Professional Documents

Culture Documents

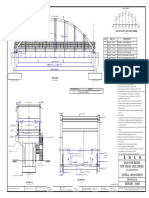

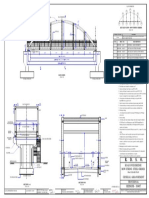

Key elevation of bow string girder

Uploaded by

goutammandOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Key elevation of bow string girder

Uploaded by

goutammandCopyright:

Available Formats

C/L OF SYMMETRY

B

C/L LINE OF SYMMETRY

ARCH

KEY ELEVATION-BOW STRING GIRDER

C/L OF BEARING

C/L OF BEARING

(SCALE 1:400)

HANGER S.NO. DRG. NO. DESCRIPTION

HAND RAIL

1. RDSO/B - 10406 GENERAL ARRANGEMENT

2. RDSO/B - 10406/1 DETAILS OF STEEL FRAME

3. RDSO/B - 10406/2 DETAILS OF ARCH & TOP JOINTS

4. RDSO/B - 10406/3 DETAILS OF TOP TIE BEAM

BEARING 5. RDSO/B - 10406/4 DETAILS OF HANGER & JOINT L0

BOTTOM LONG. BEAM

CONCRETE PEDESTAL

6. RDSO/B - 10406/5 DETAILS OF BOTTOM LONG. BEAM

7. RDSO/B - 10406/6 DETAILS OF BOTTOM CROSS BEAM

8. RDSO/B - 10406/7 DETAILS OF CONCRETE DECK SLAB

A B 9. RDSO/B - 10406/8 SPLICING LOCATIONS

NOTE:-

ELEVATION 1. All dimensions are in mm.

(SCALE 1:120)

2. No dimensions shall be scaled from this drawing, only written dimension shall be

SUITABLE FOUNDATION SUITABLE FOUNDATION

followed.

3. This bridge span is designed for 70R and A-class loading as per IRC:6-2010.

4. This bridge span is designed for earthquake zone IV.

5. Analysis and design of steel frame is as per IRC:24-2001.

6. Analysis and design of composite concrete deck is as per IRC:22-1986.

7. This bridge shall not be converted into three lane after removal of RCC crash barrier

because it is designed for two lane loading only ( as per IRC:6-2010).

6. All steel plates used in fabrication of this bridge are of grade Fe 490B.

Only ISMB 600 is of grade Fe 410C.

7. Grade of concrete for deck, crash barrier and concrete panels shall be M40.

C/L OF CARRIAGE WAY

8. All material shall pass test/analysis prescribed by relevant IS specifications.

9. All steel work fabrication shall be done in accordance with Indian Codes.

10. Workshop welding:

ARCH

a. All workshop fabrication shall be done using SAW (Submerged Arc Welding)

TIE BEAM

process only.

ARCH 11. On site welding

a. All welding, other than workshop welding, shall be done through Gas Shielded

M. S. HAND RAIL FCAW (Flux Core Arc Welding) process only. SMAW (Shielded Metal Arc

WITH WELD

MESH Welding) also known as Manual Metal Arc Welding shall NOT be permitted

RCC CRASH BARRIER

anywhere in the structure.

b. The gas Shield to be used in the FCAW process may be CO Argon or CO -Argon

POT/PTFE mixture.

BEARING

c. In FCAW process, wind screen and/or enclosures shall be provided around the

BOTTOM CROSS BEAM welding location to prevent shielding gas from blown out.

RCC BEARING d. Welding shall be performed on prepared metal surfaces free from rust, dust,

PEDESTAL STAIR CASE IS SITE SPECIFIC

moisture etc. and before every new pass, slag must be carefully chipped off

from weld surface.

12. Radiography test shall be conducted to ensure weld quality.

CARRIAGE WAY

RCC PIER CAP 13. Method of launching shall be approved by RDSO.

HANGER 14. Pier and foundation used here are to represent arrangement of bow string girder.

Actual dimensions of pier and foundation is site specific.

