafri100% (4)

- Blasting & Painting Report for Project NOV OCS/BPR/1115/001Document2 pagesBlasting & Painting Report for Project NOV OCS/BPR/1115/001vinothNo ratings yet

- Itp For InsulationDocument14 pagesItp For InsulationHytham El-NoubyNo ratings yet

- Itp Concrete CoatingDocument4 pagesItp Concrete Coatingkaml100% (1)

- Painting Inspection ReportDocument1 pagePainting Inspection Reportsandipthummar1743100% (3)

- Itp PaintingDocument14 pagesItp PaintingNamta George100% (4)

- Kalseng 2 CFSPP Painting Inspection ReportDocument2 pagesKalseng 2 CFSPP Painting Inspection ReportKilerz 91100% (2)

- Painting Report FormatDocument1 pagePainting Report FormatZulHafiz100% (1)

- Inspection and Test Plan For Fire Proofing Sealer ApplicationDocument6 pagesInspection and Test Plan For Fire Proofing Sealer Applicationmoytabura96100% (6)

- Repair Touch-Up Paint ProcedureDocument10 pagesRepair Touch-Up Paint ProcedureLiyakathalikhan Shahjahan100% (1)

- Sample For Painting ReportDocument1 pageSample For Painting ReportSơn Nguyễn TháiNo ratings yet

- Painting Inspection ReportDocument1 pagePainting Inspection Reportakturkam8571% (7)

- Checklist For Painting WorksDocument4 pagesChecklist For Painting WorksifyNo ratings yet

- Method Statement For Blasting and Painting of Process EquipmentDocument11 pagesMethod Statement For Blasting and Painting of Process EquipmentNnamdi Amadi100% (3)

- Site Paint Repair Procedure IntumescentDocument4 pagesSite Paint Repair Procedure Intumescentrimshadtp100% (3)

- Method Statement For Cold GalvanizationDocument1 pageMethod Statement For Cold GalvanizationsaravanakumarpalaniNo ratings yet

- Painting Report Cd2Document139 pagesPainting Report Cd2sivaNo ratings yet

- Internal Painting Works ITPDocument2 pagesInternal Painting Works ITPPrasanna Kumar100% (1)

- RLC-AH-QP-91-3001 Inspection Test Plan For Plumbing Works-1Document6 pagesRLC-AH-QP-91-3001 Inspection Test Plan For Plumbing Works-1nighttrasherNo ratings yet

- Inspection & Test Plan Project Name: Coring and Concrete Cutting of R/C WallsDocument1 pageInspection & Test Plan Project Name: Coring and Concrete Cutting of R/C WallsA S80% (5)

- Inspection & Test Plan for HVAC Duct InstallationDocument1 pageInspection & Test Plan for HVAC Duct InstallationDong VanraNo ratings yet

- Blast & Paint Inspection Report SummaryDocument1 pageBlast & Paint Inspection Report SummaryChethan100% (1)

- Joint Coating Application & Pipe Coating Procedure-009-RappDocument8 pagesJoint Coating Application & Pipe Coating Procedure-009-Rappgst ajahNo ratings yet

- ItpDocument7 pagesItpJose Sherin100% (1)

- Procedure For Painting of TanksDocument18 pagesProcedure For Painting of TanksJijesh Arayarath100% (3)

- Report PaintDocument1 pageReport PaintEhsan KhanNo ratings yet

- ITP Check List For Metal Deck InstallationDocument2 pagesITP Check List For Metal Deck InstallationLeo PascualNo ratings yet

- Checklist Mechanical Block-Outs and Pipe SleevesDocument2 pagesChecklist Mechanical Block-Outs and Pipe SleevesImho Tep100% (1)

- 000-A-Ee-0190470 Rev1 Painting Repair ProcedureDocument34 pages000-A-Ee-0190470 Rev1 Painting Repair Procedureonur gunes100% (2)

- ITP-P-001 ITP For Above Ground Piping Rev. ADocument9 pagesITP-P-001 ITP For Above Ground Piping Rev. APhong Đỗ100% (1)

