Professional Documents

Culture Documents

1F BCSI General Corrosion

Uploaded by

Yordan PerdomoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1F BCSI General Corrosion

Uploaded by

Yordan PerdomoCopyright:

Available Formats

What is CORROSION ?

BROWN CORROSION SERVICES, INC.

Only as Good as the Weak Link

BROWN CORROSION SERVICES, INC.

1. The reaction of a solid with

its environment

2. the eating away of metal by

electrochemical action

3. rusting and pitting of

pipelines, tanks, vessels and

other metal structures

BROWN CORROSION SERVICES, INC.

1. The reaction of a solid with

its environment

2. the eating away of metal by

electrochemical action

3. rusting and pitting of

pipelines, tanks, vessels and

other metal structures

BROWN CORROSION SERVICES, INC.

An undesirable loss of

metal by environmental

attack

BROWN CORROSION SERVICES, INC.

Metallic Oxides & Salts

Add Energy

Makes

Metals

Lose Energy

Makes

Metallic Oxides & Salts

BROWN CORROSION SERVICES, INC.

What Causes Corrosion?

There are two main factors:

1. The nature of the metal.

2. The characteristics of the environment.

BROWN CORROSION SERVICES, INC.

Five Main Causes

of Internal Corrosion

Oxygen

Carbon Dioxide (CO2)

Hydrogen Sulfide (H2S)

Chlorides (Salts)

Bacteria (MIC)

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

Typical Oxygen Corrosion

BROWN CORROSION SERVICES, INC.

CO2 Sweet Corrosion

Corrosion from the

presence of water with

dissolved CO2

BROWN CORROSION SERVICES, INC.

CO2 Sweet Corrosion

Sweet Corrosion takes the form of deep

pitting.

Gas operations that are wet and oil wells that

have water are the most common areas for

CO2 corrosion.

Gas lift and gas injection areas are prone to

CO2 corrosion.

BROWN CORROSION SERVICES, INC.

Typical CO2 Corrosion on Oilwell Tubing

BROWN CORROSION SERVICES, INC.

Gas Well Tubing with Severe CO2 Corrosion

BROWN CORROSION SERVICES, INC.

Severe CO2 Corrosion

BROWN CORROSION SERVICES, INC.

Close-up of CO2 Pitting

BROWN CORROSION SERVICES, INC.

Top-of-line CO2 Corrosion

Note wall thinning

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

Sour well with

Sucker rod pump.

Note corrosion on

valve and that

sucker rod is FBE

coated for

corrosion control

BROWN CORROSION SERVICES, INC.

Tube sheet with severe sour corrosion. This metal loss in

One Heating Season in Croatia.

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

CO2 Corrosion

Section of Pressure Vessel wall showing crack

BROWN CORROSION SERVICES, INC.

Paint bubbles due to Hydrogen Permeation

BROWN CORROSION SERVICES, INC.

Hydrogen Patch on Acid Gas Line

BROWN CORROSION SERVICES, INC.

Hydrogen Patch Operation

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

Chloride Corrosion

Corrosion from the

chlorides and water

both internal and

external

BROWN CORROSION SERVICES, INC.

Flanges Offshore is Chloride Environment

BROWN CORROSION SERVICES, INC.

Pipe Clamp in Chloride Environment & Galvanic Corrosion

BROWN CORROSION SERVICES, INC.

Helideck Guard Chloride Corrosion

BROWN CORROSION SERVICES, INC.

Firewater Piping in Salt Environment

Plus Galvanic

BROWN CORROSION SERVICES, INC.

Firewater Line with Internal Corrosion (saltwater) & REPAIR?

BROWN CORROSION SERVICES, INC.

Bacteria Corrosion

MIC

Microbiologically influenced Corrosion

Corrosion from the

results of bacteria

growing in the pipe or

soil surrounding the

pipe.

BROWN CORROSION SERVICES, INC.

Internal MIC

BROWN CORROSION SERVICES, INC.

