Professional Documents

Culture Documents

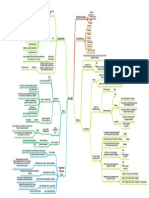

OM strategies and concepts for operations managers

Uploaded by

Clarisse AnnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OM strategies and concepts for operations managers

Uploaded by

Clarisse AnnCopyright:

Available Formats

CHAPTER 1 Just-in-time (JIT) CHAPTER 2

A philosophy designed to achieve

Operations management (OM) high-volume production through Business strategy

The business function responsible for elimination of waste and continuous A long-range plan for a business.

planning, coordinating, and controlling improvement.

the resources needed to produce a Operations strategy

companys goods and services. Total quality management (TQM) A long-range plan for the operations

Philosophy that seeks to improve function that specifies the design and

Three major business functions; quality by eliminating causes of use of resources to support the

(1) Marketing; (2) Operations; (3) product defects and by making quality business strategy.

Finance the responsibility of everyone in the

organization. Mission

Role of operations management A statement defining what business an

To transform organizational inputs into Reengineering organization is in, who its customers

outputs Redesigning a companys processes are, and how its core beliefs shape its

to make them more efficient. business.

Efficiency

Performing activities at the lowest Flexibility Environmental scanning

possible cost. An organizational strategy in which the Monitoring the external environment

company attempts to offer a greater for changes and trends to determine

Manufacturing organizations variety of product choices to its business opportunities and threats.

Organizations that primarily produce a customers.

tangible product and typically have low Core competencies

customer contact. Time-based competition The unique strengths of a business

An organizational strategy focusing on

Service organizations efforts to develop new products and Organizational Core Competencies.

Organizations that primarily produce deliver them to customers faster than (1) Workforce; (2) Facilities; (3)

an intangible product, such as ideas, competitors. Market Understanding; (4) Financial

assistance, or information, and Know-how; (5) Technology

typically have high customer contact. Supply chain management (SCM)

Management of the flow of materials Competitive priorities

Strategic decisions from suppliers to customers in order to Capabilities that the operations

Decisions that set the direction for the reduce overall cost and increase function can develop in order to give a

entire company; they are broad in responsiveness to customers. company a competitive advantage in

scope and long-term in nature. its market.

Global marketplace

Tactical decisions A trend in business focusing on (1) Cost a competitive priority

Decisions that are specific and short- customers, suppliers, and competitors focusing on low cost

term in nature and are bound by from a global perspective. (2) Quality a competitive priority

strategic decisions. focusing on the quality of goods

Sustainability and services

Industrial Revolution A trend in business to consciously High-performance design

An industry movement that changed reduce waste, recycle, and reuse focus on aspects of quality

production by substituting machine products and parts. Goods and services

power for labor power. consistency how often goods

Lean systems or services meet the exact

Scientific management A concept that takes a total system design specification

An approach to management that approach to creating efficient

focused on improving output by operations. (3) Time a competitive priority

redesigning jobs and determining focusing on speed and on-time

acceptable levels of worker output. Enterprise resource planning (ERP) delivery

Large, sophisticated software systems Rapid delivery refers to how

Hawthorne studies used for identifying and planning the quickly an order is received

The studies responsible for creating enterprise-wide resources needed to On-time delivery refers to

the human relations movement, which coordinate all activities involved in how often deliveries are made

focused on giving more consideration producing and delivering products. on time

to workers needs.

Customer relationship management (4) Flexibility a competitive priority

Human relations movement (CRM) focusing on offering a wide variety

A philosophy based on the recognition Software solutions that enable the firm of goods or services

that factors other than money can to collect customer-specific data. Product flexibility - ability to

contribute to worker productivity. offer a wide variety of goods or

Cross-functional decision making services and customize them to

Management science The coordinated interaction and the unique needs of clients

A field of study that focuses on the decision making that occur among the Volume flexibility - ability to

development of quantitative different functions of the organization. rapidly increase or decrease the

techniques to solve operations amount produced in order to

problems. accommodate changes in the

demand

Trade-off CHAPTER 3 2. Design standardization the use

The need to focus more on one of common and interchangeable

competitive priority than on others. Manufacturability parts. By using interchangeable

The ease with which a product can be parts, we can make a greater variety

Order qualifiers made. of products with less inventory and

Competitive priorities that must be met significantly lower cost and provide

for a company to qualify as a Product design greater flexibility.

competitor in the marketplace. The process of defining all of the

products characteristics. DFM Guidelines

Order winners

1. Minimize parts

Competitive priorities that win orders in Service design 2. Design parts for different products

the marketplace. The process of establishing all the 3. Use modular design

characteristics of the service, including 4. Avoid tools

Operations Strategy physical, sensual, and psychological

1. Structure operations decisions 5. Simplify operations

benefits.

related to the design of the

production process such as Product life cycle

Steps in the product design process A series of stages that products pass

facilities technology, and flow of 1. Idea development product idea

gods and services through the through in their lifetime, characterized

developed; sources can be by changing product demands over

facility customers, etc time.

2. Infrastructure operations

Benchmarking Concurrent engineering

decisions related to the planning

The process of studying the practices An approach that brings together

and control systems of the

of companies considered best-in- multifunction teams in the early phase

operation, such as organization of

class and comparing your companys of product design in order to simultaneously

operations, skills and pay of

performance against theirs. design the product and the process.

workers, and quality measures.

Primary types of technologies Reverse engineering Remanufacturing

1. Product technology which is any The process of disassembling a The concept of using components of

new technology developed by a firm product to analyze its design features. old products in the production of new

2. Process technology It is the ones.

Early supplier involvement (ESI)

technology used to improve the

Involving suppliers in the early stages TYPES OF PROCESSES

process of creating goods and

of product design.

services.