DRAIN PIPE 200 THK. WEARING COAT

15. Staircase is optional and may be modified as per site requirement.

65 MM THK. WEARING COAT

RCC CRASH

EXISTING ROAD/OGL

RCC PIER

BARRIER R. D. S. O.

M.S HANDRAIL

RCC PILE CAP 2.5% SLOPE 2.5% SLOPE

ROAD OVER BRIDGE

BOTTOM LONG.

BEAM

BOW STRING STEEL GIRDER

SUITABLE FOUNDATION

48m CLEAR SPAN

PCC LEVELING COURSE DRAIN PIPE BOTTOM CROSS BEAM

RCC SHUTTERING GENERAL ARRANGEMENT

SECTION A-A SECTION B-B PROVISIONAL

(SCALE 1:60)

(SCALE 1:100)

(PAPER SIZE A1) RDSO/B - 10406

C/L OF SYMMETRY

CALCULATION REGISTER NO. DD/2014/4 AutoCAD FILE NO.: B-10406

DRAWN BY: V. K. PANDEY (JE)

CHECKED BY: R. N. SHUKLA (SSE)

DESIGNED BY:

VIVEK KUMAR (ADEN/NCR/B&S/RDSO)

SCRUTINIZED & CHECKED BY:

SRIJAN TRIPATHI (DBS /SB-I)

APPROVED BY:

A. K. DADARYA (EDBS)

"THIS DRAWING IS THE PROPERTY OF RESEARCH DESIGN AND STANDARD ORGANIZATION ( MINISTRY

OF RAILWAY ), LUCKNOW-226011, INDIA, AND SHALL NOT BE USED, COPIED OR REPRODUCED IN PART

OR WHOLE, WITHOUT PRIOR CONSENT IN WRITING."

You might also like

- 60 M.bow String Girder-10411-RDocument1 page60 M.bow String Girder-10411-Rkesharinaresh80% (5)

- Link Road DRGSDocument8 pagesLink Road DRGSBasava Sowmya100% (2)

- 30 M Bow String Girder-10409-7rDocument1 page30 M Bow String Girder-10409-7rprejithNo ratings yet

- 60 M.bow String Girder-10411-4-RDocument1 page60 M.bow String Girder-10411-4-RkesharinareshNo ratings yet

- 42m BowStringDocument1 page42m BowStringsorowareNo ratings yet

- M Bow String Girder-10408-9-R PDFDocument1 pageM Bow String Girder-10408-9-R PDFPhanindra MajetiNo ratings yet

- 42 M Bow String Girder-10408-8-R1 PDFDocument1 page42 M Bow String Girder-10408-8-R1 PDFPhanindra MajetiNo ratings yet

- 60 M.bow String Girder 10411 1 RDocument1 page60 M.bow String Girder 10411 1 RkesharinareshNo ratings yet

- 42 M Bow String Girder-10408-R PDFDocument1 page42 M Bow String Girder-10408-R PDFPhanindra MajetiNo ratings yet

- Package V bridge drawingsDocument67 pagesPackage V bridge drawingsMandeep Singh100% (1)

- Detailed Survey Data: Public Works Region, Pune Public Works Circle, SolapurDocument23 pagesDetailed Survey Data: Public Works Region, Pune Public Works Circle, SolapurPravin MasalgeNo ratings yet

- Bow String Girder QuantityDocument3 pagesBow String Girder Quantityvsballa25% (4)

- Design of Gap SlabDocument15 pagesDesign of Gap Slabvivek100% (1)

- BOX CULVERT LSM 1 X 5 X 3 PDFDocument67 pagesBOX CULVERT LSM 1 X 5 X 3 PDFamitkukna100% (2)

- DN-101A-Design of Friction Slab-R1Document4 pagesDN-101A-Design of Friction Slab-R1jithinNo ratings yet

- 60 M.bow String Girder-10411-7-RDocument1 page60 M.bow String Girder-10411-7-RkesharinareshNo ratings yet