External MIC on Underground Storage Tank

BROWN CORROSION SERVICES, INC.

MIC Corrosion

BROWN CORROSION SERVICES, INC.

MIC at BOL & CO2 at TOL

Sometimes

more than one

mechanism

BROWN CORROSION SERVICES, INC.

Bacteria Probe

BROWN CORROSION SERVICES, INC.

Bacteria Probe

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

Inspection Techniques

1. Visual

2. Product analysis

3. Corrosion product analysis

4. Bacterial analysis

5. X-ray (radiographic)

6. SEM

7. Mag particle

8. Dye penetrant

9. Ultra sonic thickness

10. ILI

11. Caliper

12. Pit depth

13. Many more

BROWN CORROSION SERVICES, INC.

Pit Depth Gauge

BROWN CORROSION SERVICES, INC.

Performing Mag Particle Inspection

BROWN CORROSION SERVICES, INC.

Mag Particle

clearly showing

crack on weld

BROWN CORROSION SERVICES, INC.

Mag Particle defined area & length of crack on weld

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

The 7 Methods of Corrosion Control

All Methods fall into these categories

1. Coatings

2. Cathodic Protection

3. Filming Chemical Inhibition

4. Material Selection

5. Alteration of the Environment

6. Design & Alteration the Structure

7. Repair &/or Replace

BROWN CORROSION SERVICES, INC.

Onshore

BROWN CORROSION SERVICES, INC.

Offshore

BROWN CORROSION SERVICES, INC.

Offshore

BROWN CORROSION SERVICES, INC.

The 7 Methods of Corrosion Control

All Methods fall into these categories

1. Coatings

2. Cathodic Protection

3. Filming Chemical Inhibition

4. Material Selection

5. Alteration of the Environment

6. Design & Alteration the Structure

7. Repair &/or Replace

BROWN CORROSION SERVICES, INC.

The 7 Methods of Corrosion Control

1. Coatings

2. Cathodic Protection

3. Filming Chemical Inhibition

4. Material Selection

5. Alteration of the Environment

6. Design & Alteration the Structure

7. Repair &/or Replace

BROWN CORROSION SERVICES, INC.

Corrosion Control by Coatings

Coating depends upon three items

1.Product

2.Surface preparation

3.Application

If any of these is incorrect all fail !

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

Good Coating

BROWN CORROSION SERVICES, INC.

Good Coating

BROWN CORROSION SERVICES, INC.

Good Coating

BROWN CORROSION SERVICES, INC.

Good Coating

BROWN CORROSION SERVICES, INC.

Good Coating Repair

BROWN CORROSION SERVICES, INC.

Delayed Corrosion Control

Coating with

no surface

preparation

and

covering

problems!

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

Corrosion Control by Coatings

Even the best coating can fail if it is damaged

1. During handling and shipping

2. During installation

3. After installation by damage

4. Sfter installation by third party

If usually does happen !

BROWN CORROSION SERVICES, INC.

Corrosion Under Coating when not

Applied with proper surface preparation!

Coating flaked off

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

Well coated piping damaged during installation !

BROWN CORROSION SERVICES, INC.

Newly coated spool onto failed coated piping

BROWN CORROSION SERVICES, INC.

Coated Re-Bar on truck. Note steel bands! Is coating Okay?

BROWN CORROSION SERVICES, INC.

Good Coating by Bird Droppings may Cause Issues

BROWN CORROSION SERVICES, INC.

Good Coating but Boat Colisions may Cause Issues

BROWN CORROSION SERVICES, INC.

Good Coating

but laying of

pipe from spool

may cause

cracks or

damage to

coating.

BROWN CORROSION SERVICES, INC.

Protection of Coating

BROWN CORROSION SERVICES, INC.

The 7 Methods of Corrosion Control

1. Coatings

2. Cathodic Protection

3. Filming Chemical Inhibition

4. Material Selection

5. Alteration of the Environment

6. Design & Alteration the Structure

7. Repair &/or Replace

BROWN CORROSION SERVICES, INC.