- Painting Inspection Report Final CoatDocument3 pagesPainting Inspection Report Final Coatabdulgafoor54100% (1)

- Fireproofing Check List Quality Control and Inspection Report FormDocument1 pageFireproofing Check List Quality Control and Inspection Report FormAnonymous 4e7GNjzGWNo ratings yet

- Blasting and Painting ProcedureDocument9 pagesBlasting and Painting Procedureisukuru67% (12)

- Painting Procedure GlobalDocument15 pagesPainting Procedure GlobalUbed KudachiNo ratings yet

- Inspection & Test Plan for Masonry WorksDocument3 pagesInspection & Test Plan for Masonry Worksiman arief100% (4)

- Pull Off Test ReportDocument1 pagePull Off Test ReportAhmedA.Hassan100% (1)

- Inspection and Test Plan (Itp) For Staircase Handrail 1 & 2Document3 pagesInspection and Test Plan (Itp) For Staircase Handrail 1 & 2Environ Support100% (1)

- Procedure for holiday testingDocument2 pagesProcedure for holiday testingSaptarshi MandalNo ratings yet

- Itp For Painting WorksDocument28 pagesItp For Painting WorksAhmed saberNo ratings yet

- Painting & Sand Blasting Report For Trussed StructureDocument1 pagePainting & Sand Blasting Report For Trussed StructureAshwani Dogra33% (3)

- Itp Internal CoatingDocument4 pagesItp Internal CoatingkamlNo ratings yet

- ITP AllDocument1 pageITP AllMuhammadIqbalMughalNo ratings yet

- ITP PLUMBING WORKS SampleDocument1 pageITP PLUMBING WORKS SampleJay Chris L. Beron100% (1)

- DSM-xxx-0xxx-xx, Checklist For HDPE Piping InstallationDocument1 pageDSM-xxx-0xxx-xx, Checklist For HDPE Piping Installationkadir tanzania100% (4)

- Inspection and Test Plan For HVAC Cladding Works: 0-WD860-CA250-00312 0Document3 pagesInspection and Test Plan For HVAC Cladding Works: 0-WD860-CA250-00312 0ResearcherNo ratings yet

- Method Statement For Coating of TanksDocument18 pagesMethod Statement For Coating of Tanksmkcsekar79% (14)

- Painting Procedure TemplateDocument15 pagesPainting Procedure TemplateGodwin A.udo-akan100% (2)

- ITP-Inspection and Test Plan For Camp Construction With CPP Comments PDFDocument9 pagesITP-Inspection and Test Plan For Camp Construction With CPP Comments PDFanil pk100% (1)

- Painting Report TemplateDocument1 pagePainting Report TemplateFrancisco Ona Amponin Jr.0% (1)

- ITP Inspection and Test Plan 6MODocument2 pagesITP Inspection and Test Plan 6MOAS DevNo ratings yet

- Itp For Storage TanksDocument7 pagesItp For Storage TanksHamid MansouriNo ratings yet

- Inspection and Test Plan For Structure Steel Erection WorksDocument11 pagesInspection and Test Plan For Structure Steel Erection WorksVijaya BaraniNo ratings yet

- Itp For Tank Fabrication Installation Work1 Rev02 PDFDocument22 pagesItp For Tank Fabrication Installation Work1 Rev02 PDFMichelNo ratings yet

- Shop Inspection and Test Plan for FRP Water TroughDocument29 pagesShop Inspection and Test Plan for FRP Water TroughEljo AndsNo ratings yet

- 3-23 - Painting Works Inspection and Test Plan (PL212533-SP-ETG-5231-00)Document2 pages3-23 - Painting Works Inspection and Test Plan (PL212533-SP-ETG-5231-00)Walid Amdouni100% (1)

- 242694634-Itp-for-Tank-Fabrication-Installation-Work1-rev02Document22 pages242694634-Itp-for-Tank-Fabrication-Installation-Work1-rev02au9t5teyrNo ratings yet

- Ansi b36.10 Pipe SizeDocument9 pagesAnsi b36.10 Pipe SizeSpoonful BurnsideNo ratings yet

