Professional Documents

Culture Documents

BiFlex PDF

Uploaded by

vandrorobertoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BiFlex PDF

Uploaded by

vandrorobertoCopyright:

Available Formats

Bi-Flex Bi-Metal Fasteners: The corrosion resistance of

300 series stainless steel and the efficiency of drillscrews

Owners, architects and, design engineers expect longer Approvals NEW

life cycles from buildings. Extended warranties and City of Los Angeles (COLA) Research

use of more sustainable materials add up to greater

Report: RR25886 (CSI #05 05 23)

expectations for performance from structural integrity

to the purely aesthetic of all building components. Features

The Solution: Bi-Flex Bi-Metal Self-Drilling Fasteners Bi-metal 300 series

stainless

Made of 300 series (18-8) stainless steel alloy to technology steel head

provide unmatched corrosion resistance in your 300 (18- and shank

toughest applications 8) stainless

steel head

Fused and hardened steel drill point and lead threads and shank Fused and

hardened

quickly drill and tap structural steel and aluminum up

Fused and steel tapping

1/2" thick threads and

hardened drill point

Coated with silver-colored Stalgard GB, a galvanic steel drill

barrier to protect aluminum components from point

accelerated corrosion when in contact with

Silver-colored Stalgard GB coating

300 series stainless steel

Wide variety of sizes and head styles

300 series stainless alloy is virtually immune to

delayed embrittlement failures seen with hardened Benefits

400 series stainless self-drilling fasteners

Outstanding

corrosion

Prevent Corrosion in Your Applications

resistance and Silver-colored

Exposed anchoring/coastal/aggressive environments long service life Stalgard GB

coating over

Curtain wall/window wall systems/rain screen systems High strength, entire fastener

Windows/doors/awnings/thresholds ductility and

reliability

Panel systems to steel or aluminum framing

Virtually immune

Aluminum enclosures to delayed

ACQ-treated wood embrittlement Self-drilling

point

Brick veneer anchoring failures

Solar panel systems Greater

galvanic compatibility

You wont find a better, easier-to-install or more reliable in dissimilar metal applications

300 series stainless steel self-drilling screw, for your involving aluminum

toughest construction applications, than Elcos line of Quickly drill and tap into steel or

BiFlex fasteners. aluminum up to 1/2" thick

High in-place value over the life of

structures, components and systems

Selection Guide Identification

B Pieces Weight The head marking consists of the

Catalog Dia. L Drive Pt. Maximum per per number 3 above the Elco logo

No. TPI Length System Size Load-bearing Length* 1/4 Keg 1/4 Keg

as shown below.

Hex Washer Head

EAJ110 10-16 3/4" 5/16" hex 2 0.320" 5,000 32

EAJ140 10-16 1-1/2" 5/16" hex 2 1.10" 2,500 39

EAJ185 12-14 1" 5/16" hex 2 0.500" 3,000 31

EAJ215 12-14 1-1/2" 5/16" hex 2 1.00" 2,500 34 flat head hex washer

head

EAJ190 12-14 1" 5/16" hex 3 0.500" 4,000 41

EAJ220 12-14 1-1/2" 5/16" hex 3 1.00" 2,500 34 * The load-bearing length is the length of

EAJ260 12-14 2-1/2" 5/16" hex 3 2.00" 1,000 21 300 series stainless under the hex head

EAJ240 12-14 2" 5/16" hex 2 1.500" 1,500 26 or including the flat head. Hardened steel

length (lead threads and point) should

EAJ340 12-24 2" 5/16" hex 5 1.100" 2,000 35

be through the connection and not in the

EAJ415 1/4-14 1" 3/8" hex 2 0.500" 2,500 40 load-bearing section of the connection.