The 7 Methods of Corrosion Control

1. Coatings

2. Cathodic Protection

3. Filming Chemical Inhibition

4. Material Selection

5. Alteration of the Environment

6. Design & Alteration the Structure

7. Repair &/or Repalce

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

Large Chemical Injection Skid

BROWN CORROSION SERVICES, INC.

Multi Pump Chemical Injection

Pumps

BROWN CORROSION SERVICES, INC.

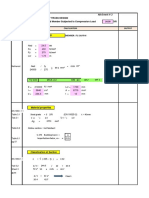

Chemical Injection System

Remote Readout

Reservoir Level Gauge Transmitter

Pump

BROWN CORROSION SERVICES, INC.

Chemical

Delivery

Chemical Line

Injection

Quill thru On-Off

Access Valve

Fitting Access

Fitting

Access

Fitting

Cover

BROWN CORROSION SERVICES, INC.

Inhibitor Injection System

BROWN CORROSION SERVICES, INC.

Inhibitor Injection System

BROWN CORROSION SERVICES, INC.

Inhibitor Injection System

Options for Chemical Injection

Pump Fitting

- Volume - Retractable

- Pressure - Retrievable

- Non Retractable

Power Type of Dispercement

- Wind - Drip

- Solar - Quill

- Mains - Atomizer

- Battery

- Line flow

BROWN CORROSION SERVICES, INC.

The 7 Methods of Corrosion Control

1. Coatings

2. Cathodic Protection

3. Filming Chemical Inhibition

4. Material Selection

5. Alteration of the Environment

6. Design & Alteration the Structure

7. Repair &/or Replace

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

Alteration of the Environment

Temperature Control Liquid Removal

BROWN CORROSION SERVICES, INC.

The 7 Methods of Corrosion Control

1. Coatings

2. Cathodic Protection

3. Filming Chemical Inhibition

4. Material Selection

5. Alteration of the Environment

6. Design & Alteration the Structure

7. Repair &/or Replace

BROWN CORROSION SERVICES, INC.

Improper Material Selection

BROWN CORROSION SERVICES, INC.

Improper Material Selection

Bad Good

BROWN CORROSION SERVICES, INC.

Improper Material Selection

BROWN CORROSION SERVICES, INC.

Proper Material Selection

Note change from metal

to fiberglass in this

offshore waterflood

application

BROWN CORROSION SERVICES, INC.

Proper Material Selection

BROWN CORROSION SERVICES, INC.

The 7 Methods of Corrosion Control

1. Coatings

2. Cathodic Protection

3. Filming Chemical Inhibition

4. Material Selection

5. Alteration of the Environment

6. Design & Alteration the Structure

7. Repair &/or Repalce

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

Elbow Subject to Corrosion/Erosion

BROWN CORROSION SERVICES, INC.

Elbow Replaced by Flow Tee or flow Cushion

BROWN CORROSION SERVICES, INC.

Gas Pipeline on Pillows off Ground

BROWN CORROSION SERVICES, INC.

Gathering Lines on Pillows

Pillows

BROWN CORROSION SERVICES, INC.

Cement Coated

Offshore

Pipeline

BROWN CORROSION SERVICES, INC.

The 7 Methods of Corrosion Control

1. Coatings

2. Cathodic Protection

3. Filming Chemical Inhibition

4. Material Selection

5. Alteration of the Environment

6. Design & Alteration the Structure

7. Repair &/or Replace

BROWN CORROSION SERVICES, INC.

BROWN CORROSION SERVICES, INC.