Intermittent operations

3. Information technology which 2. Product screening product Processes used to produce a variety of

enables communication, processing, idea evaluated; need to consider products with different processing

and storage of information. operations, marketing and requirements in lower volumes.

financial requirements

Productivity Project process

A measure of how efficiently an Break-even analysis A type of process used to make a

organization converts inputs into A technique used to compute the one-at-a-time product exactly to

outputs. amount of goods a company would customer specifications.

need to sell to cover its costs. Batch process

Total productivity

Fixed costs A type of process used to produce a

Productivity computed as a ratio of

Costs a company incurs regardless of small quantity of products in groups

output to all organizational inputs.

how much it produces. or batches based on customer orders

Partial productivity or specifications.

Variable costs

Productivity computed as a ratio of

Costs that vary directly with the Repetitive operations

output to only one input (e.g., labor,

amount of units produced. Processes used to produce

materials, machines).

one or a few standardized

Multifactor productivity 3. Preliminary design & testing products in high volume.

Productivity computed as a ratio of product prototypes, built, tested,

Line process

output to several, but not all, inputs. and refined

4. Final design final product A type of process used to produce a

large volume of a standardized

specifications completed

product.

Design for manufacture (DFM) Continuous process

A series of guidelines to follow in order A type of process that operates

to produce a product easily and continually to produce a high volume

profitably. DFM guidelines focuses on of a fully standardized product.

two issues

Process flow analysis

1. Design simplification means A technique used for evaluating a

reducing the number of parts and process in terms of the sequence of

features of the product whenever steps from inputs to outputs with the

possible. A simpler product is easier goal of improving its design.

to make, costs less, and gives

higher quality.

Process flowchart Flexible manufacturing

A chart showing the sequence of steps system (FMS) Bullwhip effect

in producing the product or service. A type of automated system that Inaccurate or distorted

combines the flexibility of intermittent demand information created

Bottleneck operations with the efficiency of in the supply chain.

Longest task in the process. continuous operations.

Causes of Bullwhip effect

Make-to-stock strategy Numerically controlled

1. Demand forecast updating

Produces standard products and (NC) machine

2. Order batching instead of

services for immediate sale or delivery. A machine controlled by a computer

placing replenishment orders right

that can perform a variety of tasks.

Assemble-to-order strategy after each unit is sold, it waits

Computer-aided design (CAD) some period of time, sums up the

Produces standard components that

number of units sold, and then

can be combined to customer A system that uses computer graphics

places the order

specifications. to design new products.

3. Price fluctuations cause

Make-to-order strategy Computer-integrated companies to buy products before

manufacturing (CIM) they need them

Produces products to customer

4. Rationing and gaming result

specifications after an order has been A term used to describe the integration

when demand exceeds supply

received. of product design, process planning,

and products are rationed to

and manufacturing using an integrated

Process performance metrics members of the supply chain.

computer system.

Measurements of different process

Service package Counteracting the Bullwhip Effect

characteristics that tell how a process

1. Change the way suppliers forecast

is performing. A grouping of physical, sensual, and

product demand by making this

psychological benefits that are

1. Throughput time average information from the final-seller

purchased together as part of the

level available to all levels of the

amount of time it takes a product service.

supply chain.

to move through the system.

2. Eliminate order batching

2. Process velocity ratio of CHAPTER 4

3. Stabilize prices

throughput time to value-added Supply chain 4. Eliminate gaming

time A network of all the activities involved

3. Productivity ratio of outputs in delivering a finished product or Automated order entry system

over inputs service to the customer. A method using telephone models to

4. Utilization ratio of time a send digital orders to suppliers.

resource is used to time it is Supply chain management

Coordinates and manages all the Electronic data interchange (EDI)

available for use

activities of the supply chain. A form of computer-to-computer

5. Efficiency ratio of actual output communications that enables sharing

to standard output Tier one supplier business documents.

Supplies materials or services directly

Information technology (IT) to the processing facility. Electronic storefronts

Technology that enables storage, On-line catalogs of products made

processing, and communication of Tier two supplier available to the general public by a

information within and between firms. Directly supplies materials or services single supplier.

to a tier one supplier in the supply

Enterprise resource planning (ERP) chain. Net marketplaces

Large software programs used for Tier three supplier Suppliers and buyers conduct trade in

planning and coordinating all a single Internet-based environment.

Directly supplies materials or services

resources throughout the entire

to a tier two supplier in the supply

enterprise. Electronic request for

chain.

quote (eRFQs)

Global positioning systems (GPS) An electronic request for a quote on

Logistics

A type of wireless technology that uses goods and services.

Activities involved in obtaining,

satellite transmission to communicate

producing, and distributing materials

exact locations. Virtual private network (VPN)

and products in the proper place and

in proper quantities. A private Internet-based

Radio frequency communications environment that is

identification (RFID) Traffic management used by the company, its suppliers,

A wireless technology that uses Responsible for arranging and its customers for day-today

memory chips equipped with radio the method of shipment for activities.

antennas attached to objects used to both incoming and outgoing

transmit streams of data. products or materials. Benefits of B2B E-Commerce

1. Lower procurement admin cost

Automation Distribution 2. Low-cost access to global

Using machinery to perform work management suppliers

without human operators. Responsible for movement 3. Lower inventory investment

of material from the manufacturer 4. Better product quality

to the customer.

Business-to-consumer Backward integration Strategies for Leveraging Supply

e-commerce (B2C) Owning or controlling sources of raw Chain Management

On-line businesses sell to individual materials and components.

consumers. 1. Regularly assess supply chain

Forward integration network

Advertising revenue model Owning or controlling the channels of 2. Have a global view of demand

Provides users with information on distribution. 3. Decide how to get products to

services and products and provides an your customers

opportunity for suppliers to advertise. Partnering 4. Improve asset productivity

Subscription revenue model A process of developing a long-term 5. Expand visibility

A Web site that charges a subscription relationship with a supplier based on 6. Know what happens, when it

fee for access to its contents and mutual trust, shared vision, shared happens

services. information, and shared risks. 7. Design to deliver

8. Track performance to allow for

Transaction fee model ISM Principles and Standards of continuous improvement

A company receives a fee for Ethical Supply Management Conduct

executing a transaction. E-distributors

1. Impropriety. Independently owned net marketplaces

Sales revenue model 2. Conflicts of interest. having catalogs representing thousands

A means of selling goods, information, 3. Influence. of suppliers and designed for spot

or services directly to customers. 4. Responsibilities to your employees purchases.