- Modified LVUP DrawingsDocument1 pageModified LVUP DrawingsAldrinNo ratings yet

- 36m BowString PDFDocument1 page36m BowString PDFgoutammand100% (2)

- Extradosed Cable Stayed Bridge Design in BSDocument111 pagesExtradosed Cable Stayed Bridge Design in BSSANDIPNo ratings yet

- Drawings For Culvert at 293+538 PDFDocument3 pagesDrawings For Culvert at 293+538 PDFSurya GowthamNo ratings yet

- Bridge BookDocument76 pagesBridge BookSunkara Hemanth KumarNo ratings yet

- Box Culvert 2 Cell x8mx5mDocument168 pagesBox Culvert 2 Cell x8mx5mrayudu vvs50% (2)

- PipeDocument30 pagesPipepudumai100% (1)

- 54 M.bow String Girder-10410-9Document1 page54 M.bow String Girder-10410-9SANJEEV VERMANo ratings yet

- DESIGN OF PIER CAPDocument13 pagesDESIGN OF PIER CAPRohit VermaNo ratings yet

- 42 M Bow String Girder-10408-1-RDocument1 page42 M Bow String Girder-10408-1-RPhanindra MajetiNo ratings yet

- Hume Pipe Culvert Drawing PDFDocument1 pageHume Pipe Culvert Drawing PDFDrainage Division CHIRALA0% (2)

- Design of PSC Box 45.0 M Span PDFDocument89 pagesDesign of PSC Box 45.0 M Span PDFsiddharth yadavNo ratings yet

- Well Tilt and Shift-Bangraghat1Document3 pagesWell Tilt and Shift-Bangraghat1ShaileshRastogiNo ratings yet

- Commentary With Worked Examples FOR IRC:6-2017: Indian Association of Structural EngineersDocument3 pagesCommentary With Worked Examples FOR IRC:6-2017: Indian Association of Structural EngineersNarayanan Jayachandran100% (3)

- Precast Pier Cap 01Document1 pagePrecast Pier Cap 01Gajendra Bisht100% (1)

- 9 Sacrificial - Shuttering-1 by RMDocument18 pages9 Sacrificial - Shuttering-1 by RMASHISANo ratings yet

- R. D. S. O.: Rdso/b - 10408/6Document1 pageR. D. S. O.: Rdso/b - 10408/6MUTHU PANDINo ratings yet

- PCC Breast Wall 11-05-2021-ModelDocument1 pagePCC Breast Wall 11-05-2021-ModelEr navneet jassiNo ratings yet

- BR - No - Staging - Solid SlabDocument6 pagesBR - No - Staging - Solid Slabmohana tNo ratings yet

- Rdso B-11753 5R1Document1 pageRdso B-11753 5R1shibnath lahiriNo ratings yet

- 42 M Bow String Girder-10408-2-R PDFDocument1 page42 M Bow String Girder-10408-2-R PDFPhanindra MajetiNo ratings yet

- Design of retaining wall toe stabilityDocument6 pagesDesign of retaining wall toe stabilitySomil YadavNo ratings yet

- RDSO Guidelines On Seismic Design of Railway Bridges PDFDocument95 pagesRDSO Guidelines On Seismic Design of Railway Bridges PDFSreeraja Sreevilasan57% (7)

- Amendment To IRC 24 - 2010Document6 pagesAmendment To IRC 24 - 2010mrraee4729100% (1)

- Designed Date Details Checked Title DocnoDocument4 pagesDesigned Date Details Checked Title DocnovivekNo ratings yet

- 40 M COMPOSITE GIRDER New-ModelDocument1 page40 M COMPOSITE GIRDER New-Modelabhijeet sahuNo ratings yet

- HI-SI Toll Plaza Marking R2-23-01-2020 Final PDFDocument4 pagesHI-SI Toll Plaza Marking R2-23-01-2020 Final PDFRamBhuvan SonkarNo ratings yet

- IRC 83-4.2014 - Amendment No. 2 - Dec 2019 PDFDocument4 pagesIRC 83-4.2014 - Amendment No. 2 - Dec 2019 PDFJayantNo ratings yet