You might also like

- SST Understanding CorrosionDocument55 pagesSST Understanding CorrosionAntonNo ratings yet

- New Reinforced Concrete Corroded ColumnsDocument23 pagesNew Reinforced Concrete Corroded ColumnsZaheer Shaik50% (4)

- Electrochemical CorrosionDocument76 pagesElectrochemical CorrosionMeshack NyitiNo ratings yet

- Polarography: by Dr. Irfan PervaizDocument41 pagesPolarography: by Dr. Irfan PervaizAyesha LiaqatNo ratings yet

- Corrosion: IntroducingDocument29 pagesCorrosion: Introducingkeval patelNo ratings yet

- Corrosion Rate MeasurementsDocument30 pagesCorrosion Rate MeasurementsNada MeselhyNo ratings yet

- Cyclic VoltammetryDocument32 pagesCyclic VoltammetryAneeqa YounasNo ratings yet

- Lecture 1 Basic Electrochemistry Presentation 2017-1Document66 pagesLecture 1 Basic Electrochemistry Presentation 2017-1Dhafin Apridhiya100% (1)

- Anodic Protection: Liquid Environment: Name: Muhammad Emir Rafiansyah Akbar NPM: 2006489193Document30 pagesAnodic Protection: Liquid Environment: Name: Muhammad Emir Rafiansyah Akbar NPM: 2006489193emir akbarNo ratings yet

- Corrosion 1Document31 pagesCorrosion 1NivindasNo ratings yet

- Design For Corrosion Resistance: Uniform AttackDocument11 pagesDesign For Corrosion Resistance: Uniform AttackIndra PradanaNo ratings yet

- Corrosion ReferencesDocument6 pagesCorrosion ReferencesKimai BrackenNo ratings yet

- Basic of Corrosion 021211Document18 pagesBasic of Corrosion 021211Sunil DeshpandeNo ratings yet

- Corrosion Measurement TechniquesDocument60 pagesCorrosion Measurement TechniquesHashem Mohamed HashemNo ratings yet

- Electrochemical Methods of AnalysisDocument153 pagesElectrochemical Methods of AnalysisGab TrinillaNo ratings yet

- Corrosion ProposalDocument13 pagesCorrosion Proposalmjrobust05No ratings yet

- Advances in Corrosion Engineering: Forms of CorrosionDocument71 pagesAdvances in Corrosion Engineering: Forms of CorrosionEDU Academic Programs CoordinatorNo ratings yet

- ChemistryDocument25 pagesChemistryHarish KumarNo ratings yet

- Types of Corrosion Explained in DetailDocument14 pagesTypes of Corrosion Explained in DetailfaranimohamedNo ratings yet

- Electrochemical TechniquesDocument48 pagesElectrochemical Techniquespkn_pnt9950No ratings yet

- Corrosion Engineering Course Forms of CorrosionDocument138 pagesCorrosion Engineering Course Forms of CorrosionAnupam Chowdhury100% (1)

- Environment and CorrosionDocument39 pagesEnvironment and Corrosionabdullah anwarNo ratings yet

- Corrosion Science and Engineering - Course Material PDFDocument481 pagesCorrosion Science and Engineering - Course Material PDFDeepak UpadhyayNo ratings yet

- Corrosionengg 151021181918 Lva1 App6891Document133 pagesCorrosionengg 151021181918 Lva1 App6891pm2013100% (1)

- Durable Design of Reinforced Concrete Elements Against CorrosionDocument9 pagesDurable Design of Reinforced Concrete Elements Against CorrosionLucky ZozagallaNo ratings yet

- Decorative Chromium Plating BasicsDocument8 pagesDecorative Chromium Plating Basicsm daneshpour100% (1)

- Corrosion: Introduction To Practical Corrosion in Aqueous EnvironmentDocument43 pagesCorrosion: Introduction To Practical Corrosion in Aqueous Environmenthengki wibowoNo ratings yet

- Corrosion Types in Naval Materials ScienceDocument13 pagesCorrosion Types in Naval Materials ScienceMad Max100% (1)

- What Is CorrosionDocument4 pagesWhat Is CorrosionOsransyah Os100% (1)

- Lecture 8 Electro-KineticsDocument63 pagesLecture 8 Electro-KineticsmainoNo ratings yet

- VoltammetryDocument37 pagesVoltammetrypramod_arya_htd100% (1)