EAJ540 1/4-20 1" 3/8" hex 3 0.500" 2,500 40

EAJ430 1/4-14 1-1/2" 3/8" hex 2 1.00" 1,000 30 NOTE: All performance data shown is

based on tests performed under laboratory

EAJ580 1/4-20 1-1/2" 3/8" hex 3 1.00" 1,000 32

conditions at independent construction

EAJ445 1/4-14 2" 3/8" hex 2 1.500" 1,500 25 testing facilities. The appropriate safety

EAJ610 1/4-20 2" 3/8" hex 3 1.500" 1,500 38 factor should be applied and code

EAJ615 1/4-20 2" 3/8" hex 5 1.100" 1,500 38 requirements factored into specification

EAJ640 1/4-20 2-1/2" 3/8" hex 3 2.000" 1,000 32 and use of these fasteners. A safety factor

of 4:1 or 25% of the ultimate average

EAJ650 1/4-20 3" 3/8" hex 3 2.500" 500 18

values shown is generally accepted

EAJ660 1/4-20 4" 3/8" hex 3 3.500" 500 22 as an appropriate working load. Final

EAJ690C 1/4-20 8" 3/8" hex 5 7.10" 150 15 determination of the appropriate safety

Flat Head Reamers w/wings factor and use of these fasteners is the

sole responsibility of the user, specifying

EBN140 10-16 1-1/2" #2 phillips 3 0.800" 3,500 30 Engineer, Architect or other responsible

person designing the connection. Due to

EBN345 12-24 2-13/16" #3 phillips 5 1.710" 1,000 21

a wide variety of application conditions or

intervening factors not under our control,

EBN645 1/4-20 2-13/16" #3 phillips 5 1.710" 1,000 28

we assume no liability for the use of the

Flat Head Undercut information provided in this document.

EBN200 12-14 1" #3 phillips 2 0.500" 4,000 31 For additional product information and

technical assistance, please contact Elco

EBN240 12-14 1-1/2" #3 phillips 2 1.00" 2,500 29 directly at 1-800-435-7213.

EBN630 1/4-20 3" #3 phillips 2 2.500" 500 18

EBN640 1/4-20 4" #3 phillips 2 3.500" 500 22

Performance Data

Pull-Out Values Ultimate Strengths**

Pull-Out (Lbs) Shear

Tensile Average Lbs

Drill Drill Steel RB60-75 Aluminum 6063-T5

Size (Lbs) Ultimate

Screw Point Cap 50 66KSI 22KSI

10-16 1847 1282

Size Type (in.) 18 ga. 16 ga. 14 ga. 12 ga. 1/8" 3/16" 1/4" 1/8" 1/4"

12-14 2628 1950

10-16 2 0.150 455 677 793 1394 1906 994

12-24 2734 2284

10-16 3 0.187 616 684 1242 1605 1527 961

1/4-14 3459 2676

12-14 2 0.187 528 750 892 1536 2602 2514 1132

12-14 3 0.210 417 679 802 1371 2028 2499 974 1/4-20 4124 2860

12-24 5 0.500 2110 2781 538 1995

1/4-14 2 0.210 619 885 1082 1830 2943 3535 1310 ** Values are for 300 series stainless

1/4-20 3 0.312 680 780 1442 2623 3684 4069 1037 2786 fastener threaded shank

1/4-20 5 0.500 2622 1724

Elco Construction Products

800.435.7213

Fax: 563-387-3540

www.elcoconstruction.com

Elco, Bi-Flex, Stalgard, iForm and Infastech are trademarks of Infastech Intellectual Properties Pte Ltd. Avdel is a registered trademark of Avdel UK Ltd.

2011 Infastech Intellectual Properties, Pte Ltd. All rights reserved. Rev. 06/11

You might also like

- Calculating OEE WorksheetDocument2 pagesCalculating OEE WorksheetPravin BabarNo ratings yet

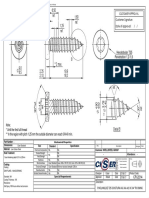

- Ciser Parafusos e Porcas Property DocumentDocument1 pageCiser Parafusos e Porcas Property DocumentvandrorobertoNo ratings yet

- Fast Guide To Oee PDFDocument27 pagesFast Guide To Oee PDFAtakan TunaliNo ratings yet

- Fast Guide To Oee PDFDocument27 pagesFast Guide To Oee PDFAtakan TunaliNo ratings yet

- Hexalobe Flyer 2010Document6 pagesHexalobe Flyer 2010vandrorobertoNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Methanol Production Using Carbon Capture Technology: An OverviewDocument6 pagesMethanol Production Using Carbon Capture Technology: An OverviewmohdaizadahmadNo ratings yet

- Flyer Nutri 2023 23 MeiDocument2 pagesFlyer Nutri 2023 23 Meihanifah al khairiyahNo ratings yet