- Awwa C208-17Document32 pagesAwwa C208-17Pablo DM100% (1)

- KeyDocument18 pagesKeyAmer Y KNo ratings yet

- Structural Steel Painting DFT Inspection Record (Beams) : Readings ( )Document5 pagesStructural Steel Painting DFT Inspection Record (Beams) : Readings ( )Amer Y KNo ratings yet

- Daikin Constant Volume With Reheat Systems AppGuide AG31-023 LR PDFDocument2 pagesDaikin Constant Volume With Reheat Systems AppGuide AG31-023 LR PDFAmer Y KNo ratings yet

- Diesel CoolerDocument1 pageDiesel CoolerAmer Y KNo ratings yet

- Key 2Document17 pagesKey 2Amer Y KNo ratings yet

- Daikin Constant Volume With Reheat Systems AppGuide AG31-023 LR PDFDocument2 pagesDaikin Constant Volume With Reheat Systems AppGuide AG31-023 LR PDFAmer Y KNo ratings yet

- Key 2Document17 pagesKey 2Amer Y KNo ratings yet

- Key 2Document18 pagesKey 2Amer Y KNo ratings yet

- Advance Steel AttributesDocument2 pagesAdvance Steel AttributesAmer Y KNo ratings yet

- TANK-01 Layout1Document1 pageTANK-01 Layout1Amer Y KNo ratings yet

- 1 Software / Instruction Manuals: A. Communications & NetworkingDocument2 pages1 Software / Instruction Manuals: A. Communications & NetworkingAmer Y KNo ratings yet

- CO2Document2 pagesCO2Amer Y KNo ratings yet

- UL Certificate of Compliance MK6s 05-02-16Document1 pageUL Certificate of Compliance MK6s 05-02-16Amer Y KNo ratings yet

- Advance Steel AttributesDocument2 pagesAdvance Steel AttributesAmer Y KNo ratings yet

- TCV Modification PlanDocument1 pageTCV Modification PlanAmer Y KNo ratings yet

- 1 Software / Instruction Manuals: A. Communications & NetworkingDocument2 pages1 Software / Instruction Manuals: A. Communications & NetworkingAmer Y KNo ratings yet

- Sadelmi Qapco CCPP 3Xhaust By Pass System Shop Coating & Painting SpecificationDocument1 pageSadelmi Qapco CCPP 3Xhaust By Pass System Shop Coating & Painting SpecificationAmer Y KNo ratings yet

- Silicone SealantDocument2 pagesSilicone SealantAmer Y KNo ratings yet

- ASME B16.4 Example 1Document8 pagesASME B16.4 Example 1Amer Y KNo ratings yet

- Petrochemical Grade Cementitious Fireproofing Product InformationDocument2 pagesPetrochemical Grade Cementitious Fireproofing Product InformationAmer Y KNo ratings yet

- Avikote AV 650-5Document2 pagesAvikote AV 650-5Amer Y KNo ratings yet

- Avikote AV 650-5 PDFDocument2 pagesAvikote AV 650-5 PDFAmer Y KNo ratings yet

- Monokote MK 6s 17Document2 pagesMonokote MK 6s 17Amer Y KNo ratings yet

- NFPA Fire Code ListDocument8 pagesNFPA Fire Code ListAnindito NurprabowoNo ratings yet

- Gantt Project Planner1Document1 pageGantt Project Planner1Amer Y KNo ratings yet

- Zamil Airconditioning Delivery - 9-8-2015Document3 pagesZamil Airconditioning Delivery - 9-8-2015Amer Y KNo ratings yet

- Pipe Identification ModelDocument1 pagePipe Identification ModelAmer Y KNo ratings yet

- AtlasConcorde NashDocument35 pagesAtlasConcorde NashMadalinaNo ratings yet

- HSSC English Model PaperDocument32 pagesHSSC English Model PaperMaryam Abdus SalamNo ratings yet

- Lecture NotesDocument6 pagesLecture NotesRawlinsonNo ratings yet

- Induction ClassesDocument20 pagesInduction ClassesMichelle MarconiNo ratings yet