Affiliate revenue model 5. Promote positive supplier and

Companies receive a referral fee for customer relationships E-purchasing

directing business to an affiliate. 6. Sustainability and social Companies that connect on-line MRO

responsibility suppliers to businesses that pay fees

Intranets 7. Confidential and proprietary to join the market, usually for long-term

Networks that are internal to an information contractual purchasing.

organization. 8. Reciprocity

9. Applicable law, regulations, and Value chain management (VCM)

Extranets trade agreements Automation of a firms purchasing or

Intranets that are linked to the Internet 10. Professional competence selling processes.

so that suppliers and customers can

be included in the system. General warehouse Exchanges

Green supply chain management Used for long-term storage. A marketplace that focuses on spot

Focuses on the role of the supply requirements of large firms in a single

chain with regard to its impact on the Distribution warehouse industry.

environment. Used for short-term storage,

consolidation, and product mixing. Industry consortia Industry-owned

Requisition request markets that enable buyers to purchase

Request indicating the need for an Postponement direct inputs from a limited set of

item. A strategy that shifts production invited suppliers.

differentiation closer to the consumer

Price and availability by postponing final configuration. Supply chain velocity

The current price of the item and The speed at which product moves

whether the quantity is available when Crossdocking through a pipeline from the

needed. Eliminates the storage and order- manufacturer to the customer.

Purchase order picking functions of a distribution

warehouse. CHAPTER 5

A legal document committing the

company to buy the goods and TYPES OF CROSS DOCKING

providing details of the purchase. Total quality management (TQM)

1. Manufacturing crossdocking An integrated effort designed to

Incoming inspection The receiving and consolidating of improve quality performance at every

Verifies the quality of incoming goods. inbound supplies and materials to level of the organization.

support just-in-time manufacturing.

Sourcing strategy Customer-defined quality

2. Distributor crossdocking

A plan indicating suppliers to be used The meaning of quality as defined by

The receiving and consolidating of

when making purchases the customer.

inbound products from different

Vertical integration vendors into a multi-SKU pallet.

DEFINITIONS OF QUALITY

A measure of how much of the supply 3. Transportation crossdocking

chain is actually owned or operated by Consolidation of LTL shipments to Conformance to specifications

the manufacturing company. MKT gain economies of scale. How well a product or service meets

the targets and tolerances determined

Insource 4. Retail crossdocking by its designers.

Processes or activities that are Sorting product from multiple

completed in-house. vendors onto outbound trucks Fitness for use

headed for specific stores. A definition of quality that evaluates

Outsource

how well the product performs for its

Processes or activities that are

intended use.

completed by suppliers.

Value for price paid Plandostudyact (PDSA) cycle 6. Process management quality

Quality defined in terms of product or A diagram that describes the activities should be built into the process;

service usefulness for the price paid. that need to be performed to incorporate sources of quality problems

continuous improvement into the should be identified and corrected

Support services operation. The specific steps in the

Quality at the source

Quality defined in terms of the support cycle:

(1) Plan (2) Do (3) Study (4) Act The belief that it is best to uncover the

provided after the product or service is

source of quality problems and

purchased.

Benchmarking eliminate it.

Psychological criteria Studying the business practices of

other companies for purposes of 7. Managing supplier quality

A way of defining quality that focuses

comparison. quality concepts must extend to a

on judgmental evaluations of what

companys suppliers

constitutes product or service

3. Employee Empowerment seek

excellence.

out, identify, and correct quality Malcolm Baldrige

problems National Quality Award

Most common Quality definition

An award given annually to companies

Quality circle

Conformance the degree to that demonstrate quality excellence

which a product characteristic A team of volunteer production

and establish best practice standards

meets preset standards employees and their supervisors who

in industry.

meet regularly to solve quality

Performance

problems.

Reliability product will function Deming Prize

as expected without failure A Japanese award given to companies

4. Use of quality tools ongoing

Durability expected operational to recognize efforts in quality

life of the product employee training in the use of

improvement.

quality of tools

Serviceability how readily a

product can be repaired Cause-and-effect diagram ISO 9000

A chart that identifies potential causes A set of international quality standards

Prevention costs of particular quality problems. and a certification demonstrating that

Costs incurred in the process of companies have met all the standards

preventing poor quality from occurring. Flowchart specified. Three new standards-

A schematic of the sequence of steps

involved in an operation or process. ISO 9000:2000, Quality

Appraisal costs Management Systems

Costs incurred in the process of Checklist Fundamentals and Standards:

uncovering defects. A list of common defects and the Provides the terminology and

number of observed occurrences of definitions used in the standards.

Internal failure costs these defects.

Costs associated with discovering poor ISO 9001:2000, Quality

product quality before the product Control charts Management Systems

reaches the customer. Charts used to evaluate whether a Requirements: This is the

process is operating within set standard for the certification of a

External failure costs expectations. firms quality management system.