- AC Mit PowerTool Quick Guide PrciDocument23 pagesAC Mit PowerTool Quick Guide PrciJoe BlagNo ratings yet

- Concrete CorrosionDocument4 pagesConcrete CorrosionAhmadYossryMuham'madNo ratings yet

- Corrosion Problems and Their Solution in Waste Water Treatment PlantDocument15 pagesCorrosion Problems and Their Solution in Waste Water Treatment PlantayeshayusufbelenNo ratings yet

- Electrochemistry of CorrosionDocument19 pagesElectrochemistry of CorrosionElambarithi KalyanakumarNo ratings yet

- Carbon Steel Corrosion in Clay-Rich EnvironmentDocument10 pagesCarbon Steel Corrosion in Clay-Rich Environmentblackcurse29No ratings yet

- Corrosion Assessment in Reinforced Concrete StructuresDocument32 pagesCorrosion Assessment in Reinforced Concrete Structuresdineshkumar rNo ratings yet

- Corrosion of Steel in ConcreteDocument2 pagesCorrosion of Steel in ConcreteaaNo ratings yet

- Corrosion ManualDocument125 pagesCorrosion ManualBilal KhashanNo ratings yet

- CorrosionDocument14 pagesCorrosionChalakAhmedNo ratings yet

- Principle of Corrosion EngineeribgDocument82 pagesPrinciple of Corrosion Engineeribgmm11_ned100% (1)

- Water Line Stray Current ControlDocument18 pagesWater Line Stray Current ControlVinzoKeiNo ratings yet

- Techniques For Accelerated Corrosion TestsDocument4 pagesTechniques For Accelerated Corrosion TestsComet AstroNo ratings yet

- ACI & Eurocode Approaches for Flexural Crack ControlDocument29 pagesACI & Eurocode Approaches for Flexural Crack ControlMohd Sulahuddin RamlyNo ratings yet

- CEOCOR 87 Cathodic Disbonding of Steelpipe CoatingsDocument26 pagesCEOCOR 87 Cathodic Disbonding of Steelpipe CoatingsMAHESH CHANDNo ratings yet

- Lunit-V CorrosionDocument14 pagesLunit-V CorrosionMidhunRameshThuvasseryNo ratings yet

- Effect of Chemical Composition of Zinc Phosphating Solution On Phosphate Coating PropertiesDocument12 pagesEffect of Chemical Composition of Zinc Phosphating Solution On Phosphate Coating PropertiesJhon QsacNo ratings yet

- Corrosion PresentationDocument22 pagesCorrosion PresentationIshu Attri100% (1)

- Relationship Between Grain Size and Corrosion Rate in MetalsDocument4 pagesRelationship Between Grain Size and Corrosion Rate in MetalsGajendra Pratap SinghNo ratings yet

- Clays and Clay Minerals: Proceedings of the Fourteenth National Conference, Berkeley, CaliforniaFrom EverandClays and Clay Minerals: Proceedings of the Fourteenth National Conference, Berkeley, CaliforniaS. W. BaileyNo ratings yet

- Chrom I TingDocument11 pagesChrom I TingAshish RawatNo ratings yet

- Grade 2205 DuplexDocument9 pagesGrade 2205 Duplexkresimir.mikoc9765No ratings yet

- Industrial Chemistry B - Lecture 6Document64 pagesIndustrial Chemistry B - Lecture 6Daniel Rsix CornwallNo ratings yet

- ASTM G170-2006 (2012) Evaluating and Qualifying Oilfield and Refinery CorrosionDocument3 pagesASTM G170-2006 (2012) Evaluating and Qualifying Oilfield and Refinery CorrosionTariqNo ratings yet

- Corrosion and Corrosion Control: An Introduction to Corrosion Science and EngineeringFrom EverandCorrosion and Corrosion Control: An Introduction to Corrosion Science and EngineeringNo ratings yet

- Tubular Vent BinderDocument12 pagesTubular Vent BinderbayuNo ratings yet

- 4-Electrochemical Kinetics of CorrosionDocument84 pages4-Electrochemical Kinetics of Corrosion이선엽No ratings yet