- Shimla Bypass Cable Stayed Bridge BOQDocument11 pagesShimla Bypass Cable Stayed Bridge BOQShaileshRastogi100% (1)

- Design - PCC Toe WallDocument10 pagesDesign - PCC Toe Wallsiddharth yadavNo ratings yet

- Joint Details of Bridge StructureDocument1 pageJoint Details of Bridge StructurePhanindra MajetiNo ratings yet

- GAD of Structure - A-13 - 2 PDFDocument30 pagesGAD of Structure - A-13 - 2 PDFmayank007aggarwal0% (1)

- 36m BowString PDFDocument1 page36m BowString PDFD SRINIVASNo ratings yet

- Typical Design Calculations of PierDocument40 pagesTypical Design Calculations of PierAjayvidyanand Sharma100% (1)

- Bato-Cogon Pertcpm (Final)Document1 pageBato-Cogon Pertcpm (Final)MANNY CARAJAYNo ratings yet

- Rigid Pavement Details - 13.01.2022Document5 pagesRigid Pavement Details - 13.01.2022Sambit NayakNo ratings yet

- NAS1713Document2 pagesNAS1713Bogdan RusuNo ratings yet

- Accent 2012 1.6 AC Auto 1Document1 pageAccent 2012 1.6 AC Auto 1Vince MichaelsNo ratings yet

- Wall Section 2Document1 pageWall Section 2sadafNo ratings yet

- BILL OF MATERIALS LISTDocument1 pageBILL OF MATERIALS LISTNanang SujanaNo ratings yet

- 005 15 1-2'' String Stabilzer Am-Pt-Sstb-15120013 (12-12-21) PmiDocument1 page005 15 1-2'' String Stabilzer Am-Pt-Sstb-15120013 (12-12-21) PmiAboozar FathinejadNo ratings yet

- Samsung+max909 910 916 929 930 932 (P) 936 938 939 940 941 PDFDocument7 pagesSamsung+max909 910 916 929 930 932 (P) 936 938 939 940 941 PDFSergioNo ratings yet

- Bill of Materials for Wegmans Food Markets Harrison NY ProjectDocument1 pageBill of Materials for Wegmans Food Markets Harrison NY ProjectCursed SquadNo ratings yet

- A509r SM 4712746327 PDFDocument30 pagesA509r SM 4712746327 PDFjuampere2No ratings yet

- Fixture 2023Document8 pagesFixture 2023goutammandNo ratings yet

- Main Draw List 1 Yonex Sunrise 46th Junior National Badminton Championships 2023 at BangaloreDocument19 pagesMain Draw List 1 Yonex Sunrise 46th Junior National Badminton Championships 2023 at BangaloregoutammandNo ratings yet

- Images More Tools - Size Color Type Time Usage Rights: Allmapsnews VideosDocument10 pagesImages More Tools - Size Color Type Time Usage Rights: Allmapsnews VideosgoutammandNo ratings yet

- Images More Tools: Allnews BooksmapsDocument3 pagesImages More Tools: Allnews BooksmapsgoutammandNo ratings yet

- Bihar: From Wikipedia, The Free EncyclopediaDocument19 pagesBihar: From Wikipedia, The Free EncyclopediagoutammandNo ratings yet

- Images More Tools: Allmapsnews VideosDocument3 pagesImages More Tools: Allmapsnews VideosgoutammandNo ratings yet

- Bhopal: From Wikipedia, The Free EncyclopediaDocument15 pagesBhopal: From Wikipedia, The Free EncyclopediagoutammandNo ratings yet

- Rules Football U17Document1 pageRules Football U17goutammandNo ratings yet

- Government of Assam: Skip To Main ContentDocument10 pagesGovernment of Assam: Skip To Main ContentgoutammandNo ratings yet

- JapanDocument19 pagesJapangoutammandNo ratings yet

- Images More Tools: All NewsmapsbooksDocument5 pagesImages More Tools: All NewsmapsbooksgoutammandNo ratings yet