Costs associated with quality problems Scatter diagrams ISO 9004:2000, Quality

that occur at the customer site. Management Systems

Graphs that show how two variables

are related to each other. Guidelines for Performance:

Robust design

Provides guidelines for

A design that results in a product that Pareto analysis

establishing a quality

can perform over a wide range of A technique used to identify quality

management system

conditions. problems based on their degree of

importance. ISO 14000

Taguchi loss function

Histogram A set of international standards and a

Costs of quality increase as a

A chart that shows the frequency certification focusing on a companys

quadratic function as conformance

distribution of observed values of a environmental responsibility, focus on

values move away from the target.

variable. three major areas:

CONCEPTS of the TQM PHILOSOPHY Management systems

5. Product design products need standards measure systems

1. Customer focus goal is to to be designed to meet customer development and integration of

expectations environmental responsibility into

identify and meet customer needs

Quality function deployment (QFD) the overall business

2. Continuous improvement a Operations standards include

A tool used to translate the preferences

philosophy of never-ending the measurement of consumption

of the customer into specific technical

improvement of natural resources and energy

requirements.

Kaizen Environmental systems

A Japanese term that describes the Reliability standards measure emissions,

notion of a company continually The probability that a product, service, effluents, and other waste systems.

striving to be better through learning or part will perform as intended.

and problem solving.

CHAPTER 6 Range (R) chart Defining beliefs of JIT

A control chart that monitors changes Broad view of operations, simplicity,

Statistical quality control (SQC) in the dispersion or variability of a continuous improvement, visibility, and

The general category of statistical process. flexibility.

tools used to evaluate organizational

quality. Three broad categories: P-chart Types of waste

1. Descriptive statistics A control chart that monitors the Material, energy, time, and space.

proportion of defects in a sample.

Statistics used to describe quality

characteristics and relationships. Broad view of the organization

C-chart

Tasks and procedures are important

2. Statistical process control (SPC) A control chart used to monitor the

only if they meet the companys overall

A statistical tool that involves number of defects per unit.

goals.

inspecting a random sample of the

Process capability

output from a process and deciding Simplicity

The ability of a production process to

whether the process is producing The simpler a solution, the better it is.

meet or exceed preset specifications.

products with characteristics that fall

within a predetermined range. Product specifications Continuous improvement

3. Acceptance sampling Preset ranges of acceptable quality (kaizen)

The process of randomly characteristics. A philosophy of never-ending

inspecting a sample of goods improvement.

and deciding whether to Process capability index

accept the entire lot based on An index used to measure process Visibility

the results. capability. Problems must be visible to

be identified and solved.

Six Sigma quality

Common causes of variation

A high level of quality associated with Flexibility

Random causes that cannot be

approximately 3.4 defective parts per A company can quickly adapt

identified

million. to the changing needs of its

Assignable causes of variation customers.

Operating characteristic (OC) curve

Causes that can be identified and

A graph that shows the probability or JIT system

eliminated.

chance of accepting a lot given various The three elements are just-in-

proportions of defects in the lot. time manufacturing, total

Mean (average)

A statistic that measures the central quality management, and

Acceptable quality level (AQL) respect for people.

tendency of a set of data. The small percentage of defects that

consumers are willing to accept. Three basic elements work together to

Range

The difference between the largest complete a JIT system

Lot tolerance percent

and smallest observations in a set of defective (LTPD) Just-in-time manufacturing

data. The upper limit of the percentage of The element of JIT that focuses on the

defective items consumers are willing production system to achieve value

Standard deviation to tolerate. added manufacturing.

A statistic that measures the amount of

data dispersion around the mean. Consumers risk Total quality management (TQM)

The chance of accepting a lot that An integrated effort designed to

Control chart contains a greater number of defects improve quality performance at every

A graph that shows whether a sample than the LTPD limit. level of the organization.

of data falls within the common or

Respect for people

normal range of variation. Producers risk

An element of JIT that considers

The chance that a lot containing an

human resources as an essential part

Out of control acceptable quality level will be rejected

of the JIT philosophy.

The situation in which a plot of data

falls outside preset control limits. Average outgoing quality (AOQ)

The expected proportion of defective Setup cost

items that will be passed to the Cost incurred when setting up

Types of Control Charts

customer under the sampling plan. equipment for a production run.

Variable a product characteristic

that can be measured and has a CHAPTER 7 Quality at the source

continuum of values (e.g., height, Uncovering the root cause of a quality

weight, or volume). Just-in-time (JIT) philosophy problem.

Getting the right quantity of goods at

Attribute a product characteristic the right place at the right time. Pull system

that has a discrete value and can JIT is based on a pull system rather

be counted. Waste than a push system.

Anything that does not add value.

x-bar chart Kanban card

A control chart used to A broad view of JIT A card that specifies the exact quantity

monitor changes in the mean A philosophy that encompasses the of product that needs to be produced.

value of a process. entire organization.

Production card Key Elements of JIT Supplier Types of Forecasting Methods

A kanban card that authorizes Relationship

production of material. Suppliers viewed as external factory.

Use of single-source suppliers.

Withdrawal card Long-term supplier relationships

A kanban card that authorizes developed.

withdrawal of material. Suppliers locate near customer.

Stable delivery schedules.

Small-lot production Cost and information sharing.

The ability to produce small quantities

of products. Benefits of JIT

Reduction in inventory

Internal setup Improved quality

Requires the machine to be stopped in Reduced space requirements **QUALITATIVE METHODS**

order to be performed. Shorter lead times Executive opinion

Lower production costs Forecasting method in which a group

External setup

Increased productivity of managers collectively develop a

Can be performed while the machine

Increased machine utilization forecast.

is still running.

Greater flexibility

Market research

Uniform plant loading Implementing JIT Approach to forecasting that relies on

A constant production plan for a facility 1. Make quality improvements. surveys and interviews to determine

with a given planning horizon. 2. Reorganize workplace customer preferences.