- Barrier-Adhesion Principle For Corrosion PrtotectionDocument10 pagesBarrier-Adhesion Principle For Corrosion PrtotectionINRO Ingeníeria100% (1)

- Filming Corrosion Inhibitor For Oil and Gas FieldDocument20 pagesFilming Corrosion Inhibitor For Oil and Gas FieldelsyakiebNo ratings yet

- C CC CC: by Patrick J. Dunn, Associate Member ASHRAE, and Richard NorsworthyDocument8 pagesC CC CC: by Patrick J. Dunn, Associate Member ASHRAE, and Richard NorsworthyjamesNo ratings yet

- Decreto 457 2020-03-23 PDFDocument14 pagesDecreto 457 2020-03-23 PDFYordan PerdomoNo ratings yet

- Microcor Erosion ProbesDocument3 pagesMicrocor Erosion ProbesYordan PerdomoNo ratings yet

- RSL Two-Inch System Retriever KitDocument3 pagesRSL Two-Inch System Retriever KitYordan PerdomoNo ratings yet

- RSL Two-Inch System Retriever KitDocument3 pagesRSL Two-Inch System Retriever KitYordan PerdomoNo ratings yet

- RCS Hand-Held/Portable Instrument Compatibility and Features ChartDocument1 pageRCS Hand-Held/Portable Instrument Compatibility and Features ChartYordan PerdomoNo ratings yet

- 106 Grado BDocument3 pages106 Grado BYordan PerdomoNo ratings yet

- Software Cosasco Data Offline CDOSDocument4 pagesSoftware Cosasco Data Offline CDOSYordan PerdomoNo ratings yet

- RSL Two-Inch System Retriever KitDocument3 pagesRSL Two-Inch System Retriever KitYordan PerdomoNo ratings yet

- RSL Two-Inch System Retriever KitDocument3 pagesRSL Two-Inch System Retriever KitYordan PerdomoNo ratings yet

- Chemical Injection Data Logger RDC-CIDocument2 pagesChemical Injection Data Logger RDC-CIYordan PerdomoNo ratings yet

- San Antonio 14Document5 pagesSan Antonio 14Yordan PerdomoNo ratings yet

- Chemical injection ensures corrosion controlDocument9 pagesChemical injection ensures corrosion controlYordan Perdomo100% (1)

- CosascoDocument12 pagesCosascoYordan PerdomoNo ratings yet

- 3C BCSI Retrieval Metal SamplesDocument43 pages3C BCSI Retrieval Metal SamplesYordan PerdomoNo ratings yet

- 1 BCSI Corrosion FailuresDocument46 pages1 BCSI Corrosion FailuresYordan PerdomoNo ratings yet

- 4 BCSI Corrosion CouponsDocument73 pages4 BCSI Corrosion CouponsYordan PerdomoNo ratings yet

- 5991 7215enDocument6 pages5991 7215enYordan PerdomoNo ratings yet

- CEPA FIMP RP 1stedition 2013 PDFDocument57 pagesCEPA FIMP RP 1stedition 2013 PDFgersonvc25No ratings yet

- D 5623 RefDocument4 pagesD 5623 RefseterisparigusNo ratings yet

- KIRLOSKAR HVAC BrochureDocument24 pagesKIRLOSKAR HVAC Brochureedward baskaraNo ratings yet

- Flux Skimming PDFDocument6 pagesFlux Skimming PDFpbp2956No ratings yet

- Sheet PilingDocument12 pagesSheet PilingTanvi Rane100% (1)

- Astm A560Document5 pagesAstm A560MAX ALBERTO JUAREZ AVALOSNo ratings yet

- Support Issues at AEP Lawrenceburg and Waterford PlantsDocument11 pagesSupport Issues at AEP Lawrenceburg and Waterford Plantsfaizan abbasiNo ratings yet