- The FishbowlDocument3 pagesThe FishbowlGrace RtnNo ratings yet

- Non Centroidal RotationDocument6 pagesNon Centroidal RotationJohn Lloyd AnogNo ratings yet

- Oral Cavity AnatomyDocument40 pagesOral Cavity AnatomyharisNo ratings yet

- Baraka Blessings in ClayDocument7 pagesBaraka Blessings in ClayOmnia AANo ratings yet

- Textual Analysis of PoemDocument4 pagesTextual Analysis of Poemzebra_t00No ratings yet

- Music ArticleDocument34 pagesMusic ArticleHenry SpencerNo ratings yet

- Jokes CollectionDocument204 pagesJokes CollectionNatalia LupascoNo ratings yet

- Rehabilitation Will Increase The Capacity of Your Insert Musculoskeletal Tissue Here Defining Tissue Capacity A Core Concept For CliniciansDocument3 pagesRehabilitation Will Increase The Capacity of Your Insert Musculoskeletal Tissue Here Defining Tissue Capacity A Core Concept For CliniciansChristhoper HermosillaNo ratings yet

- Motivation and Work Life Balance in The Lives of Delivery Personnel in Lucknow CityDocument3 pagesMotivation and Work Life Balance in The Lives of Delivery Personnel in Lucknow CityVivek AnandanNo ratings yet

- Burgundy Fees and Charges As On 2019 09Document7 pagesBurgundy Fees and Charges As On 2019 09Shivanshu SinghNo ratings yet

- The August Fraternity. Order of The Rose Cross in America... And... H. Spencer Lewis, by Dr. Clymer.Document56 pagesThe August Fraternity. Order of The Rose Cross in America... And... H. Spencer Lewis, by Dr. Clymer.Clymer777100% (5)

- Konica 7155Document2 pagesKonica 7155isyo411No ratings yet

- ICJ Judgment on Philippines' Bid to Intervene in Indonesia-Malaysia Maritime Boundary CaseDocument8 pagesICJ Judgment on Philippines' Bid to Intervene in Indonesia-Malaysia Maritime Boundary CaseZayd Iskandar Dzolkarnain Al-Hadrami100% (1)

- The Psychology of Pain: George R. Hansen, MD, Jon Streltzer, MDDocument10 pagesThe Psychology of Pain: George R. Hansen, MD, Jon Streltzer, MDRobi Maulana100% (1)

- Safety Data Sheet: AnakinraDocument5 pagesSafety Data Sheet: AnakinratuhinNo ratings yet

- House of SaudDocument10 pagesHouse of SaudGregory HooNo ratings yet

- Accounting Textbook Solutions - 48Document19 pagesAccounting Textbook Solutions - 48acc-expertNo ratings yet

- Matrik Artikel Bu TiwiDocument87 pagesMatrik Artikel Bu Tiwilisa yuliaNo ratings yet

- Course Package in PATH-FIT II DANCE 2nd Semester AY 2021-2022Document52 pagesCourse Package in PATH-FIT II DANCE 2nd Semester AY 2021-2022John Ian NisnisanNo ratings yet

- Golden Trowel Awards-Part 6Document23 pagesGolden Trowel Awards-Part 6Fransisca WijayaNo ratings yet

- Burleigh, Harry Thacker-Negro Minstrel MelodiesDocument58 pagesBurleigh, Harry Thacker-Negro Minstrel MelodiesKay Gould50% (2)

- GMAT Demo Session Handout Jan 12 For Video Sessions 3 3Document1 pageGMAT Demo Session Handout Jan 12 For Video Sessions 3 3raviNo ratings yet

- 170D PC Sel 53831 PDFDocument14 pages170D PC Sel 53831 PDFstefan corjucNo ratings yet

- MCQsDocument17 pagesMCQsbilal100% (1)

- 3 - ATPL Questions AGK2-Electricity - ElectonicsDocument94 pages3 - ATPL Questions AGK2-Electricity - ElectonicsTanvir HasanNo ratings yet

- Yeshu 3Document187 pagesYeshu 3sinan pediaNo ratings yet

- Ed 319 Lesson Plan 1 DiversityDocument12 pagesEd 319 Lesson Plan 1 Diversityapi-340488115No ratings yet

- Bone Marrow, Blood, Formation, Med TechDocument47 pagesBone Marrow, Blood, Formation, Med TechAngela Louise SmithsNo ratings yet