3. Reduce setup times

Multifunction workers 4. Reduce lot sizes and lead times Delphi method

Capable of performing more than one 5. Implement layout changes Approach to forecasting in which a

job. 6. Switch to pull production forecast is the product of a consensus

7. Develop relationship with among a group of experts.

Cell manufacturing suppliers

Placement of dissimilar machines and Qualitative Forecasting method

equipment together to produce a family Examples of JIT concepts seen in

of products with similar processing service firms

requirements. Improved quality

Uniform facility loading

Jidoka Use of multifunction workers

Authority given to workers to stop the Reductions in cycle time

production line if a quality problem is

Minimizing setup times and parallel

detected.

processing

Workplace organization

Poka-yoke

Foolproof devices or mechanisms that CHAPTER 8

prevent defects from occurring.

Forecasting **QUANTITATIVE METHODS**

Bottom-round management Predicting future events. 1. Time series models based on

Consensus management by the assumption that a forecast can

committees or teams. Features Common to all Forecasting be generated from the information

Models contained in a time series of data.

Quality circles 1. Forecasts are rarely perfect Time series a series of

Small teams of employees that 2. Forecasts are more accurate for observations taken over time.

volunteer to solve quality problems. groups or families of items

2. Causal models based on the

rather than for individual items

assumption that the variable being

Role of Production Employees in JIT 3. Forecasts are more accurate for

forecast is related to other variables

Have cross-functional skills shorter than longer than horizons

in the environment.

Actively engaged in solving

production and quality problems Steps in the Forecasting Process

1. Decide what to forecast TIME SERIES MODELS

Empowered to make production and

2. Evaluate and analyze Types of data patterns:

quality decisions

appropriate data 1. Level or horizontal data values

Quality is everyones responsibility

3. Select and test the forecasting

Responsible for recording and model

fluctuate around a constant mean

visually displaying performance data 2. Trend data exhibit increasing or

4. Generate the forecast decreasing values over time

Work in teams to solve problems 5. Monitor forecast accuracy

Decisions made through bottom- 3. Seasonality regularly repeats

round management itself and is constant in length

Qualitative forecasting methods

Responsible for preventive 4. Cycles data patterns created by

Forecast is made subjectively by the

maintenance economic fluctuations

forecaster.

Single-source suppliers Quantitative forecasting methods Random variation

Suppliers that supply an entire family Forecast is based on mathematical Unexplained variation that cannot be

of parts for one manufacturer. modeling. predicted.

Quantitative Forecasting Models

Type Description Strength Weaknesses

Time Series Models

Nave Uses last periods actual value Simple and easy to Only good if data change little

as a forecast use from period to period

Simple mean Uses an average of past data Good for level pattern Requires carrying a lot of

as a forecast data

Simple A forecasting method in which Only good for level Important to select the proper

moving only n of the most recent pattern moving average

average observations are averaged

Weighted A forecasting method where n Good for level pattern; Selection of weights requires

moving of the most recent observations allows placing different good judgment

average may have different weights weights on past

demands

Choice of alpha is critical

Exponential A weighted average procedure Provides excellent

smoothing with weights declining forecast results for

exponentially as data become short-to medium-length

older forecasts.

Trend-adjusted An exponential smoothing Provides good results Should only be used for data

exponential model with separate equations for trend data with trend

smoothing for forecasting the level and

trend

Linear trend Technique uses the least- Easy to use and Data should display a clear

line squares method to fit a straight understand trend over time

line to past data over time

Seasonal Computes the percentage Simple and logical Make sure seasonality is

indexes amount by which data for each procedure for actually present

season are above or below the computing seasonality.

mean.

Causal (Associative) Models

Linear Uses the least-squares Easy to understand; Make sure a linear

regression method to model a linear provides good forecast relationship is present

relationship between two accuracy

variables.

Multiple Similar to linear regression, but A powerful tool in Significantly increases data

regression models the relationship of forecasting when and computational

multiple variables with the multiple variables are requirements

variable being forecast. being considered.

MEASURING FORECAST ACCURACY

Forecast error Factors that influencing selection of a 4. Is it possible to implement new

Difference between forecast and actual forecasting model methods?

value for a given period. 5. Do you require interactive or repetitive

1. Amount and type of available data forecasting?

Mean absolute deviation (MAD) 2. Degree of accuracy required 6. Do you have a very large data sets?

Measure of forecast error that computes 3. Length of forecast horizon 7. Is there any local support?

error as the average of the sum of the 4. Data patterns present 8. Does the package give the right

absolute errors. answers?

Forecasting software packages

Mean squared error (MSE) 1. Spreadsheets

Measure of forecast error that computes 2. Statistical packages

error as the average of the squared error. 3. Specialty forecasting packages

Forecast bias Guidelines in selecting forecasting software

A persistent tendency for a forecast to be 1. Does the package have the facilities

over or under the actual value of the data. you want?

2. What platform is the package

Tracking signal available for?

Tool used to monitor the quality of a 3. How easy is the package to learn and

forecast. use?

Collaborative planning, forecasting, 2. Develop capacity alternatives

and replenishment (CPFR) nine-step (1) Do nothing, (2) Expand

process large now, and (3) Expand

small now, with option to add

1. Establish collaborative

later

relationships

3. Evaluate capacity alternatives

2. Create a joint business plan

3. Create a sales forecast

Decision tree

4. Identify exceptions for sales

Modeling tool used to evaluate

forecasts

independent decisions that must be

5. Resolve/collaborate on

made in sequence. It contains the

exceptions to sales forecasts

following information:

6. Create order forecast

7. Identify exceptions for order Decision points represented by

forecast squares, called nodes

8. Resolve/collaborate on Decision alternatives represented

exceptions to order forecast by branches or arrows leaving a

9. Generate order decision point

Chance events events that could

CHAPTER 9 affect the value of a decision

Outcomes

Capacity

The maximum output rate that can be Expected value (EV)

achieved by a facility. A weighted average of chance events,

where each chance event is given a

Capacity planning probability of occurrence.

The process of establishing the output

rate that can be achieved by a facility. Location analysis

Techniques for determining location

Two (2) Measures of Capacity decisions.