- Key Fact Sheet (HBL FreedomAccount) - July 2019 PDFDocument1 pageKey Fact Sheet (HBL FreedomAccount) - July 2019 PDFBaD cHaUhDrYNo ratings yet

- Technical specifications for JR3 multi-axis force-torque sensor modelsDocument1 pageTechnical specifications for JR3 multi-axis force-torque sensor modelsSAN JUAN BAUTISTANo ratings yet

- Speed Reducer GearboxDocument14 pagesSpeed Reducer Gearboxعبد للهNo ratings yet

- Statistical Quality Control, 7th Edition by Douglas C. Montgomery. 1Document76 pagesStatistical Quality Control, 7th Edition by Douglas C. Montgomery. 1omerfaruk200141No ratings yet

- Propoxur PMRADocument2 pagesPropoxur PMRAuncleadolphNo ratings yet

- Draft SemestralWorK Aircraft2Document7 pagesDraft SemestralWorK Aircraft2Filip SkultetyNo ratings yet

- Paper SizeDocument22 pagesPaper SizeAlfred Jimmy UchaNo ratings yet

- Test Bank For Fundamental Financial Accounting Concepts 10th by EdmondsDocument18 pagesTest Bank For Fundamental Financial Accounting Concepts 10th by Edmondsooezoapunitory.xkgyo4100% (47)

- Reading Comprehension Exercise, May 3rdDocument3 pagesReading Comprehension Exercise, May 3rdPalupi Salwa BerliantiNo ratings yet

- United-nations-Organization-uno Solved MCQs (Set-4)Document8 pagesUnited-nations-Organization-uno Solved MCQs (Set-4)SãñÂt SûRÿá MishraNo ratings yet

- Condition Based Monitoring System Using IoTDocument5 pagesCondition Based Monitoring System Using IoTKaranMuvvalaRaoNo ratings yet

- Allan S. Cu v. Small Business Guarantee and FinanceDocument2 pagesAllan S. Cu v. Small Business Guarantee and FinanceFrancis Coronel Jr.No ratings yet

- TJUSAMO 2013-2014 Modular ArithmeticDocument4 pagesTJUSAMO 2013-2014 Modular ArithmeticChanthana ChongchareonNo ratings yet

- Problem Set SolutionsDocument16 pagesProblem Set SolutionsKunal SharmaNo ratings yet

- Cell Organelles ColoringDocument2 pagesCell Organelles ColoringThomas Neace-FranklinNo ratings yet

- Jesd8 15aDocument22 pagesJesd8 15aSridhar PonnurangamNo ratings yet

- The Service Marketing Plan On " Expert Personalized Chef": Presented byDocument27 pagesThe Service Marketing Plan On " Expert Personalized Chef": Presented byA.S. ShuvoNo ratings yet

- Indian Standard: Pla Ing and Design of Drainage IN Irrigation Projects - GuidelinesDocument7 pagesIndian Standard: Pla Ing and Design of Drainage IN Irrigation Projects - GuidelinesGolak PattanaikNo ratings yet

- Checklist of Requirements For OIC-EW Licensure ExamDocument2 pagesChecklist of Requirements For OIC-EW Licensure Examjonesalvarezcastro60% (5)

- Dep 32.32.00.11-Custody Transfer Measurement Systems For LiquidDocument69 pagesDep 32.32.00.11-Custody Transfer Measurement Systems For LiquidDAYONo ratings yet

- Managerial EconomicsDocument3 pagesManagerial EconomicsGuruKPONo ratings yet

- Arta Kelmendi's resume highlighting education and work experienceDocument2 pagesArta Kelmendi's resume highlighting education and work experienceArta KelmendiNo ratings yet

- Busbar sizing recommendations for Masterpact circuit breakersDocument1 pageBusbar sizing recommendations for Masterpact circuit breakersVikram SinghNo ratings yet

- Role of PAODocument29 pagesRole of PAOAjay DhokeNo ratings yet

- I Will Be Here TABSDocument7 pagesI Will Be Here TABSEric JaoNo ratings yet

- Command List-6Document3 pagesCommand List-6Carlos ArbelaezNo ratings yet