- Joints in Steel Construction - Simple Connections - Part 22 PDFDocument1 pageJoints in Steel Construction - Simple Connections - Part 22 PDFkakem61No ratings yet

- SR20715152848 - Very ImportantDocument6 pagesSR20715152848 - Very Importantlogan firemanNo ratings yet

- Introduction To Properties of Materials: Badi 1 John Errington MSCDocument42 pagesIntroduction To Properties of Materials: Badi 1 John Errington MSCgereNo ratings yet

- Unit 203 Principles of Manufacturing Technology: Level: 2 Credit Value: 7 Uan: K/503/0175 Unit AimDocument4 pagesUnit 203 Principles of Manufacturing Technology: Level: 2 Credit Value: 7 Uan: K/503/0175 Unit AimEóin O CeranaighNo ratings yet

- Code Requirements Critical Dimension PDFDocument4 pagesCode Requirements Critical Dimension PDFSong phamNo ratings yet

- Adfreezing and Frost Heaving of FoundationsDocument9 pagesAdfreezing and Frost Heaving of FoundationsAhmed AbdelazizNo ratings yet

- Catalogue Fan Coil Unit Fudfwcfwwfwefwk PDFDocument17 pagesCatalogue Fan Coil Unit Fudfwcfwwfwefwk PDFMinh Nhut LuuNo ratings yet

- Ebara 3M IE3 UKDocument19 pagesEbara 3M IE3 UKAfraz ShaikhNo ratings yet

- Truss Design DocumentationDocument2 pagesTruss Design DocumentationNiroj MaharjanNo ratings yet

- ChemFlo AsDocument2 pagesChemFlo Assmart construction solution solutionNo ratings yet

- Domestic Timber Deck Design: Technical Design Guide Issued by Forest and Wood Products AustraliaDocument24 pagesDomestic Timber Deck Design: Technical Design Guide Issued by Forest and Wood Products AustraliaHaibo LVNo ratings yet

- V9520 Trespa Meteon Exterior Panels (Incl Color Collection) 03 2010 Tcm9-36023Document14 pagesV9520 Trespa Meteon Exterior Panels (Incl Color Collection) 03 2010 Tcm9-36023dannykilNo ratings yet

- Upright Sprinkler VK300Document4 pagesUpright Sprinkler VK300james alfarasNo ratings yet

- Prestressed Concrete AdvantagesDocument18 pagesPrestressed Concrete AdvantagesLarete PaoloNo ratings yet

- 5 6138727946501751075Document3 pages5 6138727946501751075Xkarr RastaNo ratings yet

- Jobsheet MasonDocument6 pagesJobsheet MasonLudivino Toto Ledesma CondalorNo ratings yet

- RAM Foundation User ManualDocument122 pagesRAM Foundation User ManualJohn DoeNo ratings yet

- 1033 H000 A11000 019 XXXX XXXX (Construction Manual For Final) Rev 00Document107 pages1033 H000 A11000 019 XXXX XXXX (Construction Manual For Final) Rev 00vhpatel67No ratings yet

- Waterproofing MethodsDocument21 pagesWaterproofing MethodsM.IDREES KhanNo ratings yet

- ASME 2017 SA 312 Sublimentry RequirementsDocument2 pagesASME 2017 SA 312 Sublimentry RequirementsKathir VelNo ratings yet

- 01 ElevatorsDocument14 pages01 Elevatorsengineer63No ratings yet

- Water Treatment DegasifierDocument6 pagesWater Treatment DegasifierEDUARDONo ratings yet

- Division 16 - Electrical Section 16720 - Fire Alarm SystemsDocument3 pagesDivision 16 - Electrical Section 16720 - Fire Alarm SystemsMd. Mominul IslamNo ratings yet

- Barrier Performance of Common Plastic FilmDocument1 pageBarrier Performance of Common Plastic FilmAriane Victoria DantesNo ratings yet

- 2099 Robor Corrugated Liet PDFDocument2 pages2099 Robor Corrugated Liet PDFJosef StrydomNo ratings yet