1. Design capacity the maximum

output rate that can be achieved by Factors Affecting Location Decisions

a facility under ideal conditions.

1. Proximity to sources of supply

2. Effective capacity the maximum 2. Proximity to customers

output rate that can be sustained 3. Proximity to Source of Labor

under normal conditions. 4. Community considerations

5. Site considerations

Capacity utilization 6. Quality-of-life issues

Percentage measure of how well 7. Other considerations

available capacity is being used.

Globalization

Best operating level The process of locating facilities

The volume of output that results in the around the world.

lowest average unit cost.

Procedures for Evaluating Location

Economies of scale Alternatives

A condition in which the average cost

of a unit produced is reduced as Factor rating

the amount of output is increased. A procedure that can be used to

evaluate multiple alternative locations

Diseconomies of scale based on a number of selected factors.

A condition in which the cost of each

additional unit made increases. Loaddistance model

A procedure for evaluating location

Focused factories alternatives based on distance.

Facilities that are small, specialized,

and focused on a narrow set of Rectilinear distance

objectives. The shortest distance between two

points measured by using only north

Three-step procedure for making south and eastwest movements.

capacity planning decisions

1. Identify capacity requirements Break-even analysis

Capacity cushion additional Technique used to compute the

capacity added to regular amount of goods that must be sold just

capacity requirements to to cover costs.

provide greater flexibility.

You might also like

- Reviewer in OMGTDocument11 pagesReviewer in OMGTana delacruzNo ratings yet

- Opsession GD-PI CompendiumDocument10 pagesOpsession GD-PI CompendiumvidishaniallerNo ratings yet

- High-Performance Design - Goods and Services Consistency - How Often GoodsDocument10 pagesHigh-Performance Design - Goods and Services Consistency - How Often GoodsMariel PilamingNo ratings yet

- Understanding Operations Management (OM) QDocument5 pagesUnderstanding Operations Management (OM) QaidynnNo ratings yet

- Resumos GLODocument20 pagesResumos GLOSarah PereiraNo ratings yet

- Operations Management Lect. 2 "Operations Strategy": DR: Aly Hassan ElbatranDocument29 pagesOperations Management Lect. 2 "Operations Strategy": DR: Aly Hassan Elbatraneslam hamdyNo ratings yet

- BME Chapter 3 Notes Products and Service DesignDocument5 pagesBME Chapter 3 Notes Products and Service DesignRomel BucaloyNo ratings yet

- Strategic Planning SummaryDocument13 pagesStrategic Planning SummaryStark WayneNo ratings yet

- CHAPTER 2 Strategy, Competitiveness and ProductivityDocument58 pagesCHAPTER 2 Strategy, Competitiveness and Productivitymohammed mohammedNo ratings yet

- CHAPTER 2 Strategy, Competitiveness and ProductivityDocument58 pagesCHAPTER 2 Strategy, Competitiveness and Productivitymohammed mohammedNo ratings yet

- Chapter 2 ManACDocument7 pagesChapter 2 ManACRizza Mae RaferNo ratings yet

- Chapter 14 Operations - Producing Goods and Services: Learning ObjectivesDocument29 pagesChapter 14 Operations - Producing Goods and Services: Learning ObjectivesZeeshan AslamNo ratings yet

- Week 3 - Strategic Cost Management Linked With StrategiesDocument8 pagesWeek 3 - Strategic Cost Management Linked With StrategiesXandra AbitriaNo ratings yet

- OM ImportanceDocument49 pagesOM Importanceshahid razzakNo ratings yet

- Competitiveness and Operations StrategyDocument29 pagesCompetitiveness and Operations StrategySoyerji BeheraNo ratings yet

- MAS D Strategic Cost ManagementDocument6 pagesMAS D Strategic Cost ManagementMingNo ratings yet

- DM PPT Chapter 02 DEMAND - MANAGEMENTDocument20 pagesDM PPT Chapter 02 DEMAND - MANAGEMENTzobayer ahamedNo ratings yet

- Managerial Prelim PPT Compilation'Document315 pagesManagerial Prelim PPT Compilation'Maviel SuaverdezNo ratings yet

- Wa0000.Document9 pagesWa0000.manikdarshanNo ratings yet

- Global Operations Strategy for Multinational CorporationsDocument29 pagesGlobal Operations Strategy for Multinational CorporationsSanjay ThakurNo ratings yet

- Reviewer DeptalsDocument18 pagesReviewer DeptalsJerby Jewel acostaNo ratings yet

- Recent Trends in OmDocument3 pagesRecent Trends in OmSathiyan HR50% (2)

- SCM 303 KeywordsDocument3 pagesSCM 303 KeywordsMudie De SanctisNo ratings yet

- Operations Strategy and Competitiveness (Assignment # 2) : PriceDocument5 pagesOperations Strategy and Competitiveness (Assignment # 2) : PriceSheila Mae LiraNo ratings yet

- Strama Reviewer For MTDocument4 pagesStrama Reviewer For MTDawn BitangcorNo ratings yet

- Operations ManagementDocument3 pagesOperations Managementlykaquinn.25No ratings yet

- SCMPE Theory Notes Nov 23 and OnwardsDocument60 pagesSCMPE Theory Notes Nov 23 and OnwardsvenkatprashanthNo ratings yet

- MAS D Strategic Cost ManagementDocument6 pagesMAS D Strategic Cost ManagementVenus Palmenco100% (1)

- Chp. 3-5 Strategic Cost Mgmt.Document17 pagesChp. 3-5 Strategic Cost Mgmt.Marie dela serna100% (1)

- Chapter 1-: Operations & Supply Chain StrategyDocument40 pagesChapter 1-: Operations & Supply Chain StrategyDv DickosNo ratings yet

- Picpa - Managing CostDocument138 pagesPicpa - Managing CostRodel Ryan YanaNo ratings yet