- Images More Tools: All MapsnewsvideosDocument5 pagesImages More Tools: All MapsnewsvideosgoutammandNo ratings yet

- Images More Tools - Size Color Type Time Usage Rights: Allmapsnews VideosDocument10 pagesImages More Tools - Size Color Type Time Usage Rights: Allmapsnews VideosgoutammandNo ratings yet

- Images More Tools: All MapsnewsbooksDocument4 pagesImages More Tools: All MapsnewsbooksgoutammandNo ratings yet

- Images More Tools - Size Color Type Time Usage Rights: Allmaps NewsvideosDocument6 pagesImages More Tools - Size Color Type Time Usage Rights: Allmaps NewsvideosgoutammandNo ratings yet

- Images More Tools - Size Color Type Time Usage Rights: Allmaps NewsvideosDocument5 pagesImages More Tools - Size Color Type Time Usage Rights: Allmaps NewsvideosgoutammandNo ratings yet

- Images More Tools - Size Color Type Time Usage Rights: Allmapsnews VideosDocument9 pagesImages More Tools - Size Color Type Time Usage Rights: Allmapsnews VideosgoutammandNo ratings yet

- Images More Tools - Size Color Type Time Usage Rights: Allmapsnews VideosDocument10 pagesImages More Tools - Size Color Type Time Usage Rights: Allmapsnews VideosgoutammandNo ratings yet

- Images More Tools - Size Color Type Time Usage Rights: Allmapsnews VideosDocument7 pagesImages More Tools - Size Color Type Time Usage Rights: Allmapsnews VideosgoutammandNo ratings yet

- Images More Tools - Size Color Type Time Usage Rights: Allmapsnews VideosDocument10 pagesImages More Tools - Size Color Type Time Usage Rights: Allmapsnews VideosgoutammandNo ratings yet

- Images More Tools - Size Color Type Time Usage Rights: Allmapsnews VideosDocument9 pagesImages More Tools - Size Color Type Time Usage Rights: Allmapsnews VideosgoutammandNo ratings yet

- Images More Tools - Size Color Type Time Usage Rights: Allmapsnews VideosDocument9 pagesImages More Tools - Size Color Type Time Usage Rights: Allmapsnews VideosgoutammandNo ratings yet

- Images More Tools - Size Color Type Time Usage Rights: Allmapsnews VideosDocument9 pagesImages More Tools - Size Color Type Time Usage Rights: Allmapsnews VideosgoutammandNo ratings yet

- Images More Tools - Size Color Type Time Usage Rights: Allnewsmaps VideosDocument8 pagesImages More Tools - Size Color Type Time Usage Rights: Allnewsmaps VideosgoutammandNo ratings yet

- Images More Tools - Size Color Type Time Usage Rights: Allmapsnews VideosDocument9 pagesImages More Tools - Size Color Type Time Usage Rights: Allmapsnews VideosgoutammandNo ratings yet

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Document4 pagesIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Vijay UrkudeNo ratings yet

- Images More Tools - Size Color Type Time Usage Rights: Allmapsnews VideosDocument9 pagesImages More Tools - Size Color Type Time Usage Rights: Allmapsnews VideosgoutammandNo ratings yet

- Essential Guide to Western AustraliaDocument9 pagesEssential Guide to Western AustraliagoutammandNo ratings yet

- India - A Diverse Nation in South AsiaDocument18 pagesIndia - A Diverse Nation in South AsiagoutammandNo ratings yet

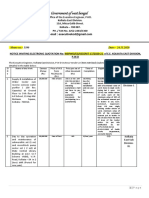

- Government of West BengalDocument10 pagesGovernment of West BengalgoutammandNo ratings yet

- Microbial biopolymers and their biodegradationDocument4 pagesMicrobial biopolymers and their biodegradationManish SoniNo ratings yet

- TEB0009 - Silane Coupling Agents - 2008Document6 pagesTEB0009 - Silane Coupling Agents - 2008nhackoloi93No ratings yet