- OpMan CompetitivenessDocument2 pagesOpMan CompetitivenessSeok Jin KimNo ratings yet

- Manufacturing of Industrial Equipment in The New Global EconomyDocument4 pagesManufacturing of Industrial Equipment in The New Global EconomyRajesh KengeNo ratings yet

- Lesson 3 ReviewerDocument7 pagesLesson 3 ReviewermeyyyyyyyyyyNo ratings yet

- Product ManagementDocument9 pagesProduct ManagementMaricris Armonio MagongNo ratings yet

- Operations Management Chapter Two-1Document37 pagesOperations Management Chapter Two-1AGNo ratings yet

- Strat Business Analysis - Module1 - L3Document5 pagesStrat Business Analysis - Module1 - L3Patricia RodriguezNo ratings yet

- StratCostMgt Unit 1 Module3Document4 pagesStratCostMgt Unit 1 Module3Kim MasapolNo ratings yet

- StratmanDocument8 pagesStratmanblueviolet21No ratings yet

- Chapter 2 Designing-Product-Services-And-PrcessesDocument31 pagesChapter 2 Designing-Product-Services-And-PrcessesRomeo De Guzman Jr.No ratings yet

- Chapter 2Document4 pagesChapter 2Mixx MineNo ratings yet

- What Is Operations and Supply Management?Document17 pagesWhat Is Operations and Supply Management?Geuroo Andrew YangNo ratings yet

- Chap 2-Competitiveness, Strategy, and ProductivityDocument15 pagesChap 2-Competitiveness, Strategy, and ProductivityNeamat HassanNo ratings yet

- Operations Management EssentialsDocument15 pagesOperations Management EssentialsBiniNo ratings yet

- Summary Chapter 5Document4 pagesSummary Chapter 5Benedictus Kevin RNo ratings yet

- Module 3.1 - PRODUCT AND SERVICE PROCESS DESIGNDocument7 pagesModule 3.1 - PRODUCT AND SERVICE PROCESS DESIGNkristel lei diamanteNo ratings yet

- Operations Management (Chapter 1) Operations Management Is The Key PointsDocument13 pagesOperations Management (Chapter 1) Operations Management Is The Key PointsMaritess MunozNo ratings yet

- SMArtica Ass1Document6 pagesSMArtica Ass1Sandy ArticaNo ratings yet

- Faculty PPT - Understanding Process Process Fundamentals and Process CapabilitiesDocument33 pagesFaculty PPT - Understanding Process Process Fundamentals and Process CapabilitiesSubhajit BoseNo ratings yet

- MD 021 - Management and OperationsDocument8 pagesMD 021 - Management and Operationssiddharth_patel_19No ratings yet

- Chapter 3 NotesDocument3 pagesChapter 3 NotesRorNo ratings yet

- Competitiveness Is How EffectivelyDocument9 pagesCompetitiveness Is How EffectivelyLyn QueraNo ratings yet

- PLM Definition CIMData-2002Document12 pagesPLM Definition CIMData-2002zazaNo ratings yet

- Chapter 1-: Operations & Supply Chain StrategyDocument41 pagesChapter 1-: Operations & Supply Chain StrategySannoush376No ratings yet

- Lesson 3-4 Reviewer (BMGT25)Document7 pagesLesson 3-4 Reviewer (BMGT25)meyyyyyyyyyyNo ratings yet

- Stratman 1Document8 pagesStratman 1blueviolet21No ratings yet

- Operations Strategy and CompetitivenessDocument36 pagesOperations Strategy and CompetitivenessYaredNo ratings yet

- Contemporary Issues in MADocument1 pageContemporary Issues in MAGlydel B. MatayaNo ratings yet

- Module 3.1 - PRODUCT AND SERVICE PROCESS DESIGNDocument7 pagesModule 3.1 - PRODUCT AND SERVICE PROCESS DESIGNkristel lei diamanteNo ratings yet

- SALESDocument1 pageSALESClarisse AnnNo ratings yet

- External and Internal Audit OrganizationsDocument6 pagesExternal and Internal Audit OrganizationsClarisse AnnNo ratings yet

- Chapter 26Document2 pagesChapter 26Clarisse AnnNo ratings yet

- Pom CH 1-2Document3 pagesPom CH 1-2Clarisse AnnNo ratings yet

- Chapter 23Document2 pagesChapter 23Clarisse AnnNo ratings yet

- Chapter 9Document1 pageChapter 9Clarisse AnnNo ratings yet

- Chapter 1Document7 pagesChapter 1Clarisse AnnNo ratings yet

- Calculating Present Value of Restructured NoteDocument5 pagesCalculating Present Value of Restructured NoteClarisse AnnNo ratings yet

- Financial Formulas - Ratios (Sheet)Document3 pagesFinancial Formulas - Ratios (Sheet)carmo-netoNo ratings yet

- Implementing Rules of Philippine Mining ActDocument144 pagesImplementing Rules of Philippine Mining Actcecilemarisgozalo98100% (2)

- Average Propensity To Consume SurveyDocument1 pageAverage Propensity To Consume SurveyClarisse AnnNo ratings yet

- Donors Tax Theory ExplainedDocument5 pagesDonors Tax Theory ExplainedJoey Acierda BumagatNo ratings yet

- Cash and Cash EquivalentsDocument2 pagesCash and Cash EquivalentsClarisse AnnNo ratings yet

- Law - IntroductionDocument3 pagesLaw - IntroductionClarisse AnnNo ratings yet

- Philippine Accounting SummaryDocument4 pagesPhilippine Accounting SummaryClarisse AnnNo ratings yet

- Philippine DepartmentsDocument1 pagePhilippine DepartmentsClarisse AnnNo ratings yet

- #01 Accounting ProcessDocument3 pages#01 Accounting ProcessZaaavnn VannnnnNo ratings yet

- Audit of ReceivablesDocument4 pagesAudit of ReceivablesClarisse AnnNo ratings yet

- Good News (The Last Supper) ActivityDocument4 pagesGood News (The Last Supper) ActivityClarisse AnnNo ratings yet

- BOA Syllabus MASDocument3 pagesBOA Syllabus MASElizabeth YgotNo ratings yet

- Supply, Demand & EquilibriumDocument4 pagesSupply, Demand & EquilibriumClarisse AnnNo ratings yet

- Obligations and ContractsDocument1 pageObligations and ContractsClarisse AnnNo ratings yet

- Ratio Analysis FormulasDocument1 pageRatio Analysis FormulasClarisse AnnNo ratings yet

- Audtheo CH 1Document3 pagesAudtheo CH 1Clarisse AnnNo ratings yet

- Basketball DiagramDocument1 pageBasketball DiagramClarisse AnnNo ratings yet

- Law - IntroductionDocument3 pagesLaw - IntroductionClarisse AnnNo ratings yet

- Adjusting EntriesDocument1 pageAdjusting EntriesClarisse AnnNo ratings yet

- Principle No. 6 - Cooperation Among Cooperatives (Pre-Final)Document42 pagesPrinciple No. 6 - Cooperation Among Cooperatives (Pre-Final)Clarisse AnnNo ratings yet

- B. Human Resources: Job Profile Job Description Job Basic Competencies Job Performance CriteriaDocument4 pagesB. Human Resources: Job Profile Job Description Job Basic Competencies Job Performance CriteriaIvOnAgellonNo ratings yet

- Tata Final File 15th May 2021Document3 pagesTata Final File 15th May 2021Deep sharmaNo ratings yet

- The Predictive Power of Students Pygmalion PerceptionsDocument23 pagesThe Predictive Power of Students Pygmalion PerceptionsErmelina BacatanNo ratings yet

- Demonstrate Personal and Professional Competence: Submission DetailsDocument11 pagesDemonstrate Personal and Professional Competence: Submission DetailsTawan PrayordNo ratings yet

- Langford - Et - Al-2017-Measuring Leader Behaviour - Evidence For A Big Five Model of LeadershipDocument39 pagesLangford - Et - Al-2017-Measuring Leader Behaviour - Evidence For A Big Five Model of LeadershipMy Nguyen Ha QTKD-5K-17No ratings yet

- Engleza An III, Sem IDocument26 pagesEngleza An III, Sem IDenise BlackNo ratings yet

- ORGANIZING NURSING SERVICES FOR PATIENT CAREDocument28 pagesORGANIZING NURSING SERVICES FOR PATIENT CAREAnusha VergheseNo ratings yet

- Encyclopedia of Peace EducationDocument4 pagesEncyclopedia of Peace EducationTeachers Without BordersNo ratings yet

- HRM 322 Course Career Path Begins Hrm322dotcomDocument13 pagesHRM 322 Course Career Path Begins Hrm322dotcommaterialNo ratings yet

- Assignment ON Balance Scorecard of Toyota: Submitted To: Submitted byDocument5 pagesAssignment ON Balance Scorecard of Toyota: Submitted To: Submitted bychani0% (1)

- BSBLDR401 Task2Document13 pagesBSBLDR401 Task2Winnie PPnapatNo ratings yet

- TCS Operations ManagementDocument18 pagesTCS Operations ManagementUmairZahid0% (1)

- EFQMModel PresentationDocument63 pagesEFQMModel PresentationdalamberosNo ratings yet

- Sample Educational Leadership EssayDocument17 pagesSample Educational Leadership Essaydirar skefNo ratings yet

- PDF-Logistics & Supply Chain ManagementDocument34 pagesPDF-Logistics & Supply Chain ManagementShyam Khamniwala73% (15)

- POLI 215 Syllabus (Spring 2019)Document11 pagesPOLI 215 Syllabus (Spring 2019)gus10110No ratings yet

- Management Fundamentals for Organizational SuccessDocument12 pagesManagement Fundamentals for Organizational Successmohamed110100% (2)

- Dubai Government Innovation FrameworkDocument103 pagesDubai Government Innovation FrameworkAshiq MaanNo ratings yet

- Impact of Leadership Style On Organization Commitment: September 2011Document9 pagesImpact of Leadership Style On Organization Commitment: September 2011seliu multi persadaNo ratings yet

- Reading 1 - Why Great Followers Make The Best LeadersDocument1 pageReading 1 - Why Great Followers Make The Best LeadersEmilyNo ratings yet

- The Six Principles of Leadership Coaching - PDDocument2 pagesThe Six Principles of Leadership Coaching - PDRobsonNo ratings yet

- Case Study AlokDocument6 pagesCase Study AlokLincy JacobNo ratings yet

- Document 1management of Nursing Educational InstitutionDocument13 pagesDocument 1management of Nursing Educational InstitutionHardeep Kaur100% (1)

- Fungsi 3 Mfa N Leg A Burn-1Document1 pageFungsi 3 Mfa N Leg A Burn-1Fatoni UlinNo ratings yet

- Axios Why ITSM Maturity Should Drive Solution ReplacementDocument57 pagesAxios Why ITSM Maturity Should Drive Solution ReplacementAdnan AbuShahadNo ratings yet

- Leader 3Document65 pagesLeader 3Aklilu100% (1)

- Iso 21500 and Pmbok GuideDocument10 pagesIso 21500 and Pmbok GuideALVARO CHAMONo ratings yet

- Syllabus in Nursing Care Management 107Document11 pagesSyllabus in Nursing Care Management 107ropido100% (3)

- Hotel Management CVDocument2 pagesHotel Management CVmrzeettsNo ratings yet

- Maximize The Synergies Between Itil and Devops: White PaperDocument15 pagesMaximize The Synergies Between Itil and Devops: White PaperEugene ArkadievNo ratings yet