- PaintDocument4 pagesPaintgreatgenius100% (2)

- Hydrocarbon IntermediatesDocument32 pagesHydrocarbon IntermediatesAlfarizi RamadhanNo ratings yet

- Processing Technology: Processing of Polymer Melts Made in GermanyDocument24 pagesProcessing Technology: Processing of Polymer Melts Made in GermanyRobel MTNo ratings yet

- Proteins, Carbohydrates, and LipidsDocument64 pagesProteins, Carbohydrates, and LipidsUxama Bin MajidNo ratings yet

- Sika PDS E Sikament FFDocument3 pagesSika PDS E Sikament FFSiradech SuritNo ratings yet

- Module 4 in ConChem 3rd GradingDocument2 pagesModule 4 in ConChem 3rd Gradingjohncarlodc99No ratings yet

- Sil Surf 2009Document19 pagesSil Surf 2009Dewi WijayantiNo ratings yet

- MiG AMMO Acrylic Paint ChartDocument2 pagesMiG AMMO Acrylic Paint ChartPablo Maicá Machado50% (2)

- Fed STD 141DDocument61 pagesFed STD 141DfedNo ratings yet

- CEM-001 CelaneseQuickRefTrifold AM 0913Document3 pagesCEM-001 CelaneseQuickRefTrifold AM 0913cesaroleinikNo ratings yet

- Victrex - High-Performance PolymersDocument5 pagesVictrex - High-Performance PolymersnomeNo ratings yet

- Roten Catalog PDFDocument107 pagesRoten Catalog PDFedekovacsNo ratings yet

- B-Lactam Ab 2Document34 pagesB-Lactam Ab 2Ph.first SNo ratings yet

- Tecnologia Del HuleDocument598 pagesTecnologia Del HuleJavier Dominguez100% (2)

- Polymerization ExperimentDocument9 pagesPolymerization ExperimentSamVicNo ratings yet

- Medi Pump PDFDocument8 pagesMedi Pump PDFwiroarNo ratings yet

- Basics Sports TextilesDocument49 pagesBasics Sports Textiles20MT31 - NAAVENDHAN SNo ratings yet

- Current Drug Delivery Volume 3 Issue 4 2006 (Doi 10.2174/156720106778559056) Yaqoob Khan, Azhar Talegaonkar, Sushama Iqbal, Zeenat Jalees - Multiple Emulsions - An OverviewDocument16 pagesCurrent Drug Delivery Volume 3 Issue 4 2006 (Doi 10.2174/156720106778559056) Yaqoob Khan, Azhar Talegaonkar, Sushama Iqbal, Zeenat Jalees - Multiple Emulsions - An Overviewagus nugrahaNo ratings yet

- Study Material of Soap & Detergent IndustryDocument24 pagesStudy Material of Soap & Detergent IndustrySk jahidul Islam100% (1)

- Ion ExchangeDocument24 pagesIon ExchangemarkNo ratings yet

- YASHICA Crease RecoveryDocument2 pagesYASHICA Crease RecoveryYashica Gupta100% (1)

- MCQ On HormonesDocument3 pagesMCQ On HormonesShamla HarisNo ratings yet

- Phyphar Chapter 2Document7 pagesPhyphar Chapter 2KATHLEEN CALALANGNo ratings yet

- 27384-Article Text-144526-1-10-20181203Document7 pages27384-Article Text-144526-1-10-20181203Cherif anisNo ratings yet

- Material Grade Comparison TableDocument6 pagesMaterial Grade Comparison TableGhazali Zuberi100% (3)

- Method Statement For Paint WorksDocument2 pagesMethod Statement For Paint WorksBadhur Zaman100% (2)

- Chanel No 5 GCMS, Circa 2000 Perfume, LaudamielDocument4 pagesChanel No 5 GCMS, Circa 2000 Perfume, LaudamielOsama MoussaNo ratings yet

- Kelani Cable - ArmouredDocument1 pageKelani Cable - Armouredsukiraj Rasalingam100% (1)